Moyno Pump Parts Diagram Overview

In the realm of fluid transfer technologies, comprehending the intricate elements that comprise advanced delivery mechanisms is essential for effective operation and maintenance. Each component plays a pivotal role in ensuring seamless functionality and durability, making it crucial for users to familiarize themselves with their specific characteristics and interrelations.

To optimize performance, one must delve into the various sections of these sophisticated systems. By gaining insights into their design and configuration, operators can enhance efficiency and preemptively address potential challenges that may arise during usage. This knowledge not only fosters improved operational reliability but also extends the lifespan of the equipment.

Furthermore, visual representations of these intricate assemblies can serve as invaluable tools for technicians and engineers. Such illustrations enable a clearer understanding of how each segment interacts within the whole, facilitating informed decision-making and effective troubleshooting. By embracing this comprehensive approach, users can achieve greater proficiency in managing their operational needs.

Moyno Pump Components Overview

This section provides an insight into the various elements that constitute a specific type of mechanical device designed for fluid transfer. Understanding these components is crucial for both operation and maintenance, ensuring optimal performance in various applications.

The main components can be categorized as follows:

- Housing: The outer shell that protects internal mechanisms and supports the overall structure.

- Rotating Element: This component is responsible for the movement of fluids, creating the necessary pressure and flow.

- Sealing Mechanism: Essential for preventing leaks, these parts maintain the integrity of the system.

- Drive System: This includes motors or other means of energy conversion that facilitate the rotation of the main element.

Each of these parts plays a pivotal role in the functionality of the device, and understanding their interplay is key to achieving efficiency. Regular inspection and timely replacement of worn components can significantly enhance longevity and reliability.

For a detailed analysis of each component’s role, consider the following list:

- Housing: Provides structural support and protection.

- Rotating Element: Generates the flow required for operation.

- Sealing Mechanism: Ensures leak prevention and maintains pressure.

- Drive System: Powers the rotation and overall function.

Familiarity with these elements is essential for anyone involved in the operation, maintenance, or troubleshooting of this type of device.

Understanding Moyno Pump Functionality

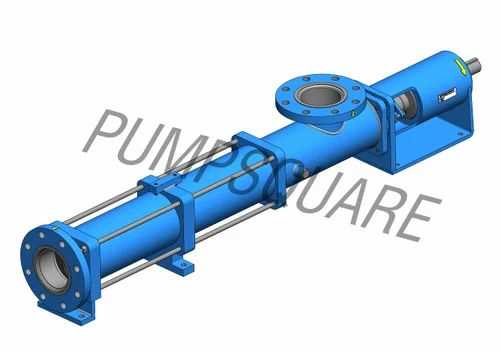

This section explores the operational principles behind a specific type of fluid transfer device widely utilized in various industries. By examining its design and mechanics, we can gain insights into how it efficiently moves different types of liquids, even those with challenging viscosities.

Core Mechanisms

At the heart of this system lies a unique configuration that ensures a consistent flow. The design typically involves a rotating element that interacts with a stationary counterpart, allowing for the smooth conveyance of fluids. This interaction creates a reliable pressure differential, essential for maintaining optimal performance.

Applications and Advantages

The versatility of this technology makes it suitable for a range of applications, from wastewater management to food processing. Its ability to handle abrasive and viscous materials sets it apart from traditional systems. Additionally, the efficiency of operation leads to lower energy consumption, making it an economical choice for businesses aiming to optimize their processes.

In summary, understanding the underlying principles of this fluid movement solution provides valuable knowledge for those involved in selecting and maintaining such equipment. By appreciating its functionality, one can make informed decisions that enhance operational efficiency.

Key Parts of Moyno Pumps

Understanding the fundamental components of a positive displacement device is essential for effective operation and maintenance. Each element plays a crucial role in ensuring efficiency, reliability, and longevity of the system. Below, we explore the primary constituents that contribute to the functionality of these devices.

