Comprehensive Parts Diagram for Craftsman LT1000 Riding Mower

Maintaining your outdoor machinery requires a thorough understanding of its various elements. Every unit comprises numerous intricate components that work in harmony to ensure optimal performance. Familiarity with these elements is essential for effective upkeep and troubleshooting.

Visualizing the Assembly can significantly aid in identifying potential issues and streamlining repairs. By examining the layout and relationships between different sections, users can better grasp how each part contributes to the overall function. This knowledge empowers operators to make informed decisions during maintenance.

Whether you’re a seasoned expert or a novice, having access to a clear representation of the machinery’s structure enhances your ability to perform necessary adjustments. Such resources not only facilitate repairs but also extend the lifespan of your equipment, ultimately leading to a more efficient gardening experience.

Understanding the Craftsman LT1000

This section aims to provide insights into a particular model of lawn maintenance equipment that has garnered attention for its efficiency and user-friendly design. With a blend of robust engineering and intuitive features, this machine has become a favored choice for homeowners looking to maintain their yards with ease.

One of the key aspects of this equipment is its powerful engine, which ensures reliable performance over varied terrains. Additionally, the cutting mechanism is designed to deliver a clean and precise trim, contributing to an aesthetically pleasing landscape.

| Feature | Description |

|---|---|

| Engine Power | Robust power to handle different lawn conditions. |

| Cutting Width | Designed for efficient grass cutting, reducing time spent on maintenance. |

| Comfort Features | Ergonomically designed seating and controls for enhanced user experience. |

| Durability | Built with high-quality materials for longevity and reliability. |

Understanding these components can aid users in making informed decisions about maintenance and repairs, ensuring optimal performance throughout the equipment’s lifespan.

Common Issues with Riding Mowers

Many individuals face various challenges when operating their outdoor machines. Understanding these common problems can help users maintain their equipment effectively and prolong its lifespan. This section explores frequent complications encountered, offering insights into potential causes and solutions.

Engine Troubles

One of the most prevalent issues is engine failure, which can stem from multiple factors, including inadequate fuel supply, spark plug malfunctions, or dirty air filters. Regular maintenance, such as checking fuel levels and replacing filters, can significantly mitigate these problems.

