Comprehensive Guide to Stihl BG 50 Replacement Parts Diagram

Maintaining outdoor tools requires a clear comprehension of their various elements. Knowing how these components interact is essential for effective operation and longevity. This section provides insights into the intricate assembly of a popular blower model, ensuring you are well-equipped for any maintenance task.

In exploring the key elements, we aim to enhance your understanding of how each piece contributes to the overall functionality. Familiarity with these details not only aids in troubleshooting but also empowers you to make informed decisions during repairs or upgrades.

Delving into the specifics can seem daunting, but grasping the ultimate configuration of your equipment simplifies the process. With the right knowledge, you can ensure your tool performs optimally, allowing you to focus on your outdoor projects with confidence.

Understanding Stihl BG 50 Components

Gaining insight into the various elements of a specific model can significantly enhance maintenance and troubleshooting efforts. Each component plays a crucial role in the overall functionality, contributing to efficiency and performance. Recognizing how these parts interact helps users ensure longevity and reliability in their equipment.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for generating power. |

| Fan Housing | Encloses the fan, directing airflow for optimal cooling. |

| Throttle Trigger | Controls the engine speed and power output. |

| Fuel Tank | Holds the mixture of gasoline and oil necessary for operation. |

| Air Filter | Prevents dirt and debris from entering the engine. |

Importance of Replacement Parts

Ensuring the longevity and efficiency of machinery relies heavily on the availability of components that can restore functionality. Without these crucial elements, performance can decline, leading to increased downtime and potential hazards during operation.

Enhancing Performance

Utilizing high-quality components can significantly improve the overall operation of equipment. When key elements are worn or damaged, they can hinder the effectiveness of the entire system.

Cost Efficiency

Investing in quality components can ultimately save money by extending the lifespan of machinery and reducing the frequency of repairs. A well-maintained machine requires less frequent intervention, allowing for better resource allocation.

