Understanding Hayward Super II Pump Parts Diagram

In the realm of aquatic maintenance, comprehending the intricate elements that contribute to efficient water circulation is essential. Proper functionality of these components not only enhances the overall performance of the system but also ensures a prolonged lifespan of the equipment.

Each element plays a pivotal role, and familiarizing oneself with their arrangement can significantly simplify the troubleshooting process. By gaining insight into the layout and function of these integral pieces, pool owners can make informed decisions about maintenance and repairs.

Moreover, a thorough grasp of the structure allows for effective upgrades and replacements, ensuring that the system operates at peak efficiency. Whether you’re a seasoned professional or a novice enthusiast, understanding the layout of these crucial components will empower you to keep your aquatic space in pristine condition.

Understanding Hayward Super II Pump

This section delves into the fundamental aspects of a popular circulation device used in swimming facilities. Recognizing its essential components and functionality is crucial for effective maintenance and optimal performance. By comprehending the intricacies of this equipment, users can ensure longevity and efficiency in their water management systems.

Functionality is at the core of this mechanism. Designed to move water efficiently, it operates by drawing in liquid and propelling it through various channels, ensuring proper filtration and sanitation. Understanding how these systems work together can aid in troubleshooting and repair.

Another important aspect is the components that comprise the device. Each element plays a specific role in maintaining flow and pressure, impacting overall efficiency. Familiarity with these parts not only enhances repair skills but also empowers users to optimize their setup for better results.

Finally, regular maintenance is vital for preserving the functionality of this apparatus. Routine checks and timely replacements of worn elements can prevent larger issues and extend the lifespan of the equipment. Knowing when and how to perform these tasks is key to effective operation.

Key Components of the Pump

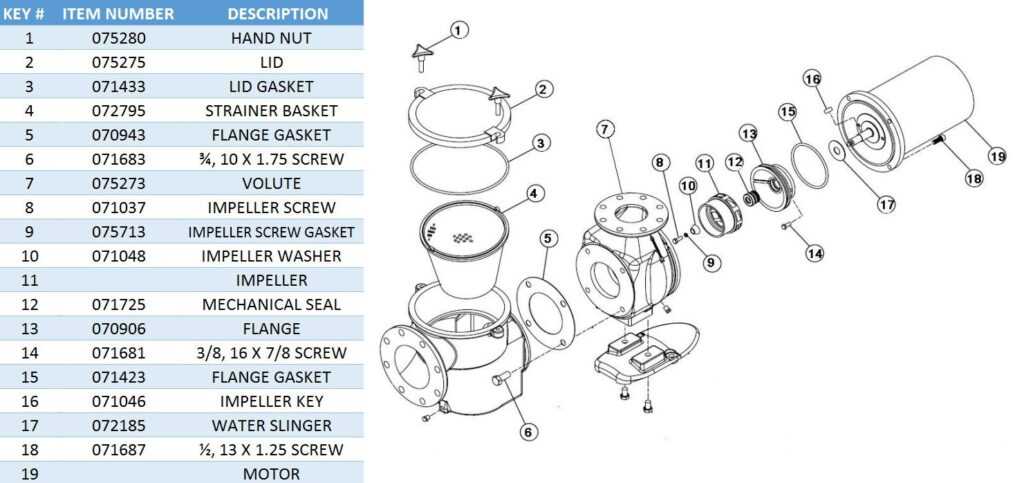

Understanding the essential elements of a water circulation system is crucial for effective maintenance and operation. Each component plays a specific role, contributing to the overall efficiency and functionality of the system. Familiarity with these key parts can aid in troubleshooting and optimizing performance.

Motor: The motor serves as the powerhouse, driving the mechanism and ensuring proper water flow. Its efficiency directly impacts the performance of the entire system.

Impeller: This crucial element is responsible for creating the water movement. The design and material of the impeller can significantly affect the system’s effectiveness and longevity.

Volute: The volute directs the flow of water coming from the impeller, converting kinetic energy into pressure. Its shape is vital for optimizing flow characteristics.

Strainer: This component filters out debris and contaminants, protecting the internal mechanisms from potential damage. Regular cleaning is essential to maintain optimal function.

Seal: Seals prevent leaks and protect the motor from water intrusion. The integrity of these components is vital for sustaining the system’s efficiency.

By comprehensively understanding these integral elements, users can ensure their systems operate smoothly and effectively, minimizing downtime and maintenance costs.

Common Issues with Super II Models

When it comes to certain models in the pool equipment category, users may encounter a variety of challenges that can affect performance and longevity. Understanding these common problems can help in maintaining the unit effectively and ensuring optimal operation.

