Understanding the Polaris XLT Parts Diagram for Better Maintenance

When it comes to maintaining and enhancing the performance of your snow machine, having a clear understanding of its components is essential. This knowledge not only aids in effective repairs but also ensures that your ride operates smoothly in various conditions. A well-organized layout of the different elements can provide valuable insights into how each part interacts with the others.

In this section, we delve into the intricate arrangements of various mechanical elements specific to your model. By familiarizing yourself with these structures, you empower yourself to make informed decisions regarding upgrades, replacements, and troubleshooting. This foundational knowledge can greatly enhance your overall experience and prolong the life of your vehicle.

Moreover, recognizing the layout of critical components allows for efficient diagnostics and maintenance. Whether you are a seasoned enthusiast or a newcomer to the world of snow machines, understanding these configurations is a crucial step towards achieving optimal performance and reliability. Let’s explore the details that make up this essential framework.

Understanding the Polaris XLT Parts Diagram

Gaining insight into the various components of a snow vehicle is essential for effective maintenance and repair. Familiarizing oneself with the layout and interconnections of these elements enhances both understanding and efficiency when addressing issues or performing upgrades. This section delves into the intricacies of the schematics that illustrate these vital parts.

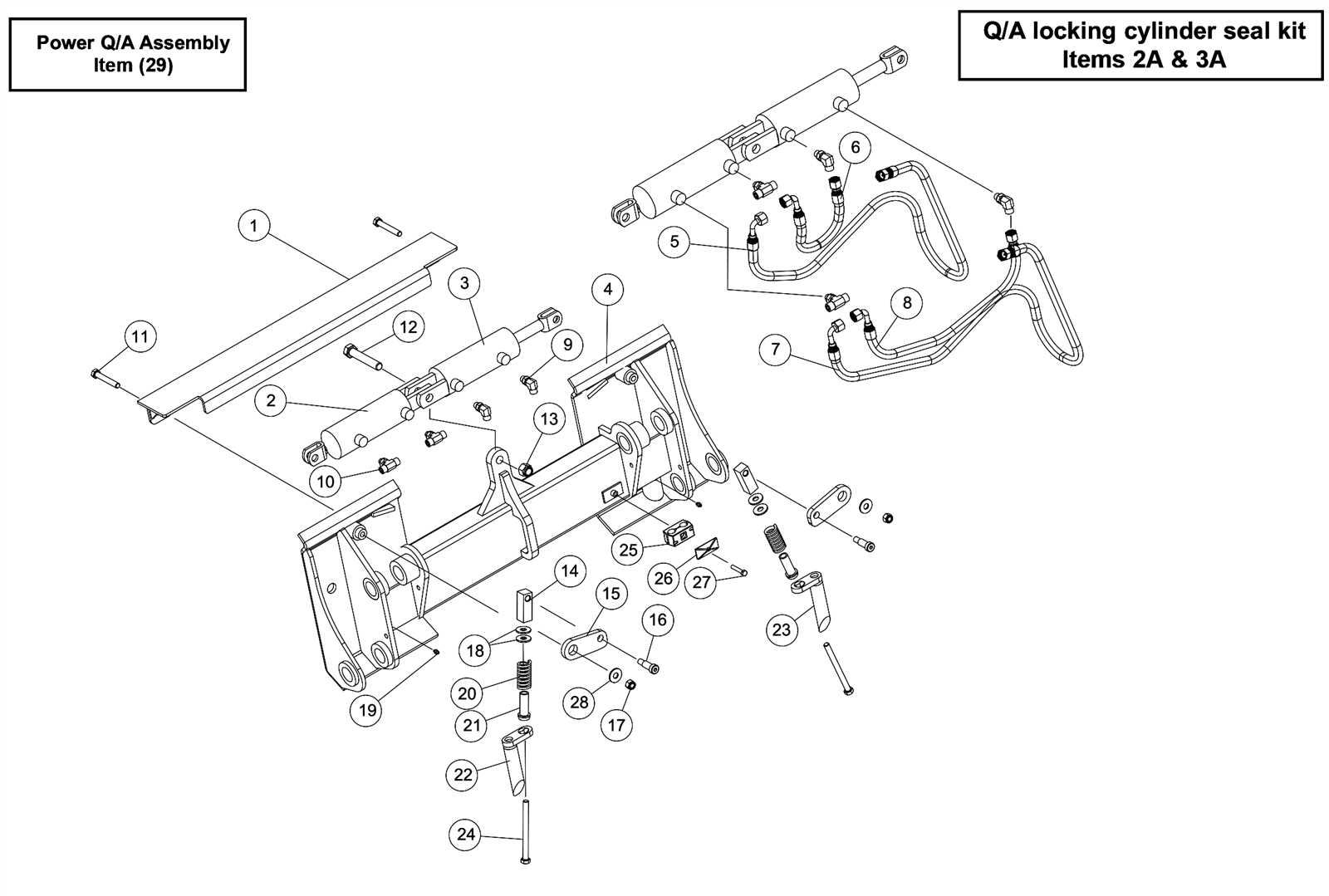

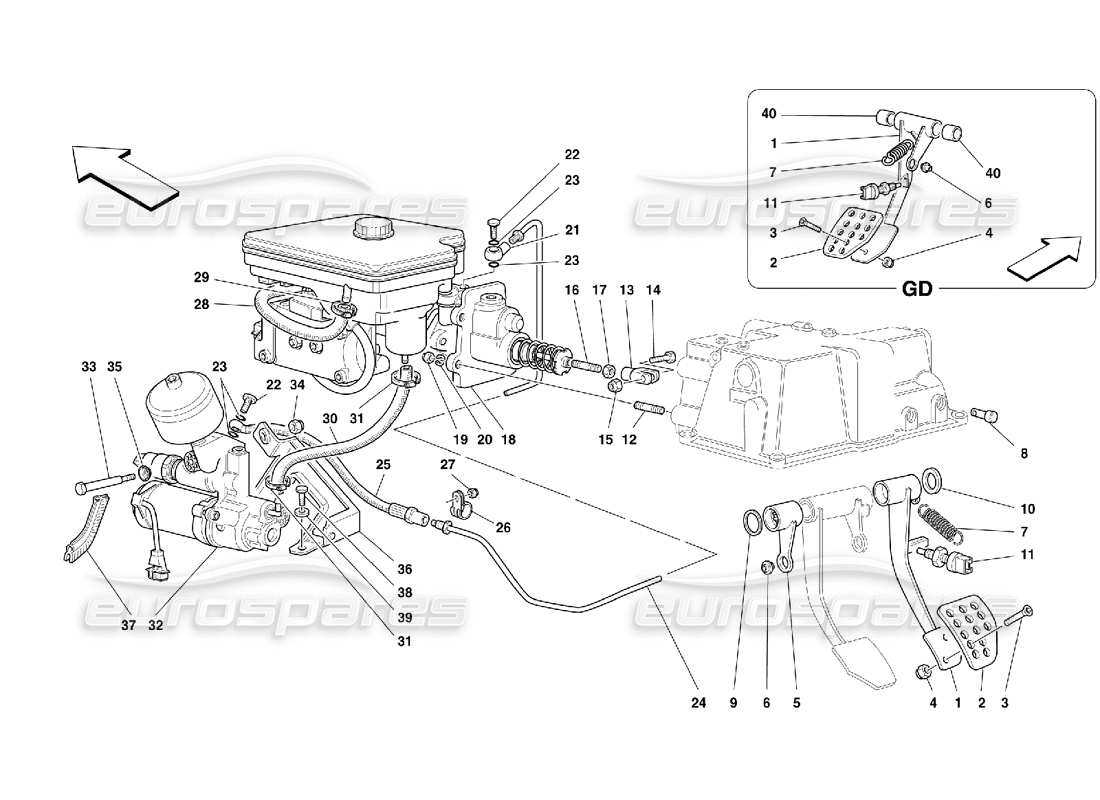

Key Components and Their Functions

The illustration serves as a visual guide, presenting each element’s placement and function within the overall system. Recognizing these components helps in troubleshooting and ensures that each part operates harmoniously with the others.

