Understanding the Parts Diagram of Polaris Glacier 1 Plow

When it comes to maintaining optimal performance in your winter machinery, having a clear understanding of the various elements involved is crucial. Each segment plays a vital role in ensuring smooth operation and efficiency during the snow-clearing process. Recognizing these components not only enhances your knowledge but also aids in effective troubleshooting and maintenance.

Visual representation of these essential elements can significantly simplify the process of identifying issues and planning necessary repairs. By examining the layout and relationships between different pieces, operators can gain insights into how everything works together. This can lead to improved functionality and longevity of the equipment.

Moreover, familiarizing yourself with these components can empower you to take proactive measures in your upkeep routine. A well-informed operator is better equipped to handle unexpected challenges, ensuring that winter weather does not hinder productivity. Embracing this knowledge ultimately contributes to a more efficient and reliable performance in the field.

Understanding Polaris Glacier 1 Plow Components

This section aims to delve into the essential elements that make up a snow removal system designed for rugged terrains. By examining each component, one can gain insights into how these intricate parts work together to facilitate efficient snow clearance and enhance overall performance during winter operations.

Key Functional Elements

Every efficient snow clearing mechanism comprises various critical components, each serving a specific purpose. The primary unit typically includes a robust blade that acts as the main tool for pushing and directing snow. This blade’s design is engineered for optimal performance, ensuring that it can handle various snow conditions with ease.

Support and Control Systems

In addition to the main blade, a series of support systems are crucial for stability and maneuverability. These include adjustable frames that allow the operator to change the angle of the blade, ensuring that snow can be managed effectively. Control mechanisms play a vital role as well, providing the operator with the ability to manage the system efficiently, ensuring precise movements and adjustments as required.

Understanding these components not only helps in maintenance but also enhances operational efficiency, leading to successful snow management in challenging conditions.

Overview of Polaris Glacier 1 Features

This section provides an insight into the remarkable characteristics of a popular snow-clearing equipment model. It is designed to enhance efficiency and performance in various snowy conditions, making it an essential tool for operators who require reliability and versatility.

Key Functionalities

Equipped with advanced technology, this model offers a range of functionalities that cater to both professional and recreational users. Its robust build ensures durability, while the innovative design facilitates ease of use. Key features include:

| Feature | Description |

|---|---|

| Durability | Constructed from high-quality materials to withstand harsh environments. |

| Versatility | Compatible with various vehicles, enhancing its usability across different platforms. |

| Efficiency | Designed to clear snow quickly and effectively, saving time and effort. |

| Ease of Control | Intuitive controls that allow for precise maneuverability and operation. |

Safety Features

Safety is a priority with this equipment. It comes with multiple safety enhancements that protect the operator and the surrounding environment. Key safety features include:

| Safety Feature | Description |

|---|---|

| Reflective Elements | Increased visibility during low-light conditions for enhanced safety. |

| Emergency Shutoff | Quick access shutoff switch to ensure immediate stoppage in case of emergency. |

| Stable Design | Low center of gravity that minimizes the risk of tipping over during operation. |

Importance of Regular Maintenance

Benefits of Consistent Upkeep

- Improved Performance: Regular maintenance helps in keeping machinery functioning at its best.

- Extended Lifespan: Consistent care can significantly prolong the life of equipment.

- Cost Efficiency: Preventive measures often reduce the need for costly repairs and replacements.

- Safety Assurance: Well-maintained equipment is less likely to malfunction, ensuring safer operation.

Key Maintenance Practices

- Regular inspections to identify wear and tear.

- Timely lubrication of moving parts to reduce friction.

- Replacement of worn components to prevent breakdowns.

- Cleaning to remove debris and contaminants that can cause damage.

Identifying Key Plow Parts

Understanding the essential components of snow removal equipment is crucial for optimal performance and maintenance. Each element plays a specific role, contributing to the overall functionality and efficiency of the system. Recognizing these key features can enhance your ability to troubleshoot issues and ensure the longevity of your machinery.

Major Components

Among the primary elements, the blade stands out as the most recognizable. This surface is designed for clearing snow effectively, and its material can greatly influence durability. Another vital component is the frame, which provides structural support and stability during operation. Additionally, the lifting mechanism enables users to raise and lower the blade, facilitating adjustments based on conditions.

