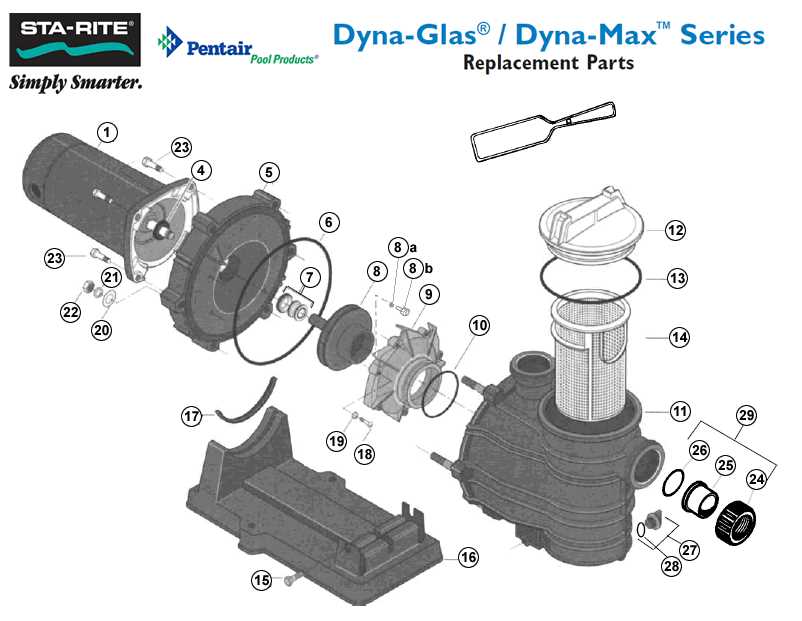

Understanding the Sta-rite Pump Parts Diagram

In the realm of fluid management, understanding the intricate elements that contribute to efficient operation is essential. Each component plays a vital role in ensuring that the entire system functions seamlessly, providing optimal performance and longevity. Familiarity with these essential elements can greatly enhance maintenance and troubleshooting efforts.

