Poulan Tiller Parts Diagram Explained

Exploring the intricate elements of a garden cultivator is essential for anyone looking to maintain or enhance their outdoor spaces. The functionality of these machines relies on a series of interconnected parts that work harmoniously to achieve optimal performance. Familiarity with these components not only aids in efficient operation but also ensures proper maintenance and longevity.

By gaining insight into the various sections and their specific roles, users can effectively troubleshoot issues that may arise. An organized reference showcasing these individual components offers a valuable resource, facilitating a deeper comprehension of how each element contributes to the overall efficiency of the cultivator. This knowledge empowers gardeners to make informed decisions regarding repairs and upgrades.

Ultimately, understanding the mechanical intricacies involved can transform the gardening experience, allowing for a more productive and enjoyable time in the soil. Whether you are a seasoned gardener or a novice, mastering these components can lead to greater success in your gardening endeavors.

Poulan Tiller Parts Overview

This section provides an insight into the various components essential for the effective functioning of gardening machinery designed for soil cultivation. Understanding these elements is crucial for maintenance and repairs, ensuring optimal performance.

- Engine: The powerhouse that drives the entire mechanism, influencing speed and efficiency.

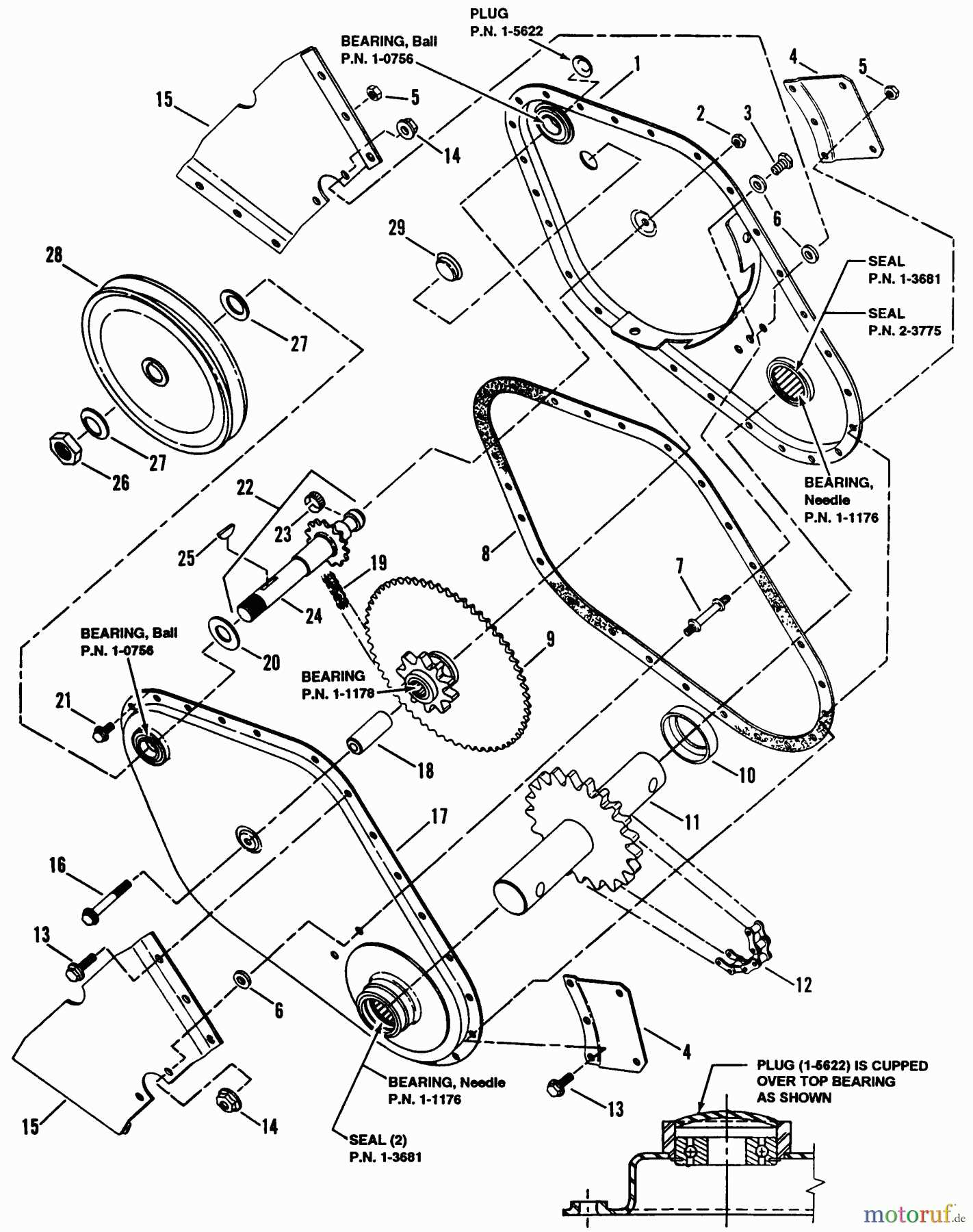

- Transmission: This system transfers power from the engine to the working parts, enabling smooth operation.

- Blades: Vital for breaking up the soil, these sharp tools are fundamental for preparing the ground.

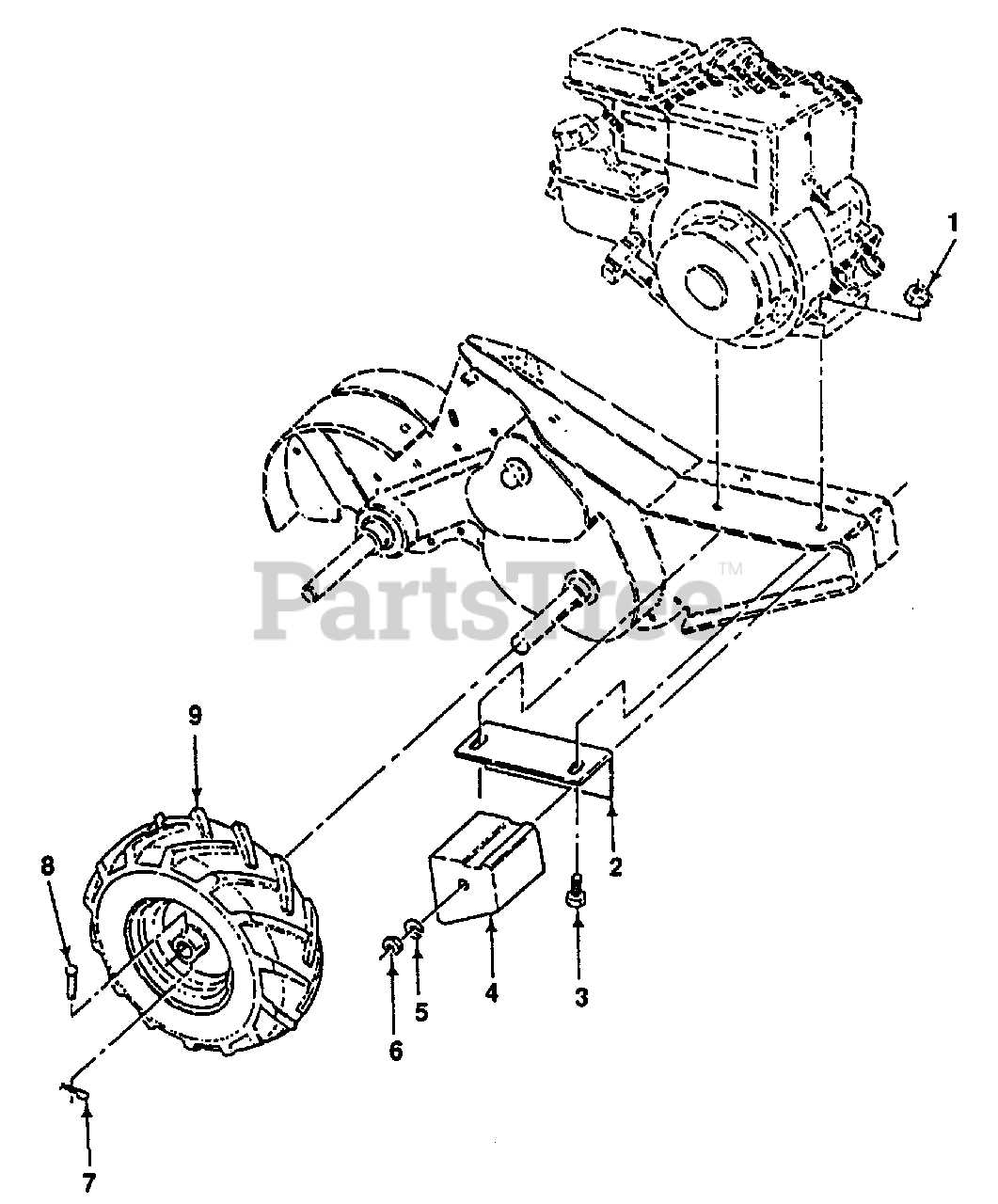

- Frame: The structural backbone that supports all components, providing stability and durability.

