2001 Polaris Magnum 325 Parts Overview

When it comes to maintaining or restoring all-terrain vehicles, having a clear picture of the component layout is essential. Knowing the position and connectivity of various elements can greatly assist in troubleshooting issues and performing repairs with confidence. This section provides an overview of how different components are arranged, ensuring a smoother repair or upgrade process.

Component arrangement plays a crucial role in the vehicle’s performance and reliability. Being aware of how each piece interacts with others helps identify potential problem areas and facilitates efficient replacement or maintenance tasks. This understanding can be especially valuable when dealing with complex mechanical systems, where precision and accuracy are key.

Whether you are an experienced technician or a hobbyist, having detailed insights into the layout of mechanical systems enables you to approach repairs and upgrades methodically. Such knowledge not only saves time but also enhances the overall quality of the work done, leading to a better-performing machine.

The purpose of this section is to provide a comprehensive understanding of the various components and their functions in this all-terrain vehicle. By exploring the different elements, readers can gain a clearer picture of how each piece contributes to the overall performance and maintenance of the machine.

Frame and Body Structure: The frame acts as the foundation, supporting other components and ensuring stability. The body panels, in turn, protect internal systems from external factors such as dirt and debris.

Engine and Powertrain Components: This section covers the primary systems responsible for generating and transferring power. Understanding these parts will help with both troubleshooting and improving overall efficiency.

Steering and Suspension Systems: Designed to provide control and comfort, these parts ensure smooth handling. Details on various elements such as shock absorbers and steering linkages will be outlined here.

Engine Components and Maintenance

The engine is a crucial element that requires regular attention to ensure long-term performance and reliability. Proper upkeep not only extends the lifespan of the machinery but also helps prevent unexpected breakdowns and costly repairs. Understanding the key components and how to maintain them is essential for any operator.

Cylinder and Piston Care: The cylinder and piston are vital parts that facilitate power generation. Regular inspection for wear, scoring, or other damage is necessary. Cleaning and lubricating these parts with the recommended oils help maintain smooth operation and reduce friction-related issues.

Cooling System: To prevent overheating, the cooling system should always be in optimal condition. Check the radiator and coolant levels periodically, ensuring there are no leaks or blockages. Replacing the coolant at scheduled intervals helps keep the engine’s temperature regulated and prevents internal damage.

Air Intake and Filtration: The air intake system ensures that clean air reaches the combustion chamber. Dirt or debris in the air filter can impede airflow, resulting in reduced efficiency.

Suspension System Breakdown

The suspension system plays a crucial role in providing a smooth and stable ride, ensuring that the vehicle can handle various terrains with ease. This section will delve into the primary components and their functions, giving an overview of how the system contributes to overall performance and ride quality. Understanding these elements can help identify potential issues and improve maintenance strategies.

Main Components and Their Roles

The suspension system consists of several interconnected parts that work together to absorb shocks and maintain traction. Key components include springs, which support the vehicle’s weight, and shock absorbers, which help control the rebound of the springs. Additionally, control arms and bushings connect the wheels to the frame, allowing for flexible movement while maintaining stability. Each of these elements plays a unique role in ensuring a balanced and comfortable driving experience.

Signs of Wear and Common Issues

Regular inspection of the suspension system is essential to detect signs of wear, such as leaking fluid from shock absorbers, uneven tire wear, or unusual noises when driving over bumps. Addressing these issues early can prevent further damage and ensure the system continues to perform optimally. Routine maintenance, including checking the condition of springs

Electrical System Parts Guide

The electrical framework is an essential component that ensures the efficient functioning of any vehicle’s mechanisms. Understanding the elements that make up this system can help identify potential issues and optimize the overall performance. This section outlines the main elements involved and their roles in maintaining proper electrical flow.

Main Components Overview

The system typically consists of several key elements, including the battery, which supplies the necessary energy, and wiring that connects various sections of the framework. Additionally, the ignition switch plays a crucial role in activating the engine’s electrical circuits, while the regulator helps to maintain a stable flow of electricity.

Common Issues and Troubleshooting Tips

Failures in this framework can often be traced back to worn-out connectors or damaged circuit components. Regular checks and timely replacements of faulty elements, such as fuses or switches, can prevent bigger issues. Keeping the cables in good condition also ensures uninterrupted energy flow, which is vital for reliable operation.

