In this section, we will explore the essential elements that ensure the smooth operation of a commonly used water circulation system. Each component plays a vital role in maintaining efficiency and functionality, contributing to the overall performance of the equipment.

Recognizing the importance of individual parts is crucial for proper maintenance and troubleshooting. By understanding how these elements work together, users can optimize the use of their system and extend its lifespan. We’ll dive into the core mechanisms that are responsible for effective water movement, helping you grasp the intricacies of this technology.

Whether you’re maintaining, repairing, or upgrading your system, knowing the roles of different key elements will provide a solid foundation for any task. Let’s take a closer look at how these components interact to achieve optimal results.

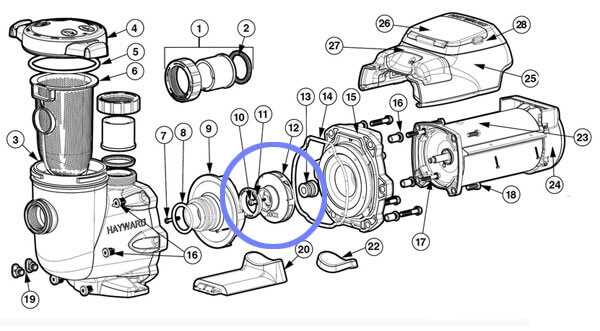

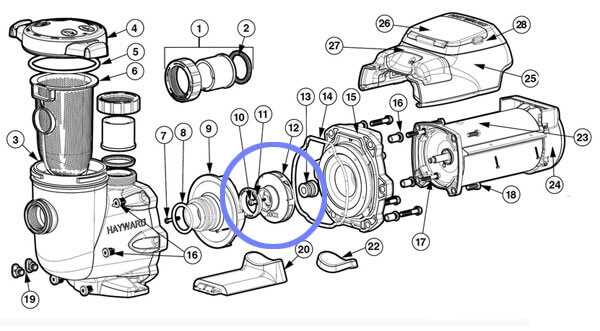

Overview of Hayward Super Pump Components

This section provides a comprehensive look at the main elements that make up the efficient and reliable water-moving system. Understanding how each part functions helps to ensure optimal performance and simplifies maintenance tasks. Below, we explore the key sections that contribute to the overall operation of this equipment.

Main Structural Elements

- Motor Housing: Protects the engine from external factors and provides a stable base for the entire mechanism.

- Impeller: Responsible for moving water through the system, ensuring smooth circulation.

- Diffuser: Guides water efficiently, preventing energy loss and improving overall system performance.

- Seal Plate: Helps prevent leaks by maintaining a tight connection between the engine and the rest of the mechanism.

Additional Key Parts

- Strainer Cover: A transparent lid allowing easy monitoring of debris buildup within the filtration basket.

- Filtration Basket: Catches leaves, dirt, and other debris to protect the internal components and maintain clear water flow.

- Baseplate: Provides a secure foundation for the entire structure, minimizing vibration and enhancing stability.

