Understanding the Polaris 360 Parts Diagram for Easy Maintenance

Exploring the intricate assembly of your aquatic machine can significantly enhance its performance and longevity. By gaining insight into its various elements, you can ensure optimal functionality and address any issues that may arise. This guide will lead you through the essential components, highlighting their roles and interconnections.

Visual representation of these elements serves as an invaluable resource for enthusiasts and professionals alike. Familiarity with the configuration not only simplifies maintenance tasks but also empowers you to troubleshoot effectively. As we delve deeper into this subject, you’ll uncover the ultimate benefits of understanding your vessel’s mechanics.

Whether you’re a seasoned expert or a newcomer, knowledge of these vital components will enhance your experience on the water. Prepare to navigate through this essential information, unlocking the full potential of your aquatic experience.

Understanding Polaris 360 Design

The intricate engineering of this aquatic device showcases a blend of functionality and aesthetic appeal. Every element is meticulously crafted to ensure optimal performance and durability in various environments.

Key components are thoughtfully arranged, promoting efficiency and ease of use. The arrangement facilitates streamlined operation, allowing users to navigate seamlessly while enjoying enhanced safety features.

Durability is a cornerstone of its construction, ensuring that the device withstands the rigors of frequent exposure to water and debris. This resilience is achieved through high-quality materials and advanced design techniques that prioritize long-term reliability.

In addition, the design incorporates innovative technology that enhances user experience, making maintenance and operation straightforward. By focusing on these essential aspects, the overall design serves its ultimate purpose effectively, providing users with a reliable tool for their aquatic needs.

