Wolf Gas Range Parts Diagram

Modern kitchen appliances are designed with precision and quality, providing users with a reliable and efficient cooking experience. These advanced devices consist of numerous interconnected elements that ensure smooth operation and control. Each component plays a vital role in maintaining the functionality and safety of the equipment, allowing users to achieve consistent results in the kitchen.

Knowing how various elements come together can help with troubleshooting, maintenance, and even improving performance. From temperature control mechanisms to ignition systems, every aspect of these devices is carefully engineered to provide optimal performance. Exploring the inner workings of such equipment offers valuable insight into how to keep it functioning efficiently over time.

For those looking to maintain their high-performance cooking equipment, understanding the layout of its internal mechanisms is essential. A thorough examination of the individual elements and how they connect to one another can make a significant difference when it comes to repairs or upgrades, ensuring a long and reliable service life.

Essential Components of Wolf Gas Ranges

In modern cooking appliances, several critical elements ensure functionality and performance. Each component plays a distinct role in delivering efficiency, control, and safety during operation. Understanding these core elements helps in maintaining and troubleshooting the equipment.

Burners are key for generating heat, allowing precise control over cooking temperatures. These elements vary in size and power, adapting to different culinary needs.

The control knobs allow users to adjust settings effortlessly. They ensure smooth transitions between various heat levels, offering enhanced control over the cooking process.

Another essential part is the ignition system, which enables quick and safe activation of the burners. It ensures reliable performance, minimizing manual efforts and enhancing convenience.

The grates, typically made from durable materials, provide stable surfaces for cookware. They are designed for even heat distribution and easy cleaning.

How Burners Work in Gas Stoves

The heating components in cooktops are essential for transforming fuel into a controlled source of heat. These devices ensure that the heat is distributed evenly and can be adjusted to the desired level. The process behind how they operate involves the interaction between fuel, air, and an ignition system that works together to provide a stable flame for cooking.

Key Components of the Burner System

- Ignition mechanism: Responsible for sparking or lighting the flame, ensuring the burner activates when turned on.

- Air-fuel mixture: Ensures the correct combination of fuel and air is supplied to create a stable flame.

- Control valve: Regulates the flow of fuel to adjust the intensity of the heat according to user preference.

How the Heat is Distributed

Once the flame is ignited, the design of the burner helps to direct and spread the heat evenly across the cookware. Small openings allow the flame to rise, while the layout of the burner ensures that the heat is dispersed in a circular pattern for consistent cooking.

- The fuel is released when the control is activated.

- The ignition system triggers a spark or flame.

- The flame rises through the burner openings to provide heat.

Main Functions of Ignition Systems

The ignition system plays a crucial role in activating the heating process by producing the necessary spark or flame to initiate the process. Its functionality ensures the seamless operation of the equipment, providing a controlled start and maintaining efficiency during operation. Without a proper ignition mechanism, the heating system would not activate reliably.

Consistency and Reliability: The ignition mechanism is designed to ensure consistent activation. Whether manually triggered or automated, it provides a stable and reliable way to initiate the heat generation process every time, minimizing potential failures.

Safety and Control: A well-functioning ignition system is essential for safe operation. It includes built-in safeguards to prevent accidental activation or malfunction, offering protection through precise control mechanisms.

Efficiency in Operation: A responsive ignition mechanism improves overall system performance. By ensuring the rapid and efficient initiation of heat, it contributes to energy savings and minimizes wear on components over time.

Understanding Gas Valves and Their Role

The regulation of fuel flow is essential for maintaining efficiency and safety in heating appliances. The control mechanisms ensure that the right amount of fuel reaches the burner, enabling precise adjustments to the intensity of the flame. This process is crucial for achieving the desired performance and conserving energy.

Valves are designed to manage the flow of fuel, allowing users to turn the system on or off and adjust the strength of the flame. These controls contribute to the overall safety of the system by preventing unwanted leaks or excess fuel from reaching the burner. Ensuring proper operation of these components is key to the functionality and longevity of the appliance.