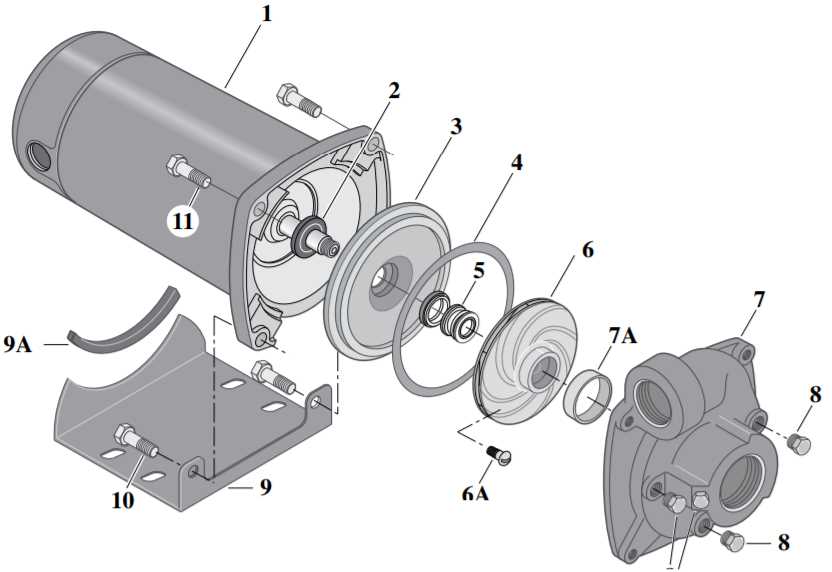

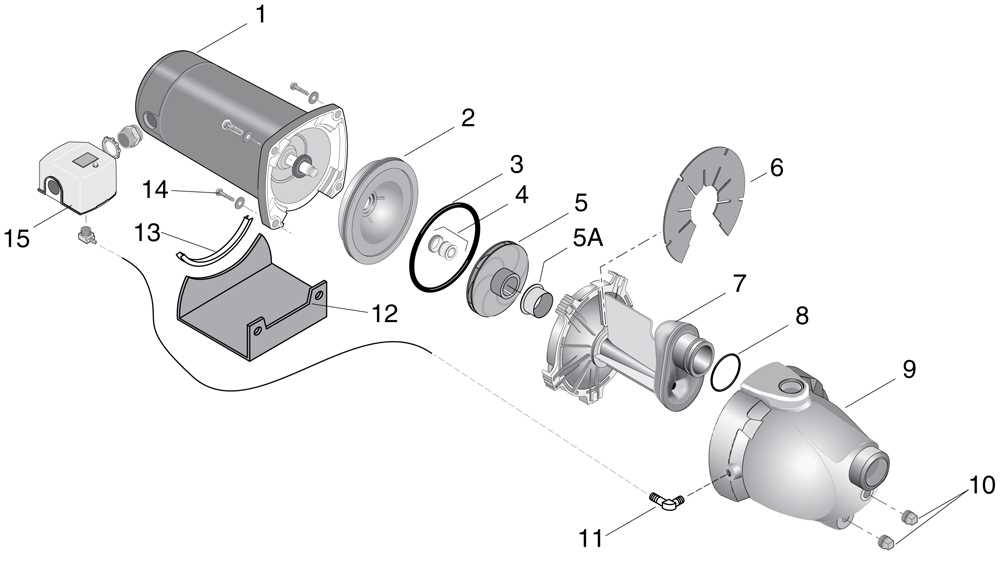

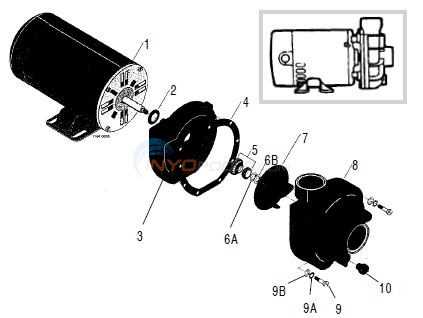

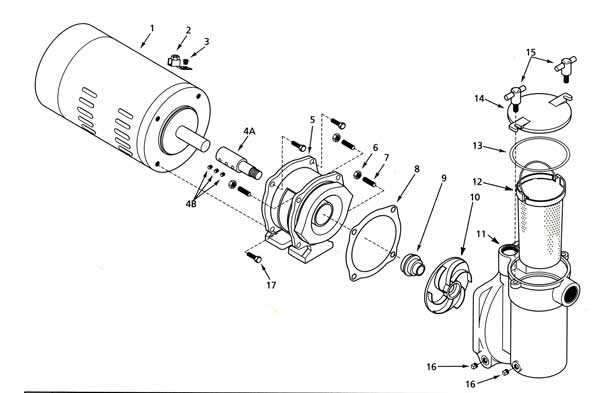

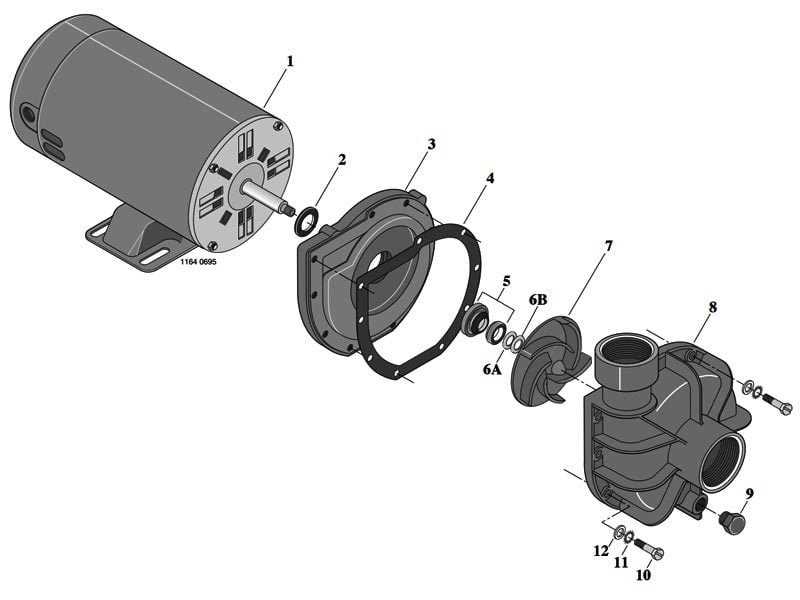

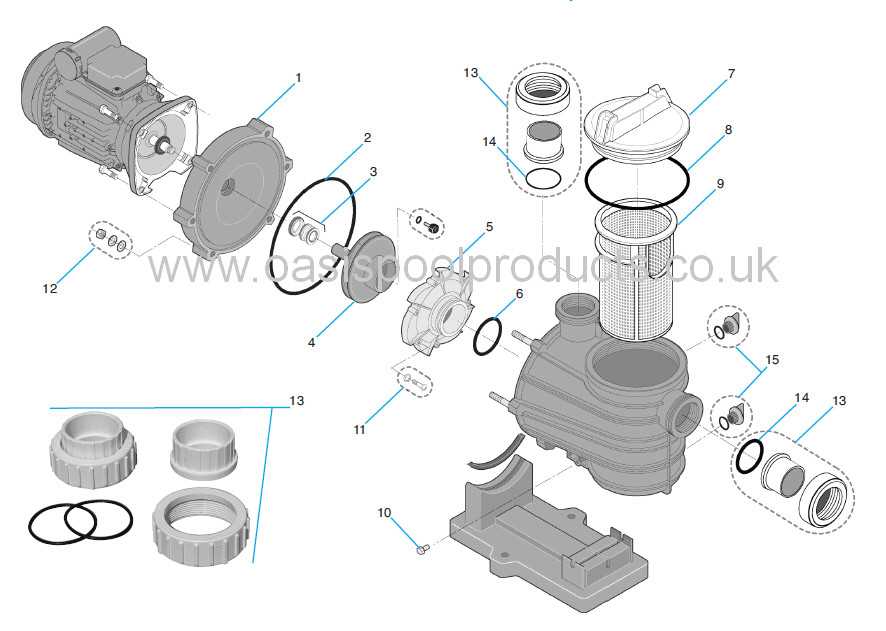

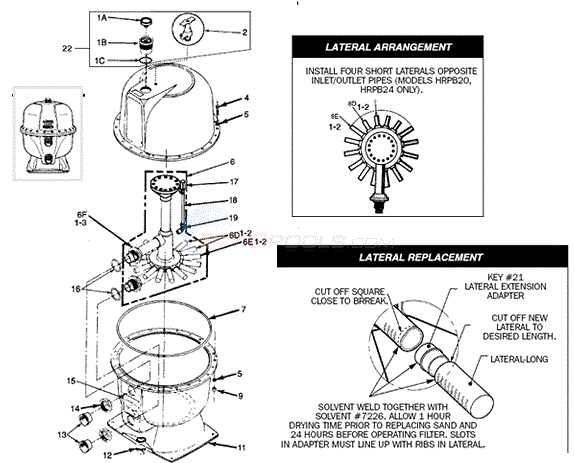

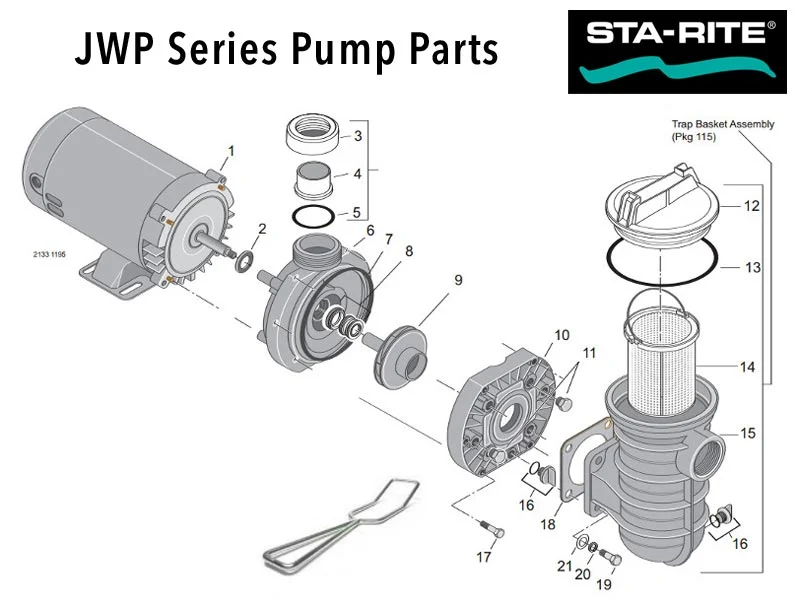

Visual representations of these components offer invaluable insights into their arrangements and interactions. By analyzing these illustrations, users can gain a clearer perspective on how each segment contributes to the overall functionality. This knowledge not only aids in the identification of potential issues but also empowers users to make informed decisions regarding repairs and upgrades.