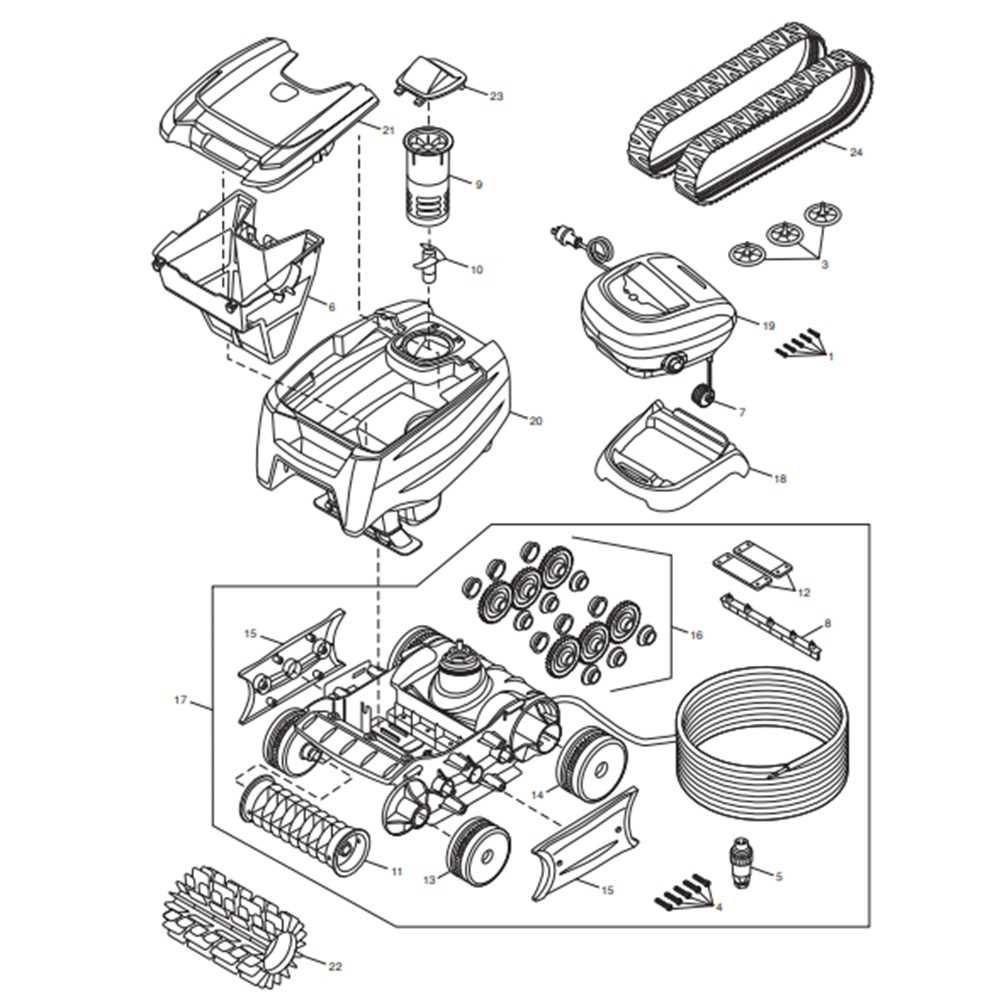

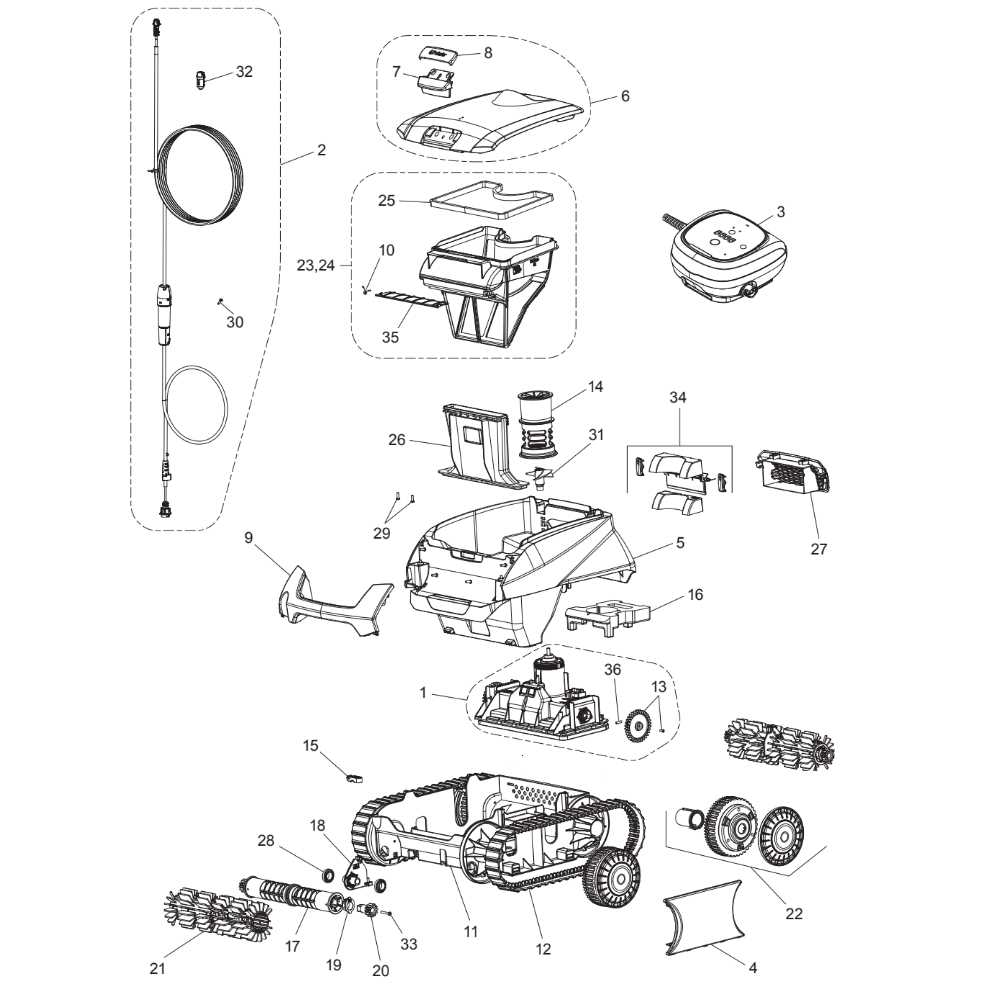

Key Components of Polaris 360

The functionality of any advanced cleaning device relies on its essential elements, each playing a crucial role in enhancing performance and efficiency. Understanding these integral parts helps users appreciate how the system operates and aids in troubleshooting any issues that may arise.

Navigation System: This feature ensures smooth movement across various surfaces, allowing the device to cover the entire area without missing spots.

Filtration Unit: An effective filtration mechanism captures debris and contaminants, maintaining water clarity and promoting a healthier environment.

Power Source: The energy supply is vital for the overall operation, determining the device’s run time and effectiveness in cleaning tasks.

Brush Mechanism: Specialized brushes are designed to scrub surfaces thoroughly, dislodging dirt and algae for optimal cleaning results.

Control Module: This central unit manages the operations, allowing users to set preferences and schedules for automated cleaning cycles.

Importance of Parts Diagram

Understanding the layout and components of machinery is crucial for effective maintenance and repairs. A visual representation serves as a roadmap, guiding users through complex systems.

- Enhances comprehension of individual elements.

- Facilitates accurate identification of replacement components.

- Streamlines the repair process, saving time and effort.

- Reduces the likelihood of errors during assembly or disassembly.

- Supports efficient inventory management for necessary supplies.

Ultimately, having a clear visual guide empowers users to tackle mechanical challenges with confidence and precision.