In addition to controlling fuel flow, these devices act as a safeguard, monitoring and shutting off the supply in case of malfunctions. Understanding how they function is vital for anyone working with such systems, as it helps maintain both efficiency and security in daily use.

Control Knobs: How They Regulate Heat

Control knobs play a crucial role in adjusting the level of warmth during cooking. These essential components allow the user to fine-tune the temperature, providing flexibility for various types of culinary tasks. By turning the knob, you can easily change the intensity of the heat to suit your cooking needs.

Precision in Heat Adjustment

One of the key functions of control knobs is their ability to offer precise regulation of warmth. Whether you’re preparing delicate ingredients or high-temperature dishes, the knob ensures accurate control over the intensity, giving you confidence in your cooking. The gradual increments help maintain consistent heat levels throughout the process.

Understanding Knob Settings

Each knob setting correlates with a specific temperature range, allowing for easy management of the heat source. Users can switch between low, medium, or high levels, depending on the requirements of the dish. This intuitive design ensures that anyone can quickly adjust the temperature, ensuring an efficient and enjoyable cooking experience.

Maintenance of Cooking Grates

Proper care and upkeep of cooking surfaces are essential for ensuring efficient cooking and longevity of your appliance. Regular maintenance not only enhances performance but also contributes to the overall safety and hygiene of the kitchen environment. Understanding how to clean and maintain these surfaces can greatly improve your culinary experience.

Cleaning Techniques

To maintain the appearance and functionality of cooking surfaces, a routine cleaning regimen is crucial. After each use, it is advisable to allow the surfaces to cool down before scrubbing them with a non-abrasive cleaner and a soft cloth or sponge. For stubborn stains, a mixture of baking soda and water can be effective. Applying this paste and letting it sit for a while before wiping can help lift tough residues.

Inspection and Replacement

Regularly inspecting the cooking surfaces for signs of wear and tear is vital. Look for any cracks, warping, or discoloration that might affect performance. If any component appears damaged, it is wise to replace it promptly to ensure safe cooking conditions. Keeping spare components on hand can be beneficial for maintaining functionality without prolonged downtime.

Safety Features in Modern Gas Ranges

Contemporary cooking appliances are designed with multiple safety mechanisms to protect users and enhance cooking experiences. These features minimize risks associated with heat and fuel, ensuring a secure environment while preparing meals.

Key Safety Mechanisms

- Flame Failure Device: This mechanism automatically shuts off the fuel supply if the flame goes out, preventing gas leakage and potential hazards.

- Child Lock: Many units are equipped with a feature that prevents accidental activation, safeguarding young ones from unintentional injuries.

- Thermal Coupling: This safety system ensures that the heat source remains functional only when the appliance is in use, further reducing risks of overheating.

- Overheat Protection: If the unit exceeds a certain temperature, it will automatically turn off, preventing damage and enhancing safety.

Additional Considerations

In addition to built-in safety features, proper installation and regular maintenance play a crucial role in ensuring safe operation. Users should follow manufacturer guidelines and schedule professional inspections to identify and address any potential issues early.

Replacing the Oven Thermostat in Wolf Stoves

Ensuring the precise temperature within an oven is crucial for achieving the best culinary results. When the temperature regulation device fails or becomes inaccurate, it can lead to poorly cooked meals. Understanding how to replace this component can restore the efficiency of your cooking appliance and enhance your culinary experience.

Identifying the Need for Replacement

Before proceeding with the replacement, it’s essential to recognize signs that indicate the need for a new temperature control device. Here are some common symptoms:

- Inconsistent cooking temperatures.

- Food taking longer than usual to cook.

- Burnt or undercooked dishes despite following recipes accurately.

- Visible damage or wear on the temperature control unit.

Steps for Replacement

Once you’ve determined that a replacement is necessary, follow these steps for a successful installation:

- Unplug the appliance from the power source to ensure safety.

- Remove the outer panel to access the temperature control unit.

- Disconnect the old temperature regulation device by unscrewing the mounting screws.

- Carefully disconnect the wiring from the old unit, taking note of how it’s connected.

