Poulan Super 250A Parts Diagram Explained

Maintaining outdoor machinery requires a comprehensive grasp of its various elements and how they interconnect. Each component plays a vital role in ensuring optimal performance and longevity. A thorough understanding of these parts is essential for effective troubleshooting and repair, allowing users to tackle issues proactively rather than reactively.

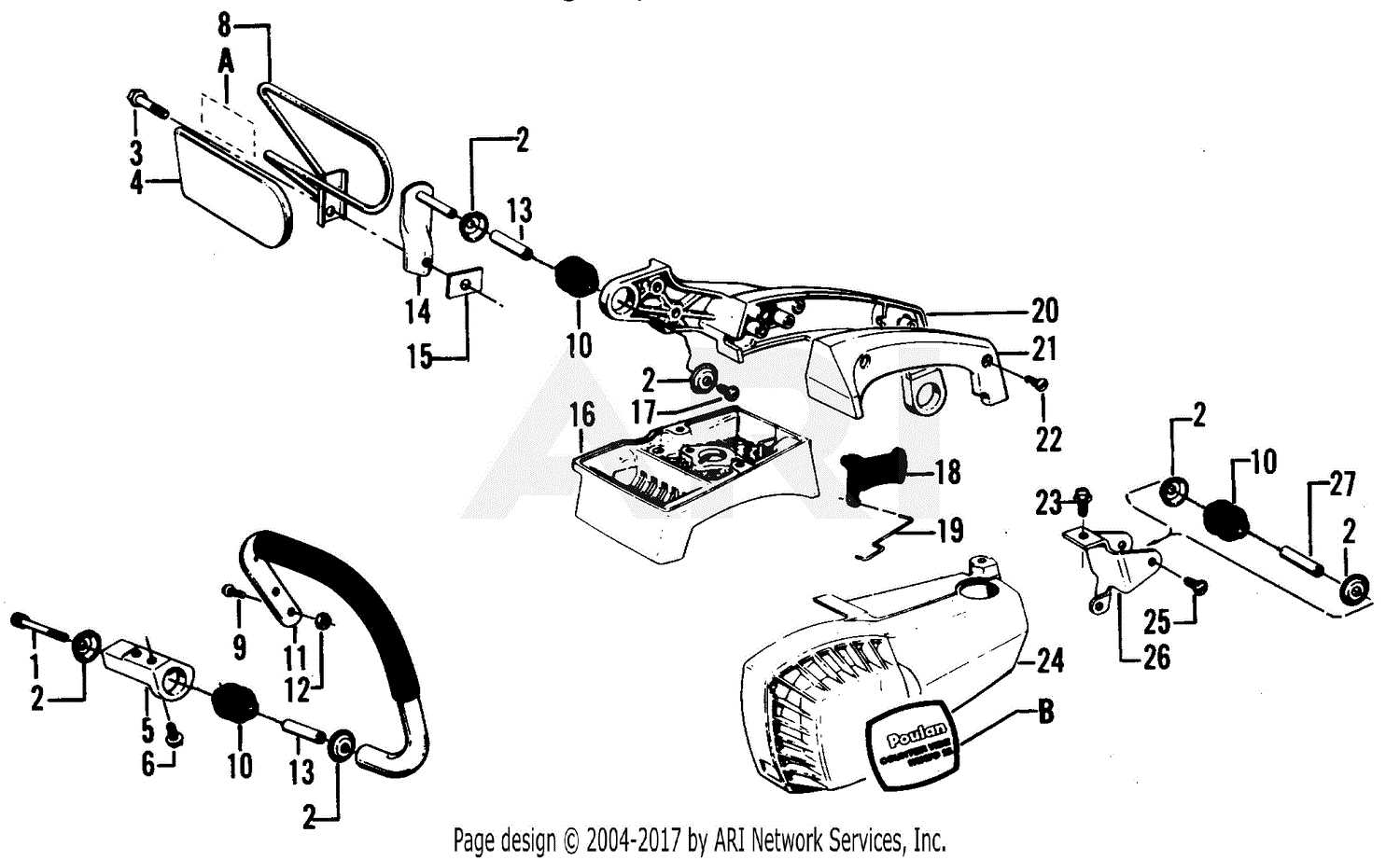

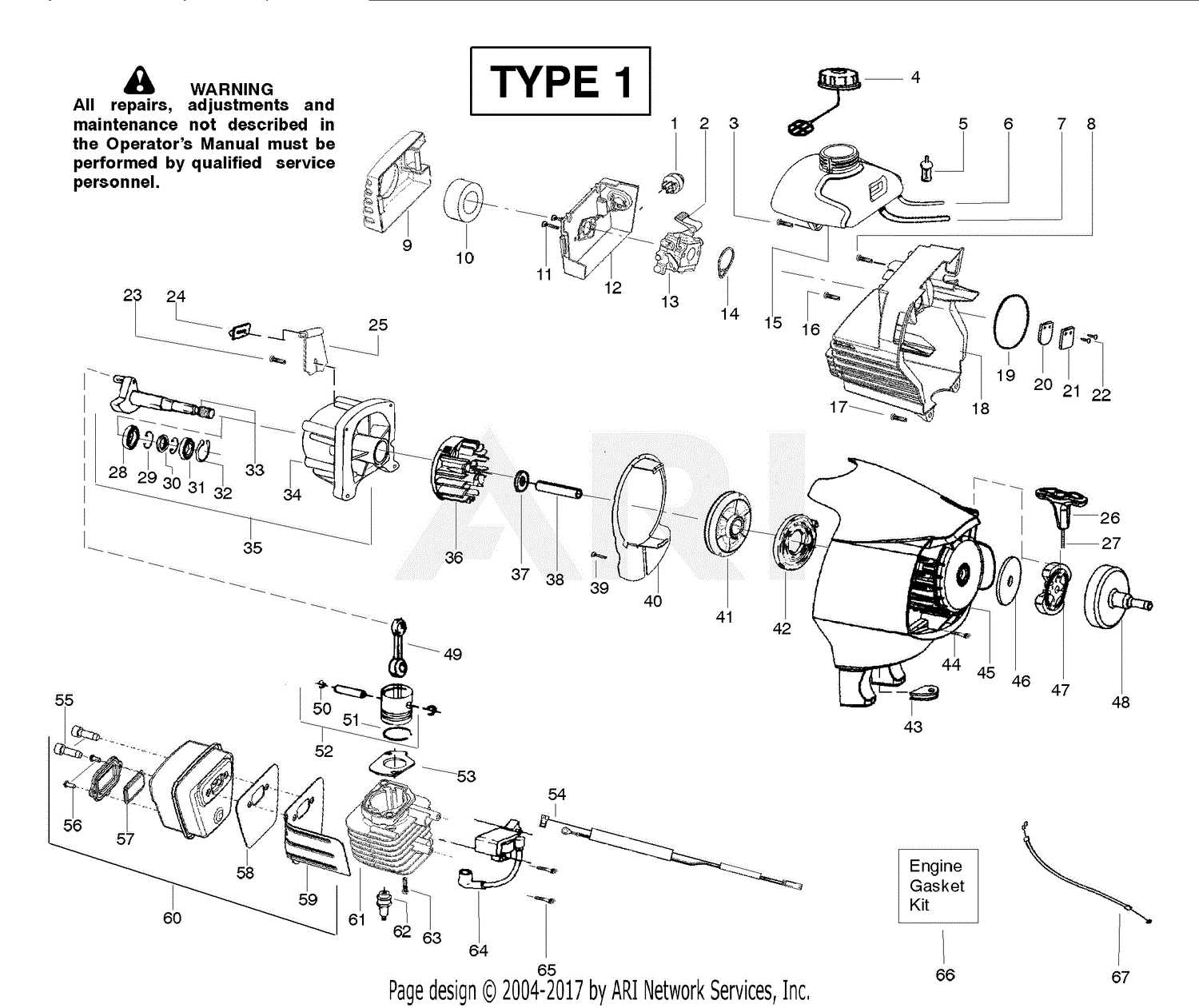

In the realm of machinery maintenance, visual aids can be invaluable. They provide clarity on the specific functions and arrangements of each element, enabling users to navigate repairs with confidence. These illustrations serve as guides, illustrating how different pieces interact and highlighting the importance of each in the overall operation.