How to Read the Diagram

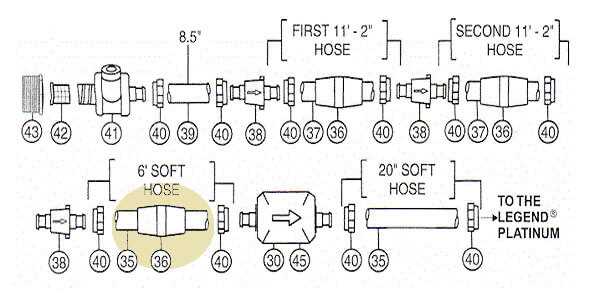

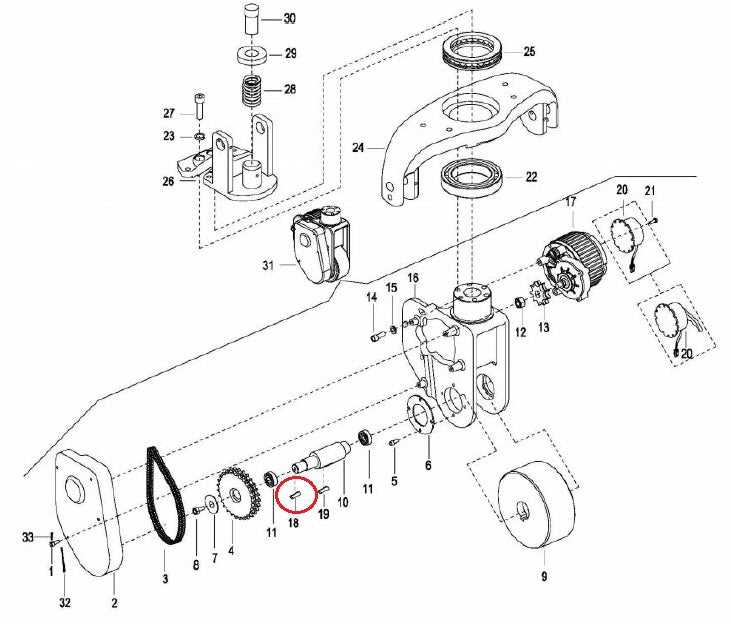

Understanding a schematic representation is essential for efficient troubleshooting and maintenance. These visuals provide a detailed view of components and their interconnections, enabling users to identify each element’s function and relationship.

Begin by familiarizing yourself with the symbols used in the illustration. Each symbol typically corresponds to a specific component, such as a valve, motor, or wiring. Recognizing these symbols is crucial for accurately interpreting the layout.

Next, pay attention to the labels and annotations accompanying the visuals. They offer vital information about each part, including specifications, connections, and orientation. Cross-referencing these notes with your actual setup can clarify any uncertainties.

Lastly, practice tracing the flow of operation through the representation. Understanding how each component interacts with others can provide insights into the overall system functionality, enhancing your ability to diagnose issues effectively.

Common Issues and Solutions

This section addresses frequent challenges encountered by users and offers effective remedies to enhance functionality and longevity.

-

Problem: Inconsistent performance

Solution: Check and clean filters regularly to ensure optimal airflow.

-

Problem: Unusual noises during operation

Solution: Inspect for loose components and tighten as necessary.

-

Problem: Leaks or fluid loss

Solution: Examine seals and hoses for wear, replacing any damaged parts.

-

Problem: Overheating

Solution: Ensure proper ventilation and clean any debris from intake areas.

By addressing these common issues proactively, users can maintain their equipment in peak condition and prevent larger complications.

Identifying Essential Spare Parts

Understanding the crucial components of your equipment is vital for maintaining optimal performance and longevity. By recognizing the key elements, you can ensure smooth operation and minimize downtime.

Key Components to Consider

- Engine parts

- Transmission components

- Electrical systems

- Chassis elements

- Cooling system elements

Tips for Identification

- Consult the manufacturer’s guide for specifications.

- Check for common wear indicators.

- Utilize online resources for visual references.

- Keep a maintenance log for tracking replacements.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention to detail. By following a few essential guidelines, you can significantly extend the life of your machinery and enhance its efficiency.

Regular Inspection

Routine checks are vital for identifying potential issues before they escalate. Focus on the following areas:

- Check for wear and tear on moving components.

- Inspect seals and gaskets for leaks.

- Monitor fluid levels and quality regularly.

Proper Cleaning

Keeping your machinery clean is crucial for preventing buildup that can lead to malfunctions. Consider these cleaning practices:

- Use appropriate cleaning agents that won’t damage surfaces.

- Remove debris and dirt after each use.

- Schedule deep cleaning sessions periodically.

By incorporating these maintenance tips into your routine, you can ensure your equipment remains in peak condition for years to come.