Utilizing the Visual Reference

Interpreting the schematic accurately can significantly simplify the repair process. It is advisable to refer to this guide whenever disassembling or inspecting the machine. Below is a simplified table summarizing essential components and their roles:

| Component | Function |

|---|---|

| Engine | Drives the vehicle and powers other systems. |

| Transmission | Transfers power from the engine to the wheels. |

| Chassis | Framework that supports all other components. |

| Suspension | Absorbs shocks and provides stability. |

| Brakes | Ensures safe stopping and control. |

Importance of Accurate Parts Diagrams

Precise visual representations of components are essential in various industries. They serve as valuable tools that facilitate the identification and understanding of individual elements within a larger assembly. Such illustrations enable users to efficiently locate, replace, or maintain specific items, thereby enhancing overall operational efficiency.

Streamlining Maintenance Processes

Accurate representations significantly streamline maintenance tasks. By providing clear visual guidance, they reduce the time spent searching for the correct components. This not only minimizes downtime but also helps technicians avoid errors that could lead to costly mistakes. When each piece is clearly delineated, the process becomes straightforward and manageable.

Enhancing Training and Knowledge

In addition to practical applications, these visual aids play a crucial role in education and training. They allow newcomers to familiarize themselves with the intricacies of a system, fostering a deeper understanding of how each element interacts within the whole. This knowledge is vital for ensuring that personnel can operate machinery safely and effectively, ultimately contributing to improved performance.

In summary, having precise visual references is invaluable in ensuring both efficiency and safety across various applications. The benefits extend beyond mere convenience, playing a pivotal role in training and operational success.

Common Components of Polaris XLT

This section provides an overview of key elements found in specific snowmobile models, focusing on their essential features and functionalities. Understanding these components is crucial for maintenance and performance enhancement.

- Engine Assembly

- Cylinder and Piston

- Carburetor

- Exhaust System

- Transmission

- Drive Belt

- Clutch Mechanism

- Gearbox

- Chassis

- Frame Structure

- Suspension System

- Track Assembly

- Electrical System

- Ignition Module

- Battery

- Wiring Harness

- Cooling System

- Radiator

- Coolant Hoses

- Thermostat

Familiarity with these elements allows for better troubleshooting and enhances the overall riding experience. Regular inspection and replacement of worn parts contribute to longevity and optimal performance.

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to identify and locate necessary items for maintenance or repair. These illustrations provide a clear overview of how various elements interact and fit together, making it easier to navigate complex machinery or systems.

Familiarize Yourself with the Layout: Start by examining the overall structure of the illustration. Typically, items are arranged in a way that mirrors their physical arrangement within the machinery. Recognizing this pattern can help you quickly locate specific components.

Identify Labels and Numbers: Most visual guides include labels or numerical references that correspond to a list of items. Pay close attention to these identifiers, as they are crucial for ensuring you are selecting the correct parts for your needs.

Note the Symbols and Lines: Symbols often indicate the type of component, while lines may represent connections or relationships between different items. Understanding these visual cues can provide insights into assembly and disassembly processes.

Refer to the Accompanying Documentation: Always consult the associated materials, which typically include descriptions and specifications. This supplementary information can offer additional context and clarification, ensuring you make informed decisions.

By mastering the art of interpreting these visuals, you’ll improve your efficiency in identifying components, facilitating smoother repairs and maintenance tasks.

Identifying Replacement Parts Easily

Finding the right components for your vehicle can often feel like a daunting task. However, understanding the layout and function of each element is essential for a seamless replacement process. By familiarizing yourself with the assembly and its various sections, you can quickly pinpoint what you need without unnecessary confusion.

One effective method is to utilize visual aids that outline each component’s location and purpose. These resources not only enhance your comprehension but also serve as a reference during the installation phase. Additionally, maintaining an organized inventory of your items can streamline the identification process, allowing you to work more efficiently.

