Understanding the Stanadyne Injection Pump Parts Diagram

In the realm of automotive technology, the intricate systems responsible for delivering fuel to the engine are crucial for optimal performance. These mechanisms consist of various components, each playing a specific role in ensuring efficient operation. By comprehending the layout and functions of these elements, enthusiasts and professionals alike can enhance their maintenance and troubleshooting skills.

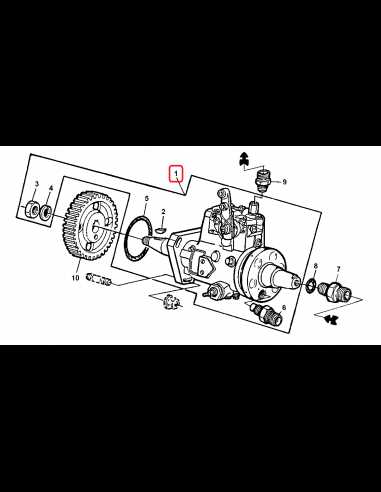

Visual representations of these systems provide valuable insights into their structure and functionality. Such illustrations serve as a roadmap for understanding how each component interacts within the larger assembly. Grasping these relationships is essential for anyone looking to delve deeper into the world of fuel delivery systems.

Furthermore, recognizing the individual roles of each element empowers users to identify potential issues more effectively. Whether it’s diagnosing a malfunction or planning an upgrade, a solid grasp of the underlying mechanics is indispensable. This exploration aims to shed light on these crucial components, enabling a more comprehensive understanding of their contributions to vehicle performance.

Understanding Stanadyne Injection Pumps

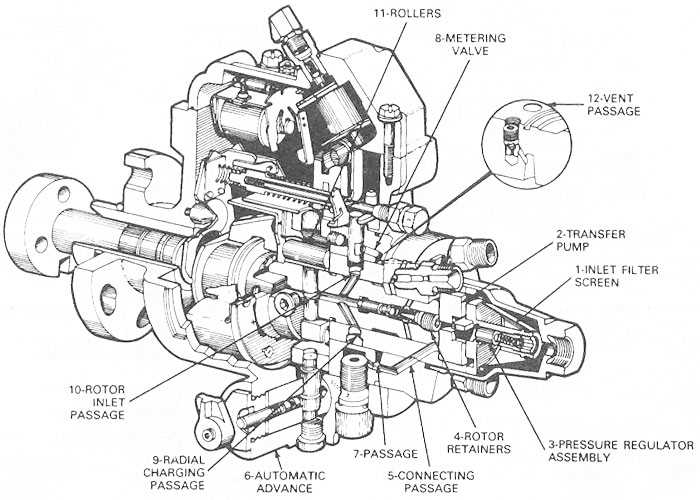

The technology behind fuel delivery systems is crucial for optimizing engine performance and efficiency. These systems ensure that fuel is precisely metered and delivered to the combustion chamber, enhancing power output and reducing emissions. A deep dive into the components of these systems reveals the intricate design and functionality that contribute to their reliability and effectiveness.

Central to this technology are various components that work together harmoniously. Each element plays a significant role in ensuring that fuel is processed correctly. Understanding these components can help in troubleshooting issues and improving maintenance practices.

| Component | Function |

|---|---|

| Fuel Metering Unit | Controls the quantity of fuel delivered based on engine requirements. |

| Drive Mechanism | Regulates the timing and operation of fuel delivery. |

| Governor | Maintains engine speed by adjusting fuel flow. |

| Return Line | Circulates excess fuel back to the tank to prevent pressure build-up. |

| Injectors | Atomizes fuel for efficient combustion. |

By understanding how each component contributes to the overall system, one can appreciate the engineering that allows modern engines to operate efficiently. Proper knowledge and maintenance of these systems can lead to improved performance and longevity of the vehicle.

