Understanding the Yth2042 Parts Diagram for Efficient Maintenance

In the realm of machinery and equipment maintenance, having a clear understanding of the various components that work in unison is crucial for optimal performance. This knowledge not only aids in troubleshooting issues but also empowers users to conduct repairs and upgrades with confidence. A detailed overview of each element’s function allows for more efficient handling and longevity of the machine.

By exploring the intricate relationships between the different parts, one can appreciate how each piece contributes to the overall functionality. This insight is essential for both novice and experienced users, ensuring that they can navigate through any challenges that may arise during operation or maintenance. Recognizing the layout and role of each segment enhances one’s ability to address problems swiftly and effectively.

Moreover, having a reference for the configuration of these components streamlines the process of replacement and repair. Users can avoid common pitfalls and make informed decisions when sourcing new parts or addressing wear and tear. This foundational knowledge serves as a key asset, enabling smoother operations and extending the life of the machinery.

Understanding Yth2042 Parts Diagram

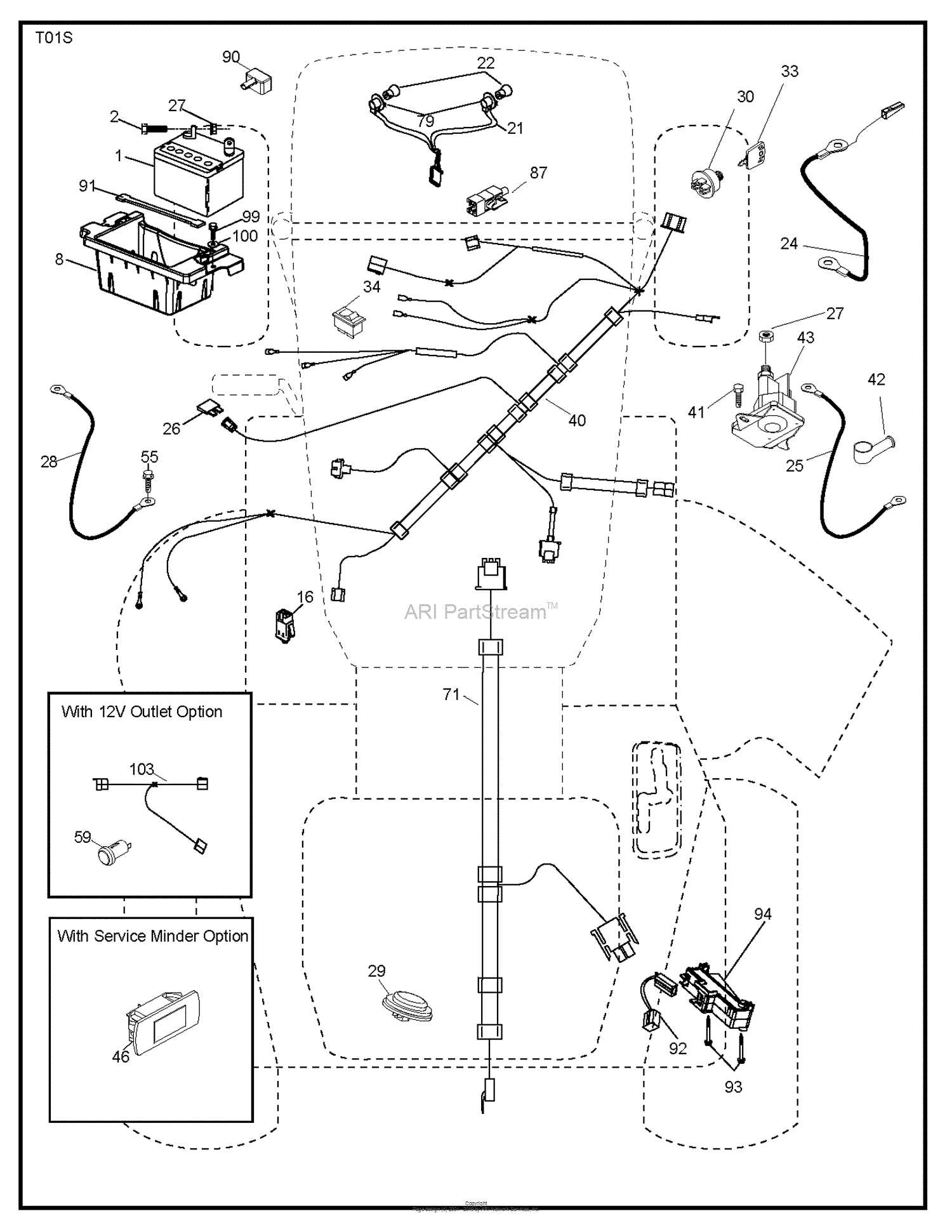

Grasping the intricacies of mechanical components is essential for effective maintenance and repair. A visual representation of various elements involved in machinery serves as a crucial tool for technicians and enthusiasts alike. It allows for a clearer understanding of how individual pieces interact and function within the larger system.