Frequent Challenges

- Noise Levels: Excessive sound can indicate issues such as wear and tear on components or misalignment.

- Reduced Efficiency: A drop in performance often suggests blockages or filter complications that need addressing.

- Leaks: Water accumulation around the unit may signal seal failures or loose connections.

Maintenance Tips

- Regularly inspect all connections and seals for wear.

- Keep filters clean and free of debris to enhance flow.

- Listen for unusual sounds during operation and address them promptly.

Importance of Regular Maintenance

Consistent upkeep of your equipment is crucial for ensuring optimal performance and longevity. Neglecting routine checks can lead to decreased efficiency, increased energy costs, and potential system failures. By investing time in regular maintenance, you not only enhance the functionality but also prevent costly repairs down the line.

Scheduled inspections allow for the early detection of wear and tear, enabling timely interventions. This proactive approach helps in identifying issues before they escalate, ultimately saving both time and resources. Regular attention to your system promotes a healthy environment and ensures it operates at peak efficiency.

Moreover, maintaining your equipment can significantly enhance safety. A well-maintained system minimizes the risk of accidents or malfunctions, providing peace of mind for users. In addition, it can contribute to better energy efficiency, reducing your overall carbon footprint and operational costs.

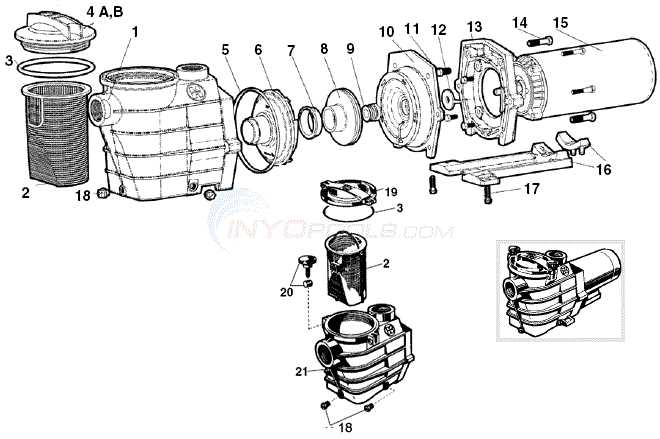

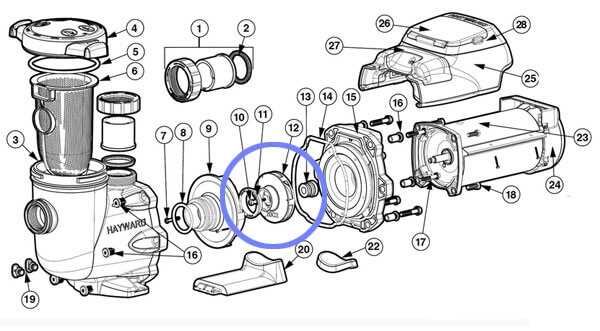

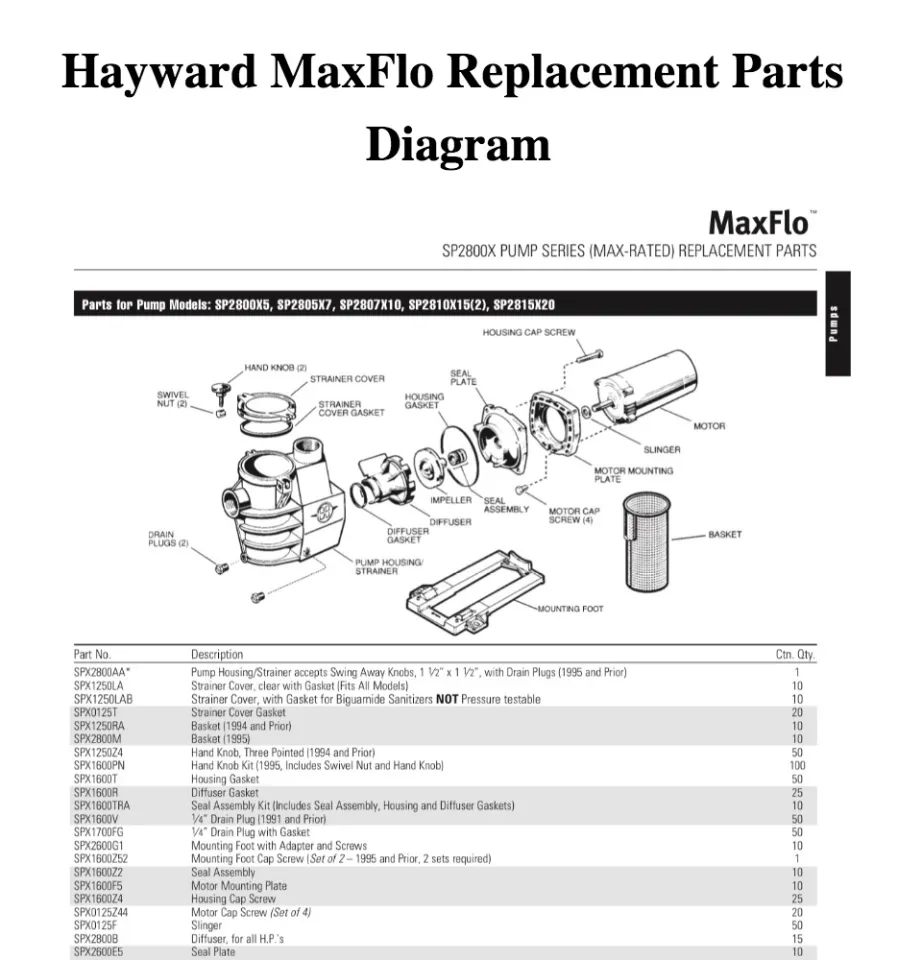

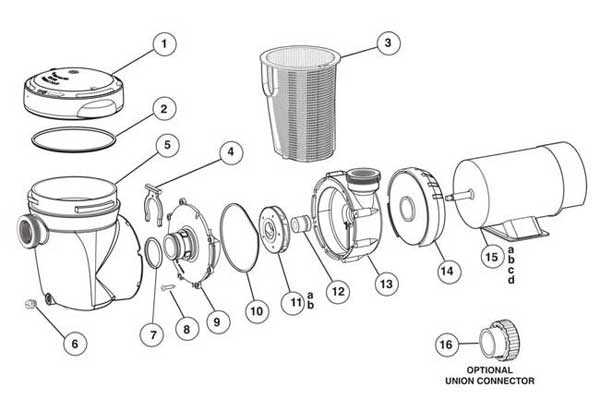

How to Identify Pump Parts

Recognizing the various components of a hydraulic system is essential for effective maintenance and troubleshooting. Understanding the distinct roles of each element can significantly enhance the efficiency of the overall mechanism. This section provides guidance on how to discern these elements accurately.

| Component | Description | Function |

|---|---|---|

| Motor | The primary driving force of the assembly. | Converts electrical energy into mechanical energy. |

| Impeller | A rotating part designed to move fluids. | Creates flow and pressure within the system. |

| Volute | A spiral-shaped casing surrounding the impeller. | Helps direct the flow of fluid out of the unit. |

| Seal | A barrier that prevents leakage between components. | Maintains system integrity and prevents contamination. |

| Strainer | A filtering device located at the inlet. | Removes debris to protect internal components. |

