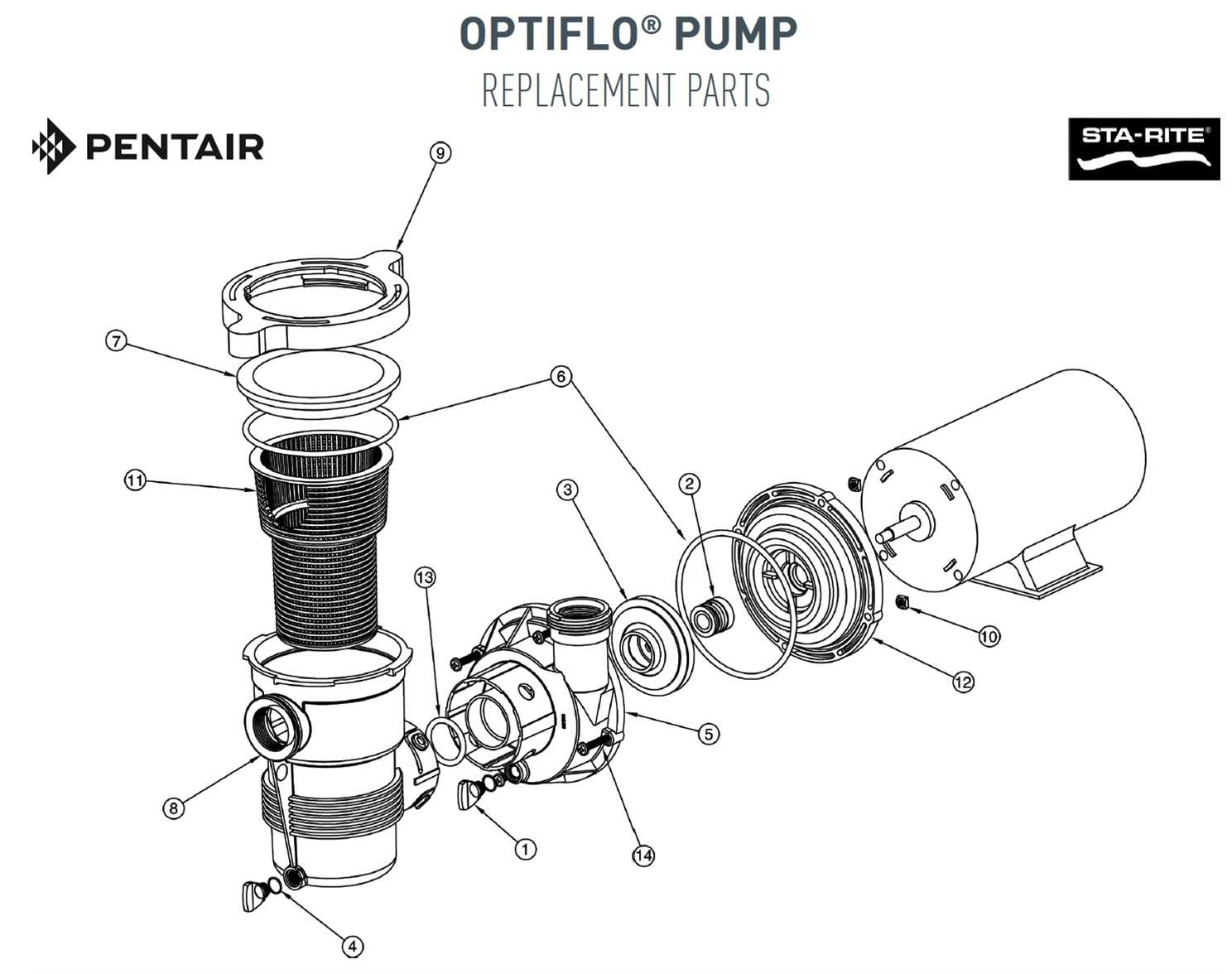

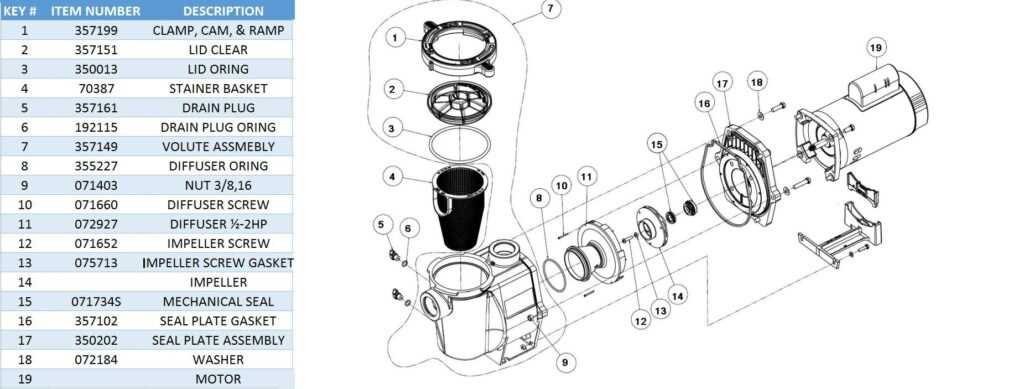

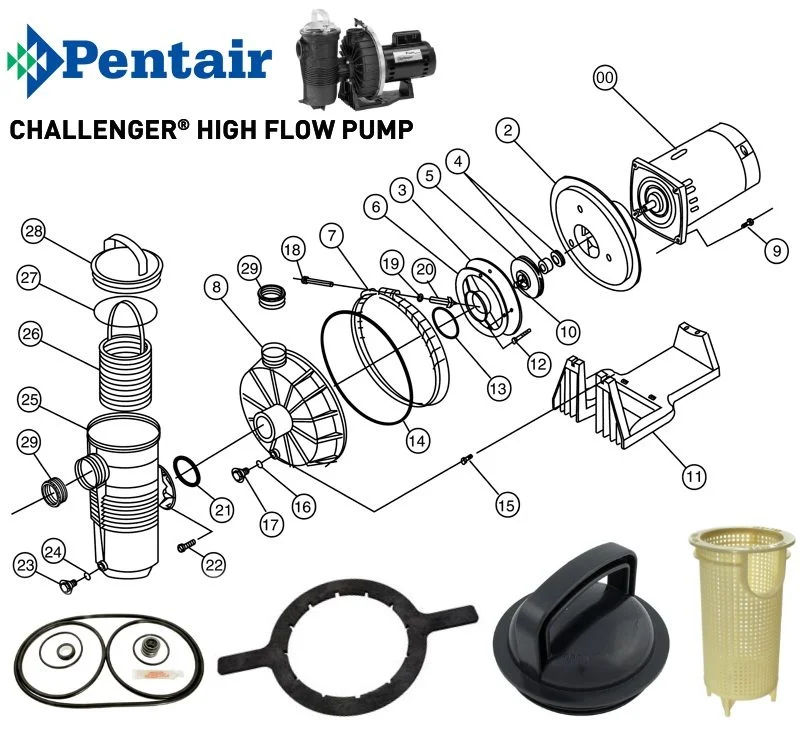

Pentair Challenger Pump Parts Diagram for Easy Reference

Exploring the intricate components of water circulation systems can significantly enhance the efficiency and longevity of your setup. Knowledge of individual elements contributes to a more streamlined maintenance process, allowing for quicker troubleshooting and repairs.

Visual aids play a crucial role in grasping the layout and functionality of various components. By having a comprehensive overview, enthusiasts and professionals alike can better appreciate how each segment interacts within the broader system.

Ultimately, a thorough understanding of these mechanisms not only facilitates effective repairs but also optimizes overall performance. Delving into the specifics empowers users to make informed decisions regarding upgrades and replacements.

Pentair Challenger Pump Overview

This section provides an essential understanding of a specific type of equipment designed for efficient water circulation and management. Its robust construction and innovative features ensure reliability and optimal performance in various applications. Users can expect enhanced functionality, making it a popular choice in the industry.

With a focus on energy efficiency and ease of maintenance, this device offers users the ultimate solution for their water handling needs. Its design prioritizes longevity and effectiveness, catering to both residential and commercial requirements. Users can benefit from various enhancements that streamline operation and reduce downtime.

In summary, this equipment stands out due to its superior capabilities and user-friendly attributes, making it an indispensable tool in effective water management systems.

