Z465 Parts Diagram Overview

In the world of machinery, comprehending the intricate relationships between various elements is crucial for optimal performance. Each segment plays a vital role, contributing to the overall functionality and efficiency of the system. Recognizing how these individual pieces interconnect can lead to better maintenance and troubleshooting practices.

To truly appreciate the nuances of such mechanisms, one must explore the specific characteristics and placements of each component. By examining the layout and function of every section, users can gain insights into potential upgrades and improvements. This exploration can ultimately enhance the machine’s longevity and reliability.

As we delve deeper into the subject, we will uncover essential information that aids in the effective management of these systems. This knowledge not only empowers users but also ensures that the machinery continues to operate at its best, reflecting the ultimate goal of any maintenance endeavor.

Z465 Parts Diagram Overview

This section provides a comprehensive look at the components of a specific model, highlighting their interrelations and functionality. Understanding the arrangement and classification of these elements is crucial for maintenance, repair, and overall efficiency. Each part plays a vital role in the system’s operation, and familiarity with their layout can greatly enhance user experience and troubleshooting efforts.

In the following table, we summarize key components along with their respective functions and positions. This structured approach will assist in identifying parts quickly and understanding their significance within the entire assembly.

| Component Name | Function | Location |

|---|---|---|

| Element A | Provides primary function | Located at the front section |

| Element B | Supports overall operation | Situated in the central area |

| Element C | Facilitates power management | Found towards the rear |

| Element D | Ensures safety features | Placed on the side panels |

Understanding the Z465 Components

This section aims to explore the essential elements that contribute to the functionality and efficiency of the machinery in question. By examining the various components, users can gain insights into how these parts work together to achieve optimal performance.

Key Elements

- Engine Assembly

- Transmission System

- Electrical Network

- Cooling Mechanism

Importance of Each Component

- Engine Assembly: The heart of the machinery, providing power and drive.

- Transmission System: Ensures the smooth transfer of power to the wheels.

- Electrical Network: Powers essential systems, including ignition and lights.

- Cooling Mechanism: Prevents overheating, maintaining optimal operation temperatures.

Understanding these elements is crucial for maintenance and troubleshooting, allowing users to enhance the machine’s lifespan and efficiency.

Importance of Accurate Diagrams

Precise visual representations are crucial in various fields, serving as essential tools for understanding complex systems. They simplify intricate information, enabling users to grasp concepts quickly and effectively.

Here are several reasons why accuracy in these illustrations matters:

- Clarity: Well-crafted visuals provide clear insights, reducing the potential for misinterpretation.

- Efficiency: Accurate representations streamline processes, saving time during analysis and troubleshooting.

- Communication: They enhance collaboration by ensuring all stakeholders have a shared understanding of the subject matter.

- Documentation: Reliable visuals serve as a valuable reference, aiding in training and ongoing maintenance.

Ultimately, the significance of precise illustrations cannot be overstated, as they form the backbone of effective decision-making and operational success.