By familiarizing yourself with these components and their specific roles, you can more easily identify any issues that may arise during operation. Regular inspection and understanding of each part’s functionality can lead to improved performance and longevity of the entire assembly.

Repair vs. Replacement Decisions

When faced with the choice between fixing a malfunctioning system or investing in a new one, several factors come into play. Evaluating the condition of the current equipment, the costs associated with repairs, and the potential benefits of upgrading can significantly influence the final decision. Understanding these elements is crucial for making an informed choice that aligns with both budget and performance expectations.

Factors to Consider

Assessing the age and efficiency of the existing unit is vital. Older models may lack modern features and energy efficiency, potentially leading to higher long-term operating costs. On the other hand, if the system is relatively new, repairing it might be the most economical option. Consideration of repair costs compared to the price of a new model is also essential, as frequent breakdowns can add up over time.

Long-Term Implications

Beyond immediate costs, it is important to think about the long-term impact of either decision. Investing in a new unit might provide improved performance and reliability, while continual repairs could result in increased frustration and downtime. Evaluating warranty options and future maintenance needs will also play a role in determining the best course of action.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for a successful outcome. Proper tools not only streamline the repair process but also ensure safety and efficiency. Understanding which instruments are required can save time and prevent frustration.

Essential Equipment: To start, a basic set of hand tools is vital. This typically includes screwdrivers in various sizes, wrenches, and pliers. These instruments will help you access and manipulate components effectively.

Specialized Tools: Depending on the complexity of the job, you may need specialized items such as socket sets for tight spaces or torque wrenches for precision. Having these tools on hand can make a significant difference in the quality of your work.

Safety Gear: Don’t overlook the importance of safety equipment. Wearing gloves and goggles is recommended to protect yourself from potential hazards during the repair process. Proper gear ensures that you can focus on the task at hand without unnecessary risks.