Components of Stanadyne Systems

The efficiency of fuel delivery systems relies on a variety of intricate components that work in harmony to ensure optimal performance. Understanding these elements is crucial for maintenance and troubleshooting, as each part plays a significant role in the overall functionality. This section will delve into the essential components that contribute to the effectiveness of these systems.

Key Elements

Among the primary elements are the precision mechanisms that regulate fuel flow and timing. These components are designed to withstand high pressures and temperatures, ensuring durability and reliability in various operating conditions. Additionally, sensors and control units monitor performance, providing real-time feedback to optimize functionality.

Supporting Structures

Supporting structures, such as housings and fittings, are also critical. They not only protect sensitive components but also facilitate seamless integration within the system. Materials used in these structures must be robust to withstand environmental factors, ensuring longevity and consistent performance over time.

Understanding the interaction and function of these components is vital for anyone involved in maintenance or development of fuel delivery technologies. Proper knowledge can lead to improved efficiency and reduced operational issues.

Common Issues with Injection Pumps

Understanding the frequent complications associated with fuel delivery systems is crucial for ensuring optimal performance and longevity of your vehicle. Various factors can lead to reduced efficiency and reliability, impacting overall functionality. Recognizing these common challenges can help in diagnosing and resolving issues effectively.

Fuel Contamination

One of the primary culprits behind operational problems is fuel contamination. Impurities in the fuel can cause wear and tear on internal components, leading to malfunctions. Regularly checking and maintaining the quality of the fuel used can significantly reduce the risk of such issues.

Mechanical Wear

Over time, mechanical wear can affect performance. Components may degrade due to prolonged use or lack of proper lubrication. Regular inspections and timely replacements of worn parts are essential to prevent breakdowns and ensure the system runs smoothly.

