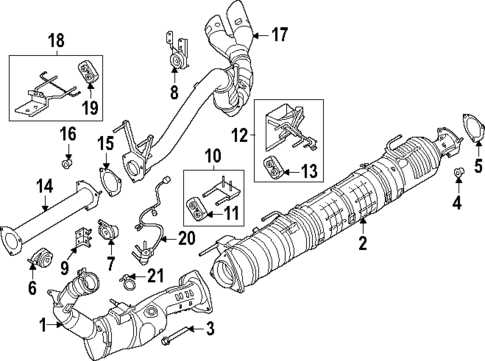

Comprehensive Diagram of 6.0 Powerstroke Injector Parts

The efficiency of modern diesel engines hinges on the intricate components responsible for fuel delivery. A comprehensive exploration of these elements reveals their critical roles in enhancing performance and reliability. Each segment of this system must work in harmony to ensure optimal combustion and engine functionality.

Focusing on the intricate mechanisms involved, we uncover the various elements that contribute to the precise injection of fuel into the combustion chamber. These components are designed to withstand extreme conditions while providing the necessary precision for effective engine operation. Understanding their layout and interaction is essential for anyone looking to optimize engine performance or engage in maintenance practices.

By delving into the specifics of these components, we can appreciate the engineering that supports high levels of efficiency and power. This knowledge is not only valuable for mechanics and enthusiasts but also for those interested in the evolution of diesel technology. A thorough grasp of these systems paves the way for better decision-making in repairs and upgrades.

Understanding 6.0 Powerstroke Injectors

Familiarity with the components that manage fuel delivery is essential for optimal engine performance. These critical elements play a pivotal role in ensuring the correct mixture of fuel and air, directly affecting efficiency and power output. Understanding their function and design is vital for both maintenance and troubleshooting.

Key Functions

- Facilitating precise fuel atomization.

- Controlling fuel flow based on engine demands.

- Contributing to overall combustion efficiency.

Common Issues

- Clogging due to impurities in fuel.

- Electrical malfunctions affecting operation.

- Wear and tear from prolonged use.

Key Components of Injector Systems

The functionality of fuel delivery mechanisms is reliant on several critical elements that work in harmony to ensure optimal performance. These components play a vital role in regulating fuel flow, atomization, and timing, which are essential for efficient engine operation.

One of the primary elements is the nozzle, which is responsible for dispersing the fuel into the combustion chamber. Its design influences the size and shape of the spray pattern, affecting how well the fuel mixes with air for combustion.

Another important component is the solenoid or electronic actuator. This device controls the opening and closing of the fuel delivery mechanism, allowing for precise timing and volume control. The responsiveness of this element is crucial for achieving the desired engine performance and efficiency.

Fuel lines and connectors also play a significant role in the overall system. These pathways must be reliable and capable of withstanding high pressure while maintaining a consistent flow to each delivery point.

Lastly, the control unit integrates data from various sensors to optimize fuel injection timing and quantity, adapting to changing operating conditions for improved efficiency and reduced emissions.

How Injectors Function in Diesel Engines

In diesel engines, the process of introducing fuel into the combustion chamber is crucial for efficient operation. This system relies on precise timing and pressure to ensure optimal performance and emissions control.

Key functions of this system include:

- Delivery of fuel in a finely atomized mist

- Regulation of fuel quantity based on engine demand

- Enhancement of combustion efficiency through proper timing

The operation can be broken down into several stages:

- Fuel Preparation: Fuel is drawn from the tank and prepared for delivery.

- Pressurization: The fuel is pressurized to ensure effective atomization.

- Injection: The pressurized fuel is injected into the combustion chamber at the correct moment.

- Combustion: The atomized fuel mixes with air and ignites, powering the engine.

Understanding this process is essential for maintaining engine health and performance.