Accessories and Enhancements

In addition to the main elements, various accessories can improve performance. Wear bars are crucial for protecting the blade from damage, while trip springs help prevent breakage when encountering obstacles. Furthermore, adding lights enhances visibility during low-light conditions, making operations safer and more efficient.

By familiarizing yourself with these fundamental components and enhancements, you can ensure that your equipment remains in peak condition and ready for any snow challenge.

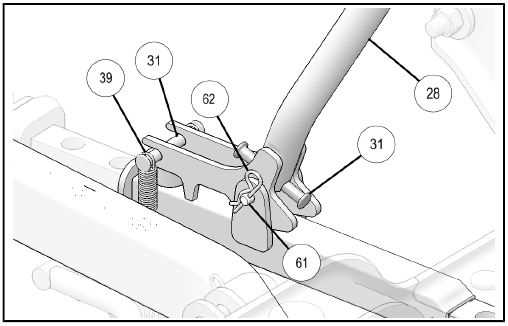

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations provide valuable insights into the assembly and functionality of various elements, allowing users to identify and locate each piece with ease. By grasping the layout and symbols used, one can enhance their comprehension of how each part interacts within the whole system.

Key Elements to Observe

When analyzing these visual guides, pay attention to the labels and numbering associated with each component. Typically, these identifiers correlate with a list or catalog that details specifications and availability. Familiarizing yourself with the legend or key can also clarify the symbols used, making it easier to navigate the schematic.

Tips for Efficient Interpretation

To effectively interpret these illustrations, start by identifying the major sections before delving into the finer details. Break down the visual into manageable parts and cross-reference with any accompanying information. This systematic approach will lead you to a clearer understanding of the overall assembly and its individual components.

Common Issues with Glacier 1 Plow

When it comes to snow removal equipment, several frequent problems can arise that hinder performance and efficiency. Understanding these issues can help operators ensure optimal functioning and prolong the lifespan of their gear.

- Hydraulic Leaks: One of the most common challenges involves fluid leaks in the hydraulic system, which can lead to a loss of power and responsiveness.

- Electrical Failures: Malfunctions in the electrical components, such as switches or wiring, may result in operational failures or erratic behavior.

- Wear and Tear: Over time, components can wear down, affecting the overall effectiveness. Regular inspections are necessary to identify signs of fatigue.

- Improper Alignment: Misalignment of the unit can cause uneven wear and reduce the effectiveness of snow clearing.

- Obstructions: Ice and debris can accumulate, blocking movement and causing strain on the machinery.

By being aware of these typical issues, operators can take proactive measures to maintain their equipment and ensure reliable performance during snow clearing operations.

Step-by-Step Assembly Instructions

This section provides a comprehensive guide to assembling the essential components of your equipment efficiently. Following these detailed steps will ensure proper functionality and durability, allowing you to maximize performance in various conditions.

Preparation Before Assembly

Before starting, gather all necessary tools and components. Ensure a clean workspace to avoid misplacing items. Reviewing the instruction manual can also provide valuable insights into specific assembly requirements.

Assembly Steps

Begin by securing the base component, followed by attaching the intermediate sections. Ensure that each connection is tight and secure, using appropriate fasteners. Finally, complete the assembly by adding any finishing elements, checking for stability and alignment throughout the process.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for efficiency and effectiveness. Proper tools not only streamline the process but also ensure that repairs are conducted safely and correctly.

Essential Hand Tools

Begin with a set of wrenches and screwdrivers, as these are fundamental for loosening and tightening various components. Additionally, pliers can assist in gripping and bending, while hammers help in aligning or dislodging parts.

Power Tools for Efficiency

For more demanding tasks, consider investing in electric drills and impact drivers. These tools can significantly reduce manual labor, allowing for quicker adjustments and assembly. Ensure you also have appropriate safety gear to protect yourself during the repair process.

Where to Purchase Replacement Parts

Finding high-quality components for your equipment is crucial for maintaining its performance and longevity. Whether you’re looking for original manufacturer items or reliable aftermarket alternatives, there are several avenues to explore for acquiring what you need.

Online Retailers

- Official Manufacturer Websites: Check the official site for a comprehensive catalog of components.

- Specialty Stores: Many online platforms focus specifically on outdoor machinery and related accessories.

- Marketplace Websites: Popular e-commerce platforms often have a wide selection from various sellers, making it easy to compare prices.

Local Dealers and Shops

- Authorized Dealerships: Visiting an authorized dealer can provide access to genuine components and expert advice.

- Local Repair Shops: Many independent shops carry essential items or can order them for you.

