Understanding the Parts Diagram of Cat Pump 5CP3120

The functionality of high-pressure machinery relies heavily on the intricate relationship between its various elements. Each component plays a critical role in ensuring optimal performance and longevity. A detailed exploration of these elements can reveal insights into maintenance and troubleshooting strategies, enhancing the overall efficiency of the system.

By examining the configuration and arrangement of these essential pieces, operators can gain a clearer understanding of their operation. This knowledge not only aids in identifying potential issues but also empowers users to execute necessary repairs with confidence. Familiarity with the layout is crucial for anyone involved in the upkeep of such equipment.

In this discussion, we will delve into the specific characteristics and functions of each segment within the system. Highlighting their interactions will provide a comprehensive view of how they contribute to the machinery’s overall effectiveness. Whether you are a seasoned technician or a novice, grasping these concepts is fundamental to mastering high-pressure operations.

Understanding Cat Pump 5CP3120

This section explores the intricacies of a specific high-performance mechanism widely utilized in various applications. By delving into its design and functionality, we aim to enhance comprehension and facilitate efficient usage.

Key Features

- Robust construction ensuring longevity and reliability.

- High efficiency leading to reduced energy consumption.

- Versatile compatibility with numerous systems.

- Simple maintenance procedures for optimal performance.

Operational Insights

- Understanding the flow dynamics within the unit.

- Recognizing the importance of regular upkeep.

- Identifying common issues and troubleshooting techniques.

- Implementing best practices for maximum efficiency.

Key Features of the 5CP3120 Model

This model is designed to deliver exceptional performance and reliability in various applications. Its engineering emphasizes durability, efficiency, and ease of use, making it a preferred choice for professionals in the field.

Durability and Construction

- Robust materials ensure longevity and withstand harsh environments.

- Corrosion-resistant components enhance the lifespan and reduce maintenance needs.

- Sealed designs prevent leaks and contamination, ensuring consistent operation.

Performance and Efficiency

- High flow rates enable effective handling of different tasks.

- Optimized energy consumption minimizes operational costs.

- Adjustable settings allow for tailored performance based on specific requirements.

Common Applications for Cat Pumps

These high-pressure devices are widely utilized across various industries due to their reliability and efficiency. Their design allows for versatile usage, making them suitable for numerous tasks that require the movement of fluids at significant pressures. From industrial cleaning to agricultural irrigation, their applications are diverse and impactful.

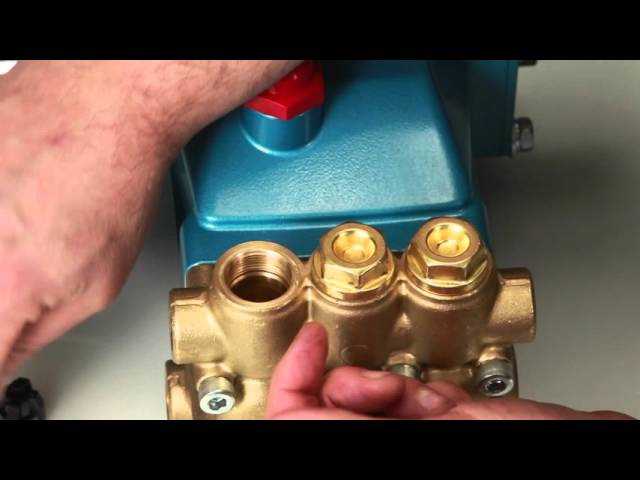

Industrial Cleaning

One of the most prominent uses of these devices is in industrial cleaning. They are essential for power washing equipment, where their ability to generate high pressure effectively removes dirt, grease, and grime from surfaces. Factories, warehouses, and manufacturing facilities benefit greatly from their performance, ensuring equipment and environments remain clean and operational.

Agricultural and Irrigation Systems

Apart from industrial settings, these mechanisms play a crucial role in agriculture. They are commonly employed in irrigation systems, delivering water efficiently to crops and maintaining optimal growth conditions. Their durability and ability to handle various fluids make them a preferred choice for farmers seeking reliable irrigation solutions.