Such illustrations provide a roadmap that highlights the placement and connectivity of each unit, aiding in both assembly and troubleshooting processes. By examining these visuals, one can quickly identify parts, recognize their roles, and pinpoint potential issues that may arise during operation.

Additionally, these representations often include annotations that clarify specific features and functions, making it easier to follow the workflow of repairs or upgrades. Understanding the layout and relationships depicted in these visuals ultimately enhances one’s ability to work efficiently and effectively with complex machinery.

Overview of Yth2042 Model Features

This section provides an in-depth look at the various characteristics and functionalities of a cutting-edge model designed for efficiency and reliability. By examining these attributes, users can better understand its capabilities and applications.

- Design and Build Quality: The model features a robust construction that ensures durability and longevity.

- Performance Efficiency: Engineered for optimal performance, it minimizes energy consumption while maximizing output.

- User-Friendly Interface: The intuitive controls make operation straightforward, even for those with minimal experience.

- Versatile Applications: Suitable for a wide range of tasks, it adapts well to different environments and requirements.

Furthermore, the integration of advanced technology enhances its overall functionality, ensuring users benefit from the latest innovations.

- Advanced Connectivity: Equipped with modern connectivity options, it allows for seamless integration with other devices.

- Safety Features: Multiple safety mechanisms are incorporated to protect users and ensure secure operation.

- Maintenance Accessibility: Designed with ease of maintenance in mind, it facilitates quick and efficient servicing.

In summary, the model stands out due to its exceptional blend of functionality, reliability, and user-centric design, making it a valuable addition to any toolkit.

Importance of Parts Diagrams in Maintenance

Effective upkeep of machinery hinges on the clarity and accessibility of information related to their components. Visual representations play a crucial role in facilitating understanding and ensuring that maintenance tasks are executed efficiently. These illustrations serve as essential guides, aiding technicians in identifying specific elements and their interconnections.

Understanding Complex Systems

In intricate machinery, a comprehensive visual aid simplifies the comprehension of complex systems. It allows maintenance personnel to quickly locate and assess individual elements, reducing the time spent troubleshooting and enhancing overall productivity. With accurate illustrations, professionals can navigate through assemblies with greater confidence, minimizing errors and misdiagnoses.

Streamlining Repair Processes

When maintenance procedures are supported by detailed visual guides, the repair process becomes significantly more streamlined. Technicians can follow step-by-step instructions, ensuring that each component is addressed appropriately. This organized approach not only saves time but also helps in preventing damage to surrounding parts during repairs.

Training and Knowledge Transfer

Visual aids are invaluable for training new personnel. They provide a clear reference that aids in the transfer of knowledge and skills, allowing trainees to familiarize themselves with the machinery’s design and functionality. This foundational understanding is vital for developing competent technicians who can perform maintenance tasks with proficiency.

Enhancing Safety

Additionally, well-structured visual guides contribute to enhanced safety during maintenance operations. By clearly delineating components and their functions, they help workers identify potential hazards associated with specific parts, fostering a safer work environment. This awareness is crucial for preventing accidents and ensuring compliance with safety standards.

In summary, visual representations of machinery components are indispensable in maintenance practices. They enhance understanding, streamline repairs, facilitate training, and improve safety, ultimately contributing to the longevity and reliability of equipment.

Common Components in Yth2042 Design

The intricate design of modern devices incorporates a variety of essential elements that contribute to functionality and efficiency. Understanding these fundamental components allows for a deeper appreciation of how these systems operate and interact with one another.

Key Elements Overview

Among the most crucial parts of these systems are the structural frameworks, which provide stability and support, as well as various electronic modules that enable connectivity and processing capabilities. Each component plays a vital role in ensuring optimal performance.