| Benefits | Description |

|---|---|

| Improved Efficiency | Ensures smooth operation and optimal performance. |

| Increased Lifespan | Helps maintain equipment for longer periods. |

| Reduced Downtime | Minimizes interruptions in productivity. |

| Cost Savings | Lower maintenance and repair costs over time. |

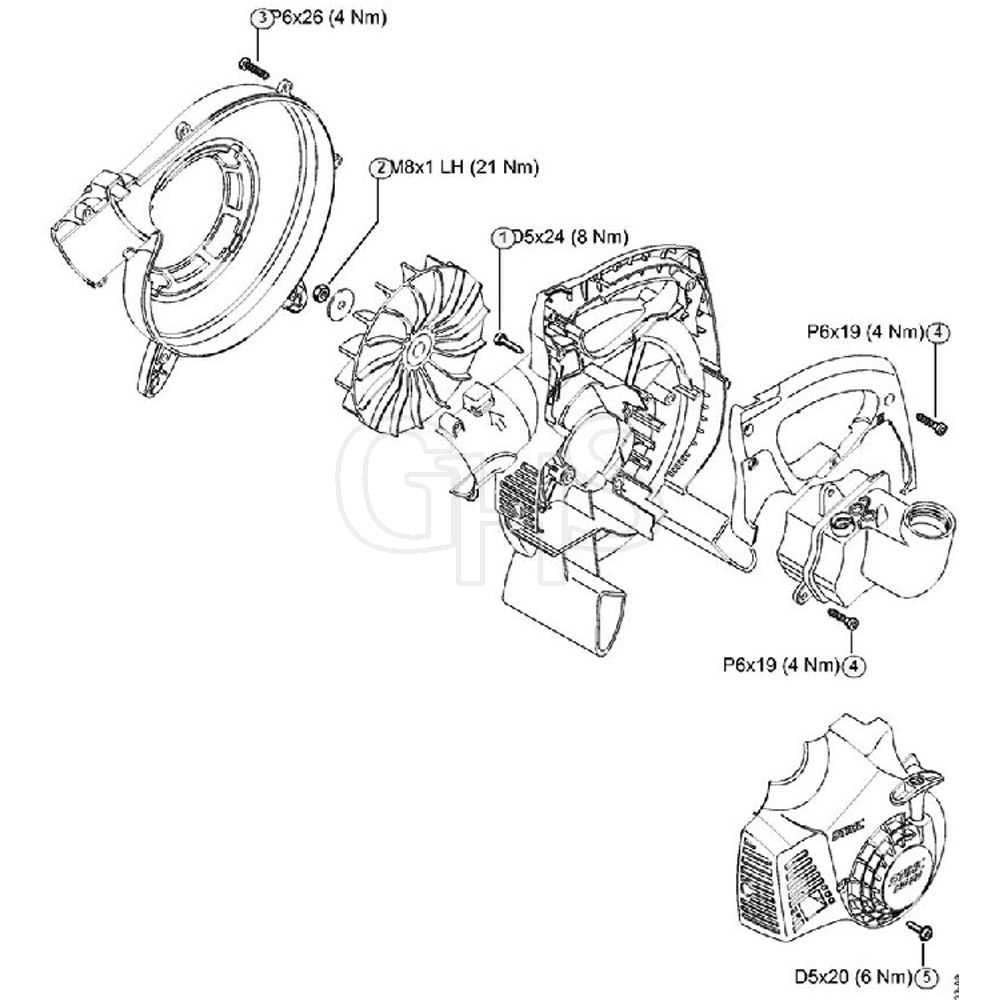

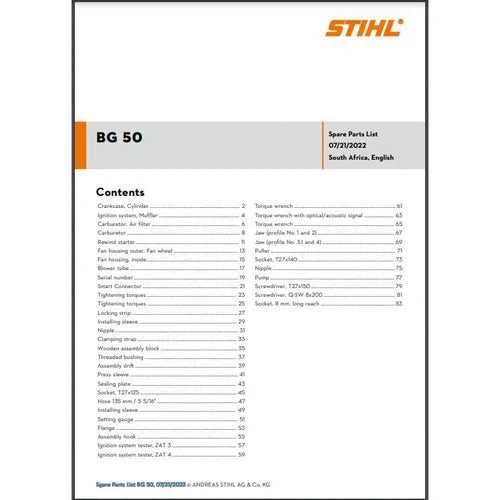

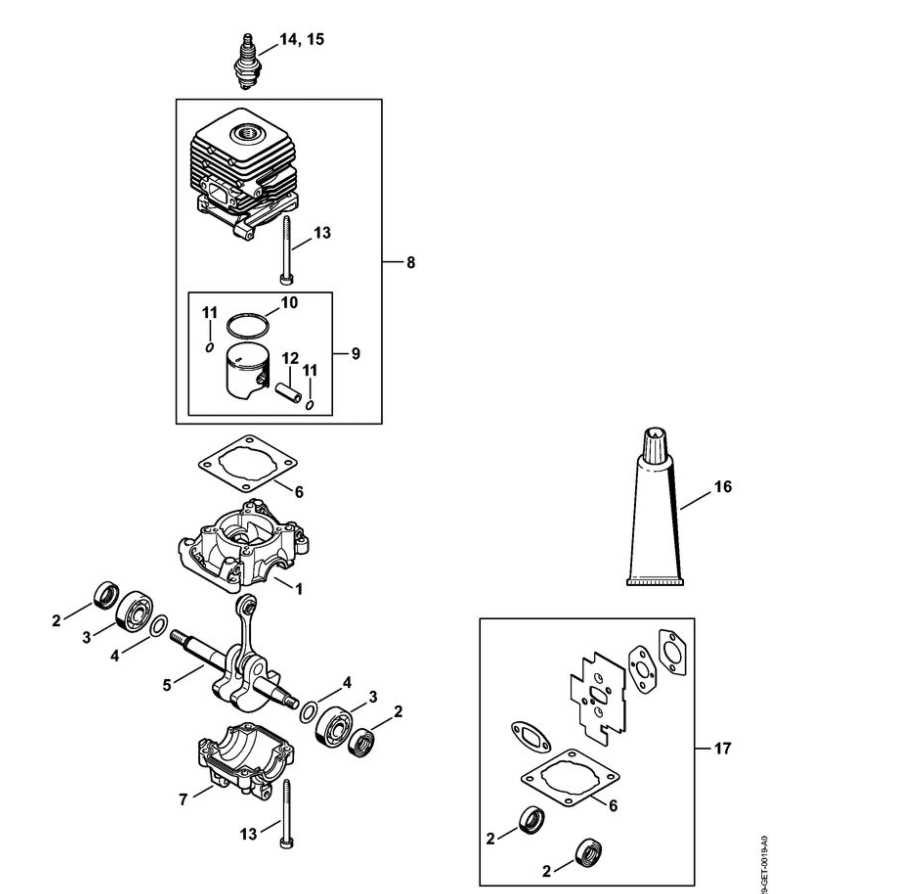

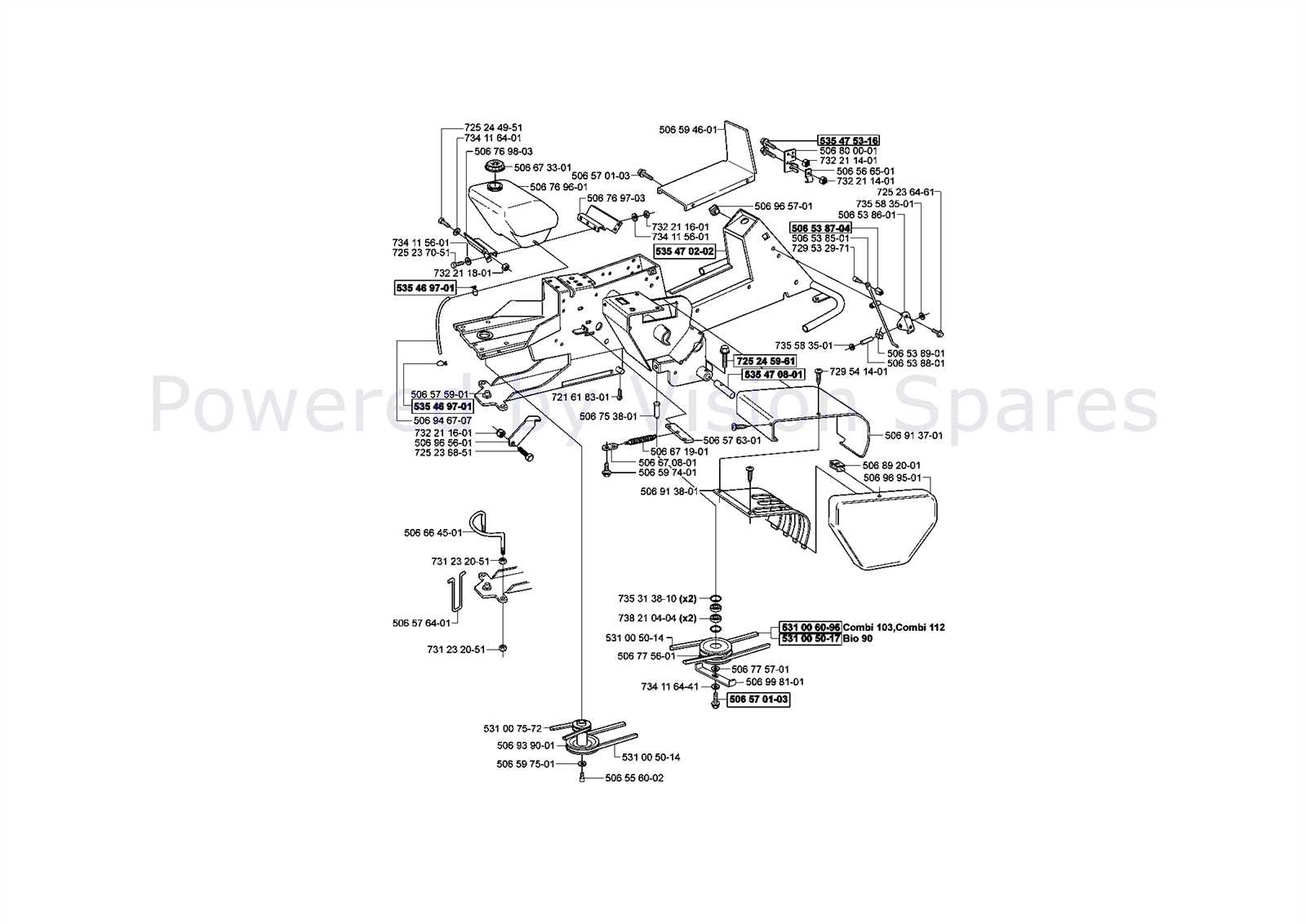

Detailed Diagram Overview

This section offers an in-depth look at the various components and their interrelationships within the equipment. Understanding the layout can significantly enhance maintenance and troubleshooting efforts.

Key Components

Familiarity with essential elements is crucial. Each component serves a unique function, contributing to the overall efficiency and performance of the machine. Identifying these parts can help in diagnosing issues and ensuring optimal operation.

Functionality and Interactions

Exploring how different elements interact provides insights into the machine’s workings. Recognizing the role of each segment not only aids in repair but also promotes a deeper appreciation for the technology behind the equipment.