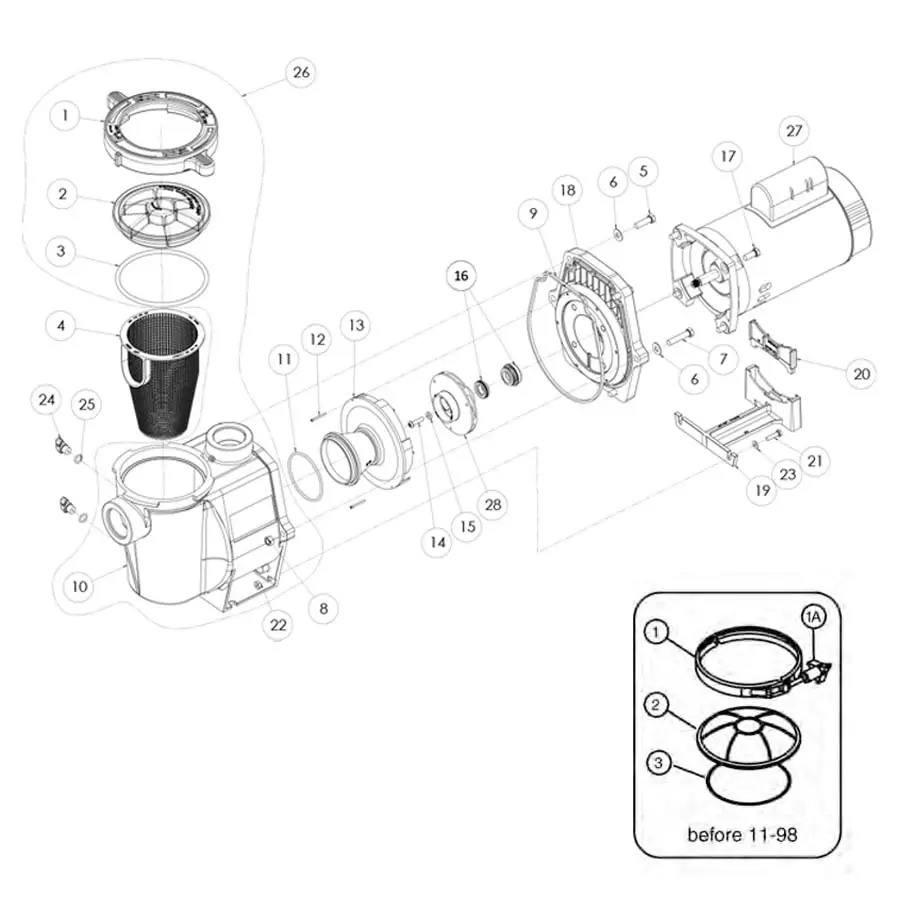

Understanding Pump Components

Comprehending the essential elements of hydraulic systems is crucial for effective maintenance and operation. Each segment plays a vital role in ensuring optimal performance, contributing to the overall efficiency and reliability of the entire mechanism.

Inlet and Outlet: These openings are critical for fluid entry and exit, influencing the flow rate and pressure within the system. Proper sizing and alignment are necessary for seamless operation.

Impellers: The heart of the mechanism, these rotating blades are responsible for moving the fluid. Their design can significantly affect the efficiency and capacity of the operation.

Seals: Essential for preventing leaks, these components maintain pressure and protect internal parts from external contaminants. Their integrity is paramount for longevity.

Bearings: These reduce friction and wear on moving parts, ensuring smooth operation. Regular inspection can prevent premature failure and costly repairs.

Motor: The driving force behind the movement, this element converts electrical energy into mechanical energy. Understanding its specifications is key for proper matching with other components.

Each of these components works in concert to deliver the ultimate performance of the system. Regular maintenance and thorough knowledge of these elements can enhance functionality and extend service life.

Benefits of Proper Maintenance

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. Neglecting routine care can lead to a range of issues, including decreased efficiency and unexpected failures. By prioritizing maintenance, users can enjoy numerous advantages that enhance both functionality and reliability.

1. Enhanced Performance: Keeping machinery in good condition significantly improves its operational effectiveness. Regular checks and necessary adjustments ensure that all components work harmoniously, maximizing output and efficiency.