Functional Categories

| Component Type | Function |

|---|---|

| Power Supply | Provides energy necessary for operation |

| Control Unit | Manages system operations and processes data |

| Sensors | Collects data from the environment |

| Communication Modules | Facilitates data exchange with other systems |

| Actuators | Executes physical actions based on commands |

Each of these elements is designed to work in harmony, contributing to the overall efficacy and responsiveness of the device. A thorough understanding of their interdependencies is essential for anyone involved in development and maintenance.

How to Read a Parts Diagram

Understanding a visual representation of components can greatly enhance your ability to assemble, repair, or maintain machinery. This guide provides insights into effectively interpreting these illustrations, allowing you to identify various elements and their relationships within a system.

Identifying Key Components

Start by familiarizing yourself with the main features shown in the illustration. Each element is usually labeled with a unique identifier, which can include numbers or letters. These identifiers correspond to a list or legend that details specifications or descriptions, helping you grasp the function of each part. Pay close attention to any special symbols or color codes that may indicate important characteristics or assembly order.

Understanding Relationships and Connections

Next, focus on how the various components interact with one another. Lines or arrows often depict connections or flow, guiding you on how parts fit together. This visual guidance can clarify the assembly process or highlight critical links that affect functionality. By comprehending these relationships, you will be better equipped to troubleshoot or enhance performance.

Tools Needed for Yth2042 Repairs

When it comes to maintaining and fixing machinery, having the right tools is essential for effective repairs. Ensuring that you are equipped with the necessary instruments can significantly simplify the process and enhance the overall outcome. Below is a detailed overview of the essential tools you will need for a successful repair job.

Essential Hand Tools

- Socket set: A variety of sockets will help in loosening or tightening bolts and nuts.

- Wrenches: Both adjustable and fixed wrenches are necessary for various fasteners.

- Screwdrivers: A complete set of Phillips and flat-head screwdrivers is crucial for assembling and disassembling components.

- Pliers: Needle-nose and standard pliers will aid in gripping and manipulating small parts.

Specialized Equipment

- Torque wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Useful for diagnosing electrical issues by measuring voltage, current, and resistance.

- Diagnostic tools: Specialized devices may be required for troubleshooting specific systems within the machinery.

- Cleaning supplies: Solvents and brushes will help maintain the integrity of components during repairs.

Having these tools on hand will streamline the repair process and contribute to achieving optimal performance in your equipment.

Identifying Replacement Parts Easily

Locating the right components for maintenance or repair tasks can often be a daunting process. However, with a systematic approach, one can streamline this task, ensuring efficiency and accuracy. Understanding the fundamental aspects of identification allows for quicker resolutions and enhances overall performance.

Utilizing Visual Resources

One effective method for simplifying component identification is through the use of visual aids. Illustrative guides and photographs can significantly reduce confusion. By referring to high-quality images that highlight specific details, one can quickly match the necessary items without extensive searching.

Consulting Reference Materials

In addition to visual resources, reference manuals and catalogues play a crucial role in identifying suitable replacements. These documents often contain detailed descriptions, specifications, and compatibility information. Having access to comprehensive resources ensures that the correct items are selected, minimizing the risk of errors during the replacement process.

Frequently Replaced Parts in Yth2042

Maintaining optimal performance in machinery often requires the timely replacement of certain components. Over time, various elements may wear down or become less effective, necessitating their substitution to ensure smooth operation. Understanding which components are frequently replaced can aid in efficient maintenance planning and prolonging the lifespan of the equipment.

| Component | Common Issues | Recommended Replacement Frequency |

|---|---|---|

| Battery | Decreased charge retention | Every 2-3 years |

| Belts | Cracking or fraying | Annually or as needed |

| Filters | Clogging and reduced airflow | Every 6 months |

| Blades | Dulling and wear | After 20-25 hours of use |

| Oil Seals | Leakage | Every 1-2 years |

Being proactive about replacing these components can significantly enhance the efficiency and reliability of the machinery. Regular inspections and adherence to replacement schedules are vital for optimal operation.

Step-by-Step Repair Guide for Yth2042

This guide aims to provide a comprehensive approach to addressing common issues encountered in your machinery. By following these clear and concise instructions, you can effectively troubleshoot and resolve problems, ensuring optimal performance and longevity.

-

Identify the Issue:

- Observe any unusual sounds or performance discrepancies.

- Check for visible signs of wear or damage.

- Refer to the user manual for specific troubleshooting tips.

-

Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches of various sizes

- Replacement components as needed

- Safety gear (gloves, goggles)

-

Preparation:

- Ensure the machine is turned off and unplugged.