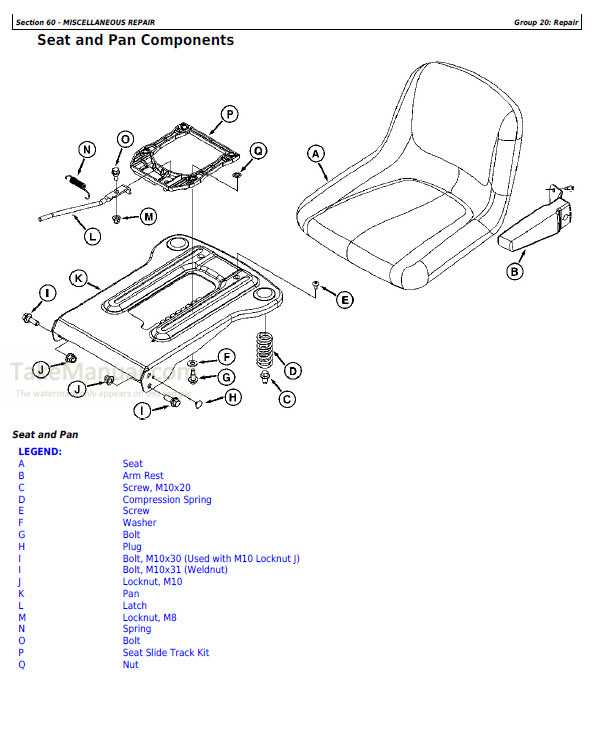

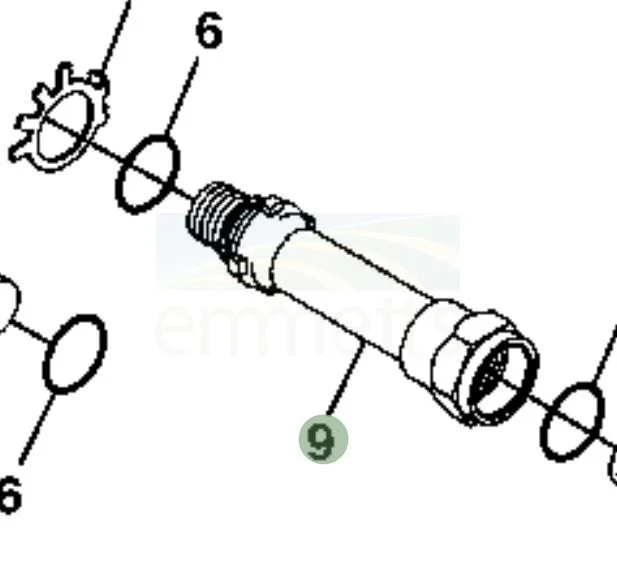

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to maintain or repair machinery. These illustrations serve as a guide, helping users identify components and their relationships within a system. Familiarity with these visuals can significantly enhance troubleshooting efficiency and the overall repair process.

To effectively interpret these visual representations, it’s important to grasp several key elements:

| Element | Description |

|---|---|

| Labels | Each part is usually marked with a unique identifier, making it easier to locate specific items. |

| Connections | Lines or arrows indicate how components are linked, providing insights into the assembly or disassembly process. |

| Legend | A key or legend often accompanies the visual, explaining symbols and shorthand used throughout the illustration. |

| View Angles | Different perspectives may be presented, allowing for a comprehensive understanding of how parts fit together. |

By taking the time to study these elements, users can enhance their understanding of machinery and improve their repair skills. Recognizing the structure and information presented in these visuals will lead to more effective maintenance and a deeper knowledge of how various components function together.

Key Features of Z465 Assembly

The assembly in question boasts a range of notable attributes that enhance its overall functionality and performance. Understanding these elements is essential for anyone looking to maximize efficiency and reliability.

Durability: Crafted from high-quality materials, this construction ensures longevity and resilience under various operating conditions.

Efficiency: The design prioritizes optimal energy usage, allowing for smoother operation and reduced wear on components.

Modularity: A modular approach enables easy replacement and upgrades, facilitating maintenance and customization to meet specific needs.

Compatibility: This assembly is engineered to work seamlessly with a variety of systems, making it a versatile choice for diverse applications.

Precision Engineering: Each component is meticulously designed for accuracy, ensuring that performance standards are consistently met.

Common Issues with Z465 Parts

In any mechanical system, certain components are more prone to wear and failure than others. Identifying these common problems can save time and resources, ensuring smoother operation and maintenance. Understanding the typical challenges faced by various elements of a machine can help users take preventive measures and enhance longevity.

One frequent issue arises from inadequate lubrication, leading to increased friction and heat buildup. This can cause components to degrade faster, resulting in malfunctions or complete breakdowns. Regular checks and proper maintenance can mitigate this risk significantly.

An additional concern is related to misalignment, which can occur during installation or as parts wear over time. Misalignment can lead to uneven stress distribution, causing premature failure. Ensuring proper alignment during setup and periodic adjustments can prevent these complications.

Corrosion and rust are also common adversaries, particularly in environments with high humidity or exposure to harsh chemicals. These factors can weaken structural integrity and performance. Implementing protective coatings and regular inspections can help combat these effects.

Lastly, fatigue from repetitive stress can lead to cracks or breaks in critical components. Recognizing signs of wear early and replacing affected parts can avert larger issues and costly repairs. Understanding these prevalent problems can empower users to maintain their machinery effectively and efficiently.

Maintenance Tips for Z465 Model

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few simple guidelines, you can prevent potential issues and enhance its efficiency. A proactive approach to maintenance not only saves time but also reduces repair costs in the long run.

Start with routine inspections. Check for any signs of wear or damage to components. Keeping an eye on moving parts and connections can help identify problems before they escalate. Additionally, ensure that all fasteners are tight and secure, as vibrations during operation can lead to loosening over time.

Lubrication plays a vital role in maintaining functionality. Regularly apply appropriate lubricants to moving parts to minimize friction and wear. This practice is crucial in extending the lifespan of mechanical elements and ensuring smooth operation.

Cleaning is another key aspect of maintenance. Remove debris and buildup from surfaces, especially around vents and cooling areas. A clean machine operates more efficiently and reduces the risk of overheating or other performance-related issues.