- Automotive Stores: Some general automotive parts suppliers may also stock what you need.

Cost Considerations for Plow Maintenance

Maintaining snow removal equipment involves various financial factors that should be carefully evaluated. Regular upkeep not only ensures optimal performance but also extends the lifespan of the machinery. Understanding these costs can help operators make informed decisions about repairs and replacements.

Labor Costs: One of the significant expenses associated with maintenance is labor. Hiring skilled technicians can increase overall costs, but their expertise may prevent more severe issues down the line. It’s essential to balance quality service with affordability.

Replacement Parts: Over time, components wear out and require replacement. Budgeting for high-quality, durable replacements can save money in the long run, reducing the frequency of repairs. Consider investing in parts that offer warranties for added peace of mind.

Preventive Maintenance: Implementing a routine maintenance schedule may initially seem like an added expense, but it often leads to cost savings. Proactive checks can identify minor issues before they escalate into costly repairs, making this approach ultimately economical.

Storage and Protection: Proper storage facilities can protect equipment from environmental damage, thus minimizing repair costs. Investing in a suitable shelter may require an upfront cost but can be beneficial over time.

In conclusion, evaluating these financial aspects is vital for effective machinery management. By understanding the costs associated with upkeep, operators can make strategic decisions that lead to long-term savings and enhanced operational efficiency.

Upgrades for Enhanced Performance

Enhancing the functionality of your winter equipment can lead to significant improvements in efficiency and effectiveness. By integrating specific modifications, operators can experience better handling, increased durability, and improved overall performance in challenging conditions. This section explores a variety of upgrades that can transform your machinery into a powerhouse on the snow.

Powertrain Enhancements

One of the most impactful upgrades involves the powertrain. Installing a high-performance engine kit can boost torque and horsepower, allowing for quicker response times and smoother operation. Additionally, upgrading the transmission can enhance gear shifting, leading to a more responsive driving experience. Consider aftermarket exhaust systems that can improve airflow, further enhancing engine performance and fuel efficiency.

Attachment and Support Modifications

Improving attachment systems can significantly affect maneuverability and effectiveness. Upgrading to a heavy-duty mount ensures stability and reliability during operation, while an enhanced hydraulic system can provide faster actuation of attachments. Investing in improved blade materials can also increase longevity and effectiveness, making it easier to clear large areas without wear and tear.

Safety Tips for Plowing

When navigating winter landscapes, prioritizing safety is essential. Understanding potential hazards and implementing precautionary measures can help prevent accidents and ensure a smooth experience. Here are some crucial guidelines to keep in mind.

1. Wear Proper Gear: Always dress in layers, ensuring you have insulated, waterproof clothing, sturdy boots, and gloves to protect against the cold.

2. Inspect Equipment: Before starting, thoroughly check all machinery for any signs of wear or malfunction. Regular maintenance is key to optimal performance.

3. Be Aware of Surroundings: Keep an eye on your environment, including pedestrians and other vehicles. Use mirrors and cameras if available to enhance visibility.

4. Avoid Distractions: Stay focused on the task at hand. Avoid using mobile devices or engaging in conversations while operating machinery.

5. Take Breaks: Fatigue can lead to mistakes. Schedule regular breaks to stay alert and refreshed throughout your work.

6. Know Your Limits: If conditions become too challenging, do not hesitate to stop. It’s better to wait for safer weather than to risk an accident.

By following these safety tips, you can effectively navigate winter tasks while minimizing risks to yourself and others.

Customer Reviews and Experiences

This section highlights the feedback and insights shared by users who have interacted with various equipment designed for snow management. Understanding customer experiences can provide valuable information for potential buyers, helping them make informed decisions based on real-life usage and satisfaction levels.

Overall Satisfaction

Many users express a high degree of satisfaction with their acquisition, noting that the machinery performs effectively in challenging winter conditions. Users often commend the durability and efficiency, with some stating that it has significantly improved their snow clearing tasks. One customer shared, “I was amazed at how quickly I could clear my driveway; it made the harsh winter months much easier to handle.”

Challenges Faced

While the majority of reviews are positive, some users have encountered challenges. Issues such as maintenance requirements and initial setup difficulties are common themes in feedback. As one reviewer noted, “The first time I used it, I struggled a bit with the adjustments, but once I got the hang of it, it worked like a charm.” This highlights the importance of understanding the product thoroughly for optimal performance.