Importance of Regular Maintenance

- Prevention of Failures: Consistent upkeep reduces the likelihood of major malfunctions, which can lead to costly repairs.

- Increased Efficiency: Well-maintained systems operate more smoothly, leading to better productivity and lower energy consumption.

- Safety Assurance: Routine checks help identify potential hazards, ensuring a safer working environment for all personnel.

- Cost-Effectiveness: Investing in regular service can minimize long-term expenses associated with major repairs and replacements.

- Extended Lifespan: Proper care significantly prolongs the operational life of equipment, maximizing return on investment.

In summary, prioritizing regular maintenance is essential for sustaining the functionality and reliability of machinery, ultimately benefiting both operations and budget.

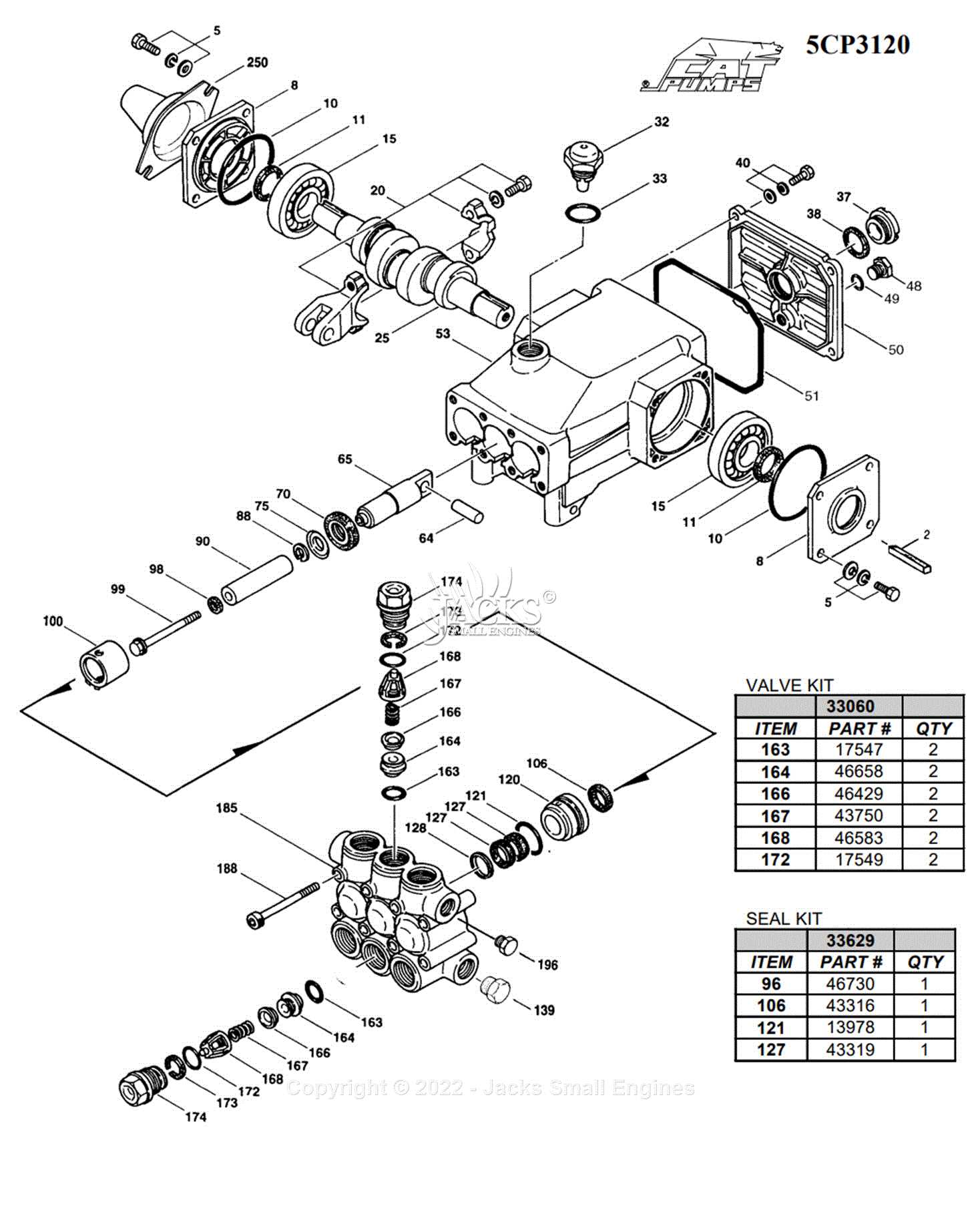

Parts Identification for 5CP3120

Understanding the components of a specific mechanical assembly is crucial for effective maintenance and repair. Identifying each element accurately ensures that replacements are made correctly, contributing to optimal performance and longevity of the device. This section focuses on the essential features and identifiers associated with a particular model.

Component Overview: Each element plays a vital role in the overall functionality of the machine. Familiarity with these components allows for better troubleshooting and efficient repairs. From seals and valves to pistons and connectors, recognizing their unique characteristics can prevent potential malfunctions.

Identification Techniques: To effectively identify each part, utilizing visual references and part numbers is advisable. Many resources are available, including manuals and online databases, which provide detailed images and specifications. Ensuring the right component is selected for replacement or repair can significantly impact the operational efficiency of the entire system.

Exploring the Parts Diagram

Understanding the intricacies of a mechanical assembly is essential for effective maintenance and repair. This section delves into the visual representation of components within a specific system, allowing users to familiarize themselves with the various elements and their functions.

Such visual aids serve multiple purposes:

- Clarification of assembly relationships

- Identification of individual components

- Facilitation of troubleshooting processes

- Guidance for replacement and repair

When examining the illustration, it is crucial to consider the following aspects:

- Component Labels: Each part is typically marked with a unique identifier, making it easier to locate and reference.