By familiarizing oneself with the assembly and arrangement of the components, users can enhance their technical skills and gain greater insight into their equipment’s functionality. This knowledge not only aids in repair efforts but also empowers users to perform routine maintenance, ultimately prolonging the life of their machinery and ensuring its efficiency in the field.

Poulan Super 250A Overview

This section provides a comprehensive look at a well-known outdoor power tool designed for efficiency and reliability. With its robust construction and user-friendly features, this equipment is favored by both professionals and enthusiasts alike. It combines power and precision, making it suitable for various tasks in lawn care and maintenance.

Key Features

The tool is equipped with a powerful engine that ensures high performance during operation. Its lightweight design allows for easy maneuverability, reducing fatigue during extended use. Additionally, it boasts a variety of attachments, enhancing versatility for different gardening tasks.

Maintenance and Care

Regular upkeep is essential for optimal performance. Users should follow recommended guidelines for cleaning and servicing the tool to prolong its lifespan. Proper handling and storage practices also contribute to maintaining its efficiency and reliability.

Importance of Parts Diagrams

Understanding the intricate details of machinery and equipment is crucial for effective maintenance and repair. Visual representations that illustrate component relationships enhance the ability to identify and address issues promptly.

These illustrations serve several key purposes:

- Clarity: They provide a clear view of how various elements fit together, making it easier to understand the overall structure.

- Efficiency: Technicians can quickly locate specific components, reducing the time spent searching for parts during repairs.

- Accuracy: Visual aids minimize the risk of errors during reassembly by ensuring that each piece is placed correctly.

In addition, these visual guides are beneficial for:

- Training: New personnel can learn the layout and function of components more effectively.

- Inventory Management: Understanding which components are needed for repairs helps in maintaining adequate stock levels.

- Documentation: They provide a reference for future maintenance, ensuring that the same mistakes are not repeated.

Overall, such visual representations are invaluable tools that contribute significantly to the maintenance and longevity of equipment.

Common Parts for Poulan Chainsaws

Understanding the essential components of a chain-cutting tool is crucial for maintaining its performance and longevity. Various elements work in unison to ensure efficient operation, and knowing these parts can help users troubleshoot issues and perform necessary replacements when needed.

Key Components

One of the primary elements is the engine, which powers the device and is typically either gas or electric. Alongside the engine, the bar and chain are vital for the cutting action, with different sizes available to suit various tasks. Additionally, the fuel system plays a significant role, including the tank, lines, and filter, all of which contribute to the engine’s functionality.

Maintenance Essentials

Regular upkeep of the air filter is essential to maintain optimal airflow and performance. The spark plug is another crucial component, as it ignites the fuel mixture for combustion. Users should also pay attention to the clutch and chain brake, which enhance safety and control during operation. By familiarizing oneself with these fundamental elements, operators can ensure their tools remain in peak condition.

Understanding the Fuel System

The fuel system is crucial for ensuring that the engine operates efficiently and reliably. It involves various components that work together to deliver the right amount of fuel for combustion, impacting performance and longevity. Understanding each part’s function can help in troubleshooting and maintenance.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel until needed by the engine. |

| Fuel Line | Transports fuel from the tank to the engine. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Carburetor | Mixes fuel with air to create a combustible mixture. |

| Fuel Pump | Moves fuel from the tank to the carburetor or injectors. |

Identifying Electrical Components

Understanding the various electrical elements within a device is crucial for effective maintenance and troubleshooting. Each component plays a specific role, contributing to the overall functionality of the system. By familiarizing oneself with these parts, one can ensure optimal performance and longevity.

The primary electrical components include resistors, capacitors, and switches, each with distinct characteristics and functions. Resistors limit the flow of electric current, while capacitors store and release energy as needed. Switches control the flow of electricity, allowing users to turn devices on or off with ease.

Additionally, connectors and wires facilitate the transfer of electricity between components. Identifying these elements accurately can prevent misconfigurations and potential damage. A clear understanding of how these parts interact is essential for effective repairs and enhancements.

Lastly, always refer to appropriate documentation when working with electrical components. Diagrams and schematics provide valuable insights into the layout and function of each part, aiding in the identification and resolution of issues.