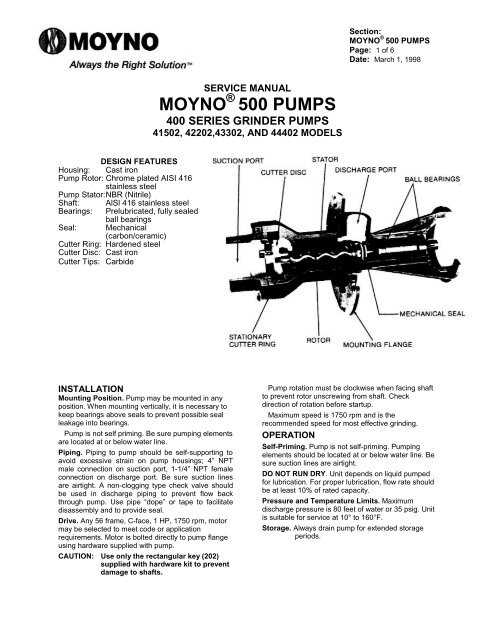

1. Stator: This stationary component forms a critical part of the assembly, providing a cavity for the rotor’s movement. Its design is pivotal for maintaining pressure and facilitating the flow of materials through the system.

2. Rotor: This rotating element interacts directly with the stator, creating the necessary suction and discharge action. Its shape and size are designed to optimize performance and minimize wear.

3. Seal: Ensuring a tight fit between moving and stationary parts, this element prevents leakage and maintains the integrity of the system. Proper sealing is vital for operational efficiency.

4. Drive Shaft: Connecting the rotor to the motor, this component transmits torque and facilitates the rotational movement necessary for the device’s operation. Its durability is essential for consistent performance.

5. Inlet and Outlet Connections: These ports allow for the entry and exit of materials. Their design must accommodate the specific requirements of the application, ensuring optimal flow rates and minimal back pressure.

6. Bearings: Supporting the rotor and minimizing friction, bearings are critical for smooth operation. They help extend the lifespan of the device by reducing wear on moving parts.

Each of these components contributes to the overall effectiveness of the mechanism. Regular maintenance and understanding of their function can significantly enhance performance and operational longevity.

Diagrams for Moyno Pump Assembly

This section provides a comprehensive overview of the visual representations essential for the assembly of specific equipment. These illustrations serve as a vital resource for understanding the configuration and interaction of components, ensuring efficient and accurate assembly processes.

Importance of Visual Aids

Visual aids are crucial in any technical assembly process. They not only simplify complex instructions but also enhance the understanding of the relationship between different elements. Utilizing clear illustrations can significantly reduce the likelihood of errors during assembly.

Components Overview

Understanding the various elements involved in the assembly is key to successful operation. Below is a summary table highlighting some essential components along with their descriptions:

| Component | Description |

|---|---|

| Rotor | Drives the fluid movement through the system. |

| Stator | Houses the rotor and directs fluid flow. |

| Seals | Prevent leaks and maintain pressure within the assembly. |

| Drive Shaft | Connects the rotor to the motor, enabling rotation. |

Maintenance Tips for Moyno Pumps

Proper upkeep of equipment is crucial for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and reduces operational costs. Implementing a systematic approach can significantly improve reliability and extend the service life of your machinery.

Here are some essential tips for maintaining your equipment:

| Tip | Description |

|---|---|

| Regular Inspections | Conduct periodic checks to identify wear and tear or any unusual sounds. Early detection of issues can prevent costly repairs. |

| Lubrication | Ensure that all moving components are adequately lubricated according to the manufacturer’s recommendations to minimize friction and wear. |

| Seal Integrity | Inspect seals frequently for any signs of damage or degradation. Replacing worn seals promptly prevents leaks and maintains efficiency. |

| Cleaning | Keep the external surfaces and intake areas free from debris. Regular cleaning helps avoid blockages and maintains airflow. |

| Monitoring Performance | Track operational metrics to identify any deviations from normal performance. Implementing a monitoring system can alert you to potential issues before they escalate. |

By adhering to these guidelines, you can significantly enhance the operational reliability of your equipment, ensuring it remains functional and efficient for years to come.

