Understanding the Yth1542xp Parts Diagram for Efficient Maintenance

In the realm of machinery and equipment, comprehending the intricate layout of essential elements is crucial for optimal functionality. This knowledge not only enhances maintenance but also facilitates efficient troubleshooting, ensuring that every component operates harmoniously within the larger system.

For enthusiasts and professionals alike, the ability to visualize the arrangement of critical components can make a significant difference in performance and longevity. Whether you are a novice looking to grasp the basics or an expert aiming to refine your skills, mastering this knowledge is an ultimate goal.

By exploring the various configurations and interconnections, users can delve into a deeper understanding of how each piece contributes to the overall efficacy of the machine. This insight paves the way for more informed decisions and enhances overall user experience.

Understanding Yth1542xp Components

Grasping the various elements that comprise a complex machine is essential for both functionality and maintenance. Each component plays a vital role, contributing to the overall performance and reliability of the system. By familiarizing oneself with these parts, one can better appreciate their interconnectivity and the engineering behind them.

Key Features

Among the most significant aspects are the structural elements that provide stability and support. Additionally, mechanisms that facilitate movement and control are crucial for operation. Understanding how these features work together can enhance troubleshooting and repair efforts.

Maintenance and Upgrades

Regular inspection and knowledge of replacement options can significantly prolong the life of the system. Being aware of potential upgrades can also lead to improved efficiency and performance, ensuring that the machine remains at its ultimate operational capacity.

Overview of Yth1542xp Functionality

This section delves into the essential features and capabilities of a specific model designed for efficiency and precision. Understanding these functionalities can provide insights into its overall performance and utility in various applications.

The system is engineered to offer several key advantages:

- Efficiency: Optimized for low energy consumption while maintaining high output.

- Durability: Constructed with high-quality materials to withstand demanding conditions.

- Versatility: Adaptable to various tasks, making it suitable for multiple environments.

Among its prominent functionalities are:

- Automated Operations: Reduces the need for manual intervention, streamlining workflows.

- Advanced Control Systems: Allows for precise adjustments and monitoring of performance parameters.

- User-Friendly Interface: Simplifies interaction, ensuring that operators can easily navigate settings and configurations.

Overall, this model exemplifies a blend of innovation and practicality, making it a reliable choice for those seeking a robust solution in their respective fields.