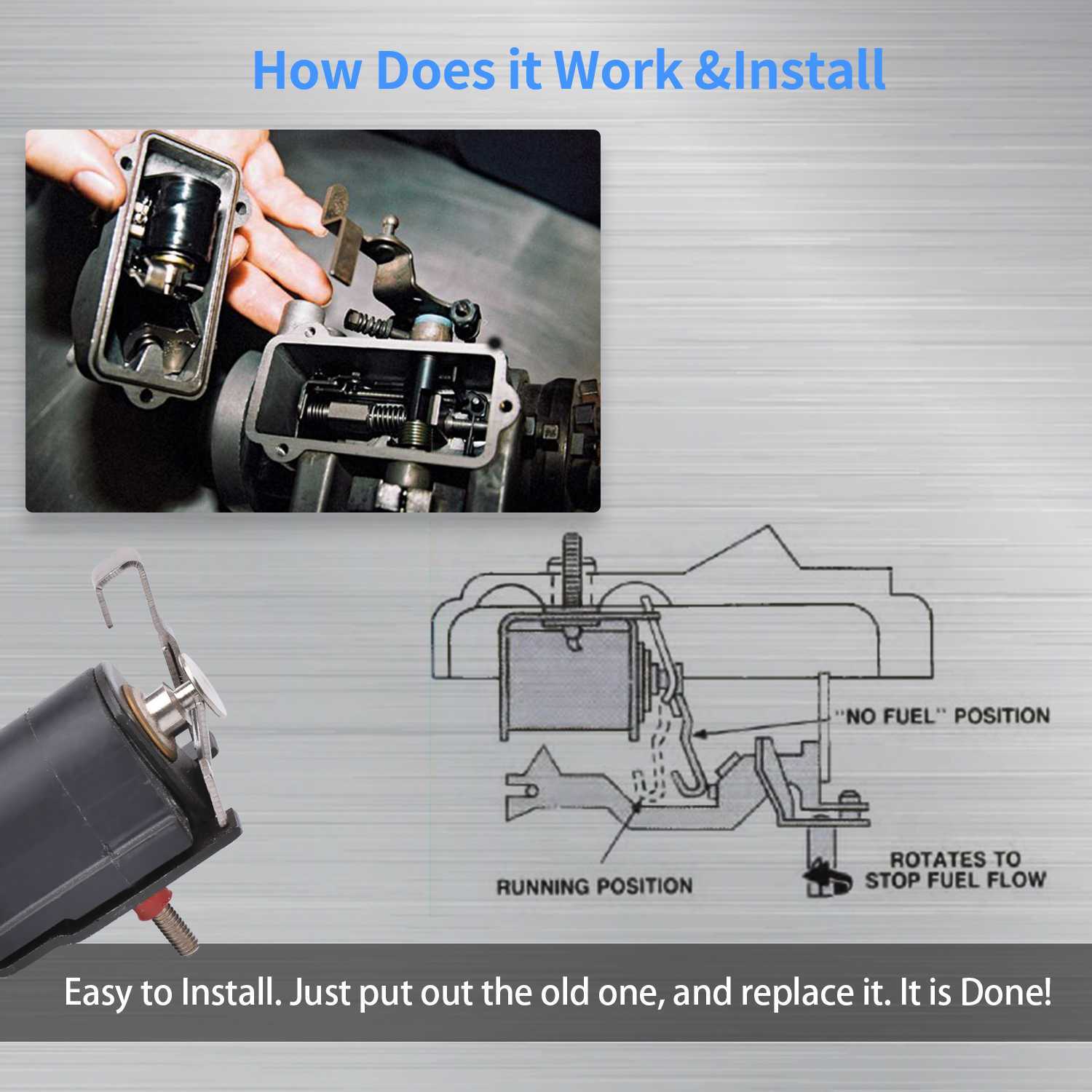

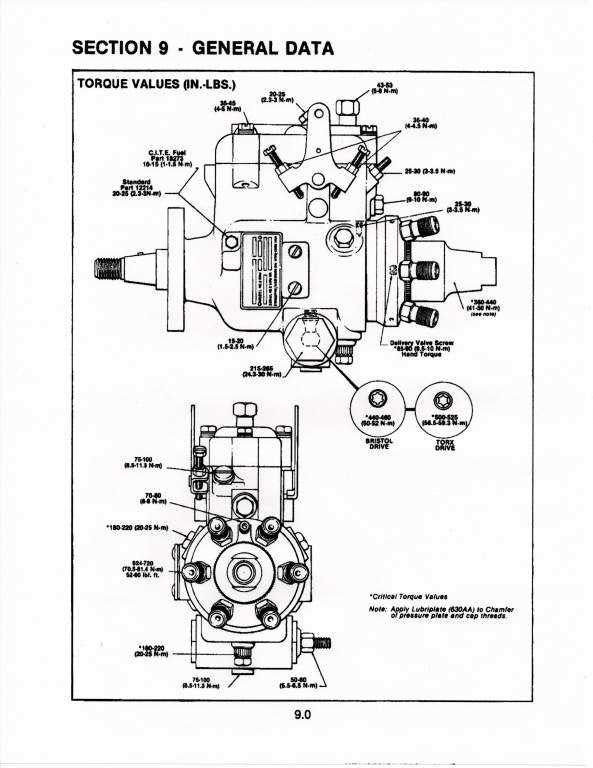

Importance of Accurate Diagrams

Clear and precise representations are essential in any technical field. They serve as vital tools that facilitate understanding and communication among professionals. Without these visual aids, complex systems can become overwhelming, leading to misunderstandings and errors in execution.

In any maintenance or repair scenario, a well-crafted illustration can significantly enhance efficiency. It allows technicians to identify components quickly and comprehend their functions without confusion. Accuracy in these visuals ensures that every element is correctly represented, reducing the likelihood of costly mistakes.

Furthermore, these visuals can serve as educational resources. Training new personnel becomes more effective when they can rely on accurate representations, enabling them to grasp intricate details that are crucial for their tasks. In summary, the role of precise visuals cannot be overstated; they are indispensable in fostering clarity and proficiency within technical operations.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance not only extends the life of your equipment but also enhances its performance. Following a structured maintenance routine is key to preventing issues before they arise and minimizing downtime.

