Poulan Pro PP28 Parts Diagram Overview

When it comes to maintaining outdoor machinery, having a clear understanding of each component is crucial. A well-functioning unit relies on numerous interconnected parts that work in harmony to achieve optimal performance. Familiarity with these elements not only aids in effective repairs but also enhances overall operational efficiency.

Identifying and analyzing the specific sections of your equipment can empower users to troubleshoot issues more effectively. By dissecting the various assemblies, operators can gain insights into the functionality and maintenance of their tools, ensuring longevity and reliability in demanding tasks. This knowledge can be a game-changer for anyone looking to maximize their equipment’s potential.

In this exploration, we will delve into detailed representations of the various components, offering a visual reference that simplifies the maintenance process. With a focus on clarity and practicality, this guide aims to serve as an essential resource for both novice and experienced users alike. Understanding each part’s role will facilitate better care and enhance performance for years to come.

Poulan Pro PP28 Overview

This section provides a comprehensive insight into a versatile gardening tool designed for efficiency and ease of use. Ideal for both professionals and enthusiasts, this device excels in various landscaping tasks, making it an essential addition to any toolkit.

Key features of this model include:

- Powerful engine that ensures optimal performance.

- Lightweight construction for ease of handling.

- User-friendly design aimed at reducing fatigue during extended use.

- Adjustable components to suit different tasks and preferences.

The tool’s adaptability allows it to perform effectively in various environments, from residential gardens to larger agricultural settings. With proper maintenance, it can provide reliable service for many seasons.

Overall, this equipment represents a blend of innovation and practicality, catering to a wide range of user needs.

Understanding Parts and Functions

Exploring the various components and their roles in equipment is essential for effective maintenance and optimal performance. Each element is designed to work in harmony with others, contributing to the overall functionality. By comprehending how these elements interact, users can ensure longevity and efficiency in their machinery.

Main Components Overview

The primary elements include the engine, which provides power; the cutting mechanism, responsible for executing tasks; and the housing that protects internal systems. Understanding each component’s specific purpose allows for better troubleshooting and repair, enhancing the user’s ability to manage the equipment effectively.

Regular upkeep is crucial for maintaining the efficiency of these components. Routine checks help identify wear and tear, ensuring that each part functions as intended. By prioritizing maintenance, users can prevent malfunctions and extend the life of their machinery, ultimately leading to improved performance in the long run.

Common Issues with PP28 Models

Users often encounter several recurring challenges with this specific outdoor equipment, which can impact performance and longevity. Understanding these issues is crucial for effective maintenance and troubleshooting.

Starting Problems

One of the most frequent complaints involves difficulties in starting the machine. This can stem from issues such as stale fuel, clogged air filters, or problems with the ignition system, requiring thorough inspection and potential replacement of components.

Loss of Power

Another common concern is a noticeable decrease in power during operation. This may result from a dirty carburetor, worn spark plugs, or insufficient fuel flow. Regular cleaning and timely part replacements can help restore optimal performance.

Maintenance Tips for Longevity

Ensuring the durability of your outdoor equipment requires regular attention and care. Proper maintenance not only enhances performance but also extends the lifespan of the machine, saving time and money in the long run. By following a few essential guidelines, you can keep your tools in optimal condition for years to come.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Check and clean air filter | Every 25 hours of use | Improves airflow and engine efficiency |

| Sharpen cutting blades | Every 10 hours of use | Ensures clean cuts and reduces strain on the engine |