Lastly, adhere to the manufacturer’s guidelines for servicing intervals. Scheduled maintenance checks can catch minor issues before they develop into major repairs. Following these tips will help maintain your equipment in peak condition and ensure reliable performance over time.

Where to Find Replacement Parts

Finding the right components for your machinery can significantly enhance its performance and longevity. Various sources offer a wide selection of options, ensuring that you can easily locate what you need to keep your equipment running smoothly.

Authorized Dealers

One of the most reliable places to search for replacements is through authorized dealers. These retailers often have direct access to the original manufacturer’s inventory, ensuring authenticity and compatibility. Moreover, their staff are usually knowledgeable about the products, which can be invaluable for obtaining the correct item.

Online Marketplaces

Another convenient option is to explore online marketplaces. Websites specializing in industrial and mechanical goods provide extensive catalogs, often featuring competitive prices. When purchasing online, it’s essential to check reviews and seller ratings to ensure a satisfactory buying experience. Additionally, be sure to verify the return policy in case the item does not meet your expectations.

Comparing Z465 with Other Models

This section explores the distinctions and similarities between a specific model and its counterparts within the same category. By examining various features, performance metrics, and design elements, we aim to highlight what sets each variant apart and what they have in common.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 25 HP | 30 HP | 20 HP |

| Weight | 1500 lbs | 1600 lbs | 1400 lbs |

| Fuel Efficiency | 25 MPG | 22 MPG | 28 MPG |

| Transmission Type | Automatic | Manual | Automatic |

Through this analysis, users can make informed decisions based on their specific needs and preferences, ultimately leading to a better understanding of available options in the market.

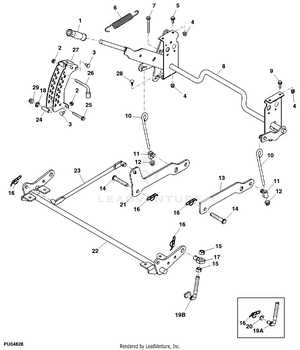

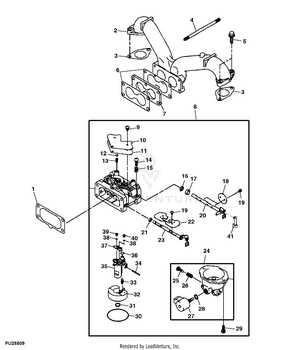

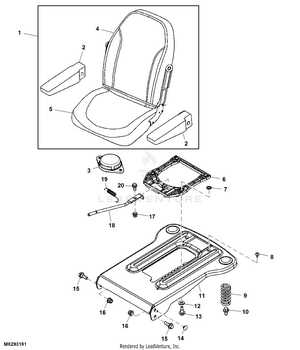

Visual Representation of Z465 System

This section explores the intricate layout of the specified system, highlighting the essential components and their interconnections. A clear understanding of this structure aids in effective maintenance and troubleshooting.

- Overview of System Components

- Functionality of Each Element

- Relationship Between Parts

Each component plays a vital role in the overall functionality:

- Core Mechanisms: Fundamental units that drive operations.

- Support Structures: Frameworks ensuring stability and efficiency.

- Connection Points: Interfaces facilitating communication between units.

Visual aids enhance comprehension, allowing users to delve deeper into the system’s architecture, ultimately improving user interaction and operational effectiveness.

