Poulan Pro 550E Parts Diagram Guide

In the world of outdoor machinery, comprehending the intricate arrangement of components is crucial for efficient operation and maintenance. Every piece of equipment consists of various elements that work in harmony to ensure optimal performance. A thorough understanding of these elements can significantly enhance the user experience.

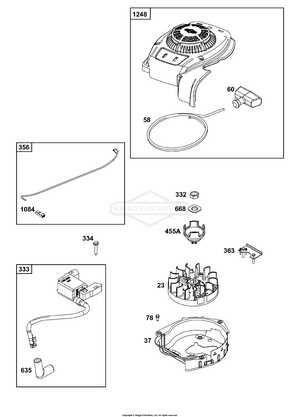

When delving into the specifics of machinery, visual representations serve as ultimate tools for grasping the relationships between different parts. By examining these illustrations, users can gain valuable insights into the structure and functionality of their equipment, enabling them to identify and address potential issues effectively.

Whether you are a seasoned operator or a novice, familiarizing yourself with the layout of these components can empower you to make informed decisions. This knowledge not only aids in troubleshooting but also fosters a deeper appreciation for the technology behind your tools.

Poulan Pro 550E Overview

This section provides a comprehensive understanding of a specific model known for its reliability and performance in outdoor equipment. Designed for both casual users and professionals, it offers efficient functionality for various tasks, ensuring that users can tackle their projects with ease and confidence.

Equipped with a robust engine, this model excels in delivering consistent power while remaining user-friendly. Its ergonomic design enhances comfort during prolonged use, making it an ideal choice for those who value both performance and ease of handling.

Maintenance and durability are key features, allowing users to depend on it for numerous seasons. The accessibility of replacement components further supports its longevity, making repairs straightforward and hassle-free.

In summary, this model stands out in the market for its combination of power, comfort, and ease of maintenance, appealing to a wide range of users seeking reliable outdoor solutions.

Essential Components of the 550E

Understanding the critical elements of this particular model is vital for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and longevity. Familiarizing oneself with these key parts will aid in troubleshooting and enhancing functionality.

One of the primary components is the engine, which provides the necessary power for operation. Additionally, the ignition system is crucial for starting and maintaining the motor’s function. The fuel delivery system ensures a steady flow of fuel, while the air intake system maximizes combustion efficiency. Furthermore, the exhaust system helps in expelling gases, contributing to cleaner operation.

Other essential elements include the bar and chain assembly, vital for cutting, and the housing that protects internal mechanisms from damage. Understanding how these parts work together can significantly improve user experience and equipment reliability.

Common Issues with Poulan Pro 550E

Every machine can encounter challenges, and understanding these can significantly enhance performance and longevity. Common problems often arise from wear and tear, improper maintenance, or environmental factors. Identifying these issues early can prevent further complications and ensure smooth operation.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Difficulties | Engine may fail to start or requires multiple attempts. | Check fuel quality, inspect spark plug, and ensure the choke is properly set. |

| Excessive Vibration | Unusual shaking during operation, indicating potential imbalance. | Inspect blades for damage, tighten screws, and check for any loose components. |

| Overheating | Machine may become excessively hot, risking damage. | Ensure airflow is not obstructed, clean cooling fins, and monitor fuel levels. |

| Poor Cutting Performance | Inability to cut effectively, leaving untrimmed areas. | Sharpen or replace cutting blades, adjust height settings, and check for debris. |

| Fuel Leaks | Visible leaking of fuel, posing safety risks. | Inspect fuel lines for cracks, replace seals, and ensure tank is not damaged. |

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing common issues with outdoor power equipment. By following these steps carefully, you can restore functionality and extend the life of your machinery.

Tools Required

- Screwdriver set

- Wrench set

- Replacement components

- Safety goggles

- Gloves

Repair Steps

- Identify the problem by assessing performance and visual inspection.

- Gather the necessary tools and components for the repair.

- Disconnect the power source for safety.

- Carefully disassemble the equipment, noting the order of parts.

- Replace any faulty components with new ones.

- Reassemble the unit, ensuring all parts fit securely.

- Reconnect the power source and conduct a test run.

Where to Find Replacement Parts

Finding the right components for your equipment can be a daunting task, but with the right resources, it becomes manageable. There are several avenues to explore, each offering unique benefits and potential savings. Understanding where to look can make a significant difference in your maintenance routine.

Online Retailers

One of the most convenient options is to browse various online retailers. Websites dedicated to outdoor machinery and tools often carry a vast selection of items. Make sure to utilize the search feature and check product descriptions carefully. You can often find customer reviews and ratings, which help ensure you are purchasing quality components.

Local Dealers and Repair Shops

Visiting local dealerships and repair shops can provide valuable insights and hands-on assistance. Many of these establishments stock essential items and can offer expert advice on installation and compatibility. Additionally, building a relationship with local professionals may lead to future discounts or recommendations for sourcing specific components.