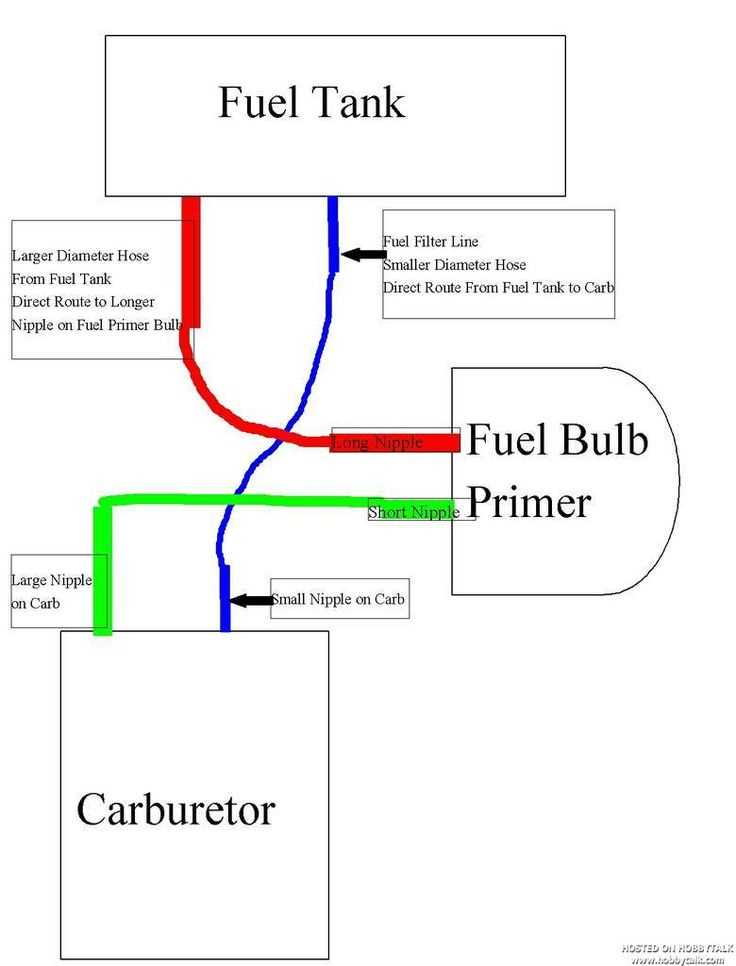

| Inspect fuel lines and connections | Monthly | Prevents leaks and maintains performance |

| Change oil | Every 50 hours of use | Keeps engine components lubricated and reduces wear |

| Check spark plug condition | Every season | Ensures reliable starting and smooth operation |

By adhering to these practices, you will enhance the reliability and efficiency of your machinery, allowing you to tackle outdoor tasks with confidence and ease.

Where to Find Replacement Parts

When it comes to maintaining outdoor equipment, sourcing the right components is crucial for ensuring optimal performance. Fortunately, there are several avenues available for locating suitable replacements that can restore your machine to full functionality.

Online Retailers

The internet offers a vast marketplace for components. Here are some reliable options:

- Specialized Websites: Numerous online platforms focus specifically on outdoor machinery, providing a wide range of options.

- General E-commerce Sites: Websites like Amazon or eBay often stock a variety of components, sometimes at competitive prices.

- Manufacturer Websites: Checking the official site of the manufacturer can lead you directly to authentic parts tailored for your equipment.

Local Stores and Repair Shops

In addition to online sources, local businesses can be invaluable for finding what you need:

- Hardware Stores: Many local hardware retailers carry a selection of essential components for common outdoor tools.

- Specialty Repair Shops: These establishments often have knowledgeable staff who can help you locate specific items or suggest alternatives.

- Community Resources: Local forums or groups can be excellent places to seek advice on where to find components or even trade with others.

Step-by-Step Assembly Guide

This section provides a detailed walkthrough for assembling your equipment efficiently. Following these steps will ensure that each component fits correctly and operates smoothly, contributing to optimal performance.

Preparation Before Assembly

Before starting the assembly process, gather all necessary tools and components. This will streamline your workflow and minimize interruptions.

- Check the contents of your package.

- Gather essential tools: screwdriver, wrench, and safety gear.

- Find a clean, spacious area for assembly.

Assembly Steps

- Base Assembly: Begin by connecting the base components securely.

- Attach the Handle: Position the handle and fasten it using the provided screws.

- Connect the Motor: Align the motor with the designated brackets and tighten it in place.

- Install the Safety Guard: Ensure the safety guard is attached properly to avoid accidents.

- Final Adjustments: Check all connections for tightness and stability before testing.

By following these guidelines carefully, you will achieve a successful assembly, ready for use and enjoyment.