Importance of Parts Diagrams

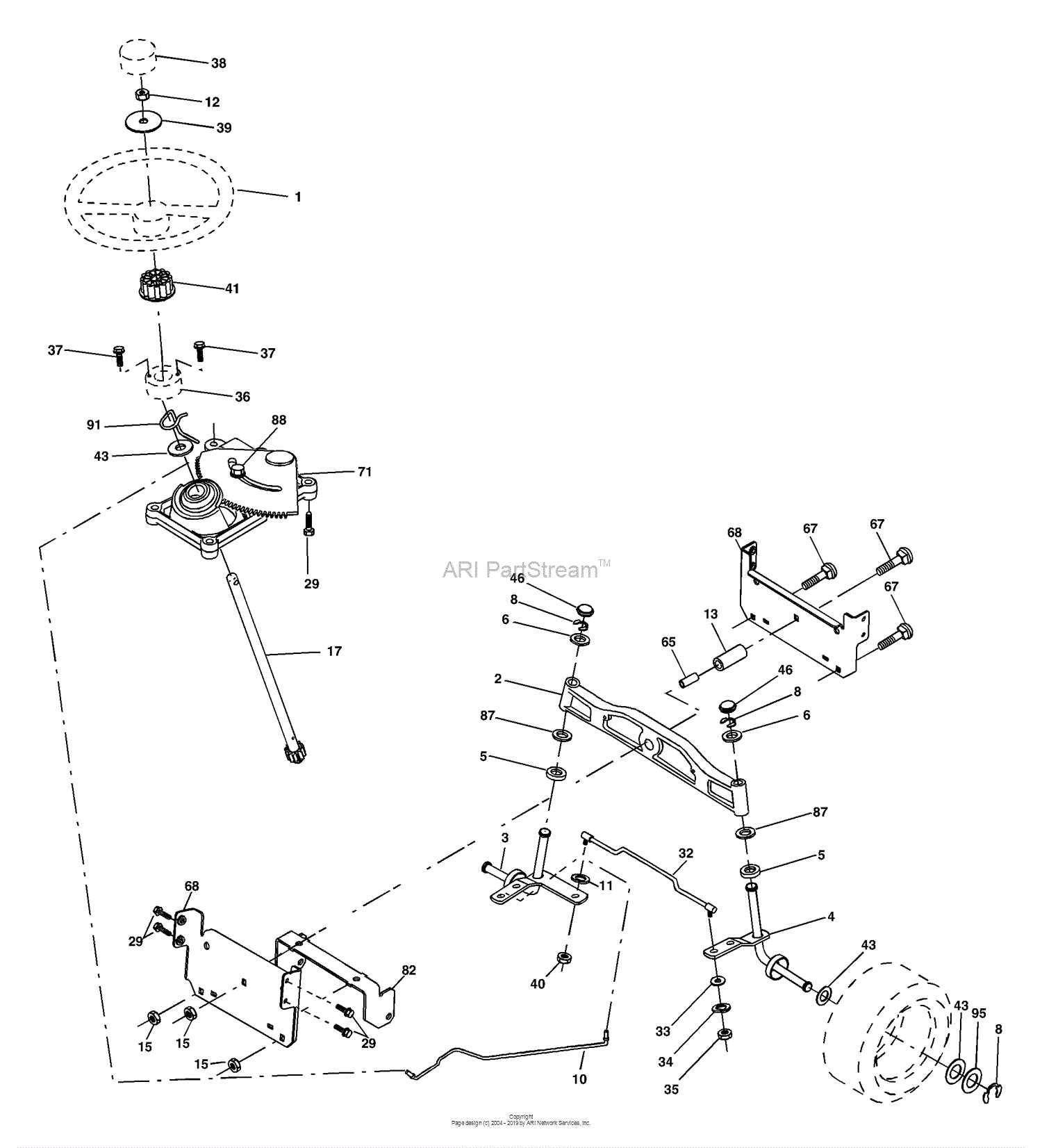

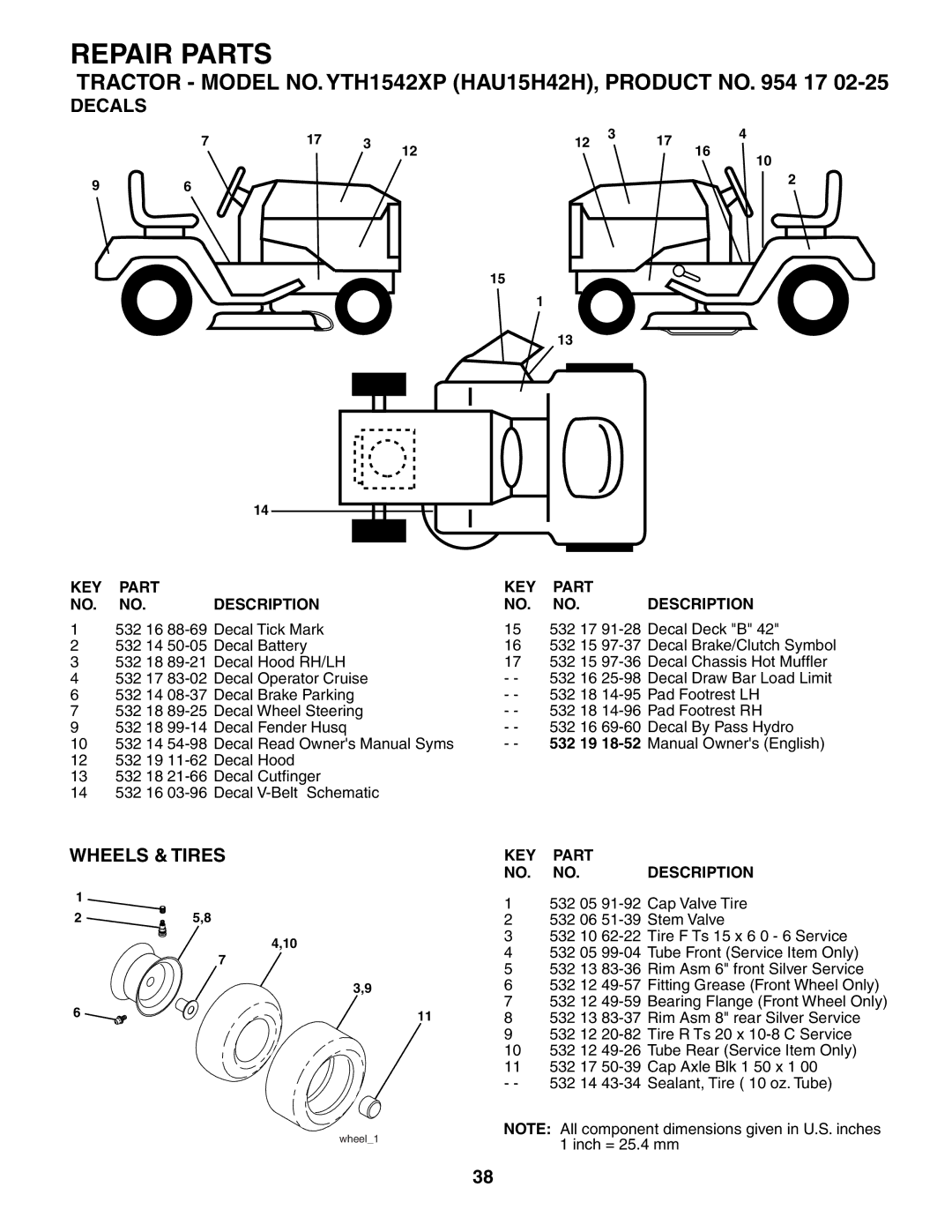

Understanding the components of a mechanical system is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and users alike, offering clarity on the arrangement and interaction of various elements. By providing a detailed overview, these illustrations enhance the ability to identify, troubleshoot, and replace specific items when needed.

Accurate depictions facilitate quicker diagnosis of issues, enabling users to locate faults efficiently. This not only saves time but also minimizes the risk of further damage during repairs. Moreover, having a clear reference helps in ensuring that replacements are compatible and meet the necessary standards.

In summary, these visual guides are invaluable resources that improve understanding, streamline processes, and ultimately contribute to the longevity and performance of equipment.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding you through the intricate network of machinery. Familiarity with how to interpret these visuals can significantly enhance your troubleshooting skills and efficiency.

Here are some key elements to consider when studying these illustrations:

- Symbols and Notations: Different shapes and lines represent various components and their relationships. Familiarize yourself with common symbols to grasp the overall layout.

- Labels: Descriptive tags often accompany visual elements, providing essential information about each component. Pay close attention to these annotations.

- Numbers and Codes: Parts are usually identified by unique codes. These identifiers can help you locate the specific items needed for repairs or replacements.

- Views and Angles: Various perspectives may be used to depict components. Understanding these angles can help you visualize how parts fit together in real-life applications.

To further enhance your understanding, follow these steps:

- Start with the Overview: Begin by examining the entire visual to get a sense of the system layout.

- Focus on Sections: Break down the illustration into smaller parts to analyze individual components more thoroughly.

- Cross-reference with Manuals: Use service manuals or guides to gain deeper insights and context for each element.

- Practice: Regularly reviewing similar visuals can improve your ability to quickly interpret them in the future.

By honing these skills, you will enhance your capability to work effectively with mechanical systems, ensuring better performance and longevity.

Common Issues with Yth1542xp

In the realm of machinery, certain models often encounter recurring challenges that can hinder their performance and longevity. Understanding these frequent problems can aid in troubleshooting and maintenance, ensuring smooth operation and minimizing downtime.

Frequent Problems

Users often report various malfunctions that can stem from wear and tear, improper use, or lack of maintenance. Here are some of the most common issues that arise:

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Excessive heat can lead to shutdowns or performance drops. | Ensure proper ventilation and check coolant levels. |

| Start-up Problems | Difficulty in initiating operations may arise. | Inspect the battery and electrical connections. |

| Noise Issues | Unusual sounds can indicate mechanical failure. | Check for loose components and lubricate moving parts. |

Maintenance Tips

Regular upkeep is essential for preventing these issues. Scheduled inspections, timely replacements, and adherence to operational guidelines can significantly reduce the likelihood of encountering these common setbacks.

Key Components and Their Functions

Understanding the primary elements of a system is essential for effective operation and maintenance. Each component plays a critical role, contributing to the overall functionality and efficiency. Recognizing their specific purposes can greatly enhance troubleshooting and repair processes.