- Install the new temperature control device by reversing the disconnection process.

- Reattach the outer panel securely.

- Plug the appliance back in and test the temperature settings to ensure proper functionality.

Following these guidelines will help maintain the performance of your cooking equipment, ensuring optimal results for your culinary endeavors.

Cleaning the Pilot Assembly for Optimal Performance

Maintaining the pilot assembly is essential for ensuring reliable operation and efficiency in your cooking equipment. Over time, residue and debris can accumulate, leading to inconsistent flame performance and potential safety issues. Regular cleaning helps to prevent these problems and promotes the longevity of the unit.

Steps to Clean the Pilot Assembly:

Begin by disconnecting the power supply to the equipment to ensure safety during maintenance. Once powered down, carefully remove any protective covers to access the pilot assembly. Using a soft brush or cloth, gently clean the area to remove any accumulated dirt and grease. Pay particular attention to the nozzle and surrounding components, as these areas are critical for proper functionality.

After cleaning, inspect the assembly for any signs of wear or damage. If necessary, replace worn parts to restore optimal performance. Once the assembly is clean and intact, reassemble the unit and reconnect the power supply. Finally, conduct a thorough test to ensure that the pilot light ignites properly and burns with a steady, blue flame.

Regular maintenance of the pilot assembly not only enhances performance but also contributes to the overall safety of your cooking equipment.

The Role of Convection Fans in Cooking

Convection fans play a crucial role in enhancing the cooking process by promoting even heat distribution throughout the cooking chamber. This technology is designed to create a consistent temperature, allowing food to cook more uniformly and efficiently. As a result, dishes often achieve better texture and flavor, making convection fans an essential feature in modern cooking appliances.

The benefits of using convection fans include:

- Improved cooking efficiency: Hot air circulates evenly, reducing cooking times.

- Enhanced browning and crisping: Foods develop a golden crust while remaining tender inside.

- Versatile cooking options: Ideal for baking, roasting, and dehydrating various dishes.

- Reduced temperature fluctuations: Maintains a stable environment for consistent results.

Understanding how these fans operate can significantly impact your culinary outcomes. When utilizing convection, it is essential to adjust cooking times and temperatures, as foods may cook faster compared to traditional methods. Embracing this technology can elevate your cooking experience and yield restaurant-quality results at home.

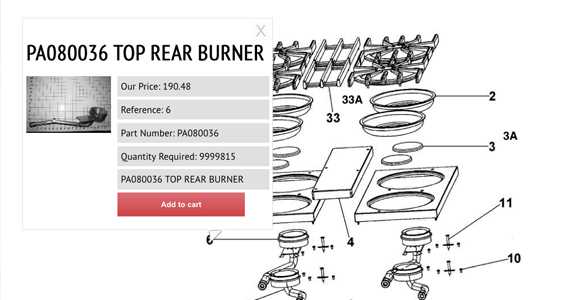

Identifying and Replacing Sealed Burners

Understanding the functionality and maintenance of sealed heat sources is crucial for optimal performance in cooking appliances. These components play a vital role in directing heat effectively, ensuring uniform cooking and efficiency. Knowing how to identify and replace them can enhance the longevity of the appliance and improve overall cooking results.

To recognize a sealed burner, look for its distinct features such as a flat surface with a central opening where flames emerge. Typically, these units are designed to provide an even heat distribution while minimizing the risk of spills entering the burner assembly. When the burner becomes damaged or clogged, it may affect cooking efficiency and require replacement.

| Signs of Damage | Replacement Steps |

|---|---|

| Uneven flame distribution | Turn off the power and gas supply. |

| Burner caps not fitting securely | Remove the existing burner by lifting it straight up. |

| Corrosion or discoloration | Clean the area where the burner sits to remove debris. |

| Persistent ignition issues | Install the new burner by aligning it with the socket and pressing down firmly. |

| Visible cracks or breaks | Test the new burner for stability and proper fit before use. |

Following these guidelines will ensure the effective identification and replacement of sealed heating elements, ultimately leading to enhanced cooking experiences and appliance reliability.