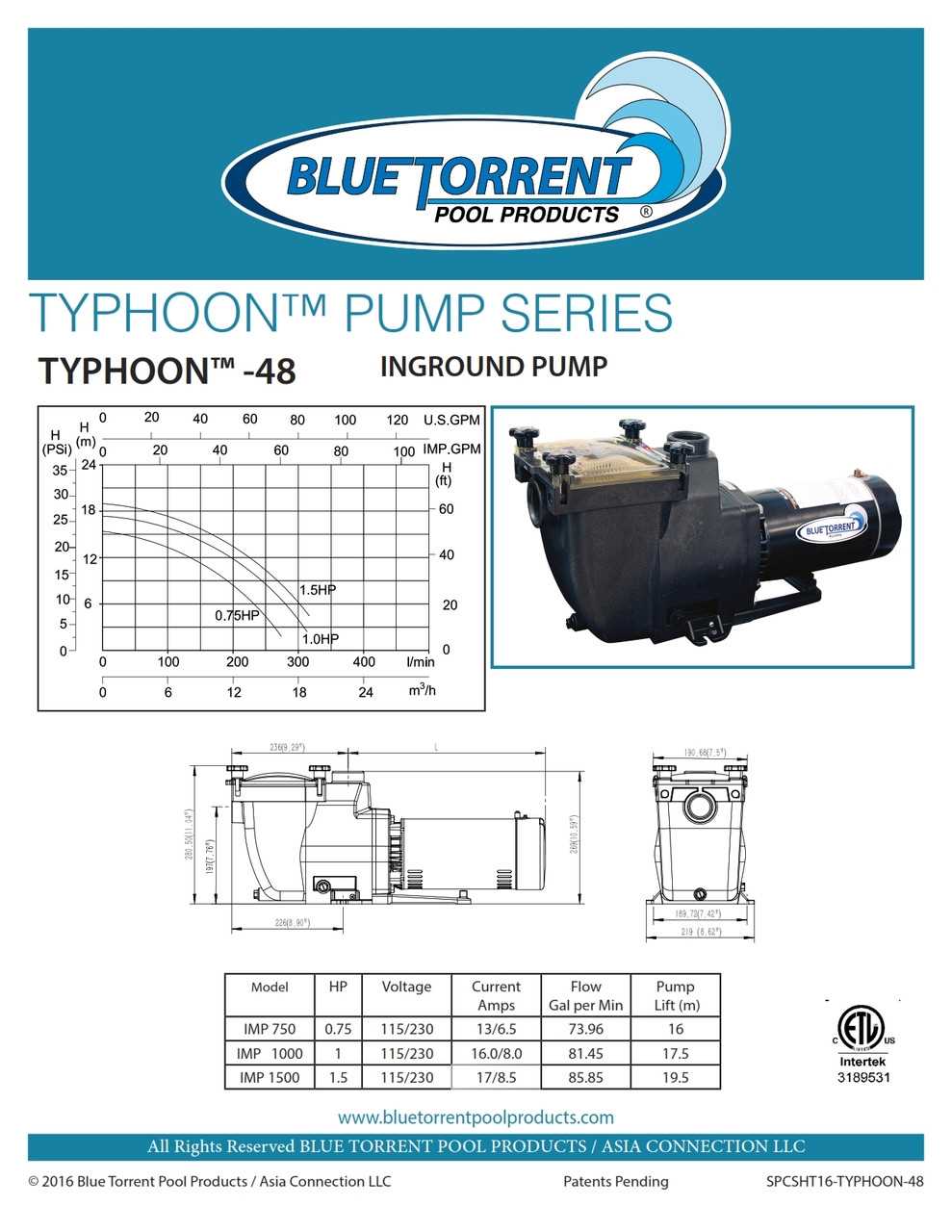

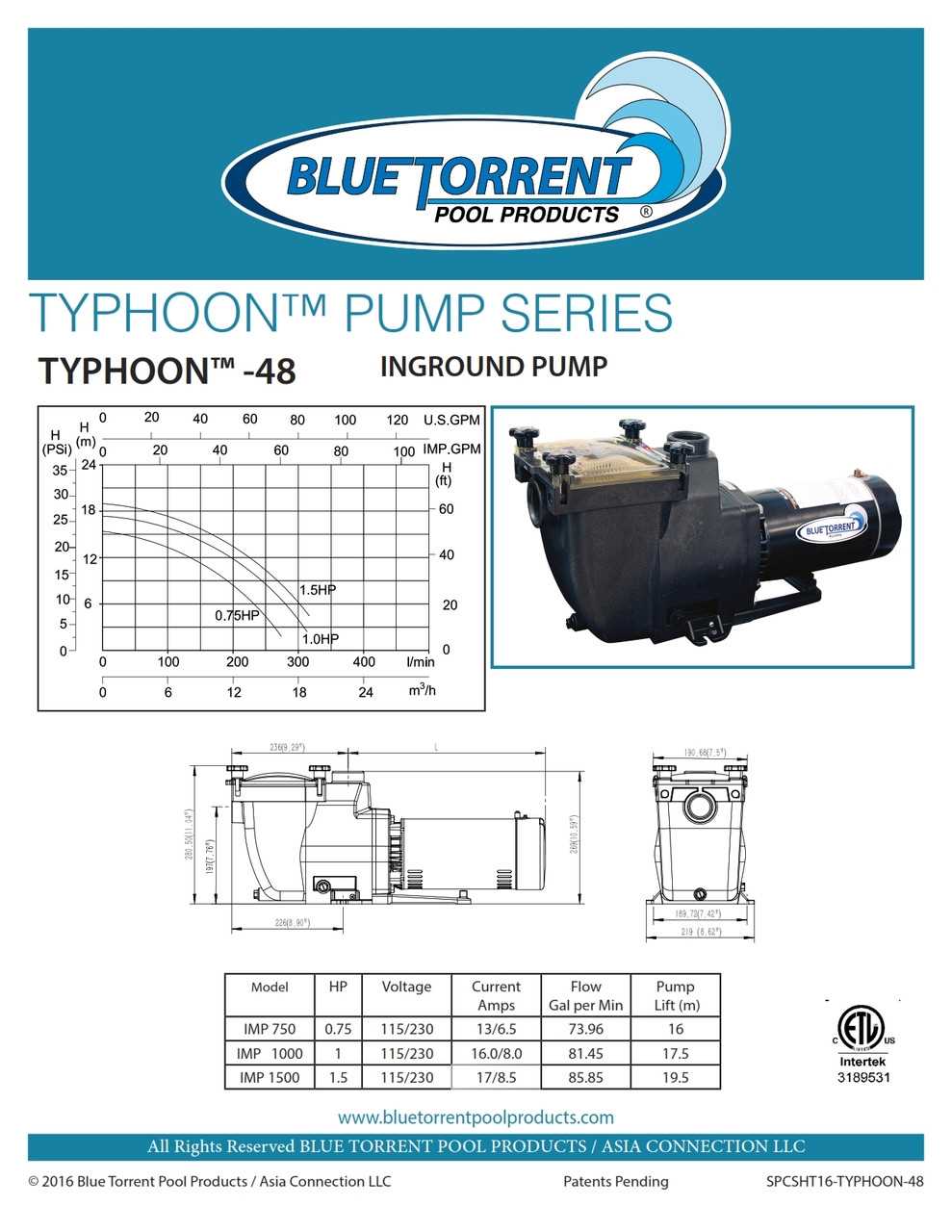

Key Features of the 1.5 HP Model

This model is known for its efficiency and reliability in various water circulation systems. Designed for long-lasting performance, it offers robust functionality and ease of maintenance, making it a solid choice for those who require dependable operation in demanding conditions.

- Powerful Motor: The motor is optimized to provide strong flow rates, ensuring effective circulation even in larger setups.

- Durable Construction: Built with high-quality materials, this model withstands wear and tear, prolonging its lifespan in different environments.

- Energy Efficient: Designed to minimize energy consumption, the unit delivers effective performance while helping reduce operational costs.

- Quiet Operation: Despite its power, the model operates quietly, ensuring a peaceful environment around it.

- Easy Maintenance: The design allows for straightforward cleaning and servicing, reducing downtime and ensuring smooth operation.