- Clear the workspace to prevent accidents.

- Organize tools and parts for easy access.

-

Dismantle Carefully:

- Remove the outer casing using appropriate tools.

- Take note of the arrangement of internal components.

- Store screws and small parts in labeled containers.

-

Inspect Components:

- Examine belts, gears, and electrical connections for damage.

- Look for loose or corroded connections.

- Check for signs of overheating or wear.

-

Replace or Repair:

- Replace any damaged parts with new ones.

- Tighten loose connections and clean corroded areas.

- Follow manufacturer specifications for component installation.

-

Reassemble:

- Carefully put the outer casing back in place.

- Ensure all screws are tightened securely.

- Double-check that no tools are left inside.

-

Test the Machine:

- Plug the machine back in and power it on.

- Monitor for any unusual noises or issues.

- Ensure it operates smoothly and efficiently.

By adhering to this structured guide, you can effectively manage repairs and maintain the functionality of your equipment, ultimately extending its lifespan and enhancing performance.

Where to Find Official Diagrams

Accessing accurate visual representations is crucial for understanding complex systems. Whether for assembly, troubleshooting, or general reference, having reliable sources can greatly enhance the user experience. This section will guide you through the most effective avenues for obtaining official illustrations.

Manufacturer Websites: The primary resource for authentic visuals is the official website of the manufacturer. These sites often feature dedicated sections for documentation, where you can download necessary materials directly.

User Manuals: Often included with your product, user manuals provide comprehensive details, including annotated illustrations. They can usually be found in the packaging or available for download online.

Community Forums: Engaging with community forums can also yield valuable insights. Many users share their findings and resources, including links to verified materials that can aid in your search.

Technical Support: Don’t hesitate to reach out to technical support for assistance. They can often provide direct links or files that contain the required visuals.

Online Marketplaces: Certain online marketplaces and resource hubs specialize in technical documents. Here, you may find official reproductions or user-uploaded files that are both informative and practical.

By utilizing these resources, you can ensure that you have the most reliable and precise information at your fingertips.

Tips for Ordering Replacement Parts

When it comes to obtaining components for your equipment, ensuring accuracy and efficiency in your order is crucial. The following guidelines can help streamline the process and reduce the likelihood of errors.

| Tip | Description |

|---|---|

| Identify the Model | Always confirm the model number of your machine to ensure compatibility with the items you are ordering. |

| Check Specifications | Review the specifications of the needed components to avoid any mismatch with existing parts. |

| Use Trusted Suppliers | Select reputable vendors known for quality and reliable service to guarantee you receive genuine components. |

| Read Customer Reviews | Look for feedback from other buyers to assess the reliability of the products and the vendor’s service. |

| Keep Documentation Handy | Maintain records of previous orders, including invoices and part numbers, to simplify future purchases. |

| Verify Return Policies | Understand the return and exchange policies of the supplier to ensure you have options in case of issues. |

By following these tips, you can enhance your ordering experience and ensure that you receive the correct items in a timely manner.

Maintaining Your Yth2042 for Longevity

Ensuring the prolonged performance of your machine requires regular attention and care. By following a consistent maintenance routine, you can prevent potential issues and enhance its overall efficiency. Proper upkeep not only prolongs the lifespan of your equipment but also helps to maintain its resale value.

Regular Inspections: Conducting routine checks on various components is crucial. Look for signs of wear, rust, or other damage that may affect functionality. Identifying these problems early can save time and resources down the line.

Fluid Changes: Keeping fluids at optimal levels is essential. Regularly change the oil and other necessary liquids to ensure smooth operation. Clean fluids help to minimize friction and prevent overheating.

Cleaning: A clean machine performs better. Regularly remove dirt, debris, and grass clippings to prevent clogging and overheating. Use appropriate cleaning agents to avoid damaging any surfaces.

Sharpening Blades: If your machine has cutting components, ensure they are sharp and well-aligned. Dull blades can cause strain on the engine and lead to uneven cuts. Regular sharpening will improve performance and reduce wear.

Storage Practices: When not in use, store your equipment in a dry, sheltered location. Protecting it from the elements can prevent rust and other deterioration. Covering it appropriately can also keep pests at bay.

By incorporating these practices into your routine, you can enjoy a reliable and efficient machine for years to come. Prioritizing maintenance not only safeguards your investment but also enhances your overall experience.