Bestway Pool Pump Parts Overview

Water circulation systems play a crucial role in maintaining the cleanliness and clarity of recreational water bodies. By ensuring proper water flow and filtration, these systems help create a safe and enjoyable environment for users. A comprehensive grasp of the various components involved is essential for effective operation and maintenance.

Familiarizing oneself with the layout and functionality of these components enables users to identify potential issues and make informed decisions regarding repairs or replacements. Understanding how each element interacts within the system is vital for optimizing performance and longevity.

By delving into the specifics of each component’s configuration, users can enhance their troubleshooting skills, leading to more efficient management of their water systems. Knowledge of these intricacies ultimately contributes to a better overall experience and reduces the need for frequent interventions.

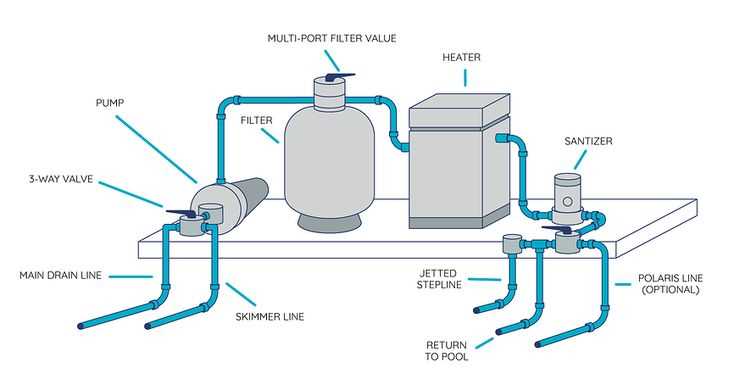

This section aims to provide a comprehensive overview of the various elements that make up a circulation system for water management. Understanding these components is essential for maintenance, troubleshooting, and enhancing the overall performance of the system. Each element plays a crucial role in ensuring efficiency and longevity.

Key Elements of Water Circulation Systems

Water circulation systems consist of several integral components, each serving a distinct purpose. Here are the main elements:

- Motor: The driving force behind the system, responsible for powering the entire operation.

- Filter: Essential for removing impurities and debris from the water, maintaining clarity and hygiene.

- Hoses: These connect various components, facilitating the flow of water throughout the system.

- Skimmer: Helps to collect surface debris and prevent clogging within the filtration system.

- Return Jets: Disperse filtered water back into the environment, ensuring proper circulation.

Importance of Each Component

Each component of a water circulation system is vital for optimal functionality:

- Efficiency: A well-maintained motor ensures energy savings and effective operation.

- Cleanliness: A quality filter is critical for keeping water clean and safe for use.

- Connection: High-quality hoses prevent leaks and maintain the integrity of the system.

By understanding the roles and functions of these components, users can effectively manage and enhance their water circulation systems, ensuring a long-lasting and efficient operation.

Essential Parts of a Pool Pump

Understanding the crucial components of a water circulation system is fundamental for maintaining its efficiency and functionality. Each element plays a significant role in ensuring clean and clear water, contributing to the overall performance of the system. Knowledge of these components allows for better maintenance and quicker troubleshooting when issues arise.

The primary elements of a water circulation system include various mechanical and electrical components that work together harmoniously. Each piece is designed to facilitate the movement and filtration of water, ensuring optimal performance and longevity of the entire setup.

| Component | Function |

|---|---|

| Motor | Drives the system, providing power to circulate water. |

| Impeller | Moves water through the system, creating flow. |

| Strainer | Removes debris and larger particles before water enters the system. |

| Filter | Traps smaller particles, ensuring water clarity and cleanliness. |

| Valves | Control the flow of water, allowing for adjustments and maintenance. |

| Hoses | Connect various components, facilitating water movement. |

How to Read Pump Diagrams

Understanding technical illustrations is essential for anyone working with mechanical devices. These visuals provide critical information about the components and their relationships, helping users to grasp how systems operate. By learning to interpret these representations, you can troubleshoot issues and perform maintenance more effectively.