Identifying Common Pump Issues

Understanding the typical challenges faced by fluid transfer devices is essential for maintaining their efficiency and longevity. Various symptoms can indicate underlying problems, and recognizing these early can prevent more significant complications. This section outlines common signs of malfunction and their possible causes.

Common Symptoms

- Unusual Noises: Grinding, squealing, or thumping sounds often signal mechanical issues or misalignment.

- Leakage: Fluid escaping from seals or joints may indicate wear or damage, necessitating immediate attention.

- Pulsation: Irregular flow can suggest air entrapment or blockages in the system.

- Reduced Output: A noticeable drop in performance can be linked to clogs or failing components.

Possible Causes

- Wear and Tear: Over time, components may degrade due to continuous use, affecting overall function.

- Improper Installation: Misalignment during setup can lead to strain and eventual failure of parts.

- Contamination: Debris in the fluid can cause damage and lead to blockages.

- Inadequate Maintenance: Regular checks and servicing are crucial to prevent issues from escalating.

By being vigilant and addressing these signs promptly, one can ensure optimal operation and prolong the service life of fluid handling systems.

Replacement Parts for Moyno Models

Maintaining optimal performance in various models often necessitates the replacement of specific components. Ensuring the availability of high-quality alternatives is crucial for extending the lifespan and efficiency of equipment. Understanding the different elements that may require attention can help users make informed decisions about their maintenance strategies.

Commonly Replaced Components

Several elements frequently need to be updated due to wear and tear. Seals and gaskets play a vital role in preventing leaks and ensuring operational integrity. Additionally, rotor and stator assemblies are essential for the proper functioning of the system, as they directly impact the flow dynamics. Regular inspection of these components can help identify issues before they lead to significant downtime.

Quality Considerations

When sourcing replacements, it is important to prioritize quality and compatibility. Utilizing reliable suppliers ensures that the components meet the required specifications and standards. Investing in high-grade materials can lead to improved performance and reduced maintenance costs over time. Always consult technical documentation or professionals for guidance on the right components for your specific model.

Importance of Correct Pump Alignment

Proper alignment is crucial for ensuring the optimal performance and longevity of machinery. Misalignment can lead to a cascade of issues that not only affect efficiency but also increase wear and tear on components. By maintaining precise alignment, operators can enhance the reliability of their systems and reduce the likelihood of costly repairs.

Consequences of Misalignment

- Increased vibration, leading to further mechanical issues.

- Higher energy consumption due to inefficient operation.

- Shortened lifespan of rotating elements.

- Potential for catastrophic failure, causing downtime.

Benefits of Proper Alignment

- Improved efficiency and reduced operational costs.

- Extended lifespan of machinery and components.

- Minimized vibration, enhancing overall performance.

- Lower risk of unexpected failures and maintenance needs.

Ensuring accurate alignment is not just a technical requirement; it is essential for maintaining a well-functioning system that supports productivity and operational success.

Fluid Dynamics in Moyno Pumps

The behavior of fluids within various systems is crucial for understanding how they function efficiently. In certain mechanical devices, the flow characteristics and the interaction between different components play a significant role in optimizing performance. Analyzing these aspects allows for enhanced operation and longevity of the equipment.

Flow Characteristics

The movement of liquid through a system is influenced by factors such as viscosity, pressure, and the design of internal structures. Efficient flow dynamics minimize turbulence and ensure a smooth transition of materials from one point to another. Understanding the ideal flow rate is essential for maintaining balance and preventing wear on components.

Impact of Design on Efficiency

The configuration of internal elements directly affects the overall efficiency of the mechanism. A well-designed structure will promote uniform flow, reducing energy losses and allowing for effective handling of various materials. By optimizing the layout and dimensions of critical components, one can achieve significant improvements in performance and reliability.

Choosing the Right Pump Size

Selecting the appropriate size for your fluid transfer system is crucial for ensuring efficiency and reliability. An oversized unit can lead to unnecessary energy consumption and wear, while an undersized one may struggle to meet demand, resulting in operational failures. This section provides insights into the key factors to consider when determining the ideal dimensions for your application.

