Understanding the Wood Mizer Parts Diagram for Efficient Maintenance

In the world of machinery, a thorough grasp of each element’s configuration is vital for optimal performance and maintenance. Recognizing how individual segments interact can significantly enhance operational efficiency and longevity. This knowledge serves not only as a guide for troubleshooting but also as a foundation for effective upgrades and repairs.

Each mechanism comprises various essential components, each playing a unique role in the overall functionality. By dissecting these elements and visualizing their arrangement, users can better appreciate their contributions to the system’s success. This understanding fosters a proactive approach to equipment care, allowing operators to anticipate issues before they escalate.

Moreover, comprehending the assembly and connections among these pieces empowers users to execute modifications and improvements confidently. Whether for enhancing productivity or ensuring safety, this foundational insight is indispensable for anyone working with complex machinery.

Understanding Wood-Mizer Components

To fully appreciate the functionality of a sawmill, it’s essential to grasp the various elements that contribute to its operation. Each component plays a critical role in the efficiency and effectiveness of the machine, influencing everything from the precision of cuts to the overall durability of the equipment.

Core Elements include the framework, which provides stability, and the cutting mechanism that determines the quality of the timber processed. These foundational parts must work in harmony to achieve optimal performance.

Additional Accessories enhance usability and safety, ensuring that operators can work efficiently while minimizing risks. Understanding how these components interact allows users to make informed decisions regarding maintenance and upgrades.

By familiarizing oneself with these essential parts, users can optimize their experience, ensuring longevity and superior results in every project undertaken.

Importance of Parts Diagrams

Understanding the components of any machinery is crucial for efficient operation and maintenance. Visual representations of these elements play a vital role in providing clarity and guidance, ensuring users can easily identify and locate each section. Such illustrations enhance the user experience, making it simpler to comprehend complex systems and facilitate repairs or replacements.

Utilizing these visuals not only aids in troubleshooting but also serves as an educational tool for new users. By showcasing how individual components interact within the overall structure, these representations can significantly reduce the learning curve associated with machinery operation.

| Benefits | Description |

|---|---|

| Clarity | Visual aids help users understand intricate systems. |

| Efficiency | Streamlined repairs and maintenance processes. |

| Education | Helps newcomers learn about machinery quickly. |

| Communication | Facilitates discussions among users and technicians. |

In conclusion, having a comprehensive visual reference is indispensable for effective machine handling, ensuring longevity and optimal performance. This approach not only fosters a deeper understanding but also encourages a proactive maintenance culture among users.

Key Components of Wood-Mizer Machines

Understanding the essential elements of these processing units is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance, durability, and safety. This section will explore the main features that contribute to the effectiveness of these machines.

Frame: The structural base provides stability and support for all other components. A robust frame is essential for handling the stresses during operation, ensuring precision and reliability.

Blade System: This is the heart of the machine, responsible for cutting through materials. The design and sharpness of the blades significantly influence the quality of the final product.

Feed Mechanism: This element controls the movement of the material being processed. An efficient feed system ensures smooth transitions and uniform cutting, reducing waste and enhancing productivity.

Drive Unit: This component powers the entire operation, converting energy into mechanical motion. A reliable drive unit is crucial for maintaining consistent speed and performance.

Control Panel: The interface for the operator allows for adjustments and monitoring of the machine’s functions. A user-friendly control panel enhances ease of use and helps in fine-tuning operations.

Safety Features: Incorporating protective elements is vital for operator safety. These may include emergency stops, guards, and alarms to prevent accidents during operation.

By recognizing the significance of each component, users can ensure better upkeep and enhance the overall efficiency of their machines.