Engine: The heart of the machinery, responsible for converting fuel into mechanical energy, driving the entire system’s performance.

Transmission: This component transfers power from the engine to the wheels, ensuring smooth acceleration and deceleration through various gears.

Cooling System: Vital for maintaining optimal operating temperatures, this system prevents overheating and ensures longevity of the engine components.

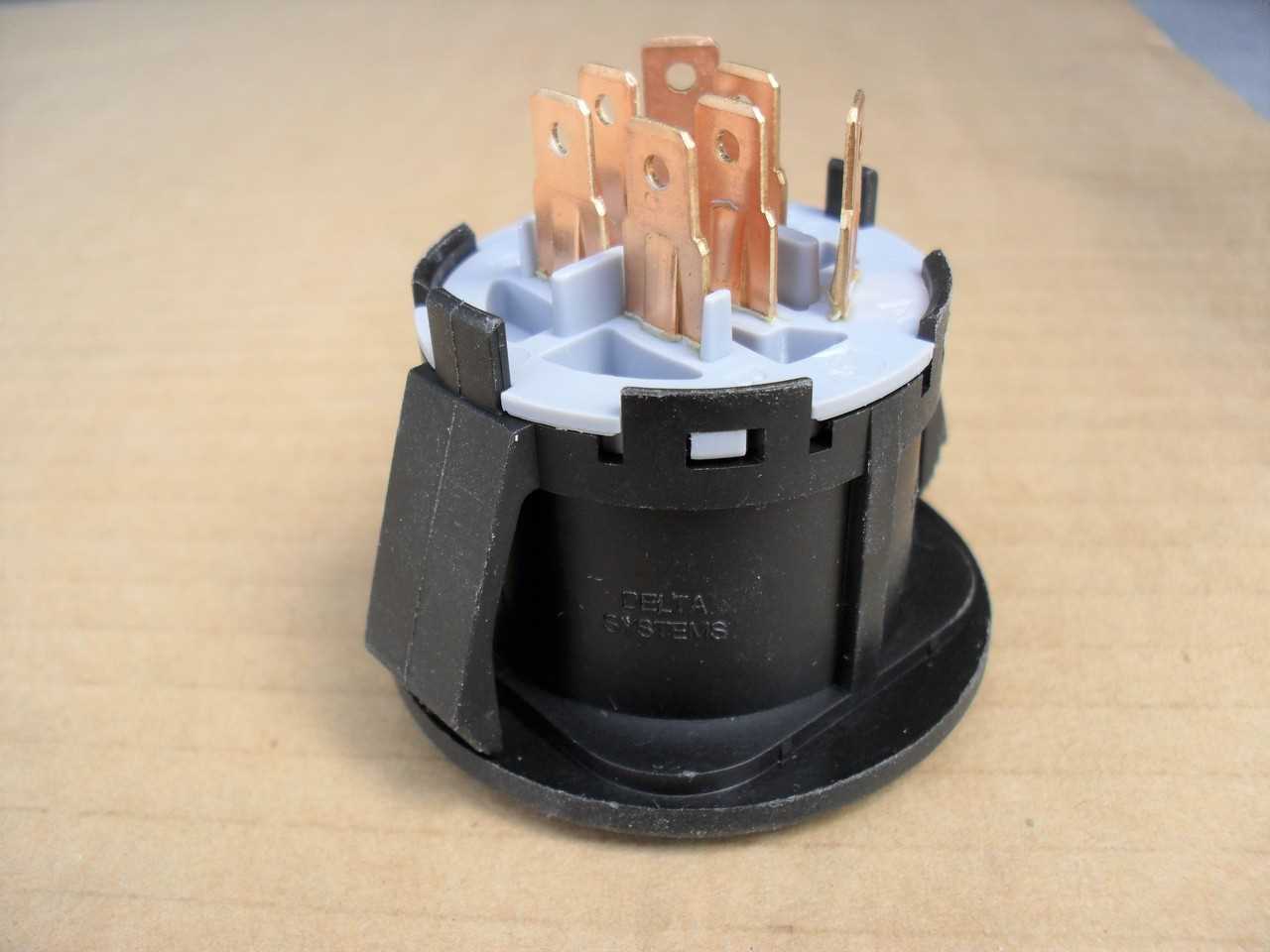

Electrical System: Responsible for powering various functionalities, including ignition, lighting, and instrumentation, it plays a crucial role in the overall operation.

