Exploring the Ranger R76ATR Parts Diagram for Ultimate Maintenance

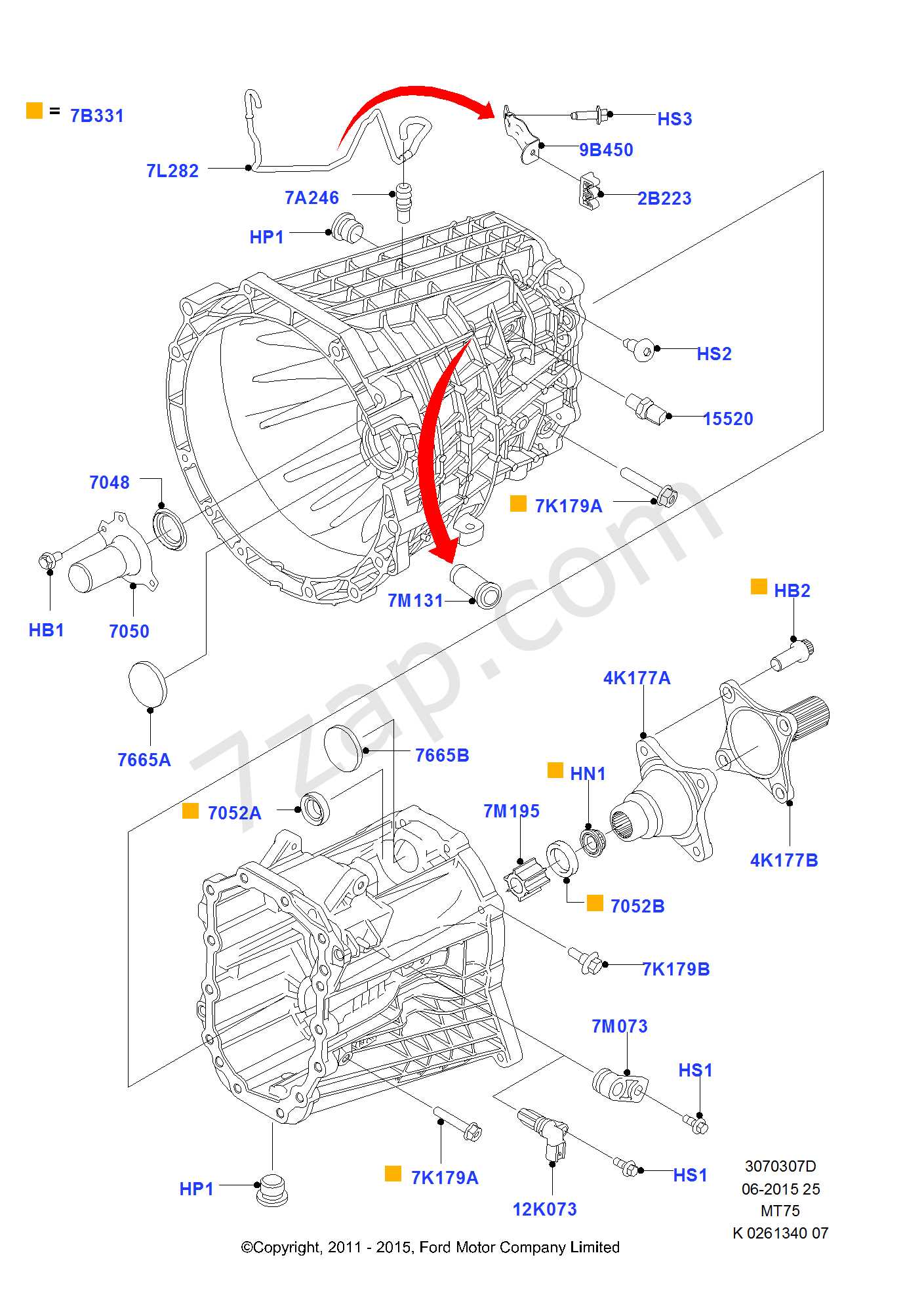

In the realm of machinery and equipment, a comprehensive grasp of how individual elements interact is essential for effective maintenance and troubleshooting. An organized representation of these components can greatly aid in identifying specific areas requiring attention. This understanding not only enhances the efficiency of repairs but also contributes to the overall longevity of the system.

When examining a particular model, the arrangement of its various parts reveals crucial insights into its operation and functionality. By studying the configuration and relationships between components, one can develop a clearer picture of the mechanics at play. This approach facilitates informed decision-making when it comes to repairs or upgrades.