2. Cost Savings: Investing time and resources in maintenance can save considerable money in the long run. Preventive care reduces the likelihood of major breakdowns, which often require expensive repairs or replacements.

3. Increased Lifespan: Routine maintenance prolongs the life of equipment. By addressing minor issues before they escalate, users can extend the operational period of their investments, ensuring they serve their purpose for years to come.

4. Safety Assurance: Well-maintained systems are crucial for safe operation. Regular inspections help identify potential hazards, reducing the risk of accidents and ensuring a secure working environment for everyone involved.

5. Environmental Impact: Efficient machinery typically consumes less energy and produces fewer emissions. By maintaining equipment properly, users can contribute to a more sustainable future while also adhering to regulatory standards.

In summary, dedicating time to the maintenance of equipment not only enhances performance but also offers significant financial, safety, and environmental benefits. Embracing a proactive approach to care is a smart choice for anyone invested in their operational success.

Common Issues with Challenger Pumps

Understanding typical challenges faced by these water circulation systems is essential for effective maintenance and longevity. Users often encounter various operational problems that can affect performance and efficiency. Here are some common concerns to be aware of:

Frequent Operational Problems

- Noisy Operation: Excessive noise can indicate wear or misalignment within the internal components.

- Inadequate Flow Rate: A reduction in water flow may result from clogs or worn impellers.

- Overheating: Insufficient cooling or blockage can cause the unit to overheat, leading to potential damage.

Maintenance-Related Issues

- Seal Failures: Deterioration of seals can lead to leaks, necessitating replacement.

- Clogged Filters: Regularly checking and cleaning filters is crucial to avoid flow restrictions.

- Electrical Problems: Faulty wiring or connections may disrupt power supply, causing performance issues.

Proactive measures and regular inspections can help mitigate these common issues, ensuring smooth operation and extending the lifespan of the system.

Replacement Parts Availability

When it comes to maintaining essential equipment, access to quality components is crucial for optimal performance and longevity. Ensuring that replacement items are readily available can significantly reduce downtime and enhance the overall efficiency of your system. Understanding where to find these components and the variety of options can help streamline repairs and upkeep.

Local Suppliers often carry a range of components, providing the advantage of immediate access. These outlets typically offer knowledgeable staff who can assist in identifying the right pieces for your specific needs. Establishing a relationship with a trusted local vendor can facilitate quicker repairs and personalized service.

Online Retailers have become increasingly popular for sourcing various components. A plethora of websites specializes in these products, often featuring detailed specifications and user reviews to aid in your selection process. However, it’s essential to ensure that the retailer is reputable to avoid counterfeit or substandard items.

Aftermarket Options can also be a viable choice, providing cost-effective solutions without sacrificing quality. Many manufacturers and independent companies produce compatible components that meet or exceed the original specifications, offering a reliable alternative for those looking to save on expenses.

In summary, having multiple sources for obtaining necessary components not only enhances the repair process but also empowers users to maintain their equipment effectively, ensuring a reliable operation for years to come.