Whether you are a novice seeking to expand your knowledge or a seasoned professional looking for a refresher, exploring the layout of these crucial elements can be incredibly beneficial. Embracing this understanding enables individuals to navigate the complexities of their systems with confidence and efficiency, ultimately leading to enhanced reliability and performance.

Understanding Sta-Rite Pumps

In the realm of fluid management, certain devices play a crucial role in ensuring efficiency and reliability. These mechanisms are designed to facilitate the movement and circulation of liquids, making them indispensable for various applications. A deeper comprehension of these systems allows users to optimize their performance and maintain functionality over time.

Key Components of Fluid Circulation Devices

Every efficient system comprises several integral components that work in harmony. Understanding these elements not only aids in troubleshooting but also enhances operational knowledge.

| Component | Description |

|---|---|

| Motor | Provides the necessary force to drive the mechanism, converting electrical energy into mechanical energy. |

| Impeller | Helps in moving the liquid by converting rotational energy into kinetic energy, creating flow. |

| Diffuser | Reduces the velocity of the liquid exiting the impeller, allowing for an increase in pressure. |

| Seal | Prevents leaks and protects internal components from contamination and damage. |

Maintaining Optimal Performance

Regular maintenance is essential for ensuring longevity and efficient operation. Proper care includes routine inspections, cleaning of components, and timely replacements of worn parts. By prioritizing maintenance, users can avoid unexpected failures and extend the lifespan of their equipment.

Components of Sta-Rite Pumps

Understanding the essential elements that make up these devices is crucial for effective maintenance and optimal performance. Each element plays a significant role in the overall functionality, contributing to efficiency and reliability. The interplay of these components ensures smooth operation and longevity.

Motor: The driving force behind the entire system, it converts electrical energy into mechanical energy, enabling the movement of fluid.

Impeller: A vital component that creates the necessary pressure to move liquids through the system. Its design is crucial for maximizing flow rates.

Volute: This element helps direct the flow of fluid from the impeller, converting kinetic energy into pressure energy, which is essential for effective circulation.

Seal: This component prevents leakage by creating a barrier between moving and stationary parts. It is crucial for maintaining the integrity of the system.

Strainer: Positioned at the inlet, it filters out debris and particles, protecting the internal components from potential damage and ensuring uninterrupted flow.

Diffuser: It plays a critical role in converting high-velocity fluid flow into a more uniform flow, enhancing the efficiency of the overall mechanism.

Base: The foundation that supports all components, providing stability and minimizing vibrations during operation.

Each of these elements contributes to the effective operation of the system. Understanding their functions can aid in troubleshooting and maintenance, ensuring longevity and reliability.

Functionality of Pump Parts

The various components of a fluid-moving device play a crucial role in ensuring its efficiency and reliability. Each element is designed to perform specific functions, contributing to the overall operation of the system. Understanding these roles helps in recognizing how they interact to maintain optimal performance and extend the lifespan of the device.

Essential Components and Their Roles

Among the essential elements, the motor serves as the driving force, converting electrical energy into mechanical energy to initiate movement. The impeller, with its rotating blades, creates the necessary pressure to move the fluid. Additionally, seals and bearings support smooth operation by reducing friction and preventing leaks. Each component is vital, and a failure in one can disrupt the entire system.

Maintenance and Efficiency

Regular upkeep of these elements is vital for sustaining performance. Checking for wear and tear, ensuring proper lubrication, and replacing damaged components can significantly enhance operational efficiency. By prioritizing maintenance, users can prevent unexpected breakdowns and prolong the functional lifespan of the equipment.

Identifying Common Issues

Understanding potential complications in your equipment can greatly enhance its performance and longevity. By recognizing typical signs of malfunction, users can address issues promptly, ensuring efficient operation and minimizing costly repairs. This section outlines common problems encountered in various systems, along with tips for identification and resolution.

Frequent Symptoms of Malfunction

Several indicators can signal underlying troubles within your apparatus. Unusual noises, inconsistent operation, or unexpected fluctuations in performance are often the first signs that something is amiss. Observing these symptoms early allows for quicker interventions, which can prevent further deterioration.

Preemptive Maintenance Tips

Regular upkeep is essential for preventing issues before they escalate. Routine inspections, proper cleaning, and timely replacements of worn components can significantly reduce the likelihood of problems arising. Establishing a consistent maintenance schedule is key to sustaining optimal functionality.