Fuel System Overview and Tips

The fuel system is essential for the engine’s performance, ensuring that the right amount of fuel reaches the combustion chamber for optimal operation. Understanding how this system works and knowing how to maintain it can help prevent common issues and improve reliability. This section provides an overview of the fuel system components and offers practical advice for keeping them in good condition.

Main Components of the Fuel System

The fuel system consists of several key parts, including the fuel tank, fuel pump, filter, and carburetor. Each component plays a specific role in delivering fuel efficiently. The fuel tank stores the gasoline, while the fuel pump ensures it reaches the carburetor under the right pressure. A filter is used to remove impurities, ensuring only clean fuel enters the engine.

Maintenance Tips for a Healthy Fuel System

Regular inspection and cleaning are essential to keep the fuel system in top shape. Always check the filter for clogs and replace it if necessary. Cleaning the carburetor periodically can prevent buildup that affects performance. Additionally, make sure to use high-quality fuel and consider adding fuel stabilizer if the vehicle will be unused for extended periods, as this helps prevent fuel degradation.

Brake Assembly and Servicing

The brake assembly is a crucial component in ensuring the safety and reliability of any vehicle. Proper maintenance and timely servicing of the braking system can prevent accidents and enhance the overall performance of the machine. Understanding the components involved and their functions is essential for effective troubleshooting and repair.

Components of the Brake System

The braking system typically consists of various elements, including brake pads, rotors, calipers, and hydraulic lines. Each part plays a vital role in the braking process, from generating friction to slowing down the vehicle. Regular inspection of these components can help identify wear and tear, ensuring they operate efficiently.

Servicing Procedures

Routine servicing of the braking system includes checking the condition of the brake pads, ensuring adequate fluid levels, and inspecting the rotors for any signs of damage. It is important to replace worn components promptly and to follow manufacturer recommendations for maintenance intervals. By adhering to these practices, the longevity and effectiveness of the braking system can be preserved.

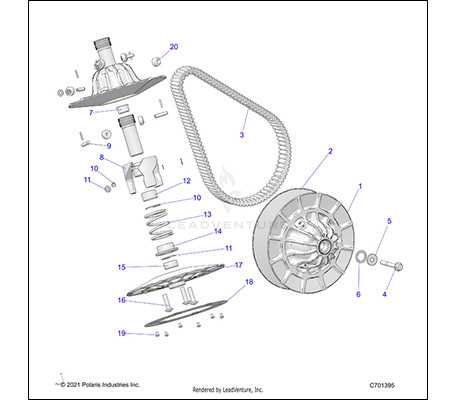

Transmission Parts and Function

The transmission system is crucial for the effective operation of any all-terrain vehicle. It facilitates the transfer of power from the engine to the wheels, allowing for smooth acceleration and deceleration. Understanding the components and their roles within this system is essential for maintenance and troubleshooting.

Key Components of the Transmission

The main components that make up the transmission include gears, shafts, and clutches. Each of these elements plays a vital role in ensuring that power is transmitted efficiently. The interaction between these parts determines how effectively the vehicle can respond to varying terrain and driving conditions.

Functionality Overview

The primary function of the transmission is to convert the engine’s rotational force into usable power for the wheels. This is achieved through a series of gear ratios, which allow the vehicle to adapt to different speeds and loads. When the driver accelerates, the transmission adjusts the gear ratio to maintain optimal performance.

| Component | Function |

|---|---|

| Gears | Change the torque and speed sent to the wheels. |

| Shafts | Transmit power between the engine and the wheels. |

| Clutches | Engage and disengage the power flow during gear shifts. |

Cooling System Components

The cooling system plays a vital role in maintaining optimal operating temperatures within an engine. It ensures that the engine functions efficiently by dissipating heat generated during combustion. Understanding the various elements of this system is crucial for effective maintenance and performance enhancement.

Key Elements of the Cooling System

This system typically includes a radiator, water pump, thermostat, and cooling hoses. Each component has a specific function, contributing to the overall efficiency of temperature regulation. The radiator dissipates heat from the coolant, while the water pump circulates the coolant throughout the engine. The thermostat controls the flow of coolant based on temperature, ensuring the engine operates within the ideal range.

Maintenance and Troubleshooting

Regular inspection of the cooling system is essential to prevent overheating and engine damage. Common issues may include leaks in hoses, a malfunctioning water pump, or a clogged radiator. Addressing these problems promptly can help maintain the system’s efficiency and prolong the life of the engine.