Moreover, having access to a detailed visual reference allows technicians and enthusiasts alike to navigate the intricacies of their equipment with confidence. It serves as a roadmap, guiding them through the often complex interplay of different parts. Ultimately, a solid understanding of this layout empowers users to maintain optimal performance and address issues proactively.

Understanding Ranger R76ATR Components

Exploring the intricacies of machinery reveals a complex interplay of various elements that work harmoniously to ensure optimal performance. Each component plays a vital role, contributing to the overall functionality and efficiency of the system. A comprehensive understanding of these parts is essential for maintenance and troubleshooting.

Key Elements of the System

- Engine Assembly

- Hydraulic System

- Transmission Unit

- Control Panel

- Frame and Chassis

Each of these elements serves a distinct purpose and must be well-maintained to prevent operational issues.

Importance of Each Component

- Engine Assembly: This is the powerhouse that drives the entire system, converting fuel into mechanical energy.

- Hydraulic System: Responsible for powering various operations, ensuring smooth movement and control.

- Transmission Unit: This component transfers power from the engine to the wheels, affecting speed and torque.

- Control Panel: Acts as the interface for operators, providing critical information and allowing for system management.

- Frame and Chassis: The structural foundation that supports all other components, ensuring durability and stability.

Understanding the roles and interconnections of these elements is crucial for effective operation and long-term reliability.

Importance of Parts Diagrams

Visual representations play a crucial role in understanding complex systems. They simplify the identification of components and their interrelations, facilitating maintenance and repairs. By providing a clear layout, these illustrations enhance comprehension, making it easier for users to troubleshoot issues efficiently.

Moreover, such visual aids serve as valuable references, guiding users through assembly processes and ensuring that every piece is correctly installed. This not only streamlines operations but also minimizes the risk of errors, leading to increased longevity and performance of the equipment.

In addition, these resources foster effective communication among technicians, enabling collaborative problem-solving. By allowing team members to refer to a common visual guide, they can share insights and suggestions more readily, ultimately leading to faster resolution of issues.

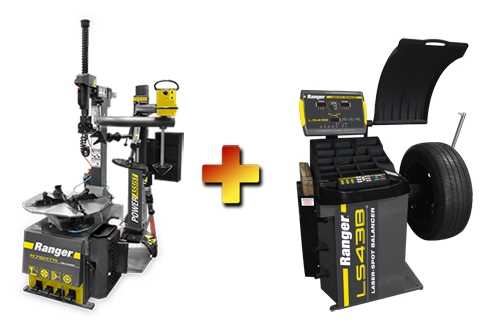

Key Features of the R76ATR

This model is designed with advanced capabilities that enhance performance and usability. Its innovative design caters to a variety of needs, making it a reliable choice for users seeking efficiency and durability.

- Robust Construction: Built to withstand challenging environments.

- High Efficiency: Optimizes resource use for superior performance.

- Advanced Technology: Incorporates cutting-edge features for ease of operation.

- User-Friendly Interface: Designed for intuitive navigation and control.

- Versatile Applications: Suitable for various tasks, ensuring flexibility.

These characteristics make the model a top choice for professionals and enthusiasts alike, providing an ultimate solution for diverse operational requirements.

Common Replacement Parts Explained

Understanding the various components of machinery is essential for effective maintenance and repair. Each element plays a crucial role in ensuring optimal performance, and recognizing when to replace these elements can significantly enhance longevity and efficiency.

Key Components to Monitor

Some critical elements to keep an eye on include belts, filters, and bearings. Belts are responsible for transferring power, and wear can lead to slippage. Filters maintain clean operation, and clogged filters can cause overheating. Bearings facilitate smooth movement, and any signs of grinding or noise indicate they may need replacement.

Signs of Wear and Tear

Common indicators of component failure include unusual noises, decreased performance, or visible damage. Regular inspections can help identify these issues early, ensuring timely interventions and minimizing potential downtime.

How to Access the Diagram

Obtaining a visual representation of components is essential for effective maintenance and repair. Understanding how to navigate and retrieve this information can save time and enhance efficiency in your tasks.

Online Resources

Numerous websites offer access to comprehensive visual guides. Utilize search engines to locate trusted platforms that host these illustrations, ensuring you can easily download or view them online.

Manuals and Documentation

Physical or digital manuals often include these illustrations. Check the official documentation related to your equipment, as it typically provides detailed breakdowns of all elements.

Maintenance Tips for R76ATR Parts

Regular upkeep of machinery components is essential for ensuring optimal performance and longevity. Adopting a proactive maintenance approach can prevent unexpected failures and enhance efficiency.

Routine Checks

- Inspect for wear and tear regularly.