Common Issues with 6.0 Injectors

In the realm of diesel engines, certain challenges frequently arise that can impact performance and efficiency. Understanding these prevalent problems can help in diagnosing issues and ensuring proper maintenance of the fuel delivery system.

Frequent Problems

Several common malfunctions are often reported, which may lead to engine misfires, decreased power, and increased emissions. These issues can stem from wear and tear, improper installation, or inadequate maintenance.

| Issue | Description |

|---|---|

| Leakage | Fuel can escape from the sealing areas, causing performance loss. |

| Clogging | Debris may accumulate, restricting fuel flow and efficiency. |

| Electrical Failure | Faulty electrical components can prevent proper operation. |

Prevention and Solutions

Regular inspections and timely replacements are crucial in mitigating these issues. Employing high-quality fuel and adhering to maintenance schedules can greatly enhance the longevity of the fuel delivery components.

Visual Guide to Injector Parts

This section provides a detailed overview of the essential components involved in the fuel delivery system. Understanding these elements is crucial for anyone looking to enhance performance or troubleshoot issues. Each component plays a vital role in ensuring efficient operation and reliability.

Key Components Explained

Within this intricate system, several key elements work together harmoniously. The nozzle atomizes the fuel, facilitating optimal combustion. The solenoid acts as an electronic switch, regulating the flow and timing. Additionally, the body serves as the main housing, ensuring structural integrity while accommodating the internal mechanisms.

Maintenance Tips

Regular maintenance of these components is imperative for longevity and efficiency. Ensure that connections are secure and free from debris, as buildup can impede performance. Periodic inspections can identify wear or damage early, preventing costly repairs and ensuring smooth operation.

Maintenance Tips for Injector Longevity

Ensuring the extended lifespan of fuel delivery components is essential for optimal engine performance. Proper care and attention can significantly reduce wear and tear, enhancing efficiency and reliability.

Regular Cleaning: Periodic cleaning helps prevent buildup and clogs. Use high-quality fuel additives designed to maintain cleanliness in the system, which can help in keeping the components functioning smoothly.

Quality Fuel: Always opt for premium-grade fuel. Low-quality fuel can lead to deposits and reduce the efficiency of fuel delivery mechanisms. This choice ensures better combustion and reduces the risk of premature wear.

Timely Replacements: Monitor the lifespan of related components and replace them as needed. Worn or damaged parts can affect overall performance, leading to more significant issues down the line.

Routine Inspections: Regular checks for leaks and pressure fluctuations are vital. Addressing minor issues promptly can prevent major failures and costly repairs.

Coolant Maintenance: Ensure the cooling system is functioning correctly. Overheating can negatively impact the fuel delivery components, leading to reduced efficiency and potential damage.

Engine Tune-ups: Scheduled tune-ups can optimize engine performance. This includes checking timing, air-fuel mixtures, and other essential parameters that influence the operation of fuel delivery systems.

Replacing 6.0 Powerstroke Injectors

When it comes to enhancing engine performance and efficiency, updating certain components is essential. This guide will walk you through the steps needed for a successful swap of these crucial elements in your vehicle, ensuring optimal functionality and reliability.

Preparation Steps

Before diving into the replacement process, ensure you have all necessary tools and parts at hand. Disconnect the battery and relieve any pressure from the fuel system to prevent accidents. A clean workspace is vital to avoid contamination during the installation.

Installation Process

Carefully remove the old components, taking note of the order for reinstallation. Once the old units are out, clean the mounting surfaces and install the new components. Follow the manufacturer’s torque specifications to ensure proper fitting. After everything is securely in place, reconnect the battery and test the system for leaks and functionality.