Regular Inspections

Conducting frequent inspections is essential. Look for signs of wear and tear, unusual noises, or leaks. Addressing minor issues promptly can prevent them from escalating into major problems. Ensure that all components are secure and functioning correctly. Keeping a maintenance log can help track any changes or repairs made over time.

Proper Lubrication

Maintaining adequate lubrication is critical for smooth operation. Use the recommended lubricants for your equipment and follow the manufacturer’s guidelines regarding application frequency. Regularly check lubricant levels and replace old or contaminated fluid to reduce friction and wear on moving parts.

In summary, a proactive approach to maintenance, including regular inspections and proper lubrication, will significantly enhance the longevity of your machinery, ensuring it operates efficiently for years to come.

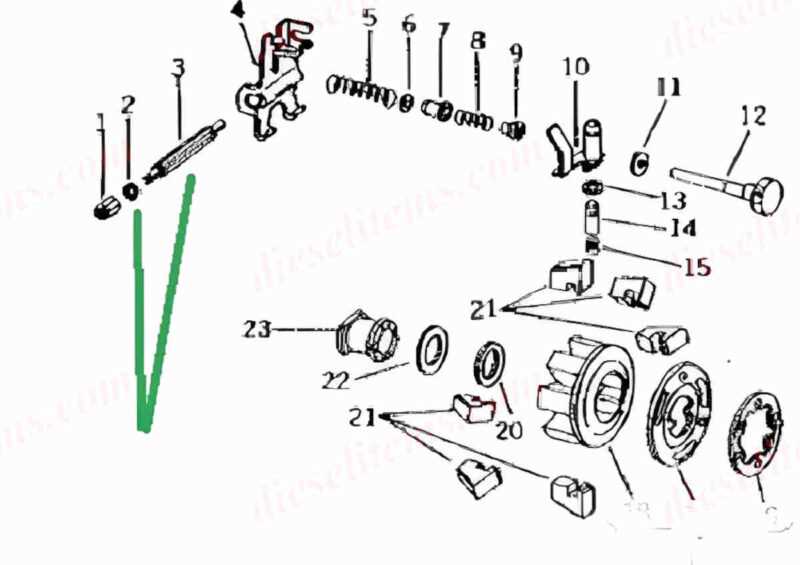

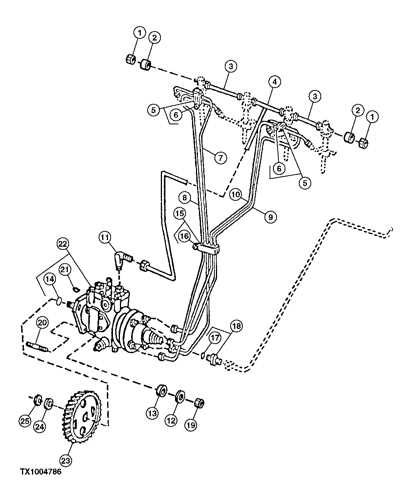

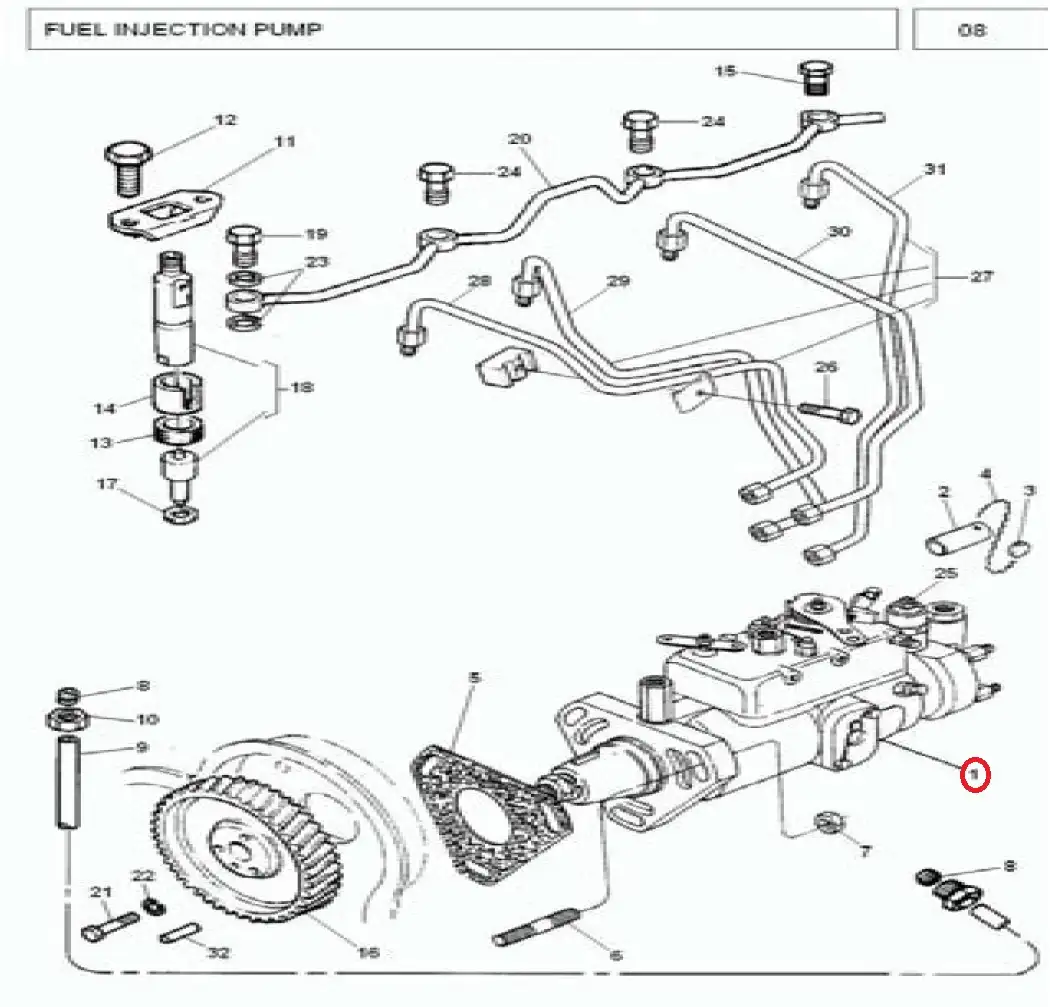

How to Read a Parts Diagram

Understanding a schematic representation of components can significantly enhance your ability to work with machinery. These illustrations serve as a visual guide, showcasing the relationships and functions of individual elements within a system. Familiarizing yourself with the layout and symbols used will empower you to diagnose issues more effectively and carry out repairs with confidence.

Start by identifying the key sections. Typically, these visual aids are divided into various segments, each representing a specific function or area. Take a moment to familiarize yourself with the overall structure before delving into the details.

Next, pay attention to the labels. Most illustrations will include identifiers for each element, often accompanied by a corresponding list or legend. This information is crucial for understanding the specific roles of the components and how they interact with one another.

Look for directional arrows, as they indicate movement or flow within the system. These indicators are essential for grasping how different parts work together in operation. Understanding the flow will help you visualize the process and troubleshoot effectively.

Finally, take note of any special symbols or notations that might denote important information, such as assembly instructions or warnings. Being aware of these details can prevent mistakes during maintenance or installation, ensuring that you handle the elements correctly and safely.

Replacing Stanadyne Pump Parts

Maintaining the efficiency of fuel delivery systems often requires the replacement of worn components. This process can enhance overall performance and ensure the reliability of the machinery. Understanding how to properly replace these crucial elements is essential for both longevity and functionality.