How to Read a Parts Diagram

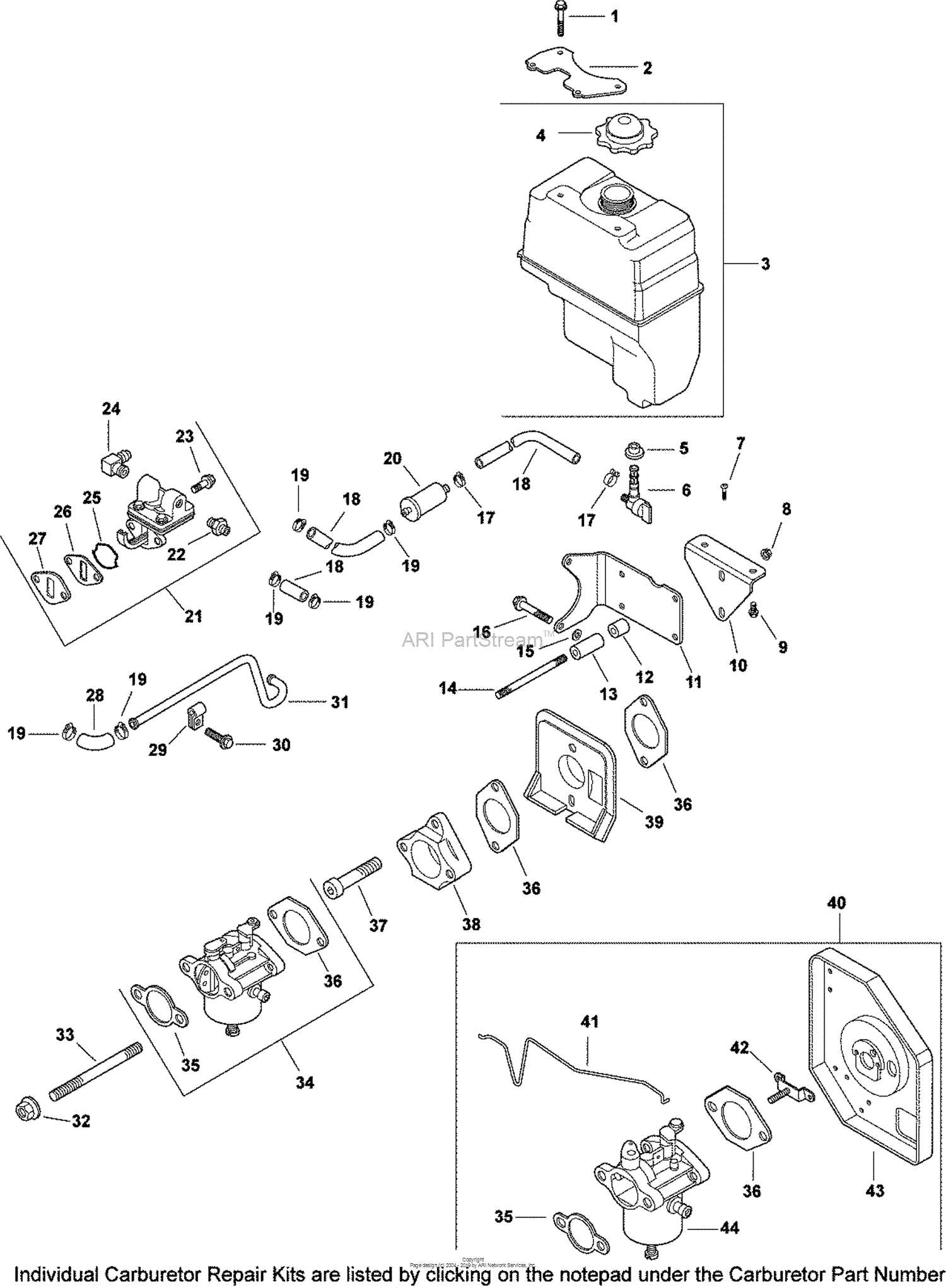

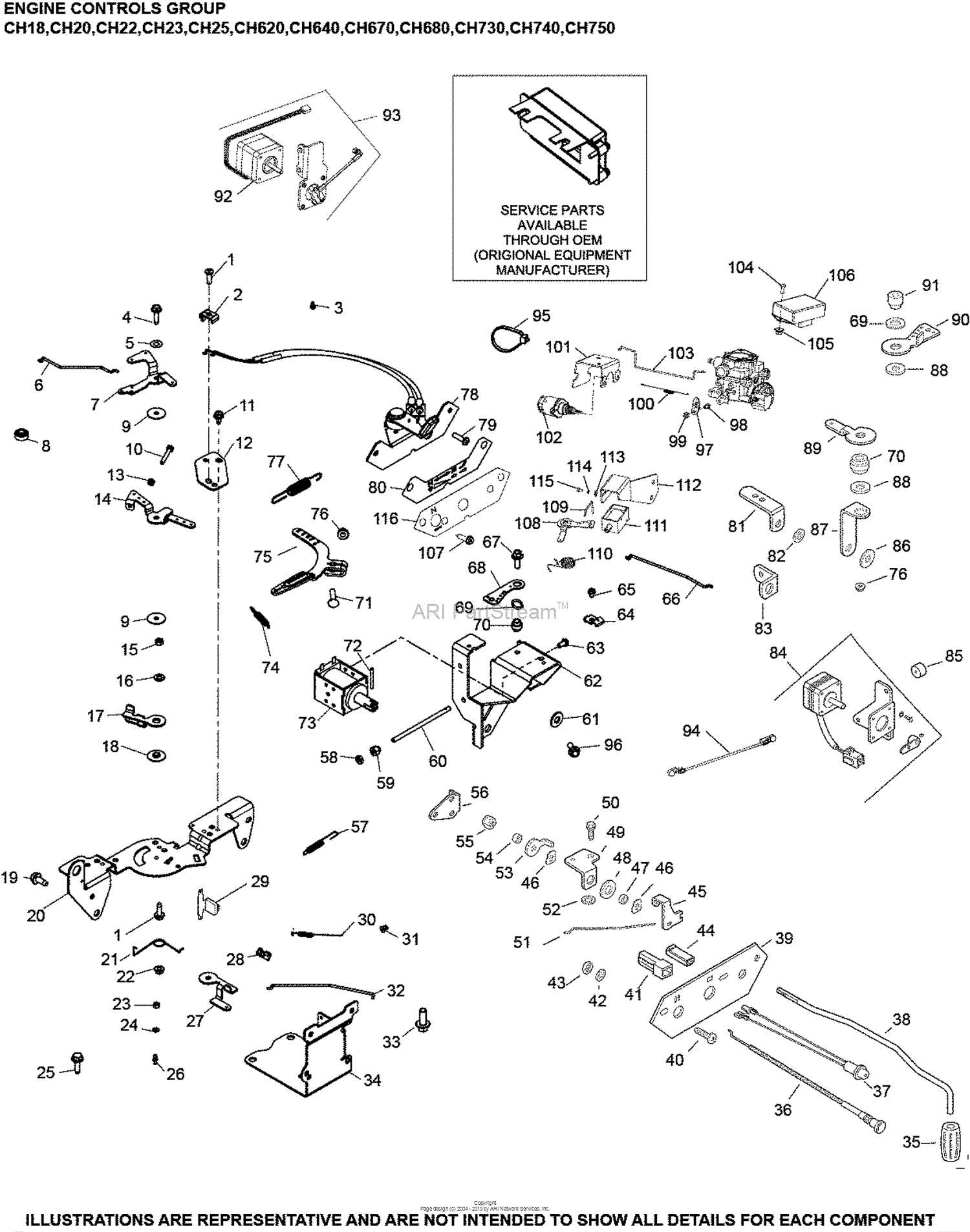

Understanding a visual representation of components is crucial for effective maintenance and repair. These illustrations serve as a guide, helping users identify individual elements and their relationships within a complex system. By mastering the interpretation of such visuals, you can streamline troubleshooting and enhance your knowledge of equipment functionality.

First, familiarize yourself with the legend, which often accompanies these representations. This key provides essential information about symbols and markings used to denote various components. Recognizing these symbols is the foundation for accurate interpretation.

Next, pay attention to the layout of the illustration. Components are usually arranged logically, often reflecting their physical configuration in the machinery. Identifying the placement and connections between elements can clarify how the system operates as a whole.

Additionally, be aware of any accompanying numbers or labels that correlate with specific components. These annotations usually indicate part numbers or reference materials, allowing for easier ordering and replacement. Cross-referencing these with a catalog or list can further enhance your understanding.

Lastly, practice is key. Regularly consulting these illustrations while working on equipment will improve your familiarity and confidence. Over time, reading and interpreting these visuals will become an intuitive process, making maintenance tasks more efficient and less daunting.

Common Issues and Solutions

In any mechanical system, certain challenges may arise that can hinder optimal performance. Understanding these issues and their corresponding solutions is essential for maintaining efficiency and longevity. Below are some frequently encountered problems along with practical remedies.