To effectively analyze these illustrations, follow these steps:

| Step | Description |

|---|---|

| 1 | Identify the components and their symbols. Familiarize yourself with common representations used in illustrations. |

| 2 | Understand the flow direction. Arrows often indicate how fluids or energy move through the system. |

| 3 | Refer to accompanying labels. These usually provide details on each element’s specifications and functions. |

| 4 | Consult the legend or key. This will help clarify any symbols or notations that are unfamiliar. |

By mastering these techniques, you’ll enhance your ability to work with mechanical illustrations, leading to more efficient repairs and upgrades.

Common Issues with Pump Parts

Various components within a fluid circulation system can encounter problems that affect overall functionality. Understanding these challenges is essential for effective maintenance and troubleshooting. Below are some frequently observed complications associated with these critical elements.

- Clogs: Obstructions can accumulate in different sections, impeding fluid flow.

- Leaks: Connections may loosen or degrade, resulting in unwanted fluid escape.

- Noise: Unusual sounds often indicate mechanical issues or misalignment of components.

Addressing these issues promptly can enhance system efficiency and extend the lifespan of its components.

- Worn Seals: Seals can degrade over time, leading to inefficiency and potential leaks.

- Electrical Failures: Malfunctions in wiring or connections can disrupt power supply, causing operational failure.

- Corrosion: Exposure to moisture can lead to rust and deterioration of metal components.

Regular inspection and timely intervention can prevent minor issues from escalating into significant complications.

Replacing Pool Pump Components

Maintaining the efficiency of your water circulation system often requires the replacement of various essential elements. Understanding the function of each component and recognizing the signs of wear can significantly enhance the lifespan of your equipment.

Identifying Necessary Replacements: The first step in this process is to identify which components need to be replaced. Common indicators include unusual noises, decreased flow rates, or visible damage. Regular inspections can help in pinpointing these issues early.

Steps for Effective Replacement: Begin by disconnecting the system from its power source. Carefully remove the damaged components, ensuring that any seals or gaskets are also inspected for wear. When installing new elements, ensure that all connections are secure and that any necessary adjustments are made for optimal performance.

In conclusion, proactively managing the replacement of key elements in your water circulation system not only improves functionality but also contributes to the overall longevity of the equipment. Regular maintenance checks and timely replacements are crucial for seamless operation.

Maintenance Tips for Pool Pumps

Proper upkeep of water circulation systems is essential for ensuring optimal performance and longevity. Regular attention to key components can prevent common issues, enhancing efficiency and reducing the need for costly repairs. Here are several strategies to maintain these crucial systems effectively.

First, regularly check and clean filters to prevent clogging and ensure smooth operation. Dirty filters can impede water flow, leading to strain on the entire system. Additionally, inspect seals and gaskets for any signs of wear or leaks, as these can significantly impact functionality. Replacing worn components promptly can save time and money in the long run.

Another important aspect is monitoring the fluid levels. Maintaining the appropriate amount of lubricating substance is vital for smooth operation. Furthermore, keep the surrounding area clear of debris to prevent obstruction and ensure efficient air circulation. Lastly, follow the manufacturer’s recommendations for seasonal maintenance and check-ups to address any potential concerns before they escalate.

Choosing Quality Replacement Parts

When it comes to maintaining your water circulation system, selecting high-quality components is essential for ensuring optimal performance and longevity. Investing in reliable replacements can prevent frequent breakdowns and enhance the efficiency of your setup.

Here are some key considerations when choosing new components:

- Material Quality: Look for parts made from durable materials that can withstand exposure to water and chemicals.

- Compatibility: Ensure that the components are compatible with your specific system to avoid functionality issues.

- Brand Reputation: Opt for products from reputable manufacturers known for their quality and customer support.

- Warranty: Consider options that come with a warranty, providing assurance against defects.

By focusing on these factors, you can make informed decisions that contribute to the overall reliability of your water management equipment.

Upgrading Your Pool Pump System

Enhancing your water circulation system can significantly improve efficiency and performance. Whether you’re aiming for better filtration or energy savings, understanding the components and options available is crucial for making informed decisions. Upgrading involves evaluating your existing setup, selecting appropriate replacements, and ensuring compatibility with your current infrastructure.