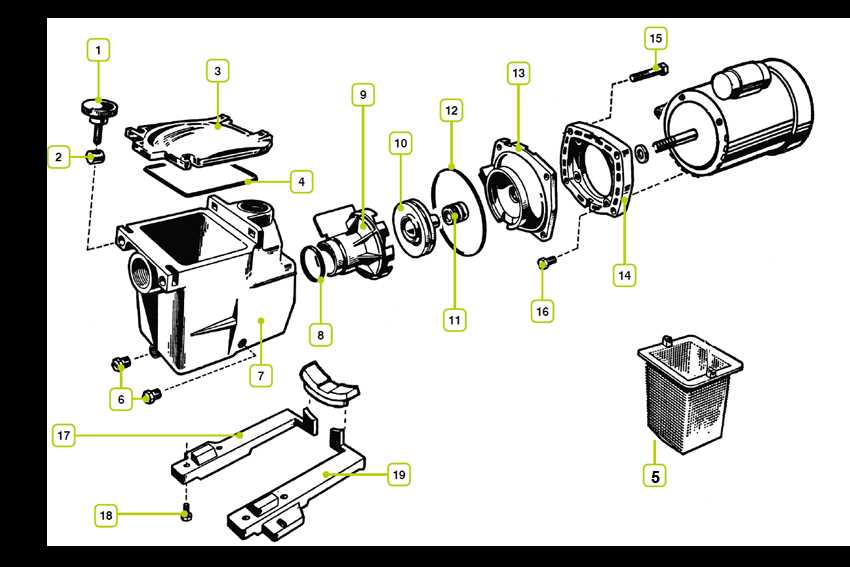

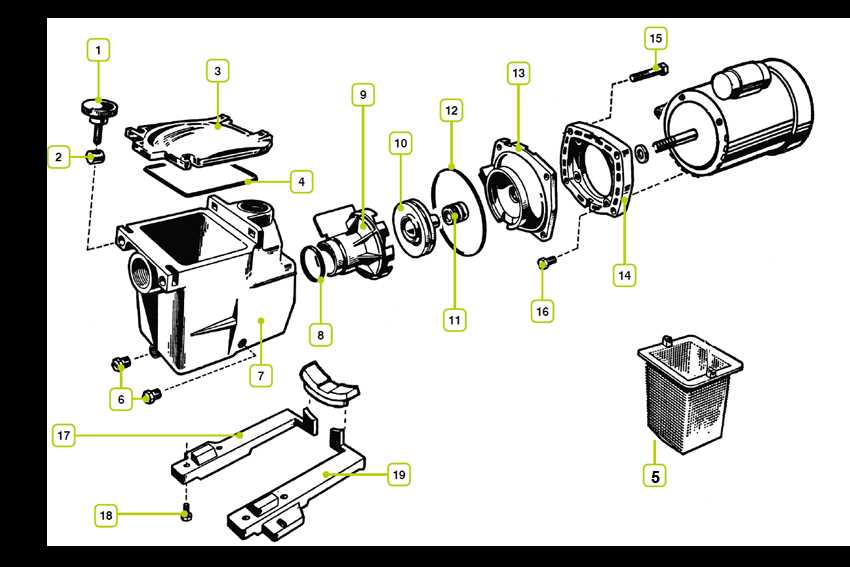

Internal Structure and Functionality

The internal components of the device are engineered to work together efficiently, ensuring optimal performance. Each element plays a crucial role in maintaining the flow and pressure within the system, allowing for smooth and reliable operation. Understanding how these parts interact can provide valuable insights into the overall functionality and longevity of the equipment.

Main Mechanical Elements

At the core of the system lies a rotating unit responsible for generating the necessary motion. This part transfers energy, initiating the movement of liquid through the device. Surrounding it are various support structures, designed to maintain stability and ensure consistent function even under continuous use. The housing around these elements not only protects them but also helps in reducing noise and vibration.

Key Functional Components

The system includes several other essential parts, such as a filtering mechanism, which prevents debris from entering critical areas. Additionally, specialized channels guide the flow of liquid, ensuring it moves efficiently without obstruction. Each of these elements works in harmony to maximize the overall efficiency, making the device both effective and durable in various conditions.

Understanding the Pump Housing Layout

The layout of the housing plays a critical role in ensuring the overall efficiency and longevity of the device. By examining the key elements of the casing, one can gain a deeper understanding of how water moves through the system, allowing for better maintenance and troubleshooting. Proper alignment of each section is essential to avoid issues related to water flow or internal wear.

