Poulan PR4218 Parts Diagram Explained

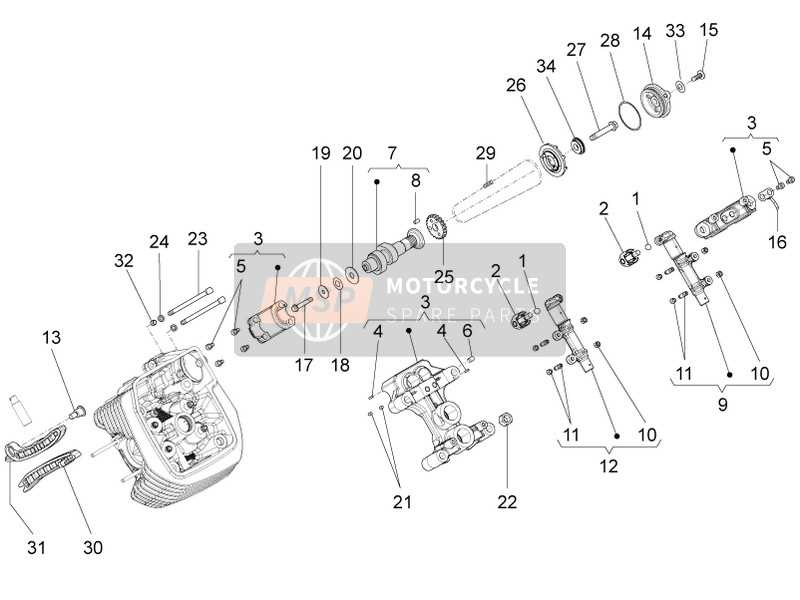

When it comes to the maintenance and repair of outdoor power equipment, having a clear visual representation of the internal components is essential. This approach not only aids in identifying specific parts but also enhances the overall understanding of the machine’s functionality. By dissecting the structure of a chainsaw, users can troubleshoot issues more effectively and ensure optimal performance.

In this section, we will explore the intricate arrangement of various elements within a popular model, focusing on how each component interacts with one another. Grasping the layout of these mechanisms is crucial for both novice users and seasoned technicians alike, as it allows for a more comprehensive comprehension of the device’s operations.

Whether you are looking to replace a worn-out piece or simply want to familiarize yourself with your tool, having access to a well-organized representation can be invaluable. It streamlines the repair process, making it easier to locate the necessary items and understand their roles in the overall system.

Poulan PR4218 Overview

This section provides an insight into a particular model of outdoor power equipment designed for cutting and trimming tasks. It combines efficiency with user-friendly features, making it suitable for both casual users and more experienced individuals.

Key Features

- Lightweight design for easy maneuverability

- Powerful engine to tackle various types of wood

- Ergonomic handle for comfortable operation

- Automatic lubrication system for enhanced maintenance

- Chain brake for increased safety during use

Applications

- Trimming branches and limbs

- Cutting firewood for home use

- Clearing fallen trees and debris

- Landscaping and yard maintenance

With these attributes, this equipment serves as a reliable tool for those engaged in outdoor maintenance and project work.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of these elements offer a clear guide for users, enhancing their ability to identify individual components and comprehend how they interconnect. Such illustrations not only streamline the process of assembly and disassembly but also promote a deeper knowledge of the equipment’s functionality.

Facilitating Troubleshooting

When issues arise, having a visual reference simplifies the troubleshooting process. Users can quickly locate malfunctioning parts, which minimizes downtime and promotes efficient repairs. Clear illustrations allow for faster identification of problems, leading to quicker resolutions and less frustration.

Enhancing Safety and Accuracy

Accurate visual guides play a vital role in ensuring safety during repairs. By providing a detailed overview of each component, users are less likely to make errors that could lead to accidents. Understanding the precise location and function of each piece not only enhances the accuracy of maintenance tasks but also fosters a safer working environment.

Key Components of Poulan PR4218

This section delves into the essential elements that contribute to the functionality and efficiency of a well-known outdoor power tool. Understanding these core parts not only aids in maintenance but also enhances the overall user experience.

Engine Assembly

The engine assembly serves as the powerhouse, driving the entire system. Its performance directly impacts the tool’s efficiency and reliability. Key features include the cylinder, piston, and ignition components, which work together to generate the necessary power for cutting tasks.

Bar and Chain System

The bar and chain mechanism is critical for achieving precise cuts. This assembly includes the guide bar and the cutting chain, which must be maintained regularly to ensure optimal operation. Proper tensioning and lubrication are vital for prolonging the life of this system.

| Component | Description |

|---|---|

| Engine Assembly | Drives the tool; includes cylinder, piston, and ignition components. |

| Bar and Chain | Essential for cutting; consists of the guide bar and cutting chain. |

| Fuel System | Ensures proper combustion; includes fuel tank and carburetor. |

| Safety Features | Includes chain brake and safety switch to protect the user. |

Common Issues with Chain Saws

Chain saws are powerful tools that can greatly simplify cutting tasks, but they are not without their problems. Users often encounter various challenges that can hinder performance and efficiency. Understanding these common issues can help in maintaining the tool and ensuring safe operation.

Starting Difficulties

One frequent complaint is difficulty in starting the engine. This can be attributed to several factors, including fuel quality, spark plug condition, or issues with the air filter. Ensuring proper maintenance and regular checks can often resolve these problems. Using fresh fuel and keeping the spark plug clean are essential steps to improve starting reliability.