When considering an upgrade, it’s essential to assess the specifications of your current components. This includes flow rates, energy consumption, and the technology used in the existing system. Below is a comparison table highlighting key factors to consider when upgrading your water circulation system.

| Feature | Current System | Upgraded System |

|---|---|---|

| Flow Rate (GPH) | 3000 | 4000 |

| Energy Efficiency | Standard | High-Efficiency |

| Noise Level (dB) | 75 | 50 |

| Maintenance Requirements | High | Low |

Choosing high-performance alternatives can lead to long-term savings and improved water quality. Be sure to consult with a professional to ensure a seamless transition to a more advanced system.

Safety Features in Pool Pumps

Ensuring the safety of water circulation devices is crucial for both users and the equipment itself. These mechanisms incorporate several protective elements designed to prevent accidents and enhance operational reliability. Understanding these features can help users make informed decisions when selecting and maintaining their systems.

- Automatic Shut-Off: This feature halts operation when specific conditions are met, such as overheating or low water levels, preventing potential damage.

- Ground Fault Circuit Interrupter (GFCI): A critical safety component that disconnects power in the event of a short circuit, reducing the risk of electric shock.

- Overload Protection: This system detects when the device is drawing excessive current, triggering a shutdown to prevent overheating and damage.

- Strainer Basket: Protects the internal mechanisms by trapping debris, ensuring that the device operates efficiently and reducing the risk of blockages.

Incorporating these safety measures not only enhances the longevity of the device but also promotes a safer environment for users. Regular maintenance and adherence to safety guidelines are essential for optimal performance.