- Interconnections: Understanding how elements interact with one another can aid in diagnosing issues.

- Assembly Sequence: The order in which parts are assembled can be vital for efficient reassembly.

- Material Specifications: Knowing the materials used can influence decisions regarding replacements.

By comprehensively analyzing the visual guide, users can enhance their knowledge, ensuring optimal performance and longevity of the system. This familiarity also empowers users to carry out informed repairs with confidence.

How to Order Replacement Parts

When it comes to maintaining your equipment, acquiring the necessary components is crucial for ensuring optimal performance. Understanding the process of ordering substitutes can save time and prevent potential issues down the line. Here’s a straightforward guide to help you navigate the ordering process efficiently.

First, gather all relevant information about the item you need. This includes the model number, serial number, and any specific details about the component itself. Having these details on hand will streamline your search and assist customer service representatives in providing accurate support.

| Step | Description |

|---|---|

| 1 | Identify the necessary component by consulting the manual or schematic. |

| 2 | Visit the official website or contact authorized dealers for availability. |

| 3 | Provide the gathered information to the representative or input it online. |

| 4 | Review pricing and shipping options before finalizing your order. |

| 5 | Confirm your order and keep a record of the transaction for future reference. |

By following these steps, you can ensure a smooth and efficient ordering process, minimizing downtime and keeping your equipment running smoothly.

Troubleshooting Common Issues

When operating hydraulic machinery, encountering challenges is not uncommon. Understanding typical problems and their solutions can enhance efficiency and extend the lifespan of your equipment. This section aims to guide you through some frequent malfunctions and offer practical advice for resolution.

Low Pressure Output

One of the most prevalent issues is insufficient pressure. This can arise from various factors, such as worn seals, air leaks, or clogged filters. To address this, inspect all connections for tightness, examine seals for wear, and ensure that filters are clean. Regular maintenance can prevent this issue from recurring.

Excessive Noise Levels

Another common concern is unusual noise during operation. This could indicate mechanical wear, insufficient lubrication, or misalignment. Start by checking the fluid levels and ensuring that all components are properly lubricated. If the noise persists, inspect for any misalignments and rectify them to restore smooth operation.