Key Components: Each part of the housing structure works together to protect and guide the internal mechanisms. The casing safeguards the internal elements from external conditions, while strategically placed seals and fasteners ensure no leaks occur. Understanding these areas is crucial for smooth operation and easy disassembly when needed.

Internal Layout: Inside, the structure is designed to manage water flow efficiently. Channels direct liquid movement, ensuring that no blockages or imbalances disrupt the system’s operation. Correct positioning of internal components ensures the smooth functioning of the entire system.

Impeller and Diffuser Configuration

The efficient operation of a water circulation system relies heavily on the precise interaction between the impeller and diffuser. These two components work together to create a smooth flow of water by converting mechanical energy into movement within the system. The arrangement and design of these elements are crucial for maintaining consistent performance and ensuring that the system runs efficiently over time.

Impeller Functionality

The impeller plays a key role in drawing water into the system and accelerating it towards the outlet. Its blades are strategically shaped to maximize water flow and reduce resistance. The proper alignment of the impeller ensures that energy is effectively transferred, leading to optimal circulation.

Diffuser’s Role

The diffuser complements the impeller by guiding the water and converting its high velocity into pressure. It also helps in maintaining a steady flow rate and minimizing turbulence within the system. The positioning and design of the diffuser are critical for ensuring smooth transitions in water movement.

| Component |

Primary Function |

Seal Plate and O-Ring Function

The seal plate and O-ring play crucial roles in maintaining the integrity of fluid systems. These components work together to create a secure barrier, preventing leaks and ensuring optimal performance. A well-functioning seal assembly is essential for the overall efficiency and longevity of the equipment.

The seal plate acts as a structural element that holds the components in place, while the O-ring provides the necessary flexibility and compression needed to form a tight seal. When properly installed, these elements protect against the ingress of contaminants and the egress of fluids, which could lead to malfunctions or failures in the system. Understanding their function is vital for effective maintenance and troubleshooting.

Regular inspection of the seal plate and O-ring is recommended to identify wear or damage. Replacing these components at the first sign of degradation helps avoid more significant issues down the line. By ensuring that the seal plate and O-ring are in good condition, users can achieve better reliability and performance from their equipment.

Motor and Electrical Connections

This section focuses on the essential components and wiring associated with the drive unit. Understanding these elements is crucial for ensuring optimal performance and safe operation of the system.

The motor serves as the heart of the system, converting electrical energy into mechanical power. Proper installation and maintenance of this component are vital for longevity and efficiency. Key aspects to consider include:

- Power Rating: Ensure the motor’s capacity matches the system’s requirements.

- Cooling Mechanism: Check for adequate ventilation to prevent overheating.

- Mounting: Secure installation is necessary to minimize vibrations.

Electrical connections are equally important for reliable operation. The following guidelines should be adhered to:

- Correct Voltage: Verify that the supply voltage aligns with the motor specifications.

- Wiring: Use appropriately rated cables to prevent electrical hazards.

- Grounding: Ensure proper grounding to enhance safety and prevent electrical shocks.

Regular inspection of both the motor and electrical connections is recommended. By maintaining these components, users can enhance the overall functionality and reliability of the system.

Strainer Basket and Cover Details

The strainer basket and its corresponding cover play a crucial role in maintaining the efficiency and longevity of water circulation systems. These components are designed to filter out debris and contaminants, ensuring that the system operates smoothly. Understanding their structure and functionality is essential for effective maintenance and performance optimization.

Component Overview

- Strainer Basket: This element is responsible for capturing leaves, dirt, and other particles. It is typically made of durable materials to withstand prolonged exposure to water.

- Cover: The cover secures the basket in place and prevents debris from bypassing the filtration process. It often features a transparent design, allowing for easy monitoring of the basket’s contents.

Maintenance Tips

- Regularly check the strainer basket for buildup of debris.

- Remove the basket and clean it with water to ensure optimal performance.