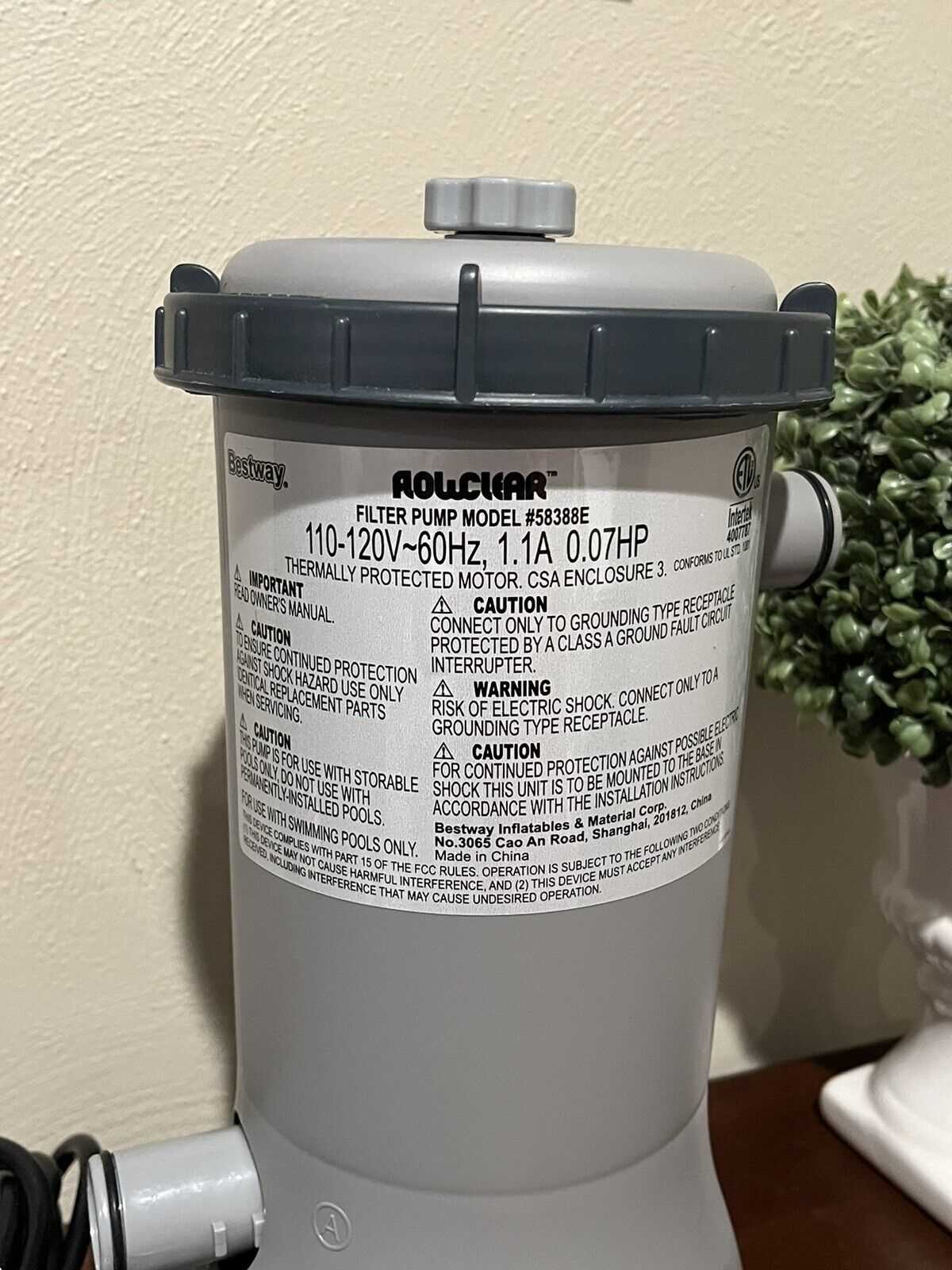

Identifying Pool Pump Model Numbers

Understanding the specific model identifiers for water circulation devices is essential for effective maintenance and repairs. Each unit typically comes with a unique code that helps users determine compatibility with various components and accessories. Knowing how to locate and interpret these identifiers can simplify troubleshooting and replacement processes.

Model numbers can often be found on a label affixed to the unit itself, usually near the motor or on the base. This information is crucial for ensuring that the correct replacements are acquired, as various models may have differing specifications and features.