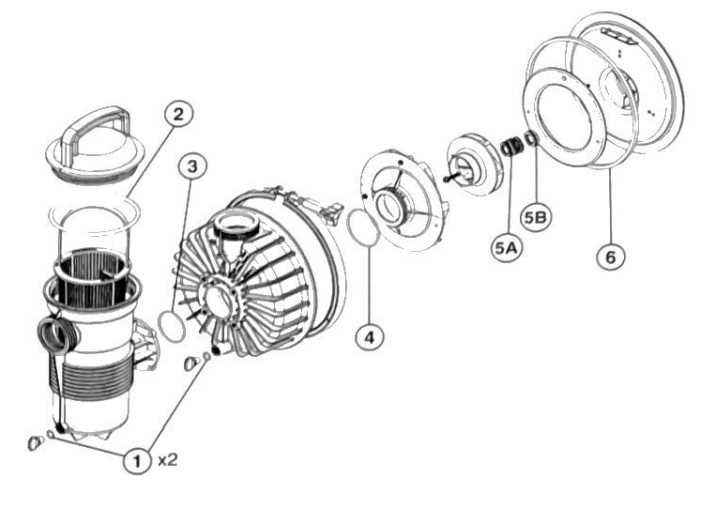

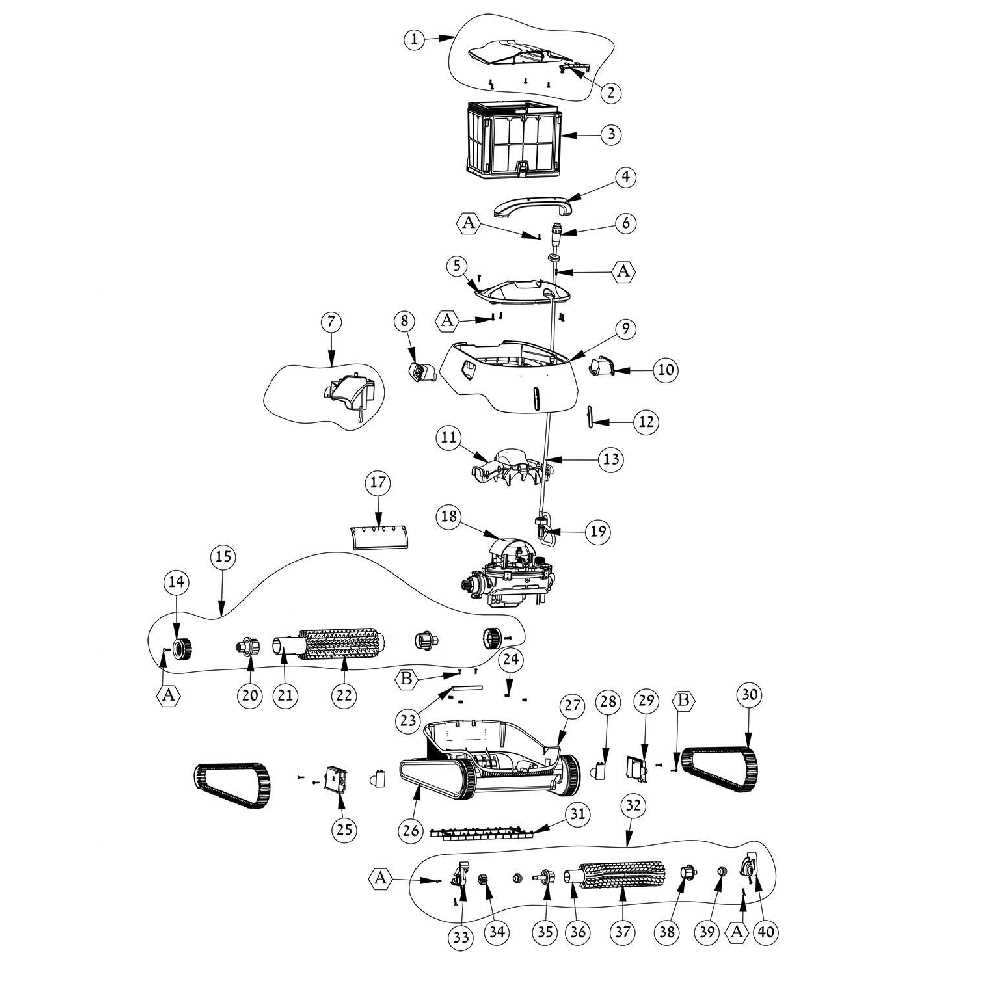

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and troubleshooting. These illustrations serve as a roadmap, guiding users through the intricate relationships and functions of various elements.

Begin by familiarizing yourself with the key symbols and notations used in the illustration. Each icon typically represents a specific component, while lines indicate connections and interactions between them. Take note of any accompanying labels that provide essential information about each element’s function.

Next, pay attention to the layout. Components are often organized logically, allowing you to trace the flow of operation. Start from the main source and follow through to the output, ensuring a comprehensive understanding of how each piece contributes to the overall system.

Finally, don’t hesitate to refer to additional resources if needed. Guides and manuals can enhance your comprehension, offering detailed explanations that complement the visual cues. With practice, interpreting these visuals will become an invaluable skill in managing your equipment effectively.

Installation Tips for New Parts

When upgrading or replacing components in your system, proper installation is crucial for optimal performance. Following best practices ensures longevity and efficiency in operation.

- Read the Manual: Always refer to the provided documentation for specific guidelines related to your model.