Maintenance and Replacement Tips

Proper care and timely updates are crucial for ensuring the longevity and optimal performance of your equipment. Regular inspections can help identify wear and tear before they escalate into major issues. This section will explore essential strategies to keep your machinery running smoothly.

Regular Inspections

Conduct frequent checks on your tools to catch any signs of damage early. Look for frayed cables, loose screws, or worn-out components. Addressing these problems promptly can prevent more extensive repairs in the future.

Replacement Guidelines

When it’s time to replace any components, choose high-quality replacements that are compatible with your model. Follow the manufacturer’s recommendations to ensure proper installation. Upgrading certain parts can significantly enhance performance and efficiency.

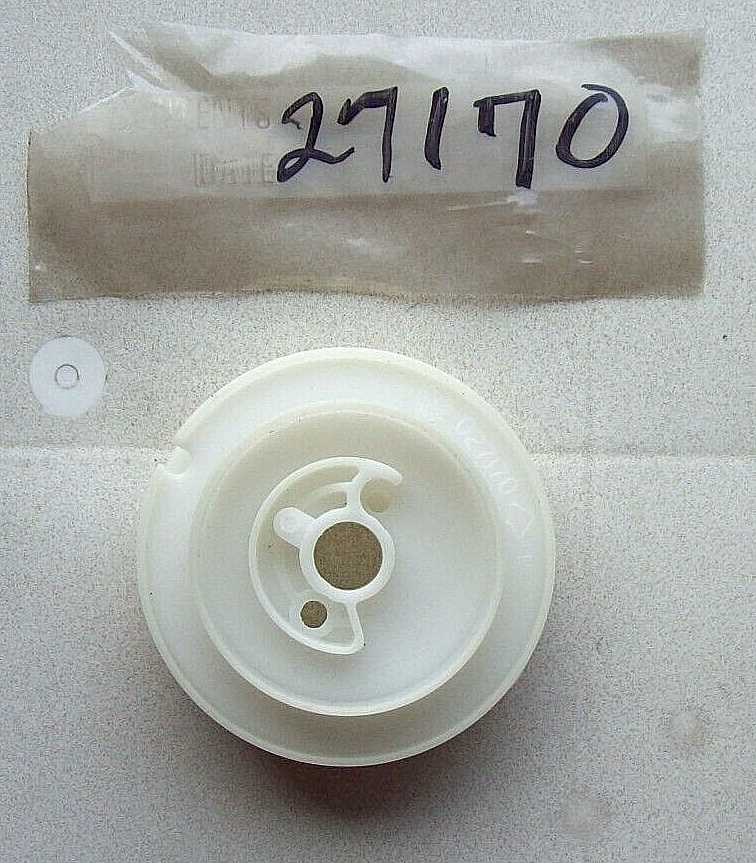

Locating the Starter Assembly

Identifying the starter mechanism within a power tool is essential for effective maintenance and repair. This component plays a crucial role in initiating the engine, making it a focal point in any troubleshooting process.

To find this assembly, first, refer to the tool’s exterior. Typically, it is situated near the rear or top section, often covered by a protective casing. Carefully examine any screws or fasteners securing the cover, as these will need to be removed to access the starter.

Once exposed, inspect the wiring and connections that lead to the starter. Ensuring these elements are intact is vital for the ultimate functionality of the tool. If necessary, consult a service manual for detailed instructions specific to your model.

Examining the Chain Brake Mechanism

The chain brake mechanism is a crucial safety feature designed to prevent accidents during operation. By engaging this system, users can quickly halt the chain’s movement, reducing the risk of injury in the event of kickback or other unforeseen circumstances.

How the Mechanism Works

This safety apparatus typically functions through a lever or handle that, when activated, locks the chain in place. The engagement process is often initiated by a sudden force or a manual action, effectively stopping the chain’s rotation and providing immediate control to the operator.

Importance of Maintenance

Regular inspection and maintenance of the chain brake system are essential to ensure its reliability. Over time, components may wear down, compromising their effectiveness. Keeping these parts in optimal condition not only enhances safety but also prolongs the life of the equipment.

Insights on the Air Filter

The air filtration system is crucial for maintaining optimal performance in outdoor power equipment. A clean and efficient filter ensures that the engine receives a steady supply of clean air, which is vital for combustion and overall functionality.