Importance of Maintenance

Regular upkeep of any mechanical system is crucial for ensuring optimal performance and longevity. Neglecting this aspect can lead to decreased efficiency, unexpected breakdowns, and costly repairs. By prioritizing routine inspections and servicing, users can identify potential issues before they escalate, ensuring smooth operation over time.

Preventive care is essential for avoiding disruptions and maintaining reliability. When components are well-maintained, they function more effectively, contributing to overall efficiency. This proactive approach not only enhances performance but also reduces energy consumption, leading to lower operational costs.

Moreover, a systematic maintenance regimen fosters safety. Regular checks help detect wear and tear that could pose hazards. Ensuring that all elements are in good condition minimizes risks, providing peace of mind for users and operators alike.

In conclusion, investing time and resources in proper care is vital. It enhances functionality, promotes safety, and ultimately extends the lifespan of the equipment. This strategic focus on maintenance leads to better performance and greater satisfaction for users.

Replacement Part Options

When it comes to maintaining your equipment, having a variety of alternatives for replacement components is crucial. These options can ensure optimal performance and longevity, allowing your system to run smoothly and efficiently. Selecting the right substitutes involves understanding compatibility and functionality.

Several categories of alternatives are available:

- OEM Components: Original parts manufactured by the equipment brand, guaranteeing compatibility and quality.

- Aftermarket Alternatives: Third-party options that may offer similar quality at a potentially lower price.

- Refurbished Parts: Previously used components that have been restored to meet original specifications, often providing a cost-effective solution.

- Custom Solutions: Tailored components designed to meet specific requirements or improve performance beyond standard offerings.

Each type of replacement has its advantages and disadvantages. It’s essential to consider factors such as price, warranty, and user reviews when making a choice. Ensuring that the selected options align with your system’s needs will help maintain efficiency and reliability.

How to Read Diagrams

Understanding visual representations is essential for comprehending complex systems. These illustrations can depict various components, their relationships, and functions in a structured format, making it easier to identify key elements and their interactions.

When approaching these representations, it’s important to familiarize yourself with common symbols and notations. Each icon or line conveys specific information, and recognizing their meanings can significantly enhance your understanding. Here are some basic elements you might encounter:

| Symbol | Meaning |

|---|---|

| Circle | Represents a junction or connection point |

| Arrow | Indicates the direction of flow or movement |

| Square | Denotes a component or element within the system |

| Dashed Line | Often indicates an alternative or optional connection |

By systematically interpreting these elements, you can gain valuable insights into the configuration and operation of the entire assembly. Remember to take your time and refer to accompanying legends or notes for further clarification, as they can provide additional context that aids in understanding the overall structure.

Safety Precautions for Repairs

When engaging in maintenance or repair activities, it is crucial to prioritize safety to prevent accidents and ensure a smooth process. Adhering to proper guidelines minimizes risks and protects both the individual and the equipment involved. This section outlines essential safety measures to follow during repair tasks.

General Safety Guidelines

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and masks, to shield yourself from harmful substances and debris.

- Ensure the work area is clean and well-lit, eliminating any potential hazards that could lead to slips or falls.

- Keep tools organized and within reach to avoid unnecessary movements that could cause injury.

- Verify that the equipment is disconnected from any power sources before beginning repairs to avoid electrical shock or accidental activation.

Emergency Preparedness

- Familiarize yourself with the location of emergency shut-off switches and fire extinguishers in case of unforeseen incidents.

- Have a first aid kit readily available to address any minor injuries that may occur during repairs.

- Know the emergency contact numbers for medical assistance and local authorities.

- Inform a colleague or supervisor of your repair activities, especially if working in isolation, to ensure assistance is available if needed.

Tools Needed for Service

Proper maintenance and repair of your equipment require a specific set of instruments to ensure efficiency and effectiveness. Utilizing the right tools not only simplifies the process but also enhances the longevity of the unit, allowing for seamless operation.

1. Screwdrivers: A variety of screwdrivers, including flathead and Phillips, are essential for loosening or tightening screws securely. Having different sizes will accommodate various screw types encountered during service.

2. Wrenches: Both adjustable and fixed wrenches are necessary for gripping and turning nuts and bolts. They provide the leverage needed to achieve the correct tightness without damaging the fittings.

3. Pliers: Pliers, particularly needle-nose and slip-joint varieties, are useful for gripping, twisting, and cutting wire. They can also assist in maneuvering components in tight spaces.

4. Multimeter: A multimeter is invaluable for checking electrical connections and measuring voltage, current, and resistance. This tool aids in diagnosing issues effectively.