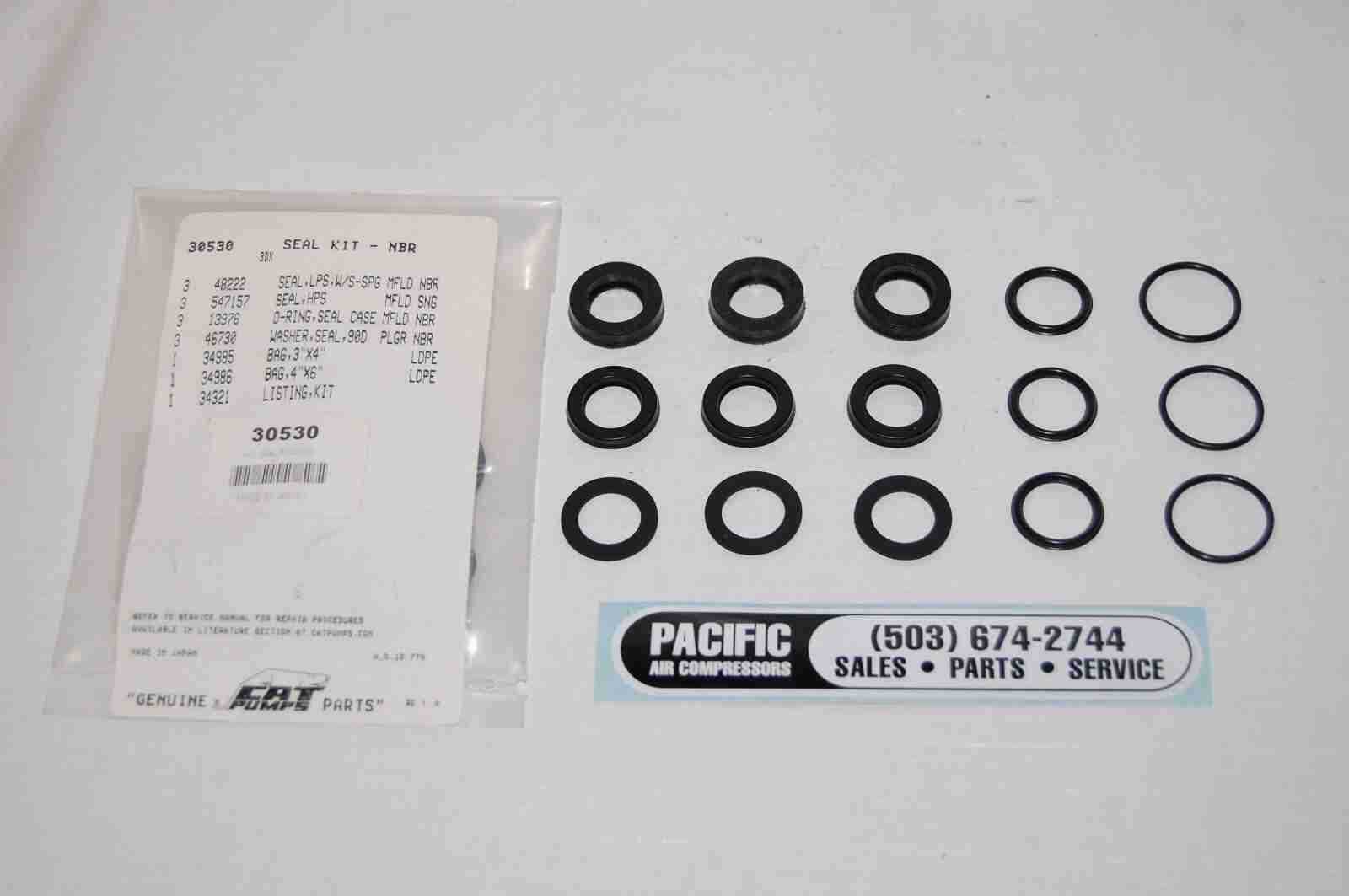

Benefits of Genuine Parts

Using authentic components in machinery and equipment ensures optimal performance and longevity. These high-quality elements are specifically designed to fit seamlessly, minimizing the risk of malfunctions and enhancing overall efficiency. When choosing replacements, the distinction between original and generic options can significantly impact the reliability of your system.

Durability is a key advantage of utilizing genuine components. Manufactured to strict standards, they withstand wear and tear better than their counterparts. This means fewer breakdowns and less frequent replacements, leading to reduced downtime and maintenance costs.