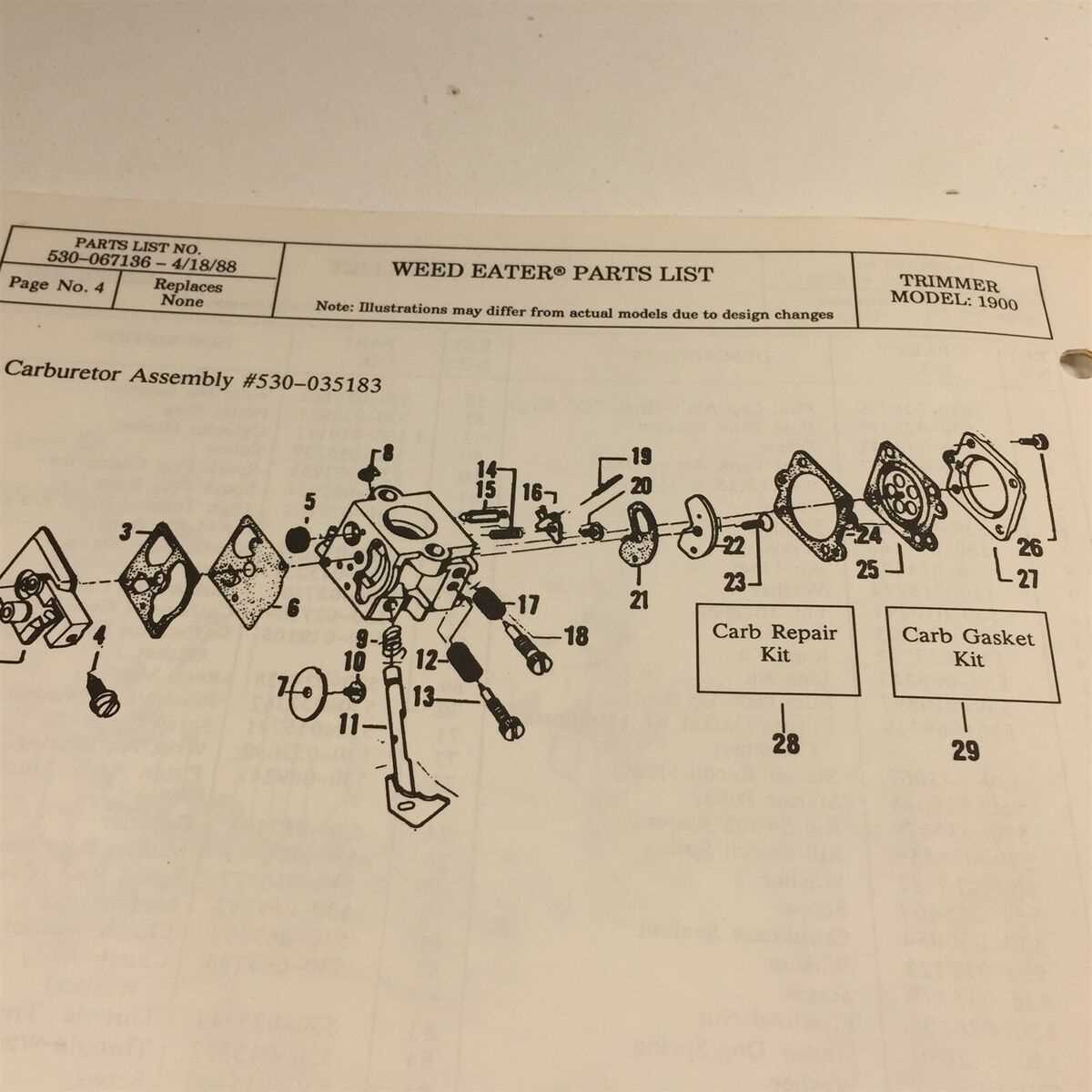

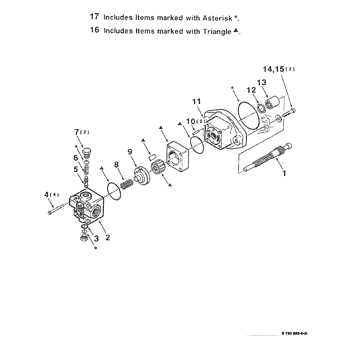

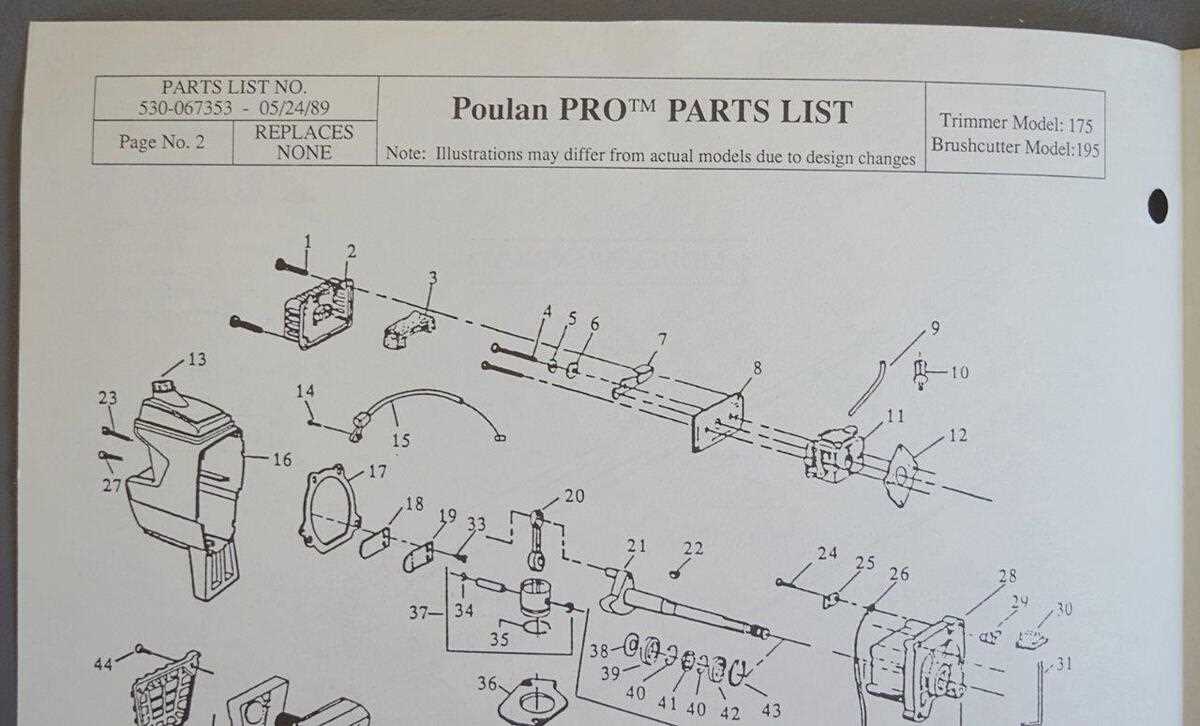

Visual Parts Diagram Explained

A comprehensive visual representation serves as a crucial tool for understanding the various components of a machine. This illustration not only simplifies identification but also enhances comprehension of assembly and functionality.

Key benefits include:

- Clarity in understanding component relationships

- Efficient troubleshooting and maintenance

- Facilitating seamless reassembly after repairs

To make the most of such a visual guide, consider the following steps:

- Identify each component by its designated number or label.

- Refer to accompanying descriptions for detailed functions.

- Utilize this information during repairs or upgrades.

By delving into this visual aid, users can achieve a deeper appreciation of their equipment, ultimately enhancing its longevity and performance.

DIY Repairs for Your PP28

Maintaining your outdoor equipment can significantly extend its lifespan and enhance performance. With a little knowledge and the right tools, you can tackle various repairs yourself, saving both time and money. This guide will explore common issues and simple solutions, empowering you to keep your machine in top condition.

Common Issues and Solutions

One frequent problem is difficulty starting the engine. Check the fuel system for clogs and ensure the spark plug is clean. Replacing it can often solve ignition issues. Additionally, inspect the air filter; a dirty filter can restrict airflow and hinder performance. Keeping these components clean will ensure smooth operation.

Maintenance Tips

Regular maintenance is key to avoiding major repairs. Always refer to your user manual for specific instructions on maintenance schedules. Lubrication of moving parts is crucial, as it reduces wear and tear. Also, make it a habit to examine belts and cables for signs of fraying or wear; replacing them promptly can prevent more significant problems down the line.

Cost-Effective Parts Solutions

Finding economical replacements for machinery components can significantly enhance efficiency and extend the lifespan of equipment. By exploring various options, users can achieve optimal performance without straining their budgets.

Benefits of Affordable Replacements

- Increased Savings: Cost-effective choices reduce overall maintenance expenses.