- Handlebars: The user interface for maneuvering the device, allowing for better control and comfort.

Additionally, understanding the roles of smaller elements is equally important:

- Wheels: These assist in mobility, allowing the machinery to traverse different terrains.

- Fuel System: This includes the tank and lines that supply energy to the engine.

- Air Filter: Essential for maintaining engine health by keeping debris out of the combustion chamber.

- Drive Belts: These are critical for transferring power and ensuring smooth operation between components.

By familiarizing oneself with these components, users can enhance their understanding of the equipment, leading to more efficient use and care.

Understanding Tiller Functionality

The effectiveness of ground preparation tools lies in their ability to break up soil and create optimal conditions for planting. These machines utilize a combination of rotating blades and powered mechanics to turn and aerate the earth, promoting healthy growth of vegetation. By analyzing their structure and operation, users can better appreciate how these devices enhance gardening and farming practices.

The main components work together to ensure that the tool can easily penetrate various soil types. The rotating mechanism is crucial, as it provides the necessary force to churn through compacted dirt. Understanding these elements helps users maximize efficiency and longevity in their equipment.

Moreover, recognizing how adjustments and maintenance can affect performance is essential. Regular checks on the blades and drive systems can lead to improved functionality, ensuring that the tool remains a valuable asset in any agricultural or gardening endeavor.

Common Issues with Tillers

When working with garden cultivation equipment, users often encounter various challenges that can hinder performance and efficiency. Recognizing these common problems is essential for proper maintenance and effective use. Addressing issues promptly not only prolongs the lifespan of the machine but also ensures optimal results in the garden.

Engine Difficulties

One of the most frequent complications involves the engine not starting or stalling during operation. This can stem from issues such as fuel contamination, a clogged air filter, or spark plug malfunctions. Regular checks on these components can significantly enhance reliability. Ensuring that the fuel is fresh and clean can also prevent many engine-related headaches.

Transmission and Tillage Problems

Another area where users may face difficulties is in the transmission system or tilling performance. Slipping gears or inadequate soil penetration can occur due to worn belts or damaged tines. Keeping these parts in good condition and replacing them when necessary is crucial for maintaining efficiency. Regular lubrication and adjustments can also mitigate many transmission-related issues.

Essential Components of a Tiller

Understanding the fundamental elements of a gardening machine is crucial for effective operation and maintenance. These vital components work together to ensure optimal performance, aiding in soil preparation and garden management. Each element plays a significant role in the overall functionality and efficiency of the equipment.

| Component | Description |

|---|---|

| Engine | The power source that drives the machine, providing the necessary energy for operation. |

| Transmission | A system that transfers power from the engine to the rotating tools, allowing for adjustable speed and direction. |

| Rotors | Cutting tools that penetrate the soil, breaking it up and preparing it for planting. |

| Frame | The structural backbone that supports all components, ensuring stability during use. |

| Handlebars | The steering mechanism that allows the operator to guide the equipment effectively. |

| Wheels | Components that provide mobility, allowing easy transport and maneuverability across different terrains. |