Moreover, compatibility is another crucial factor. Authentic parts are engineered to work together with existing systems, ensuring smooth operation and avoiding issues related to improper fit. This compatibility enhances the overall functionality, allowing equipment to operate at its best.

Additionally, opting for original components often results in better warranty coverage. Many manufacturers offer extended guarantees for genuine parts, providing peace of mind and protection against potential failures. This not only safeguards your investment but also reinforces trust in the product’s reliability.

In conclusion, investing in authentic components not only boosts the performance of your machinery but also enhances its lifespan, reduces maintenance challenges, and assures greater reliability. Choosing quality over convenience pays off in the long run.

DIY Repair Tips for Users

Embarking on a repair journey can be both fulfilling and cost-effective. Understanding the components involved and having the right approach can make the process smoother and more successful. Here are some practical tips to guide you through your repair project.

- Gather Necessary Tools: Ensure you have all essential tools on hand before starting. This includes wrenches, screwdrivers, and any specialized equipment required for the task.

- Study the Manual: Refer to the user manual or online resources for insights on assembly and disassembly. Familiarizing yourself with the layout and functionality of each element is crucial.

- Organize Components: As you disassemble, keep parts organized. Use labeled containers to avoid confusion and facilitate reassembly.

- Take Photos: Document each step with photographs. This will serve as a valuable reference when you are putting everything back together.

- Check for Wear and Tear: Examine each component for signs of damage. Identify any parts that may need replacement to ensure optimal performance.

- Test Before Final Assembly: After repairs, conduct preliminary tests to confirm everything functions correctly before fully reassembling.

- Be Patient: Take your time. Rushing through repairs can lead to mistakes. A careful, methodical approach often yields the best results.

With these tips, you can confidently tackle repairs and maintain the efficiency of your equipment. Happy fixing!

Comparison with Other Cat Pump Models

When evaluating various models from the same manufacturer, it is essential to understand the distinctions in design, performance, and functionality. Each variant is tailored to meet specific requirements, which can significantly impact efficiency and effectiveness in various applications.

The model in question showcases unique attributes that differentiate it from its counterparts. For instance, the engineering behind its pressure capabilities and flow rates can be markedly superior, making it ideal for demanding tasks. In contrast, other variants may prioritize durability or cost-effectiveness, appealing to users with different needs.

Moreover, maintenance requirements can vary significantly among models. Some designs offer easier access to components, streamlining repairs and upkeep, while others may require more intricate disassembly. Understanding these differences can aid users in making informed decisions based on their operational priorities.

Lastly, while all models share a commitment to quality, their specific applications can lead to varied performance outcomes. Users should consider not only their immediate requirements but also potential future needs to select the most suitable option.

FAQs About 5CP3120 Components

This section addresses common inquiries related to the various elements associated with the 5CP3120 model. Understanding these components is essential for optimal functionality and maintenance, ensuring users can efficiently manage and troubleshoot their systems.

What are the main components of the 5CP3120 system?

The primary elements include the housing, valves, seals, and connectors. Each component plays a critical role in the overall operation, contributing to efficiency and durability. Regular inspection of these parts can prevent potential issues and enhance performance.

How often should components be replaced?

Replacement frequency largely depends on usage and operating conditions. It is recommended to conduct routine checks and replace components as needed to avoid unexpected failures. Regular maintenance schedules can help prolong the life of the system.

Where to Find Technical Support

Accessing reliable assistance for your machinery is crucial for maintaining optimal performance and ensuring longevity. Various resources are available to help you navigate any issues that may arise, providing expert guidance tailored to your specific needs.

One of the best places to start is the official manufacturer’s website, which often features a dedicated support section. Here, you can find user manuals, troubleshooting tips, and contact information for customer service representatives who can provide direct assistance.

Additionally, many online forums and community groups focus on similar equipment, where experienced users share insights and solutions. Engaging with these communities can offer valuable perspectives and firsthand advice.

Lastly, authorized service centers offer professional support and repair services, ensuring that your equipment is handled by trained technicians familiar with the latest industry standards. Consider reaching out to these facilities for expert help whenever needed.