Body Frame and Panels Overview

The structural components of a vehicle play a crucial role in providing stability and support. This section focuses on the essential elements that constitute the frame and body panels, highlighting their functions and significance in overall performance. A well-designed frame ensures durability and optimal handling, while the panels contribute to the vehicle’s aesthetic appeal and protection against external elements.

Key Components of the Frame

- Chassis: The main structure that supports the entire vehicle and connects various components.

- Cross Members: Reinforcements that add strength and rigidity to the frame.

- Subframe: A secondary framework that supports specific components, enhancing stability.

Body Panels and Their Functions

- Fenders: Protect the wheels and reduce splash while enhancing the vehicle’s profile.

- Hood: Covers the engine compartment, contributing to the vehicle’s aerodynamics.

- Side Panels: Provide structural integrity and aesthetic appeal to the sides of the vehicle.

- Rear Panel: Encloses the back area and often houses lighting fixtures.

Understanding the relationship between the frame and body panels is vital for maintenance and repair. Regular inspections can help identify wear and damage, ensuring longevity and safe operation.

Steering Mechanism and Adjustments

The steering system plays a vital role in ensuring precise handling and control of the vehicle. It consists of various components that work together to provide a smooth and responsive steering experience. Proper adjustments and maintenance of this mechanism are essential for optimal performance and safety.

In this section, we will explore the main components of the steering assembly and how to adjust them effectively. Regular inspection and tuning can help maintain the integrity of the steering system, ultimately enhancing maneuverability.

| Component | Description | Adjustment Procedure |

|---|---|---|

| Steering Wheel | Controls the direction of the vehicle. | Ensure it is centered and aligned with the front wheels. |

| Steering Shaft | Connects the steering wheel to the gear mechanism. | Check for play and secure all connections. |

| Steering Gear | Converts the rotary motion of the wheel into linear motion. | Adjust the tension as per the manufacturer’s specifications. |

| Linkage | Transfers motion from the steering gear to the wheels. | Inspect for wear and replace if necessary. |

| Ball Joints | Allow pivoting and smooth movement of the steering linkage. | Lubricate regularly and check for any damage. |

By understanding the components and their functions, users can ensure their steering mechanism is in excellent condition, providing a safer and more enjoyable driving experience.

Exhaust System Diagram

The exhaust system plays a crucial role in the performance and efficiency of a vehicle. It is designed to direct harmful gases away from the engine and reduce noise levels. Understanding the layout and components of this system is essential for effective maintenance and troubleshooting.

Typically, the exhaust setup consists of several key elements, including the exhaust manifold, catalytic converter, muffler, and tailpipe. Each component works together to ensure optimal engine operation while minimizing environmental impact. Regular inspection of these parts can prevent issues such as leaks, reduced power output, and excessive noise.

In addition, visual representations of the exhaust configuration can assist technicians and enthusiasts in identifying specific parts and their functions. This knowledge is vital for making informed decisions during repairs or upgrades, ultimately enhancing the overall performance of the vehicle.

Aftermarket Parts and Upgrades

Exploring enhancements and alternative components for your vehicle can significantly improve performance and longevity. Upgrading to aftermarket options allows enthusiasts to tailor their machines to their specific needs, ensuring a more personalized experience. These enhancements can range from performance boosters to aesthetic modifications, each designed to elevate the overall functionality.

Performance Upgrades: Many users opt for aftermarket modifications to enhance power and efficiency. Upgrades such as high-performance air filters, exhaust systems, and ignition components can lead to noticeable gains in horsepower and torque. These modifications not only enhance speed but can also improve fuel efficiency, making them a worthwhile investment for those seeking to maximize their ride’s capabilities.

Aesthetic Enhancements: In addition to performance upgrades, many owners focus on the appearance of their vehicle. Custom body kits, graphics, and lighting options can give your machine a unique look. Aesthetic upgrades often reflect the owner’s personality and style, making the vehicle stand out on the trails or at events.

Durability and Maintenance: Aftermarket solutions often provide enhanced durability compared to stock components. Upgrading suspension systems, brake kits, and tires can lead to improved handling and safety. Additionally, choosing high-quality replacement parts can reduce maintenance costs in the long run by extending the lifespan of critical components.

Ultimately, investing in aftermarket options allows for a more customized and enjoyable experience. By carefully selecting upgrades that align with personal preferences and riding habits, enthusiasts can create a machine that truly reflects their vision.