Frequent Problems

| Issue | Description | Solution |

|---|---|---|

| Overheating | Excessive heat buildup can lead to malfunctions. | Ensure proper lubrication and check cooling systems regularly. |

| Unusual Noises | Strange sounds may indicate wear or misalignment. | Inspect components for damage and realign if necessary. |

| Poor Performance | Reduction in efficiency can occur due to various factors. | Regularly clean filters and replace worn parts. |

| Vibrations | Excessive vibration may suggest imbalance. | Check for secure fittings and balance components properly. |

Preventive Measures

To mitigate these issues, routine maintenance is crucial. Regular inspections and timely replacements can significantly enhance performance and reduce the likelihood of serious malfunctions. Implementing a comprehensive maintenance schedule ensures that potential problems are identified and addressed promptly.

Finding Replacement Parts Easily

Locating suitable components for machinery can often be a challenging task. However, with the right approach and resources, you can simplify the process significantly. Understanding where to search and how to identify the necessary items is essential for maintaining operational efficiency.

Utilizing Online Resources

Online platforms offer a wealth of information and options for sourcing the required components. Official websites frequently provide comprehensive catalogs that include specifications and compatibility details. Additionally, forums and community groups can be invaluable for recommendations and shared experiences.

Consulting Technical Manuals

Referring to technical manuals can aid in identifying specific components needed for repairs or upgrades. These documents often contain detailed illustrations and descriptions, making it easier to pinpoint exactly what you’re looking for. Keep these manuals handy for quick reference when needed.