How to Identify Parts

Understanding the components of your equipment is crucial for effective maintenance and repair. Recognizing these elements can enhance performance and longevity, ensuring your machine operates at its best.

Visual Inspection

Begin by performing a thorough visual examination. Look for any labels or markings that might indicate the specific component. Familiarize yourself with the overall layout to pinpoint areas of concern.

Consulting Manuals

Refer to the user manual or technical documentation for detailed descriptions. These resources often contain illustrations and specifications that can aid in identifying various components. Pay attention to any model-specific information, as it can greatly assist in your understanding.

Common Issues with Stihl BG 50

Many users encounter specific challenges with their handheld blowers that can affect performance and efficiency. Understanding these common problems can help in troubleshooting and maintaining optimal operation.

Engine Starting Difficulties

One frequent issue is trouble starting the engine. This can stem from fuel mixture problems, clogged filters, or issues with the ignition system. Regular maintenance and ensuring the correct fuel ratio can prevent these issues.

Loss of Power

Another common concern is a noticeable decrease in power during operation. This might be attributed to blockages in the air intake, a dirty spark plug, or issues with the carburetor. Cleaning and inspecting these components regularly can enhance performance and extend the lifespan of the device.

Finding Authentic Parts Suppliers

Locating genuine suppliers for components is essential for maintaining the efficiency and longevity of your equipment. Reliable sources not only ensure the quality of the items but also provide peace of mind regarding their performance.

Research is crucial; start by exploring trusted online marketplaces and official retailer websites. Look for reviews and ratings to gauge the reliability of these vendors.

Networking with fellow users through forums and social media can also lead to valuable recommendations. Engaging with communities can provide insights into suppliers known for their authenticity.

Lastly, always verify the credentials of any supplier by checking for certifications or partnerships with manufacturers. This step ensures you are acquiring quality items that meet your equipment’s specifications.