Ultimately, equipping yourself with the right tools and safety measures will enhance your ability to carry out effective repairs, leading to a smoother and more productive experience.

Step-by-Step Repair Guide

This section provides a detailed approach to troubleshooting and fixing common issues related to your circulation device. By following the outlined steps, you can efficiently diagnose problems and implement necessary repairs, ensuring optimal performance and longevity.

Begin by gathering essential tools and safety gear, such as screwdrivers, wrenches, and protective eyewear. Before starting any work, make sure the unit is unplugged to avoid any electrical hazards. Inspect the outer casing and look for visible signs of wear, damage, or leaks. Identifying any cracks or loose fittings early on can save time in the repair process.

Next, remove the outer casing to access the internal components. Pay close attention to the wiring and connections, as loose wires can often lead to malfunction. Document the configuration for reassembly. Check for any debris or buildup that might obstruct the flow. Clean any clogged areas thoroughly, using appropriate cleaning solutions to prevent damage to sensitive parts.

Once the internal components are visible, examine each part systematically. Look for any signs of corrosion or wear, particularly on seals and gaskets, which may need replacement. If any parts appear damaged, consult the manufacturer’s specifications for suitable replacements. When installing new components, ensure they are correctly aligned and fitted to maintain proper functionality.

After replacing any faulty parts, reassemble the unit carefully, following your earlier documentation to ensure all connections are secure. Once reassembled, conduct a test run to monitor for leaks or unusual noises. Make adjustments as necessary, and ensure that the device operates smoothly. Regular maintenance checks can help prevent future issues, prolonging the life of your equipment.

Upgrading Pump Components

Enhancing the efficiency and performance of your circulation system can significantly improve overall operation. By focusing on key elements within the assembly, you can achieve better energy consumption, quieter performance, and increased longevity of the equipment.

One of the primary areas to consider for enhancement is the motor. A more efficient motor can lead to reduced energy costs and better performance. Upgrading to a variable speed motor allows for precise control over flow rates, adapting to the specific needs of your system.

Another essential component is the impeller. Selecting a high-quality impeller designed for optimal flow can greatly affect the system’s efficiency. Materials that resist wear and corrosion can also extend the life of this component, ensuring reliable operation over time.

Don’t overlook the importance of seals and gaskets. Replacing worn-out seals can prevent leaks and improve overall efficiency. Using upgraded materials can enhance durability and reduce the frequency of maintenance required.

Finally, consider the filtering system. An advanced filtration option can enhance water clarity and reduce strain on other components. This upgrade not only improves the quality of the water but also contributes to the longevity of the entire assembly.

Safety Tips for Pump Maintenance

Ensuring the longevity and efficiency of your equipment is essential. Proper upkeep not only enhances performance but also minimizes hazards. Adopting safety measures during maintenance tasks is crucial for both your well-being and the functionality of the system.

- Always disconnect the power source before starting any maintenance work to prevent accidental activation.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the work area is well-ventilated to avoid exposure to harmful fumes or vapors.

- Keep tools and equipment organized to prevent accidents and to make the process more efficient.

- Refer to the manufacturer’s guidelines for specific maintenance instructions and safety recommendations.

Regular inspections and timely repairs can greatly reduce the risk of malfunction and potential injuries. By following these precautions, you can maintain a safe working environment.

- Conduct routine checks for leaks and wear to identify issues early.

- Store chemicals and lubricants in safe, designated areas away from children and pets.

- Educate yourself on emergency procedures in case of an accident.

By prioritizing safety, you can effectively manage your system’s maintenance and enhance its overall performance.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is crucial for optimal performance. Numerous avenues exist for acquiring the necessary replacements, each offering unique advantages to meet your needs.

Authorized Dealers are often the most reliable source. They provide genuine components that are designed to fit perfectly and function efficiently with your machinery. Additionally, purchasing from these suppliers often comes with warranties, ensuring peace of mind.

Online Retailers present a convenient alternative, boasting a wide selection of items. Websites specializing in maintenance supplies frequently have user-friendly search functions, allowing you to find specific components quickly. Be sure to verify seller ratings and read reviews to ensure product quality.

For those who prefer a more personal touch, Local Hardware Stores can be an excellent option. These establishments may carry essential items or can often order them for you, providing a quick and local solution to your needs.

Lastly, consider exploring Second-Hand Markets. While less conventional, platforms dedicated to used goods can sometimes yield valuable finds at reduced prices. Just ensure to inspect any items carefully to confirm their condition before making a purchase.