Key Considerations

When assessing the necessary size, several parameters must be evaluated, including flow rate requirements, fluid viscosity, and the characteristics of the system. Understanding these elements helps in making an informed decision that aligns with operational goals.

| Factor | Description |

|---|---|

| Flow Rate | The volume of fluid needed to be moved per unit time. |

| Viscosity | The thickness or resistance to flow of the fluid. |

| System Characteristics | The specific conditions, including pressure and temperature, that affect fluid movement. |

Conclusion

By thoroughly analyzing these factors, you can select a unit that not only meets your current requirements but also adapts to future needs. Careful consideration during this process is essential to optimize performance and extend the lifespan of your system.

Applications of Moyno Pumps

The versatile nature of these mechanical devices allows them to be utilized across various industries, addressing specific fluid transfer needs with efficiency and reliability. Their ability to handle diverse materials makes them suitable for both challenging and standard applications.

Water and Wastewater Treatment: In municipal and industrial settings, these devices play a crucial role in the transportation of sludges, slurries, and other viscous fluids. Their design ensures minimal shear, preserving the integrity of the materials being moved.

Food and Beverage Industry: These machines are employed to manage the transfer of ingredients, ensuring that delicate products maintain their quality during processing. Their sanitary design allows for compliance with stringent health regulations.

Chemical Processing: In the production of chemicals, these systems efficiently handle corrosive and abrasive substances, providing a reliable solution for various mixing and transferring tasks.

Pharmaceuticals: Precision and cleanliness are paramount in this sector, and the adaptability of these devices supports the careful movement of sensitive materials, maintaining strict quality standards throughout the manufacturing process.

Mining and Minerals: The robust design of these systems makes them ideal for transporting thick slurries and other challenging materials found in mining operations, contributing to efficient resource extraction.

Overall, the adaptability of these machines to different environments and materials highlights their importance across numerous sectors, ensuring operational efficiency and reliability in fluid handling.

Benefits of Moyno Pump Technology

The innovative technology in this field offers numerous advantages that enhance operational efficiency and reliability. Its design and functionality cater to a wide range of applications, making it an ideal choice for various industries.

Efficiency is one of the primary benefits. These systems are engineered to handle viscous fluids and solids, ensuring minimal downtime and optimal performance. This capability translates to reduced energy consumption and lower operational costs.

Another significant advantage is durability. The robust construction and high-quality materials used in these systems contribute to their longevity, allowing for extended service life and decreased maintenance needs. This reliability ensures that users can depend on their performance under demanding conditions.

Additionally, versatility stands out as a key feature. These systems can be customized to meet specific requirements, accommodating a variety of applications across different sectors. This adaptability makes them suitable for everything from wastewater treatment to food processing.

Moreover, ease of maintenance is a notable benefit. The design facilitates straightforward servicing, allowing operators to perform routine checks and repairs with minimal effort. This accessibility contributes to reduced downtime and operational efficiency.

In summary, the advanced technology in this field provides exceptional efficiency, durability, versatility, and ease of maintenance, making it an invaluable asset for industries requiring reliable fluid management solutions.

Resources for Further Learning

Expanding your knowledge on fluid machinery components can enhance your understanding and improve your skills in the field. There are numerous resources available that cater to different learning styles, whether you prefer reading, watching videos, or hands-on experience. Engaging with a variety of materials will provide a comprehensive grasp of the subject.

Books and Journals

Consider exploring technical literature that covers the fundamentals and advancements in machinery technology. Academic journals often publish peer-reviewed articles that delve into research findings and innovations. Additionally, textbooks can offer structured content, guiding you through complex concepts step-by-step.

Online Courses and Tutorials

Many platforms provide online courses focused on machinery design and operation. These courses often include video lectures, quizzes, and forums for discussion. Furthermore, tutorials available on various websites can help clarify specific topics and demonstrate practical applications.