DIY Maintenance Tips

Proper upkeep of your equipment ensures longevity and optimal performance. Regular attention to key components can prevent issues and enhance efficiency. Here are some helpful strategies to keep your tools running smoothly.

| Task | Frequency | Tips |

|---|---|---|

| Clean Air Filter | Every 10 hours of use | Remove and gently wash with soap and water; allow to dry completely. |

| Inspect Spark Plug | Every 25 hours of use | Check for wear and replace if necessary; ensure proper gap is set. |

| Sharpen Blades | As needed | Use a file or sharpening tool; maintain the original angle for effectiveness. |

| Check Fuel Lines | Every season | Look for cracks or leaks; replace any damaged lines immediately. |

| Lubricate Moving Parts | Monthly | Use appropriate lubricant for all moving components to prevent rust. |

Following these simple guidelines will help ensure that your equipment remains in top condition, allowing you to complete tasks efficiently and effectively.

Cost-Effective Replacement Solutions

Finding affordable alternatives for your outdoor equipment can significantly enhance its longevity and performance. By exploring various options, you can ensure that your tools remain functional without straining your budget. This section delves into smart strategies for sourcing economical substitutes that meet quality standards and maintain efficiency.

Aftermarket Options

Aftermarket offerings provide a viable avenue for those seeking to save money while still obtaining reliable components. Many manufacturers produce compatible items that often mirror the specifications of the originals, allowing users to benefit from lower prices. Researching reputable suppliers and comparing their offerings can lead to excellent savings without compromising on quality.

DIY Solutions

Another cost-effective strategy involves engaging in do-it-yourself projects to repair or enhance your equipment. With basic tools and some online guidance, you can tackle various issues independently, thus reducing the need for professional assistance. This approach not only saves money but also fosters a deeper understanding of your tools and how to maintain them effectively.

Installation Guide for New Parts

This section provides a comprehensive overview of how to successfully integrate new components into your equipment. Ensuring that each element is properly installed is crucial for optimal performance and longevity. Following the outlined steps will help you navigate the installation process with confidence.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Ensure that your workspace is clean and organized to facilitate a smooth process. Refer to the manufacturer’s guidelines for specific instructions regarding each item you intend to install. This will not only help you understand the requirements but also prepare you for any specific adjustments needed during the process.

Installation Process

Start by carefully removing any existing components that need to be replaced. Take note of how each piece is positioned, as this will guide you in installing the new items correctly. Once everything is cleared, proceed with attaching the new components. Ensure that all fittings are secure and aligned properly. After installation, perform a thorough check to confirm that everything is functioning as intended before operating the equipment.

Benefits of Regular Upkeep

Consistent maintenance of equipment is essential for ensuring optimal performance and longevity. By implementing a routine care schedule, users can enhance efficiency and minimize unexpected breakdowns.

- Improved Performance: Regular care keeps machinery operating smoothly, enhancing productivity.

- Cost Efficiency: Preventative measures reduce the likelihood of costly repairs and replacements.

- Extended Lifespan: Proper upkeep can significantly prolong the life of equipment, offering better value over time.

- Safety: Routine checks help identify potential hazards, ensuring safer operation.

- Enhanced Reliability: Well-maintained equipment is more dependable, reducing downtime during critical tasks.

Incorporating regular upkeep into your routine not only safeguards your investment but also ensures that you achieve the ultimate performance from your tools.

Customer Reviews and Experiences

This section delves into the thoughts and insights shared by users regarding their encounters with various components. Their feedback provides valuable perspectives that can guide potential buyers in making informed decisions. Understanding the experiences of others helps to highlight the strengths and weaknesses of specific items, ensuring a more comprehensive view of what to expect.

| Customer Name | Rating | Review |

|---|---|---|

| John D. | 5/5 | Excellent quality and durability! I’ve used it for months without any issues. |

| Linda S. | 4/5 | Very reliable, but took some time to install. Overall, a good purchase. |

| Michael R. | 3/5 | Average performance. Works fine but not as robust as I expected. |

| Sarah T. | 5/5 | Fantastic product! The efficiency is remarkable, and it exceeded my expectations. |

| David K. | 2/5 | Disappointed with the quality. Had to replace it sooner than I thought. |

User experiences not only inform potential buyers about reliability and performance but also emphasize the importance of making the right choice for their specific needs. Engaging with these reviews can help individuals feel more confident in their selections.