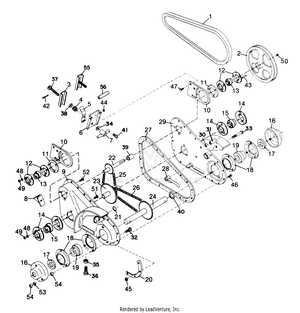

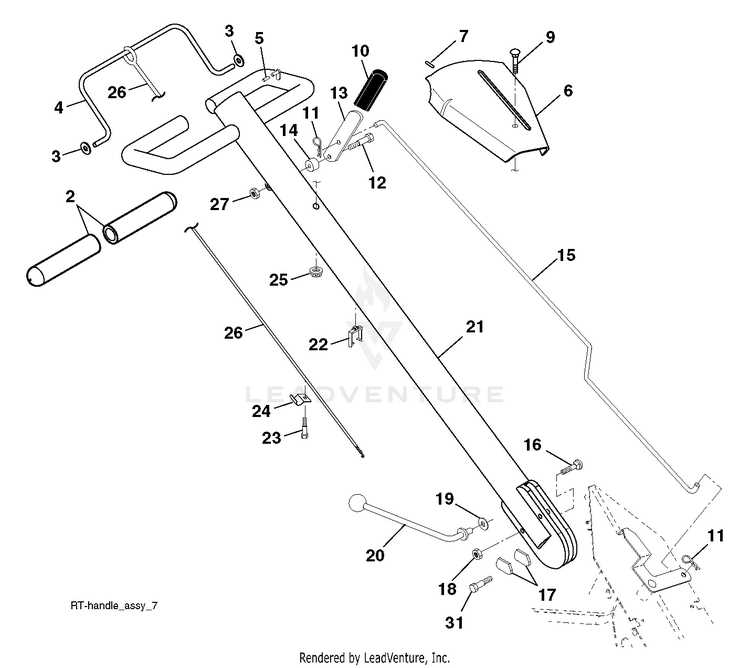

How to Read a Parts Diagram

Understanding a visual representation of components can significantly enhance your ability to identify and manage each piece. This guide aims to simplify the process of interpreting such illustrations, allowing you to navigate through various elements with ease.

Begin by familiarizing yourself with the layout; each section typically indicates specific areas of the equipment. Look for numbers or labels that correspond to a list, as these will provide details about each item. Take note of the orientation; it can influence how parts connect or function together.

Pay attention to the different symbols and lines used; they often denote various relationships or types of connections. This can be crucial for ensuring correct assembly or repair. Lastly, don’t hesitate to consult additional resources if certain elements remain unclear; the ultimate goal is to achieve a comprehensive understanding.

Identifying Tiller Parts by Number

Understanding the components of your gardening equipment is crucial for effective maintenance and repairs. By using identification numbers, you can easily find and replace specific elements, ensuring optimal performance of your machine.

Here are some steps to assist you in recognizing the components:

- Locate the Manual: Your equipment usually comes with a user manual that lists all components along with their identification numbers.

- Find the Model Number: The model number is essential for cross-referencing parts. It can typically be found on a label or stamped onto the frame.

- Use Online Resources: Many manufacturers provide online databases or forums where you can enter your model number to retrieve a list of components.

When searching for specific items, keep these tips in mind:

- Always note down the identification number before purchasing replacements.

- Check for compatibility with your particular model to avoid issues.

- Consider reaching out to customer support if you’re unsure about a specific number.

By following these guidelines, you’ll enhance your ability to manage and maintain your equipment effectively, ensuring its longevity and efficiency.

Maintenance Tips for Your Tiller

Regular upkeep is essential to ensure optimal performance and longevity of your garden equipment. By following a few simple guidelines, you can keep your machine running smoothly and efficiently throughout the growing season.

Routine Checks

- Inspect the tines for wear and damage, replacing any that show signs of excessive wear.

- Check the fuel system regularly to ensure there are no leaks and that the fuel is fresh.

- Examine the air filter and clean or replace it as needed to maintain airflow.

Seasonal Maintenance

- At the beginning of each season, perform a thorough cleaning to remove dirt and debris.

- Sharpen the cutting tools to ensure efficient soil cultivation.

- Change the oil according to the manufacturer’s recommendations to keep the engine running smoothly.

By adhering to these maintenance tips, you can enhance the performance and lifespan of your gardening equipment, making your outdoor tasks easier and more enjoyable.

Where to Find Replacement Parts

Locating suitable components for your gardening equipment can significantly enhance its performance and longevity. There are several avenues to explore when seeking these essential items.

- Authorized Dealers: Check with official retailers for authentic items that guarantee compatibility.

- Online Marketplaces: Websites like Amazon and eBay often have a variety of options available at competitive prices.

- Local Hardware Stores: Many community shops stock common components or can order them for you.

- Specialized Websites: Numerous online platforms focus on gardening machinery and can provide detailed catalogs.

Comparing prices and availability across these sources can help you make the ultimate decision for your needs.

Exploring Aftermarket Part Options

When maintaining outdoor equipment, considering alternatives to original components can provide significant benefits. These options often enhance performance and can be more cost-effective, giving users a chance to tailor their machinery to specific needs.