- Check fluid levels and replenish as necessary.

- Examine connections for any signs of looseness or corrosion.

Cleaning Procedures

- Clean components to remove dirt and debris that can hinder performance.

- Use appropriate cleaning agents to avoid damage.

- Ensure all parts are thoroughly dried after cleaning to prevent rust.

Identifying Parts by Number

Recognizing components by their assigned numbers is essential for effective maintenance and repair. This method streamlines the process, ensuring that each element is accurately sourced and replaced as needed.

Importance of Accurate Identification

Precision in identifying items minimizes errors and enhances the efficiency of repairs. It allows for quick retrieval of necessary elements, reducing downtime and improving overall performance.

Utilizing Reference Materials

Consulting reference materials is crucial in this process. Catalogs and technical manuals provide detailed information, enabling users to easily locate and confirm the correct component numbers.

Where to Purchase Spare Parts

Finding the right components for your machinery can be a straightforward process if you know where to look. Numerous options are available for sourcing replacement items, catering to various needs and budgets. Whether you prefer shopping online or visiting physical stores, understanding your options is key to a successful purchase.

Online Retailers are a popular choice due to their convenience. Websites specializing in equipment supplies often have extensive inventories and competitive prices. Be sure to read customer reviews to gauge the reliability of the seller before making a commitment.

Local Dealers can provide personalized assistance and immediate availability. Establishing a relationship with a nearby distributor can be beneficial, as they may offer insights on compatible components and additional services, such as installation advice.

Another option is auction sites and classifieds, where you can find both new and used items. This route may offer significant savings, but it’s crucial to inspect the items and verify their condition before purchasing.

Lastly, manufacturer websites often provide direct access to original components, ensuring quality and compatibility. While prices may be higher, the assurance of receiving authentic products can be worth the investment.

Compatibility with Other Models

Understanding the interchangeability of components across various equipment is essential for optimal performance and maintenance. This section explores how specific parts can be utilized in conjunction with similar models, highlighting potential synergies and advantages for users.

| Model | Compatible Parts | Notes |

|---|---|---|

| Model A | Part X, Part Y | Compatible but requires minor adjustments. |

| Model B | Part Z, Part W | Direct replacement, no modifications needed. |

| Model C | Part X | Recommended for improved efficiency. |

Common Issues and Solutions

In any mechanical system, users often encounter various challenges that can impede performance and efficiency. Understanding these common problems and their solutions can significantly enhance the overall functionality and longevity of the equipment.

Issue 1: Unresponsive Controls

If the control mechanisms fail to respond, it may indicate electrical or connectivity issues. First, check for loose wiring or damaged connections. If the problem persists, inspect the control module for faults and consider replacing it if necessary.

Issue 2: Overheating

Overheating is a frequent concern that can lead to severe damage. Ensure that the cooling system is functioning properly by checking for blockages in air vents and verifying coolant levels. Regular maintenance can prevent this issue from arising.

Issue 3: Unusual Noises

Strange sounds can signal mechanical wear or misalignment. Investigate the source of the noise and check for loose components or insufficient lubrication. Addressing these problems promptly can help avoid more significant repairs.

Issue 4: Reduced Efficiency

A decline in efficiency may be attributed to various factors, including dirty filters or worn parts. Regularly clean or replace filters and perform routine inspections to identify and rectify worn components before they affect overall performance.

By recognizing and addressing these prevalent issues, users can maintain optimal functionality and ensure the reliability of their equipment over time.

Upgrades for Improved Performance

Enhancing the efficiency and capabilities of your machine can lead to significant improvements in its overall functionality. By focusing on specific modifications, you can achieve a noticeable boost in power, speed, and responsiveness.

Engine Tuning: Adjusting the engine settings can optimize fuel consumption and increase horsepower, leading to a more dynamic experience.

Suspension Enhancements: Upgrading the suspension system provides better stability and handling, allowing for a smoother ride over various terrains.

Tire Selection: Choosing high-performance tires can improve traction and control, significantly impacting maneuverability and safety.

Advanced Technology: Incorporating modern tech features, such as GPS or telemetry systems, can enhance navigation and monitoring, contributing to a more efficient operation.

Resources for Further Information

Exploring additional materials can greatly enhance your understanding of machinery components and their functionalities. Various resources offer in-depth insights, technical specifications, and user manuals to support your learning journey.

Online Platforms

- Manufacturer’s Official Website

- Technical Forums and Community Discussions

- YouTube Tutorials and Demonstrations

Printed Materials

- Operation and Maintenance Manuals

- Industry Magazines and Journals

- Books on Mechanical Engineering Principles