It’s also beneficial to engage with communities or forums dedicated to your vehicle type. Here, enthusiasts share insights and experiences that can guide you in recognizing and sourcing the correct elements. By leveraging shared knowledge and visual tools, you can simplify your search and ensure a successful repair or upgrade.

Benefits of OEM Parts vs. Aftermarket

When it comes to vehicle maintenance and repairs, the choice between original equipment manufacturer (OEM) components and third-party alternatives can significantly impact performance, reliability, and overall satisfaction. Understanding the advantages of each option helps in making informed decisions that can enhance the longevity and efficiency of your vehicle.

Advantages of OEM Components

- Quality Assurance: OEM items are designed to meet the strict specifications set by the manufacturer, ensuring consistent quality and performance.

- Perfect Fit: These components are tailored to fit your vehicle precisely, reducing the risk of compatibility issues that can arise with aftermarket options.

- Warranty Protection: Many OEM components come with warranties, providing peace of mind and financial protection against potential defects.

- Resale Value: Using original parts can help maintain the vehicle’s resale value, as prospective buyers often prefer vehicles with genuine components.

Considerations for Aftermarket Options

- Cost-Effectiveness: Third-party components are often more affordable, making them an attractive option for budget-conscious consumers.

- Variety: Aftermarket options may offer a wider selection of styles and enhancements, catering to personal preferences and customization.

- Availability: These parts are typically more readily available, allowing for quicker repairs and less downtime.

- Innovation: Some aftermarket manufacturers focus on improving performance, offering advanced technologies that might not be available in OEM options.

Ultimately, the choice between OEM and aftermarket components depends on individual needs, budget constraints, and the specific requirements of the vehicle. Weighing these factors carefully can lead to optimal decision-making and enhanced vehicle performance.

Maintaining Your Polaris XLT Effectively

Proper upkeep of your snowmobile is essential for ensuring its longevity and performance. Regular maintenance not only enhances reliability but also maximizes enjoyment on the trails. Understanding the key components and their care can help prevent issues and keep your ride in peak condition.

Essential Maintenance Tasks

To maintain optimal performance, there are several critical tasks that should be performed regularly. These include checking fluid levels, inspecting the track, and ensuring all mechanical parts are functioning smoothly. Below is a table outlining the recommended maintenance tasks and their frequency.

| Task | Frequency |

|---|---|

| Check Oil Level | Before each ride |

| Inspect Spark Plugs | Every 100 miles |

| Examine Track Condition | Every 200 miles |

| Clean Air Filter | Every 50 miles |

| Check Brake System | Monthly |

Tips for Effective Upkeep

In addition to scheduled maintenance, adopting good practices can significantly enhance the performance of your machine. Always store it in a dry place to prevent rust, and clean it thoroughly after each use to avoid buildup of snow and dirt. Keeping an eye on wear and tear will allow you to address any issues before they escalate.

Where to Find Parts Diagrams Online

Locating detailed visual representations of components is essential for enthusiasts and mechanics alike. These resources can assist in identifying specific elements and understanding their configurations. Fortunately, numerous platforms offer comprehensive guides and illustrations that cater to various models and makes.

Manufacturer Websites

One of the most reliable sources for accurate visuals is the official websites of manufacturers. They often provide a wealth of information, including user manuals, service guides, and detailed illustrations. Exploring these sites can yield precise data tailored to your specific vehicle.

Online Forums and Communities

Another excellent avenue is engaging with online forums and communities dedicated to automotive interests. Many enthusiasts share their expertise and resources, including links to helpful visuals. These platforms foster collaboration and can lead to discovering hard-to-find resources.

Utilizing these resources can greatly enhance your understanding and maintenance of your vehicle. Always ensure the credibility of the source to obtain the most accurate information.

Using Diagrams for DIY Repairs

Visual guides are invaluable tools for individuals seeking to tackle maintenance tasks on their vehicles. These illustrations provide clear representations of components and their arrangements, enabling enthusiasts and mechanics alike to understand complex systems more intuitively. By following these graphical instructions, one can identify parts that require attention, facilitating a smoother repair process.