Comparison with Other Models

When examining the features and components of various aquatic cleaning devices, it’s essential to understand how different models stack up against each other. Each design presents unique strengths and weaknesses, influencing efficiency and usability. By exploring these distinctions, users can make informed choices tailored to their specific needs.

In terms of suction power, some competitors offer more robust options, enabling them to handle larger debris effectively. However, other models excel in maneuverability, making them ideal for intricate pool shapes. Additionally, build quality varies significantly, with certain units showcasing superior materials that enhance durability over time.

Another aspect worth noting is the technology employed in navigation and cleaning patterns. While some devices utilize advanced mapping systems for optimized routes, others rely on simpler random patterns, which may affect overall coverage. Ultimately, the right choice will depend on individual preferences and the specific requirements of the user’s environment.

Where to Find Replacement Parts

Locating suitable components for your equipment can be straightforward with the right resources. Whether you’re looking for original or aftermarket options, various avenues are available to ensure you find what you need.

- Online Retailers: Websites specializing in outdoor equipment often have extensive inventories.

- Manufacturer’s Website: Visiting the official site can provide access to genuine items and specifications.

- Local Dealerships: Authorized sellers typically stock essential components and can offer expert advice.

- Forums and Communities: Engaging with fellow enthusiasts can lead to recommendations and tips on sourcing.

- Second-Hand Markets: Consider platforms where used items are sold, but verify quality and compatibility.

Utilizing these resources can help streamline your search for the right components, ensuring optimal performance for your machinery.

Tools Needed for Repairs

Effective maintenance and troubleshooting require a well-equipped toolkit. Having the right instruments at your disposal can significantly simplify the repair process, ensuring that tasks are completed efficiently and accurately. This section outlines essential tools that will aid in various repair activities.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of sizes and types, including Phillips and flathead, for removing and securing screws. |

| Socket Wrench | Ideal for loosening and tightening nuts and bolts, offering versatility with different socket sizes. |

| Pliers | Useful for gripping, bending, and cutting wires or other materials, with various styles for specific tasks. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening. |

| Multimeter | A vital instrument for diagnosing electrical issues by measuring voltage, current, and resistance. |

| Utility Knife | Perfect for cutting various materials, from wire to plastic, with replaceable blades for longevity. |

Assembly Instructions for Users

Proper assembly is crucial for ensuring optimal performance and longevity of your equipment. This section provides detailed guidance on how to assemble components efficiently and safely. Follow these instructions carefully to achieve the best results.

Before starting the assembly process, gather all necessary tools and components. Familiarizing yourself with each piece will help streamline the procedure and prevent any mistakes.

| Step | Action | Notes |

|---|---|---|

| 1 | Lay out all components on a clean, flat surface. | Ensure everything is within reach to avoid interruptions. |

| 2 | Refer to the component list to verify you have all necessary items. | Check for any missing pieces before proceeding. |

| 3 | Start with the main assembly frame and secure all joints. | Use appropriate fasteners as indicated in your guide. |

| 4 | Attach additional components according to the order specified. | Follow the sequence to maintain structural integrity. |

| 5 | Double-check all connections for tightness and stability. | This step is crucial for safe operation. |

| 6 | Perform a final inspection to ensure everything is assembled correctly. | Look for any signs of misalignment or loose parts. |

By adhering to these steps, you can ensure a successful assembly process. Proper installation not only enhances performance but also extends the lifespan of your equipment.

Upgrading Your Polaris 360

Enhancing your aquatic cleaning device can significantly improve its efficiency and longevity. By focusing on specific components, you can elevate performance, ensure thorough cleaning, and enjoy a seamless experience. Understanding which elements to upgrade is key to achieving optimal results.

Key Components to Consider

- Filter System: Upgrading the filtration can trap smaller debris and improve overall cleanliness.

- Propulsion Mechanism: A more efficient motor will enhance mobility and reduce operational time.

- Brush Types: Different brushes can tackle various surfaces more effectively.

Benefits of Upgrading

- Improved cleaning efficiency.

- Extended lifespan of the device.

- Enhanced user experience with quieter operation.

Resources for Further Learning

Expanding your knowledge in the realm of mechanical components can greatly enhance your understanding and maintenance skills. Numerous resources are available to help you explore the intricacies of these systems, whether through books, online courses, or community forums.

Books: Look for technical manuals and guides that delve into the fundamentals of machinery and repair techniques. These can provide valuable insights and detailed explanations.

Online Courses: Websites like Coursera and Udemy offer courses on mechanics and engineering that cater to various skill levels. These platforms can be an ultimate resource for structured learning.

Community Forums: Engaging with online communities can lead to valuable discussions and troubleshooting tips. Participating in these forums allows you to connect with experienced individuals who share their expertise.

YouTube Channels: Many channels focus on repair tutorials and detailed breakdowns of mechanical systems. Visual learning can be particularly effective for grasping complex concepts.