5. Lubricants and Cleaners: Quality lubricants ensure smooth operation of moving parts, while cleaners help maintain components free from debris and buildup, contributing to overall efficiency.

6. Safety Gear: Always wear appropriate safety equipment such as gloves and goggles to protect yourself from potential hazards during maintenance tasks.

Having these essential tools on hand will facilitate a smoother servicing experience, ultimately promoting optimal functionality and reliability.

Where to Buy Parts

Finding reliable sources for replacement components can significantly enhance the longevity and performance of your equipment. Several options are available, ranging from local retailers to online marketplaces, each offering various advantages.

- Local Hardware Stores: Visit nearby shops that specialize in home improvement or outdoor equipment. Staff members can often provide valuable insights and recommendations.

- Specialty Retailers: Seek out stores that focus on specific equipment or outdoor living products. They may carry specialized items that are difficult to find elsewhere.

- Online Marketplaces: Websites like Amazon, eBay, and dedicated parts suppliers offer a wide selection of components. Check customer reviews and ratings to ensure quality.

- Manufacturer Websites: Many manufacturers sell directly through their websites, allowing you to purchase authentic components. This option often guarantees compatibility and quality.

- Second-hand Options: Consider searching for used items on platforms like Craigslist or Facebook Marketplace. This can be a cost-effective way to find what you need, though ensure to verify the condition of the items.

When purchasing, always confirm the specifications to ensure the components will fit your equipment. It is wise to compare prices and check return policies before finalizing your purchase.

Upgrading Your Pump System

Enhancing your fluid management system can significantly improve efficiency and performance. Upgrades can involve various components, from motors to control systems, ensuring optimal operation. Assessing your current setup and identifying areas for improvement is essential for achieving better functionality and longevity.

Considerations for Enhancements: When planning an upgrade, evaluate the specific needs of your system. This may include increasing capacity, reducing energy consumption, or improving reliability. Analyzing your operational requirements will help determine the most beneficial modifications.

Component Selection: Choosing high-quality components is crucial for a successful upgrade. Opt for durable materials and innovative designs that enhance performance. Researching the latest technologies and features available in the market will provide valuable insights for informed decisions.

Furthermore, collaborating with professionals can offer expert guidance tailored to your system’s unique demands. They can assist in selecting the right equipment and ensuring proper installation, ultimately leading to a more efficient and effective fluid management solution.

Comparing Models and Features

When evaluating different models of water circulation devices, it is essential to consider various characteristics that may affect performance and suitability for specific applications. Each variant offers unique functionalities, ensuring that users can find an option that meets their particular needs.

Key factors to compare include:

- Performance Capacity: Look for specifications that indicate the maximum flow rate and head height, which determine how effectively the unit can move water.

- Energy Efficiency: Assess the energy consumption of each model. High-efficiency designs can significantly reduce operational costs over time.

- Durability: Materials used in construction can affect longevity. Models made from corrosion-resistant materials are often more reliable in various environments.

- Noise Levels: Consider the sound output during operation. Some designs are engineered for quieter performance, making them ideal for residential use.

- Ease of Maintenance: Check how simple it is to access components for routine care. Models with user-friendly designs can save time and effort in upkeep.

In conclusion, understanding these distinctions can help users make informed decisions, ensuring they select the most appropriate model for their water management requirements.

Tips for Efficient Operation

Maximizing the effectiveness of your water circulation system involves several key practices that ensure smooth functionality and longevity. By following these guidelines, users can enhance performance while minimizing potential issues.

Regular maintenance is crucial for optimal operation. Schedule routine inspections to check for wear and tear, and replace any worn components promptly to avoid malfunctions. Additionally, ensure that all connections are secure to prevent leaks that could disrupt the system’s efficiency.

Proper filtration is another essential aspect. Utilizing high-quality filters can reduce debris and contaminants, promoting better circulation and extending the lifespan of the equipment. It’s important to clean or replace filters regularly to maintain their effectiveness.

Monitoring water levels and chemical balance also plays a vital role in the system’s performance. Maintaining appropriate levels helps to prevent damage and ensures that the machinery operates under ideal conditions. Invest in a reliable testing kit to monitor pH and chemical levels consistently.

Finally, consider the placement of the equipment. Ensure that it is situated in an area with adequate ventilation and access for maintenance. Proper positioning can significantly affect overall efficiency and ease of operation.