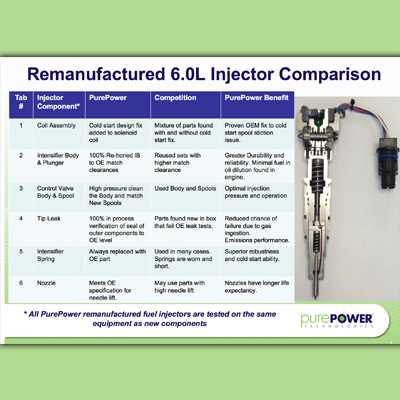

Aftermarket vs. OEM Injector Options

The choice between alternative and original components significantly impacts performance and reliability in any vehicle’s fuel system. Each option presents distinct advantages and potential drawbacks that can influence both short-term and long-term vehicle operation.

Original equipment manufacturer offerings typically ensure compatibility and adherence to factory specifications. These components often provide peace of mind due to their rigorous testing and quality assurance, making them a preferred choice for those prioritizing reliability.

On the other hand, alternative components can offer cost savings and enhanced performance features. Many aftermarket options are designed to improve efficiency or provide better responsiveness, appealing to enthusiasts seeking to maximize their vehicle’s capabilities. However, it’s essential to consider the trade-offs regarding warranty and longevity.

Ultimately, the decision should be guided by individual needs, budget constraints, and the desired balance between performance and reliability. Careful evaluation of both alternatives can lead to a more informed choice, tailored to specific requirements.

Impact of Injectors on Engine Performance

The components responsible for delivering fuel play a crucial role in determining how efficiently an engine operates. Their design and functionality directly influence the combustion process, affecting power output, fuel economy, and emissions. Understanding these elements is essential for optimizing vehicle performance and ensuring reliability.

Efficiency and Power Output

High-quality fuel delivery mechanisms can significantly enhance engine efficiency. When the mixture of air and fuel is optimal, it results in improved power generation. Precision in the delivery process ensures that the engine runs smoothly, translating into a more responsive driving experience.

Emissions and Environmental Impact

Properly functioning fuel delivery systems are essential for minimizing harmful emissions. Effective combustion leads to cleaner exhaust, which is critical in meeting regulatory standards. Consequently, investing in quality components not only boosts performance but also contributes to environmental sustainability.

Upgrades for Enhanced Fuel Delivery

Optimizing the fuel delivery system can significantly improve engine performance and efficiency. By implementing various enhancements, vehicle owners can achieve smoother operation, increased power output, and better fuel economy. Below are several upgrades that can contribute to these improvements.

- High-Performance Fuel Pumps: Upgrading to a higher-capacity fuel pump ensures consistent fuel flow under demanding conditions.

- Precision Fuel Rails: Utilizing aftermarket fuel rails can enhance distribution and pressure, leading to more efficient combustion.

- Enhanced Filtration Systems: Installing superior filters helps maintain fuel purity, preventing contaminants from affecting performance.

- Advanced Calibration Tools: Tuning the engine’s management system allows for optimal fuel mixture adjustments tailored to specific upgrades.

- Improved Delivery Lines: Using high-flow delivery lines reduces restrictions, allowing for a more efficient flow of fuel to the engine.

Each of these enhancements plays a crucial role in maximizing the overall effectiveness of the fuel system. By carefully selecting and installing these components, vehicle enthusiasts can ensure their engines perform at their best.

Understanding Injector Calibration and Settings

Calibration and settings play a crucial role in ensuring optimal performance and efficiency in fuel delivery systems. Proper adjustment allows for precise control over fuel flow and timing, which directly influences engine responsiveness and overall functionality. By grasping the fundamentals of these adjustments, one can significantly enhance engine performance and reliability.

Importance of Accurate Calibration

Accurate calibration is essential for achieving the desired fuel-to-air ratio. This balance not only affects power output but also emissions and fuel economy. A well-calibrated system minimizes the risk of misfires and ensures smooth engine operation, leading to a longer lifespan for components.

Key Considerations for Settings

When setting up the system, factors such as temperature, pressure, and flow rate must be taken into account. Each engine configuration may require unique adjustments, emphasizing the need for thorough understanding and precise tuning to achieve the ultimate performance goals.