- Gather Tools: Ensure you have all necessary tools on hand before starting the installation.

- Check Compatibility: Verify that new components are compatible with your existing setup to avoid issues.

- Clean the Area: Remove any debris or old materials from the installation site to ensure a clean fit.

- Start with a dry run: Assemble parts without sealing to check for fit.

- Apply seals and lubricants as specified in the manual for better performance.

- Tighten connections gradually to avoid damage to the components.

- Test the system after installation to confirm everything is functioning correctly.

Safety Precautions During Repair

When undertaking maintenance tasks on mechanical equipment, ensuring safety should always be the top priority. Proper precautions not only protect the individual performing the work but also prevent damage to the machinery itself. Familiarizing oneself with potential hazards is essential for a successful and secure repair process.

Before starting any repair, always disconnect the power source to avoid accidental activation. Additionally, wear appropriate personal protective equipment, such as gloves and goggles, to safeguard against sharp edges and hazardous materials. Proper ventilation in the workspace is also crucial to minimize exposure to harmful fumes.

Finally, keep a well-organized workspace, free from clutter, to reduce the risk of trips or falls. Following these safety measures will create a more efficient and secure environment, allowing for a successful and stress-free repair experience.

Signs You Need a Replacement

Over time, equipment can show signs of wear and tear, indicating that it may be time for a replacement. Recognizing these indicators early can prevent further damage and ensure optimal performance. Below are some common signs that suggest it might be necessary to invest in a new unit.

Frequent Breakdowns

If you notice an increase in the frequency of malfunctions or failures, it’s a clear signal that your unit may no longer be reliable. Ongoing issues often point to deeper problems that simple repairs cannot fix.

Declining Efficiency

A marked decrease in efficiency, such as reduced output or longer operation times, suggests that your equipment is struggling to perform its intended function. This can lead to higher energy costs and inconsistent results.

| Indicator | Action Required |

|---|---|

| Frequent breakdowns | Consider replacement |

| Declining efficiency | Evaluate for potential replacement |

| Strange noises | Inspect and replace if necessary |

| Excessive vibration | Assess condition; replacement may be needed |

Comparing Pentair Models

When selecting a specific model for fluid management, it’s essential to evaluate various offerings available in the market. Each version comes with distinct features, performance metrics, and intended applications. This section provides a comparative overview to assist in making an informed choice.

- Design Variations:

- Some models emphasize compactness, suitable for limited spaces.

- Others prioritize high capacity, ideal for larger installations.

- Performance Efficiency:

- Energy consumption can vary significantly between models.

- Flow rates and pressure capabilities are crucial for meeting specific demands.

- Durability and Materials:

- Construction materials can affect longevity and resistance to corrosive environments.

- Some versions feature enhanced protection against wear and tear.

- Maintenance Requirements:

- Accessibility for service can differ, influencing upkeep frequency.

- Some designs offer self-cleaning features to reduce manual intervention.

Understanding these distinctions is vital to select the best fit for your needs, ensuring optimal performance and reliability in fluid management tasks.

Resources for DIY Repairs

When it comes to tackling home maintenance tasks, having access to the right information can make all the difference. A variety of resources are available for those who wish to take a hands-on approach to repairs. From online tutorials to community forums, these tools empower individuals to confidently address issues on their own.

Online Tutorials: Many websites offer step-by-step guides that cater to various skill levels. These tutorials often include video demonstrations, making complex procedures easier to understand. By following these visual aids, you can gain the confidence needed to execute repairs effectively.

Community Forums: Engaging with fellow enthusiasts can provide invaluable insights. Online platforms allow you to ask questions, share experiences, and receive advice from others who have faced similar challenges. This sense of community can be incredibly motivating and educational.

Manufacturer Resources: Many brands provide official documentation and troubleshooting guides. These resources often include detailed instructions that can help you identify issues and find suitable solutions tailored to specific models.

Tool Libraries: Local tool-sharing programs are becoming increasingly popular. They allow you to borrow specialized equipment you may not want to purchase for one-time use. This can significantly reduce costs and encourage you to attempt repairs you might have otherwise avoided.

DIY Workshops: Consider attending local workshops or classes focused on home maintenance skills. These hands-on experiences can enhance your abilities and give you the opportunity to learn from experts in a supportive environment.