Benefits of Visual Guides

Utilizing visual aids offers numerous advantages for those engaging in hands-on repairs. Firstly, they enhance comprehension by breaking down intricate designs into manageable sections. This clarity helps in accurately pinpointing issues and ensuring that each element is addressed properly. Additionally, these guides often highlight important details, such as assembly directions or torque specifications, which are crucial for successful repairs.

Effective Repair Planning

Before beginning any maintenance work, it’s essential to plan effectively. Reviewing the visual representation allows one to gather necessary tools and materials in advance, reducing downtime. Below is a simple checklist to prepare for a DIY repair:

| Task | Status |

|---|---|

| Identify required tools | ✔️ |

| Gather replacement components | ✔️ |

| Review assembly instructions | ✔️ |

| Prepare workspace | ✔️ |

By leveraging these visual resources, DIY enthusiasts can approach repairs with confidence, ensuring that each task is completed efficiently and effectively.

Common Issues and Solutions

In the realm of machinery and vehicles, encountering problems is not uncommon. Understanding these challenges and knowing how to address them can enhance performance and longevity. This section highlights frequent complications and their corresponding solutions.

Frequent Problems

- Engine Starting Difficulties

- Overheating Issues

- Electrical System Malfunctions

- Suspension Concerns

- Fuel System Inefficiencies

Effective Solutions

- Engine Starting Difficulties:

- Check the battery charge and connections.

- Inspect the starter motor for any faults.

- Ensure the fuel supply is adequate.

- Overheating Issues:

- Examine the cooling system for leaks.

- Replace any worn-out hoses or belts.

- Flush the coolant and check levels regularly.

- Electrical System Malfunctions:

- Test fuses and wiring for any damage.

- Check the condition of the alternator.

- Ensure all connections are secure and corrosion-free.

- Suspension Concerns:

- Inspect shocks and struts for wear.

- Check alignment and tire pressure.

- Replace any broken components promptly.

- Fuel System Inefficiencies:

- Clean or replace the fuel filter as needed.

- Inspect fuel lines for blockages or leaks.

- Ensure the injectors are functioning properly.

Comparative Analysis with Other Models

This section delves into a comparative assessment of various snowmobiles, highlighting key differences and similarities in their design, functionality, and user experience. By examining these models, we can better understand their respective strengths and weaknesses, aiding potential buyers in making informed decisions.

Design Features

- Frame Construction: The robustness and weight distribution vary significantly among models, impacting handling and stability.

- Suspension Systems: Different approaches to suspension design affect ride comfort and performance on diverse terrains.

- Engine Specifications: Variations in horsepower and torque lead to differing acceleration and top speeds.

User Experience

- Ergonomics: The layout of controls and seating can enhance or detract from the overall comfort during extended rides.

- Maintenance Requirements: Some models demand more frequent servicing, affecting long-term ownership satisfaction.

- Fuel Efficiency: Comparing fuel consumption rates provides insight into the economic viability of each option.

By considering these factors, riders can make better choices tailored to their specific needs and preferences, ensuring a more enjoyable experience on the trails.

Tips for Ordering Parts Successfully

Acquiring the necessary components for your vehicle can be a straightforward process if you follow a few key guidelines. Understanding what to look for and how to communicate your needs will enhance your chances of receiving the correct items promptly.

Here are some helpful suggestions to ensure a smooth ordering experience:

| Tip | Description |

|---|---|

| Know Your Model | Always have your vehicle’s model and year ready. This information is crucial for identifying compatible components. |

| Use Specific Terms | When describing what you need, use precise terminology. Avoid vague phrases to reduce confusion. |

| Check Availability | Before placing an order, confirm that the item is in stock. This will prevent delays in delivery. |

| Ask Questions | If uncertain about a component, don’t hesitate to ask the supplier for clarification or recommendations. |

| Review Return Policies | Familiarize yourself with the return procedures in case the received item does not meet your expectations. |

By following these tips, you can streamline the ordering process and ensure that you receive the correct components efficiently.