| Location | Typical Format |

|---|---|

| On the motor housing | XYZ-1234 |

| Underneath the base | ABC-5678 |

| Inside the service door | MODEL: 91011 |

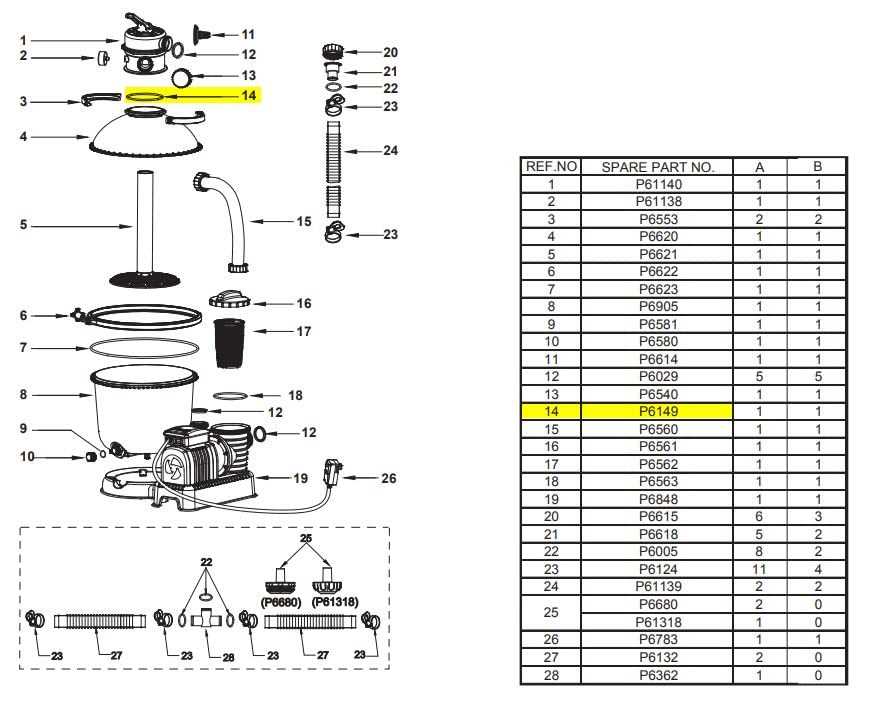

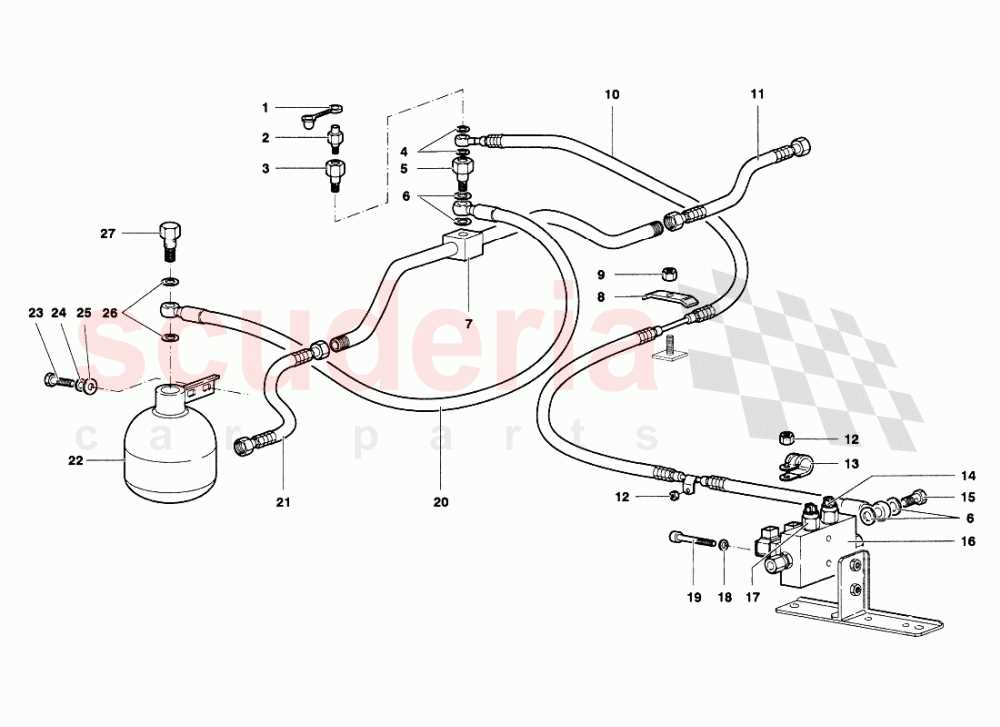

Visual Guide to Pump Assembly

This section provides an insightful overview of the components and their arrangement necessary for the successful integration of a circulation system. Understanding the configuration of these elements is crucial for effective operation and maintenance.

Here is a breakdown of the primary components typically involved in the assembly:

- Motor Unit: The driving force behind the entire system.

- Filter Housing: Essential for trapping debris and impurities.

- Inlet and Outlet Fittings: Facilitate the movement of water in and out of the system.

- Hoses: Connect various components and allow for fluid transfer.

- Clamps and Fasteners: Secure all parts together for a stable setup.

To assemble these elements effectively, follow these steps:

- Start with the motor unit as the foundation of the assembly.

- Attach the filter housing securely to ensure proper filtration.

- Connect the inlet and outlet fittings, making sure they align correctly.

- Install the hoses, ensuring they are free of kinks or obstructions.

- Use clamps and fasteners to tighten connections and maintain stability.

Referencing this guide will simplify the assembly process, ensuring each component functions harmoniously within the system.

Troubleshooting Pool Pump Problems

Identifying and resolving issues with water circulation systems is crucial for maintaining optimal performance. Various factors can lead to inefficiencies or malfunctions, and recognizing these problems early can help prevent further complications. This section will explore common challenges and their potential solutions.

Common Issues and Solutions

- Insufficient Water Flow: This can be caused by clogs in the filter or hose. Regular cleaning and maintenance of these components are essential.

- Noisy Operation: Unusual sounds may indicate loose parts or worn bearings. Inspecting and tightening connections can often resolve this issue.

- Overheating: If the motor overheats, it may be due to blocked vents or prolonged operation. Ensuring adequate ventilation and allowing breaks can mitigate this problem.

Steps to Diagnose Issues

- Check the power supply to ensure the unit is receiving electricity.

- Inspect hoses and connections for any signs of wear or leaks.

- Clean or replace filters to enhance water flow.

- Listen for any abnormal sounds while the system is running.

- Monitor the temperature of the motor during operation.

By following these guidelines, users can effectively identify and troubleshoot common issues that may arise within their circulation systems, ensuring longevity and efficiency.