- Accessibility: Affordable options are often more readily available from multiple suppliers.

- Versatility: Many economical alternatives can be used across different models.

Strategies for Sourcing Inexpensive Components

- Research Online Retailers: Explore various e-commerce platforms for competitive pricing.

- Check Local Suppliers: Visit nearby hardware stores for potential deals.

- Consider Used Options: Look for refurbished or second-hand items in good condition.

Comparing Similar Models

When evaluating equipment within the same category, it’s essential to assess various models to identify the best fit for your needs. This comparison can reveal differences in performance, design, and user experience that might influence your decision. By analyzing similar offerings, you can make an informed choice that aligns with your expectations and requirements.

Performance Metrics

One of the primary aspects to consider is the performance metrics of each model. Factors such as engine power, efficiency, and durability play a crucial role in determining how well the equipment will perform under various conditions. Analyzing these specifications can help you identify which model will meet your demands more effectively.

User-Friendly Features

Another critical element is the usability of each option. Features like weight, ease of assembly, and ergonomic design can significantly impact your overall experience. Comparing how intuitive the controls are and the accessibility of maintenance points can provide insights into which model may offer a more user-friendly experience.

Expert Recommendations for Users

For individuals utilizing outdoor power equipment, understanding maintenance and replacement components is essential for optimal performance. Following expert insights can significantly enhance the longevity and efficiency of your tools.

Key Maintenance Tips

Regular upkeep is crucial. Ensure you clean the equipment after each use, check for any wear or damage, and replace any faulty parts promptly to prevent further issues.

Choosing the Right Components

When selecting replacement items, always opt for high-quality options that meet or exceed manufacturer specifications. This choice can make a substantial difference in performance and durability.

| Maintenance Task | Frequency |

|---|---|

| Clean after use | Every use |

| Inspect for damage | Weekly |

| Replace worn components | As needed |