In summary, adopting a strategic approach by leveraging online tools and technical documentation can streamline the process of finding the necessary components, ensuring your machinery remains in peak condition.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. By following specific practices, you can extend the lifespan of your machinery and enhance its performance. Proper maintenance not only prevents unexpected breakdowns but also minimizes repair costs over time.

Routine Inspections

Conduct frequent checks on all critical components to identify wear and tear early. Look for signs of damage, such as cracks or corrosion, and replace any worn parts promptly. Regularly lubricating moving elements helps reduce friction and prolongs their functionality.

Cleanliness is Key

Keep your machinery free from debris and contaminants. Regular cleaning not only improves performance but also prevents the accumulation of harmful substances that can lead to deterioration. Use appropriate cleaning agents and techniques to maintain the integrity of the surfaces.

Comparing Different Wood-Mizer Models

This section aims to explore the various models available in the sawmill industry, focusing on their unique features and capabilities. Understanding the distinctions among these options helps users choose the right equipment for their specific needs.

Key Features to Consider

- Capacity and Size

- Power Source and Efficiency

- Portability and Setup

- Technological Enhancements

- Cost and Value

Popular Models Overview

-

Entry-Level Options:

- Ideal for beginners or small operations.

- Generally more affordable with basic functionalities.

-

Mid-Range Choices:

- Offer a balance of price and advanced features.

- Suitable for semi-professional use.

-

High-End Models:

- Designed for extensive commercial use.

- Include advanced technology and higher capacity.

Each model serves different purposes, catering to varying levels of expertise and operational requirements. Evaluating these elements can significantly enhance productivity and efficiency in any milling project.

Upgrading Your Equipment Effectively

Enhancing your machinery is crucial for maintaining productivity and ensuring optimal performance. By strategically selecting and integrating new components, you can significantly improve efficiency and extend the lifespan of your tools. This section outlines essential considerations and steps for effectively upgrading your equipment.

First and foremost, assess your current setup to identify areas that require improvement. This evaluation will help you prioritize which upgrades will yield the best results. Below is a table outlining common upgrade options and their potential benefits:

| Upgrade Option | Description | Benefits |

|---|---|---|

| Motor Replacement | Upgrading to a more powerful or efficient motor. | Increased speed and energy savings. |

| Blade Improvement | Using higher-quality or specialized blades. | Better cuts and longer blade life. |

| Control System Upgrade | Implementing advanced technology for better monitoring. | Enhanced precision and reduced downtime. |

| Frame Reinforcement | Strengthening the structure to handle heavier loads. | Improved durability and safety. |

Once you have selected the appropriate upgrades, consider the installation process. Depending on the complexity, you may choose to perform the upgrades yourself or hire a professional. Proper installation is key to ensuring the longevity and effectiveness of the enhancements.

Regular maintenance post-upgrade is equally important. Routine checks and care will help sustain the performance benefits you’ve gained from the new components. With thoughtful planning and execution, upgrading your machinery can lead to substantial improvements in your overall operational efficiency.

Resources for Wood-Mizer Owners

For those who own and operate sawmill equipment, having access to reliable resources is essential for effective maintenance and optimal performance. Whether you’re a novice or an experienced user, understanding the available tools, manuals, and support networks can significantly enhance your experience and productivity.

One valuable resource is the official website, which offers a wealth of information, including user manuals, troubleshooting guides, and maintenance tips. Online forums and community groups are also excellent platforms where owners can share experiences, seek advice, and discuss best practices with fellow enthusiasts.

Additionally, many vendors provide specialized accessories and components tailored for your machinery, ensuring you have everything you need to keep your equipment running smoothly. Workshops and training sessions often hosted by local dealers can further enhance your skills and knowledge, allowing you to maximize the utility of your investment.

Community Support and Forums

In the world of machinery and equipment, the value of community support cannot be overstated. Enthusiasts and professionals alike often turn to forums and online groups to share knowledge, troubleshoot issues, and exchange tips. These platforms serve as vital resources, fostering a sense of camaraderie among users who are passionate about their craft.

Participants can post questions, seek advice, and offer solutions based on their own experiences. This collaborative environment not only enhances individual skills but also contributes to the overall understanding of complex machinery. Many forums also feature sections dedicated to specific topics, allowing users to dive deep into particular areas of interest.

Furthermore, engaging with a community can lead to valuable networking opportunities. Members often share resources, recommend local services, and even organize meetups. This interconnectedness helps build a supportive ecosystem where everyone can benefit from collective expertise.

Whether you are a novice or a seasoned expert, these online spaces can significantly enrich your journey, providing guidance and encouragement along the way. Participating actively can lead to personal growth and a deeper appreciation of the craft.