Chain Problems

Another common issue is related to the chain itself. A dull or improperly tensioned chain can lead to inefficient cutting and increased wear on the tool. Users should regularly inspect the chain for sharpness and ensure it is adequately tightened to prevent slippage. Regular sharpening and tension adjustments can significantly enhance cutting performance and extend the life of the chain saw.

Understanding the Parts Breakdown

Analyzing the components of a machine is essential for effective maintenance and repair. A detailed overview of each element not only aids in identifying issues but also enhances overall performance. By comprehending the various sections and their functions, users can make informed decisions when it comes to repairs or upgrades.

Here are the key benefits of familiarizing yourself with the components:

- Improved Troubleshooting: Recognizing individual parts allows for quicker identification of problems.

- Enhanced Maintenance: Understanding the role of each piece promotes proactive care, extending the lifespan of the equipment.

- Informed Upgrades: Knowledge of the structure enables users to select appropriate enhancements that improve efficiency.

- Cost Efficiency: Being aware of specific components can lead to smarter purchasing decisions and reduced repair costs.

When examining the breakdown, consider the following categories:

- Power System: This includes the engine and all related elements that provide energy.

- Operational Mechanisms: Components that facilitate movement and functionality of the machine.

- Control Features: Elements responsible for user interaction and operational adjustments.

- Safety Components: Parts designed to ensure safe operation and minimize risks during use.

In conclusion, a thorough understanding of each component and its function significantly enhances the efficiency and reliability of the machine. This knowledge empowers users to perform repairs confidently and maintain their equipment in optimal condition.

How to Use the Diagram Effectively

Understanding a visual representation of components can greatly enhance your ability to troubleshoot and maintain your equipment. By familiarizing yourself with this illustration, you can quickly identify necessary elements, their functions, and their interconnections. This knowledge can save you time and effort when working on repairs or upgrades.

First, ensure you have a clear understanding of each part’s location and role within the overall assembly. Take your time to study the layout, noting how various elements interact with one another. This foundational knowledge will prove invaluable during hands-on tasks.

Next, refer to the illustration when gathering supplies or ordering replacements. By pinpointing specific components, you can avoid confusion and ensure that you obtain the correct items, minimizing delays in your project.

Additionally, consider using the visual guide as a reference during disassembly and reassembly. This can help you keep track of where each piece belongs, making the process smoother and more efficient. Taking notes on your observations can further enhance your understanding and retention of the information.

Finally, always keep the illustration accessible during your work sessions. Having it nearby allows for quick consultations, ensuring you stay on track and reducing the likelihood of errors.

Replacement Parts for Poulan PR4218

Maintaining your outdoor power equipment in optimal condition is essential for ensuring performance and longevity. When components wear out or become damaged, timely replacements can enhance efficiency and reliability. This section outlines key considerations and options for sourcing the necessary components to keep your machinery running smoothly.

Common Components to Consider

- Chains

- Guide bars

- Engines

- Filters

- Fuel lines

- Drive sprockets

Where to Find Quality Replacements

- Authorized dealers

- Online marketplaces

- Local hardware stores

- Specialty outdoor equipment retailers

By identifying reputable sources and understanding which components are critical for your equipment, you can ensure its performance remains top-notch. Regular inspections and proactive replacements are key to avoiding unexpected breakdowns.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any outdoor power equipment. By adhering to a consistent maintenance routine, users can ensure optimal performance, reduce the risk of breakdowns, and enhance the efficiency of their machinery. Below are some effective strategies to maintain your tools in excellent condition.

Regular Inspections

Conducting frequent checks can help identify potential issues before they escalate. Focus on the following areas:

- Examine the condition of the chain and bar for wear and damage.

- Inspect air filters and replace them if they appear dirty or clogged.

- Check fuel and oil levels regularly to prevent overheating.

Cleaning and Storage

Keeping your equipment clean and stored properly can significantly enhance its durability. Consider these tips:

- Clean the exterior after each use to remove debris and residue.

- Store in a dry, sheltered area to protect from moisture and rust.

- Ensure that the blade is sharpened and properly aligned before storing.

By implementing these maintenance practices, you can greatly increase the longevity and reliability of your outdoor machinery, ensuring it remains a valuable tool for years to come.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. When seeking reliable sources, it’s important to consider both quality and authenticity to avoid issues associated with counterfeit items.

One of the best places to start is the official manufacturer’s website. Here, you can find a comprehensive selection of original components that meet the required specifications. Additionally, authorized dealers and retailers often carry genuine replacements and can provide guidance on installation and compatibility.

Online marketplaces can also be a viable option, but it’s essential to verify the seller’s reputation. Look for vendors with positive reviews and a solid return policy. Local hardware stores may also stock authentic items, allowing you to inspect them before purchase.

Lastly, consider specialized online retailers that focus on your specific equipment type. These platforms often have extensive inventories and knowledgeable customer support, ensuring you get the correct items for your needs.

Resources for Repair Guides

Finding reliable materials for maintenance and troubleshooting can greatly enhance the repair process. A variety of resources are available that cater to different needs, whether you are seeking visual aids, detailed instructions, or community support. Here are some effective options to consider.

Online Manuals and Documentation

- Manufacturer Websites: Official sites often provide comprehensive manuals and schematics.

- PDF Downloads: Many platforms offer downloadable guides that can be saved for offline reference.

- Video Tutorials: Websites like YouTube host a plethora of step-by-step repair videos created by experienced users.

Community Forums and Support Groups

- Repair Communities: Online forums allow users to share experiences, tips, and solutions.

- Social Media Groups: Platforms like Facebook have dedicated groups where enthusiasts discuss repairs.

- Local Workshops: Participating in local repair classes or meetups can provide hands-on experience and valuable insights.