Functionality of the Air Filter

The primary role of the air filter is to trap dust, debris, and contaminants before they enter the engine. This process not only protects internal components but also enhances the machine’s efficiency and longevity.

Maintenance Tips

Regular maintenance of the air filter is essential for peak performance. Checking and cleaning or replacing the filter at recommended intervals can significantly impact operational efficiency.

| Maintenance Task | Frequency |

|---|---|

| Check Filter Condition | Every 25 hours |

| Clean Filter | As needed |

| Replace Filter | Every season |

Exploring the Oil Pump Functionality

The oil pump is a critical component in many mechanical systems, ensuring proper lubrication and efficiency. Its primary role is to circulate oil throughout the engine or machinery, reducing friction and preventing wear and tear on vital parts. Understanding how this mechanism operates can lead to better maintenance and performance insights.

| Function | Description |

|---|---|

| Lubrication | Distributes oil to moving parts, minimizing friction. |

| Cooling | Helps dissipate heat generated by engine components. |

| Cleaning | Flushes away contaminants from the system. |

| Pressure Regulation | Maintains optimal oil pressure for effective operation. |

Analyzing the Cutting Bar and Chain

The cutting mechanism is a crucial element in any outdoor power tool designed for slicing through wood. Understanding its components is essential for ensuring optimal performance and longevity. This section delves into the intricacies of the cutting bar and chain, exploring their functions, maintenance, and common issues that may arise during usage.

Functionality and Design

The cutting bar serves as the foundation for the chain, guiding it as it rotates around the bar’s length. This component is typically made from durable materials to withstand the rigors of frequent use. The chain, on the other hand, features sharp teeth designed to efficiently cut through various types of wood. The interplay between the bar and chain is vital; a well-matched pair enhances cutting efficiency and reduces wear on both parts.

Maintenance and Troubleshooting

Regular upkeep of the cutting assembly is necessary to maintain peak performance. It is important to keep the bar free of debris and ensure the chain is properly tensioned. A loose chain can lead to decreased cutting efficiency and increased risk of accidents. Additionally, checking for dull teeth and replacing them when necessary can prevent damage to both the chain and the bar. Neglecting these components can lead to common issues such as binding or uneven cuts, ultimately affecting the tool’s overall functionality.

By understanding the importance of these parts and their maintenance needs, users can enhance their cutting experience and prolong the life of their equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. Various resources are available that cater to different needs, whether you prefer online shopping or visiting a physical store. By exploring multiple avenues, you can ensure that you find the right items for maintenance and repairs.

Online Retailers are a popular option, offering a vast selection of components at competitive prices. Websites dedicated to tools and machinery often feature detailed catalogs, making it easy to search for specific items. Additionally, many sites provide customer reviews, helping you make informed choices about quality and compatibility.

Local Hardware Stores can be a great resource as well. They typically carry a range of replacement items and can often order what you need if it’s not in stock. The advantage of shopping locally includes the ability to speak directly with knowledgeable staff who can assist in identifying the correct components.

Specialty Shops focused on outdoor equipment may also have a selection of parts tailored specifically to your needs. These retailers often stock high-quality items and may offer expert advice or services to ensure you get the best fit for your machinery.

Online Marketplaces, such as auction or second-hand sites, can also yield valuable finds. Here, you might discover hard-to-find or discontinued components at reasonable prices. Just be sure to verify the condition and compatibility before making a purchase.

By utilizing these various sources, you can effectively track down the components necessary for keeping your equipment in optimal working condition.

DIY Repair Considerations

Embarking on a do-it-yourself repair project requires careful planning and knowledge of essential factors to ensure success. Whether tackling mechanical issues or replacing components, understanding the nuances can make a significant difference.

- Assess Your Skills: Determine if you have the necessary expertise to handle the task.

- Gather Tools: Ensure you have the right equipment to perform the repairs effectively.

- Research Components: Familiarize yourself with the necessary parts and their functions.

- Consult Manuals: Use repair manuals or guides for specific instructions and troubleshooting tips.

- Consider Safety: Always prioritize safety measures to protect yourself during repairs.

- Budget Wisely: Plan for potential costs, including tools, parts, and unforeseen expenses.

By considering these elements, you can confidently approach your repair endeavors and enhance your skills over time.