- Improved Durability: Many aftermarket components are designed to withstand tougher conditions.

- Cost Savings: Alternatives can often be found at a lower price point without sacrificing quality.

- Availability: Aftermarket options are frequently easier to source, ensuring minimal downtime.

It’s essential to evaluate the reputation of suppliers and the compatibility of components before making a purchase. This careful consideration ensures that users can maximize their equipment’s potential while exploring the ultimate choices available in the market.

Step-by-Step Repair Guide

Maintaining garden equipment can significantly enhance its longevity and performance. This guide provides a structured approach to troubleshooting and fixing common issues, ensuring your tools operate efficiently. By following each step meticulously, you can identify problems and implement effective solutions without unnecessary complications.

Identifying the Problem

Begin by observing the equipment’s performance. Listen for unusual sounds, check for vibrations, or note any irregularities in operation. Document these symptoms, as they will guide you in diagnosing the issue accurately. If available, refer to the user manual for troubleshooting tips related to specific symptoms.

Performing Repairs

Once you have pinpointed the problem, gather the necessary tools and components for the repair. Disassemble the relevant sections carefully, keeping track of each piece. Clean any dirt or debris before replacing worn or damaged elements. Reassemble the equipment following the reverse order of disassembly, ensuring all parts are secure and functioning properly. After repairs, conduct a thorough test to confirm the effectiveness of your work.

Tools Needed for Tiller Repairs

Proper maintenance and repairs require specific instruments to ensure efficiency and accuracy. Having the right tools on hand not only streamlines the process but also enhances the overall outcome of the work. Familiarizing yourself with these essential implements is crucial for successful restoration tasks.

Basic Hand Tools

Essential hand tools include wrenches, screwdrivers, and pliers. These items are fundamental for loosening and tightening various components, allowing for effective disassembly and reassembly. A reliable set of these tools is vital for addressing common issues.

Specialized Equipment

In addition to basic tools, specialized equipment such as spark plug wrenches and fuel line clamps may be necessary for more intricate repairs. These tools are designed to tackle specific challenges, ensuring that each part functions optimally. Investing in quality equipment can significantly improve repair outcomes.

Comparing Poulan Models and Parts

This section delves into the variety of models available in a particular product line, highlighting the differences and similarities among them. By understanding the components and functionalities of each version, users can make informed choices that cater to their specific needs.

Model Variations: Each variant offers unique features designed to meet different requirements. Some versions may prioritize power and efficiency, while others focus on ease of use and portability. Assessing these characteristics allows consumers to select the ideal option for their gardening tasks.

Component Compatibility: When examining the individual elements of these machines, it’s essential to recognize that not all parts are interchangeable. Familiarizing oneself with the specific components used in each model can simplify maintenance and repairs, ensuring optimal performance over time.

Performance Metrics: Different models may excel in various aspects, such as digging depth or soil aeration. Evaluating performance metrics helps users determine which machine is best suited for their gardening style and the types of soil they typically encounter.

Price Points: Analyzing the cost of different models provides insight into what features may justify higher prices. Understanding the value offered by each version enables users to find a balance between budget and functionality.

Safety Precautions During Maintenance

Ensuring a safe environment during the upkeep of gardening equipment is crucial. Proper safety measures not only protect the individual performing the maintenance but also contribute to the longevity and efficiency of the machinery. Following essential guidelines can prevent accidents and enhance the overall maintenance experience.

Essential Safety Guidelines

Before commencing any maintenance work, it is vital to adhere to a set of fundamental safety protocols. These protocols include wearing appropriate personal protective equipment, disconnecting power sources, and ensuring that the work area is clear of any hazards. By following these practices, you can significantly reduce the risk of injury and equipment damage.

Common Hazards and Mitigation

While performing maintenance tasks, be aware of potential risks such as moving parts, sharp edges, and chemical exposure. Taking proactive steps to mitigate these dangers is essential. Regular inspections and proper handling techniques can prevent injuries and ensure a smooth maintenance process.

| Hazard | Precaution |

|---|---|

| Moving Parts | Always disconnect the power source before servicing. |

| Sharp Edges | Wear gloves and protective clothing to avoid cuts. |

| Chemical Exposure | Use masks and gloves when handling chemicals. |

| Cluttered Workspace | Keep the area organized and free of obstacles. |