Fuel System: This element manages the delivery of fuel to the engine, optimizing combustion and enhancing efficiency.

By delving into these essential parts, one can appreciate how each contributes to the ultimate performance of the entire assembly.

Where to Find Parts Diagrams

Locating detailed schematics for equipment components can significantly enhance repair and maintenance efforts. Various sources provide access to these visual aids, ensuring users can effectively identify and acquire the necessary items for their machinery.

Online Resources: Numerous websites specialize in offering extensive catalogs, including breakdowns of components. Manufacturer websites are particularly reliable, often featuring downloadable resources.

Community Forums: Engaging with online communities can yield valuable insights. Many enthusiasts and professionals share their experiences and may provide links or files related to specific assemblies.

Local Dealers: Authorized dealers often possess physical copies or can request detailed schematics directly from the manufacturer. This approach ensures authenticity and up-to-date information.

Service Manuals: Purchasing or downloading service manuals can be a worthwhile investment. These manuals typically include comprehensive visuals and detailed descriptions for efficient troubleshooting.

Replacement Parts for Yth1542xp

When it comes to maintaining and enhancing the performance of your machinery, having access to reliable components is crucial. Ensuring that every element is in optimal condition can significantly extend the life of your equipment and improve its efficiency.

Identifying Necessary Components

Understanding which components require replacement is the first step. Regular inspections can help you pinpoint wear and tear. Common areas that may need attention include belts, filters, and blades.

Where to Find Quality Replacements

For sourcing quality replacements, consider reputable dealers or online retailers specializing in equipment accessories. Look for suppliers that offer a warranty on their products, ensuring that you receive durable and effective components. Choosing the right components will ultimately enhance the performance and longevity of your machinery.

Tips for Maintenance and Repair

Proper upkeep and timely fixes are essential for ensuring optimal performance and longevity of your machinery. Regular attention not only enhances efficiency but also minimizes the likelihood of unexpected breakdowns. Following a systematic approach can significantly simplify this process.

Regular Inspection

Conducting frequent assessments allows you to identify wear and tear early. Check all components for signs of damage, and ensure that connections are secure. Pay special attention to areas prone to rust or corrosion, as these can lead to larger issues if neglected.

Use Quality Components

When replacing any items, always opt for high-quality alternatives. Investing in durable materials can save you time and money in the long run by reducing the frequency of replacements and enhancing overall reliability.

Frequently Asked Questions

This section addresses common inquiries related to components and their arrangements. Here, we aim to provide clarity on typical concerns that users may have, ensuring a better understanding of the subject matter.

General Inquiries

Many users seek information about how to effectively identify and utilize various elements in their systems. Below are some of the most frequently asked questions:

| Question | Answer |

|---|---|

| What should I consider when selecting components? | It’s essential to assess compatibility, functionality, and quality to ensure optimal performance. |

| How can I troubleshoot issues related to these elements? | Start by checking connections and specifications, then refer to manuals for detailed guidance. |

Maintenance and Care

Proper maintenance can extend the lifespan of your equipment. Here are some common questions about upkeep:

| Question | Answer |

|---|---|

| How often should I perform maintenance? | Regular checks every few months are recommended, but frequency may vary based on usage. |

| What are the best practices for cleaning? | Use appropriate cleaning solutions and tools to avoid damaging sensitive components. |

Resources for Further Learning

Enhancing your understanding of machinery and their components can be a rewarding journey. Accessing a variety of educational materials and tools is essential for both beginners and seasoned professionals. This section provides valuable references to deepen your knowledge and improve your skills in this field.

Online Tutorials and Courses

Numerous platforms offer structured courses that cover essential topics. Websites like Coursera and edX provide comprehensive learning experiences on mechanical engineering principles, while YouTube features a plethora of instructional videos that offer practical insights and demonstrations.

Books and Technical Manuals

Books remain a fundamental resource for in-depth knowledge. Consider exploring titles that focus on mechanical systems and their functionalities. Additionally, technical manuals specific to various equipment can provide critical information about design and maintenance practices. Libraries and online bookstores are excellent places to find these valuable texts.