- Inspect the cover for cracks or damage, replacing it if necessary.

- Ensure the cover is properly sealed after maintenance to prevent leaks.

Disassembly and Maintenance Guide

This section provides essential instructions for the careful disassembly and upkeep of your equipment. Understanding the internal components and their functions will help you perform maintenance effectively, ensuring longevity and optimal performance. Regular inspections and servicing can prevent potential issues and enhance the efficiency of your system.

Begin by disconnecting the power supply to ensure safety during the procedure. Carefully remove any external covers or panels to access the inner mechanisms. Take note of the arrangement of parts as you proceed, as this will facilitate easier reassembly. Utilize a digital camera or sketch the layout if necessary.

During disassembly, check for signs of wear or damage on components such as seals, bearings, and impellers. Cleaning these parts thoroughly will help maintain their function. Replace any worn items with new ones to avoid future complications. Remember to consult the manufacturer’s specifications for any particular guidelines regarding maintenance intervals and part replacements.

Once you have completed the maintenance tasks, reassemble the unit in the reverse order of disassembly. Ensure that all components are securely fastened and that any seals are properly seated to prevent leaks. Finally, restore power and test the system to confirm that it operates smoothly.

Common Replacement Parts Explained

Understanding the essential components of a filtration system is crucial for effective maintenance and longevity. Regular use can lead to wear and tear, necessitating the replacement of specific elements to ensure optimal performance. This section highlights some of the most commonly replaced components and their significance in maintaining efficiency.

-

Motor: The motor is the heart of the system, responsible for driving the entire mechanism. Over time, it may experience failures due to overheating or electrical issues.

-

Seal Kit: Seals prevent leaks and ensure that the unit operates smoothly. Regularly inspecting and replacing worn seals can prevent water loss and maintain pressure.

-

Impeller: The impeller is crucial for circulating water. Damage or obstruction can impede flow, reducing the effectiveness of the system.

-

Strainer Basket: This component captures debris and prevents it from entering the system. A clogged basket can restrict water flow and increase strain on the motor.

-

Diffuser: The diffuser helps direct water flow efficiently within the system. A damaged or worn diffuser can lead to inefficient operation and reduced performance.

Regular maintenance and timely replacement of these components can enhance the overall functionality of your filtration system, ensuring clean and clear water for your pool or spa.

Troubleshooting Wear and Tear Issues

Addressing issues related to degradation is essential for maintaining optimal functionality in equipment. Regular inspections can help identify common problems that arise due to age and usage. This section offers insights into identifying and resolving these wear-related concerns effectively.

Common signs of wear include:

- Unusual noises during operation

- Decreased efficiency or performance

- Leaks around the unit

- Frequent cycling on and off

To troubleshoot these problems, follow these steps:

- Inspect for any visible damage or corrosion on components.

- Check the seals and gaskets for signs of wear or leaks.

- Ensure all connections are secure and free from debris.

- Examine the motor and electrical components for signs of overheating or failure.

Once the issues are identified, appropriate actions can be taken to repair or replace the affected parts, ensuring reliable performance for the equipment.

Upgrading Parts for Better Performance

Improving the efficiency of your equipment can significantly enhance its functionality and lifespan. By replacing outdated or underperforming components with high-quality alternatives, you can achieve better flow rates, energy savings, and overall effectiveness. This not only optimizes performance but also minimizes the need for frequent repairs and maintenance.

Identifying Key Components for Replacement

Focus on the crucial elements that impact your system’s efficiency. Consider upgrading the motor for increased power, or replacing filters with advanced models that enhance debris capture. Additionally, investing in superior seals and gaskets can prevent leaks and maintain optimal pressure, contributing to improved overall operation.

Benefits of High-Quality Upgrades

Upgrading to premium components not only boosts performance but also enhances durability. High-quality replacements often withstand wear and tear better than standard parts, leading to a longer operational life. This proactive approach can result in significant cost savings over time, as improved efficiency translates to lower energy bills and reduced maintenance expenses.