Embracing these options will enhance your chances of locating the right items quickly and efficiently. Don’t hesitate to reach out to community forums and social media groups as well, where fellow enthusiasts share their experiences and resources.

Understanding the Parts Diagram

Grasping the layout of a mechanical assembly is crucial for effective maintenance and repair. A comprehensive visual representation enables users to identify components and understand their interconnections, streamlining the troubleshooting process. This knowledge is essential for both novices and seasoned technicians alike.

Importance of Visual Aids

Visual aids serve as a roadmap, guiding users through complex structures. They simplify the identification of each element, reducing the likelihood of errors during repairs. Moreover, a clear illustration enhances learning, allowing users to familiarize themselves with specific parts and their functions.

Navigating the Layout

When exploring the illustration, pay attention to labels and numbering systems. Each segment typically correlates with a particular component, facilitating quick reference when ordering replacements. Understanding this layout ultimately leads to more efficient repairs and increased equipment longevity.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your outdoor equipment operates efficiently and lasts for many years. By following a few simple practices, you can enhance performance, reduce wear and tear, and ultimately save on replacement costs. Prioritizing maintenance not only improves functionality but also boosts safety during use.

Routine Cleaning

Keep your equipment clean by removing debris and dirt after each use. This prevents buildup that can cause corrosion and damage. Pay special attention to air filters and cooling systems, as clogs can lead to overheating and decreased efficiency. Using a soft brush or compressed air can effectively clear dust and particles from hard-to-reach areas.

Regular Inspections

Conduct regular checks on all components to identify potential issues before they escalate. Look for signs of wear, such as frayed cables or cracks in the casing. Replacing worn parts promptly can prevent more extensive damage and ensure smooth operation. Keeping an eye on fuel systems and lubrication points is equally crucial to maintain optimal performance.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right instruments at your disposal is essential for ensuring efficiency and precision. Each repair may require specific implements to address various components effectively. Familiarity with these tools not only streamlines the process but also enhances the overall outcome of your efforts.

Basic hand tools, such as screwdrivers, wrenches, and pliers, are fundamental for disassembling parts and securing fasteners. Additionally, a torque wrench is invaluable for applying the correct amount of force, preventing damage to sensitive components. For tasks that require more finesse, specialized tools, like spark plug sockets and fuel line wrenches, can greatly simplify challenging procedures.

Moreover, having a reliable work surface and proper safety equipment is crucial. A sturdy workbench provides a stable environment for repairs, while gloves and goggles protect against potential hazards. With the right toolkit, you can tackle repairs with confidence and ensure your equipment operates optimally.

Comparing with Other Poulan Models

This section explores the key differences and similarities among various models from the same manufacturer, focusing on performance, features, and usability. By analyzing these distinctions, users can make informed choices tailored to their specific needs.

Performance Variability

Different models exhibit varying power levels and efficiencies, which can significantly impact their suitability for specific tasks. Understanding the horsepower and cutting capabilities helps users select the right tool for their projects.

User Experience and Features

Ergonomics, ease of use, and additional features such as anti-vibration technology and fuel efficiency play crucial roles in user satisfaction. Comparing these attributes can lead to discovering the ultimate match for both casual and professional applications.

Customer Reviews and Feedback

Customer opinions play a vital role in understanding the quality and performance of tools. Reviews often provide insights into usability, reliability, and overall satisfaction. Gathering feedback helps potential buyers make informed decisions and enhances the overall user experience.

Positive Experiences

Many users highlight the efficiency and durability of their tools, appreciating how well they perform in various tasks. Satisfaction often stems from ease of use and effective functionality, leading to loyal customers who share their success stories.

Areas for Improvement

While most feedback is positive, some users note areas that could be enhanced, such as customer service response times and availability of replacement components. Constructive criticism helps manufacturers address these issues and improve their offerings.

| Feedback Type | Count |

|---|---|

| Positive | 75% |

| Neutral | 15% |

| Negative | 10% |

FAQs About Poulan Pro 550E

This section addresses common inquiries related to a popular model known for its reliability and efficiency. Here, you will find answers to frequently asked questions that cover various aspects of this equipment, including its maintenance, usage, and troubleshooting.

| Question | Answer |

|---|---|

| What type of fuel should I use? | It is recommended to use a mix of gasoline and two-cycle engine oil, following the manufacturer’s specified ratio. |

| How often should I clean the air filter? | The air filter should be cleaned after every 10 hours of operation to ensure optimal performance. |

| What are the signs that the spark plug needs replacement? | Indicators include difficulty starting, poor acceleration, and an inconsistent engine idle. |

| Can I use this model for heavy-duty tasks? | This equipment is suitable for moderate tasks; however, for more intensive applications, consider using a higher-capacity model. |

| How do I troubleshoot starting issues? | Check the fuel level, ensure the spark plug is in good condition, and verify that the air filter is clean. |