Assessment of the current components is the first step. Identifying signs of wear, such as leaks or irregular performance, can help determine which items need replacement. It is advisable to consult detailed schematics to locate all relevant sections and ensure a comprehensive review.

Once the necessary components are identified, disassembly becomes the next crucial phase. Carefully removing old elements requires precision to avoid damage to surrounding structures. Utilizing appropriate tools is vital in this process to maintain integrity throughout the procedure.

After successful removal, the installation of new components should be executed with attention to detail. Ensuring a proper fit is essential, as this guarantees optimal operation and minimizes the risk of future issues. Following manufacturer guidelines and specifications can aid in achieving a seamless integration.

Finally, conducting a thorough test after the replacement is critical. Observing the system’s performance can provide insights into the effectiveness of the changes made and highlight any further adjustments that may be necessary. Regular maintenance and prompt replacement of components will contribute to a more efficient and dependable system.

Tools Needed for Repair Work

Effective maintenance and repair of machinery require a specific set of tools to ensure precision and efficiency. Whether you are a seasoned technician or a DIY enthusiast, having the right equipment can make a significant difference in the quality of your work.

Essential Tools

To successfully carry out repair tasks, you should equip yourself with a variety of instruments. Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for disassembly and assembly. Additionally, a torque wrench is essential for applying the correct amount of force to fasteners, ensuring they are secured properly.

Specialized Equipment

In some cases, specialized devices may be necessary to diagnose or repair intricate components. A multimeter can help in troubleshooting electrical issues, while a set of calipers allows for precise measurements. Furthermore, having access to a hydraulic press can facilitate the replacement of worn-out elements that require significant force.

Investing in quality tools not only enhances your efficiency but also prolongs the lifespan of the machinery being serviced. Always remember that the right tools, coupled with proper techniques, lead to successful outcomes in repair endeavors.

Upgrades for Enhanced Performance

Improving the efficiency and reliability of fuel delivery systems can significantly boost overall engine performance. Various modifications can be implemented to enhance the functionality of these systems, ensuring they operate at their best. This section explores potential upgrades that can lead to improved power output, better fuel economy, and reduced emissions.

Key Enhancements

Several key upgrades can be considered for optimizing fuel systems. These enhancements can include advanced electronic controls, improved fuel delivery mechanisms, and better filtration systems. Each of these modifications plays a crucial role in ensuring the engine operates smoothly and efficiently.

| Upgrade | Description | Benefits |

|---|---|---|

| Electronic Control Unit | Incorporates advanced algorithms for better fuel management. | Increases responsiveness and improves fuel efficiency. |

| High-Flow Fuel Lines | Enhances fuel flow rates for optimal delivery. | Boosts power output and reduces pressure loss. |

| Advanced Filtration | Utilizes high-quality filters to remove contaminants. | Protects components and ensures cleaner fuel delivery. |

| Performance Nozzles | Design optimized for fine fuel atomization. | Enhances combustion efficiency and reduces emissions. |

Conclusion

Implementing these upgrades can lead to a noticeable improvement in engine performance. By focusing on optimizing fuel delivery systems, users can achieve better power, efficiency, and environmental compliance.

Where to Find Quality Parts

Finding reliable components for machinery is crucial for ensuring optimal performance and longevity. Quality materials not only enhance efficiency but also minimize the risk of malfunctions. This section outlines various sources where individuals can acquire top-notch elements for their equipment.

Online Retailers

- Major e-commerce platforms often have a wide selection of components from different manufacturers.

- Specialized websites dedicated to machinery often provide detailed product descriptions and customer reviews.

- Consider checking for authorized online distributors who focus on specific brands.

Local Suppliers

- Visiting local hardware stores can yield immediate results and allow for hands-on examination of products.

- Establishing relationships with local distributors can lead to personalized service and better deals.

- Trade shows and local expos often feature suppliers showcasing their latest offerings, providing opportunities for direct interaction.