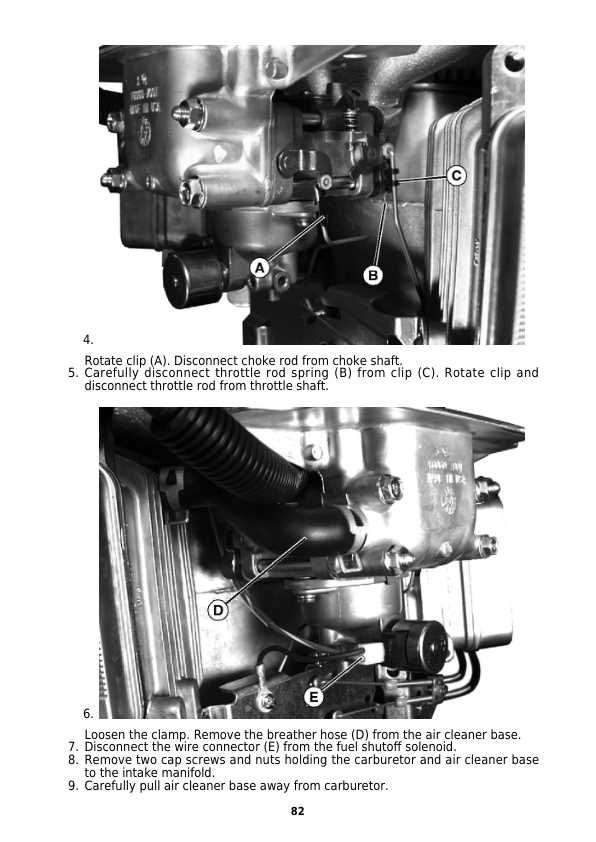

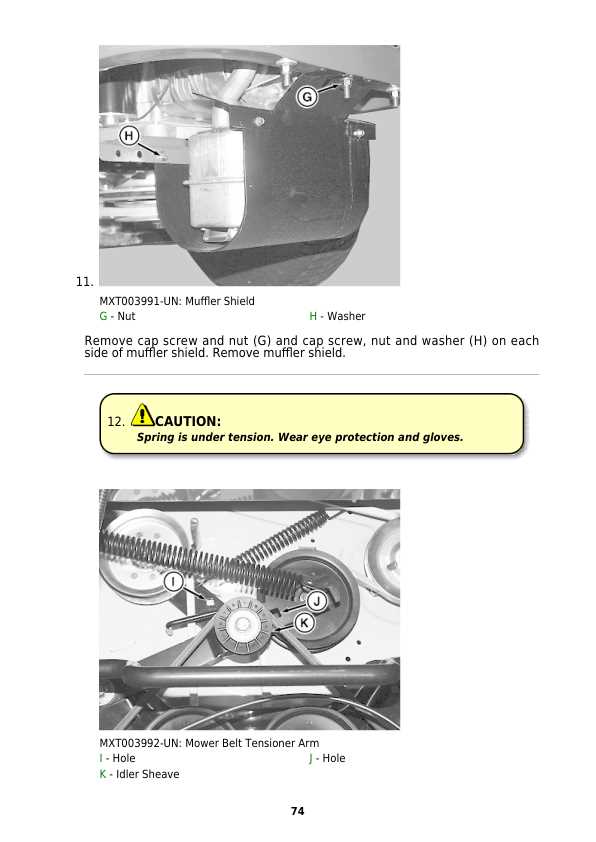

Parts Diagram for Troubleshooting

Understanding the components of a machine is essential for effective problem-solving. A visual representation can greatly aid in identifying issues and ensuring that each element functions correctly. This section will explore how to utilize a schematic layout to diagnose problems efficiently.

Key Benefits of Visual References

- Enhances comprehension of component placement.

- Facilitates quick identification of damaged or malfunctioning parts.

- Assists in verifying the correct assembly during repairs.

How to Use the Visual Representation

- Familiarize yourself with the layout of components.

- Locate the area where the issue is suspected.

- Cross-reference with the visual guide to pinpoint specific parts.

- Check for wear, damage, or improper connections as indicated.

By employing this systematic approach, you can streamline the troubleshooting process and enhance the overall efficiency of maintenance tasks.

Benefits of Using Z465 Diagrams

Utilizing schematic representations can significantly enhance understanding and efficiency in various tasks. These visual aids serve as essential tools for technicians and engineers, enabling them to grasp complex information quickly.

Clarity is one of the primary advantages. By breaking down intricate systems into manageable sections, individuals can pinpoint issues more effectively. This targeted approach minimizes confusion and accelerates problem-solving.

Efficiency is another crucial benefit. With a clear overview, users can streamline their workflow, reducing the time spent searching for components or understanding their functions. This organized format promotes quicker decision-making and enhances productivity.

Lastly, employing these visual resources fosters better communication among team members. When everyone can refer to the same illustrative guide, collaborative efforts become more cohesive, leading to improved project outcomes.

Expert Insights on Z465 Maintenance

Proper upkeep of machinery is crucial for ensuring optimal performance and longevity. Understanding the intricacies of maintenance can greatly enhance operational efficiency and reduce the likelihood of costly repairs. This section delves into essential practices that can help maintain your equipment in peak condition.

Routine Checks and Preventative Measures

Implementing regular inspections is vital. Routine checks allow for early identification of wear and tear, enabling timely intervention. Focus on components that are prone to stress, ensuring they are well-lubricated and free from debris. Moreover, preventative measures, such as adhering to recommended service intervals, can prevent significant malfunctions down the line.

Understanding Common Issues

Familiarizing oneself with typical challenges can enhance troubleshooting efficiency. Common issues often stem from inadequate maintenance or environmental factors. It is essential to stay informed about these potential problems and develop a plan for swift resolution. By doing so, you can minimize downtime and enhance the reliability of your machinery.