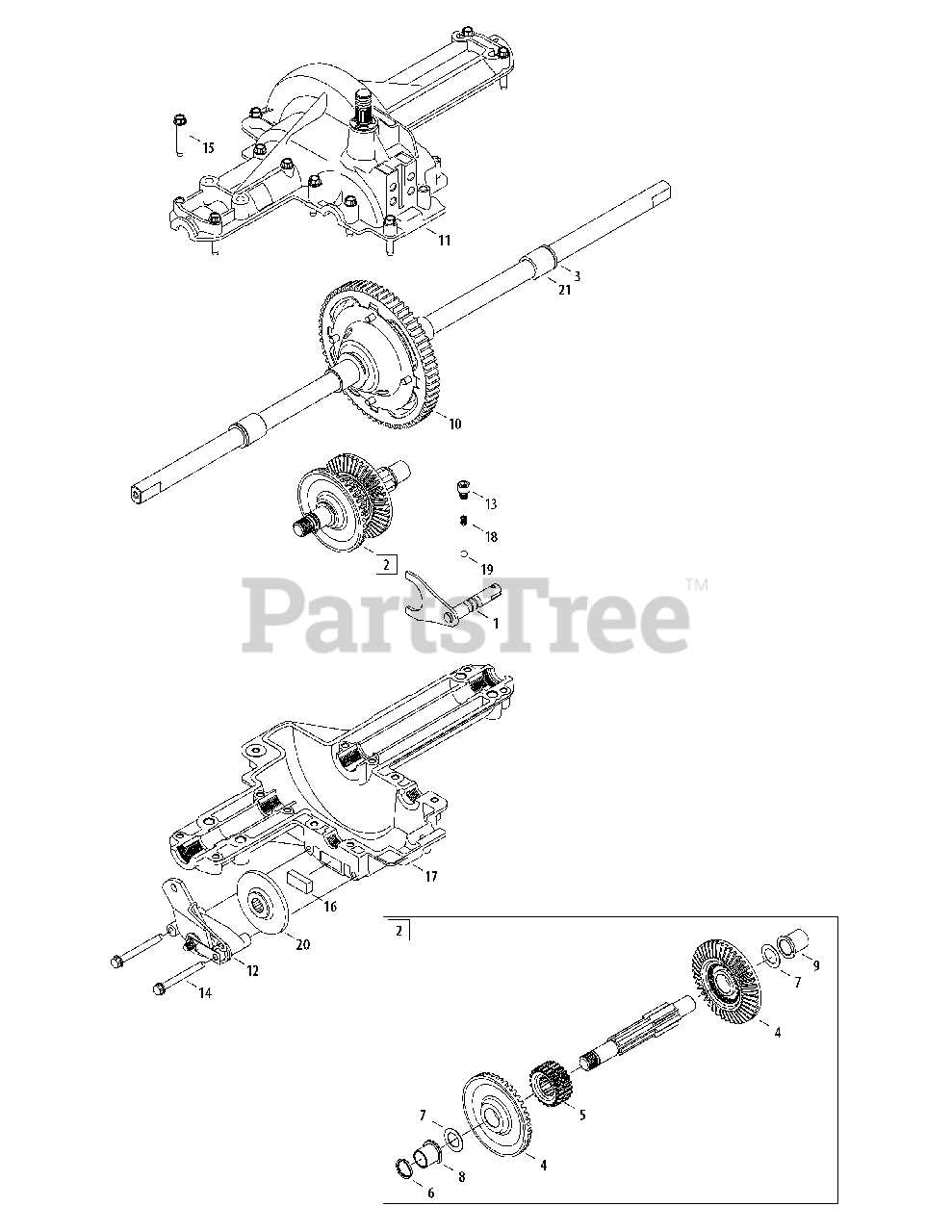

Transmission Problems

Another common concern involves transmission difficulties. Symptoms may include sluggish movement or complete loss of drive. These issues can often be traced back to low fluid levels or worn-out components. Regular inspections and timely replacements are essential for ensuring smooth operation.

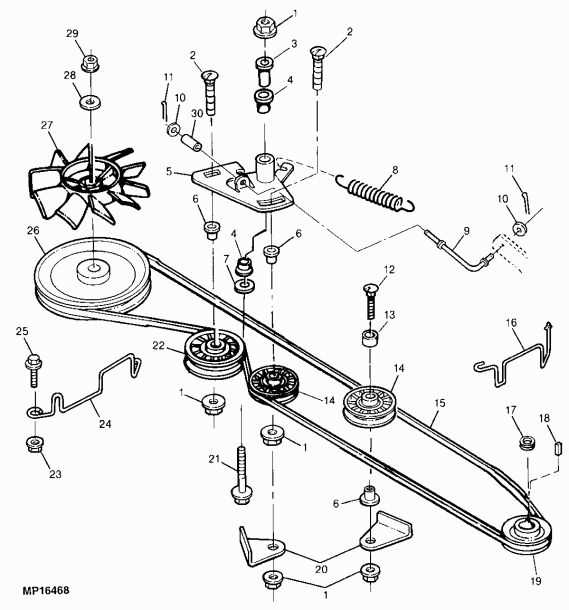

Importance of Parts Diagrams

Understanding the components of machinery is crucial for maintenance and repair. Visual representations help users identify various elements and their relationships, enhancing troubleshooting efficiency and ensuring smoother operations.

Benefits of Visual Guides

- Clarity: Simplifies complex systems into understandable visuals.

- Efficiency: Saves time by quickly locating specific components.

- Precision: Reduces the risk of errors during repairs.

Enhanced Learning Experience

- Facilitates better comprehension of machinery functions.

- Supports training for new users and technicians.

- Encourages a proactive approach to maintenance.

Where to Find Replacement Parts

Locating suitable components for your equipment can enhance performance and extend its lifespan. Fortunately, there are several reliable sources to explore when in need of these essential elements.

- Local Retailers: Visit nearby hardware or specialty stores that stock outdoor machinery supplies.

- Online Marketplaces: Websites such as eBay or Amazon offer a vast selection of components for various models.

- Manufacturer Websites: Check the official website of the manufacturer for direct purchases or authorized dealers.

- Forums and Community Groups: Engage with enthusiasts in online forums; they often share recommendations for sources.

- Recycling Centers: Consider local salvage yards where you might find used but functional components.

Utilizing these resources can help ensure you find the necessary items to keep your equipment operating efficiently.

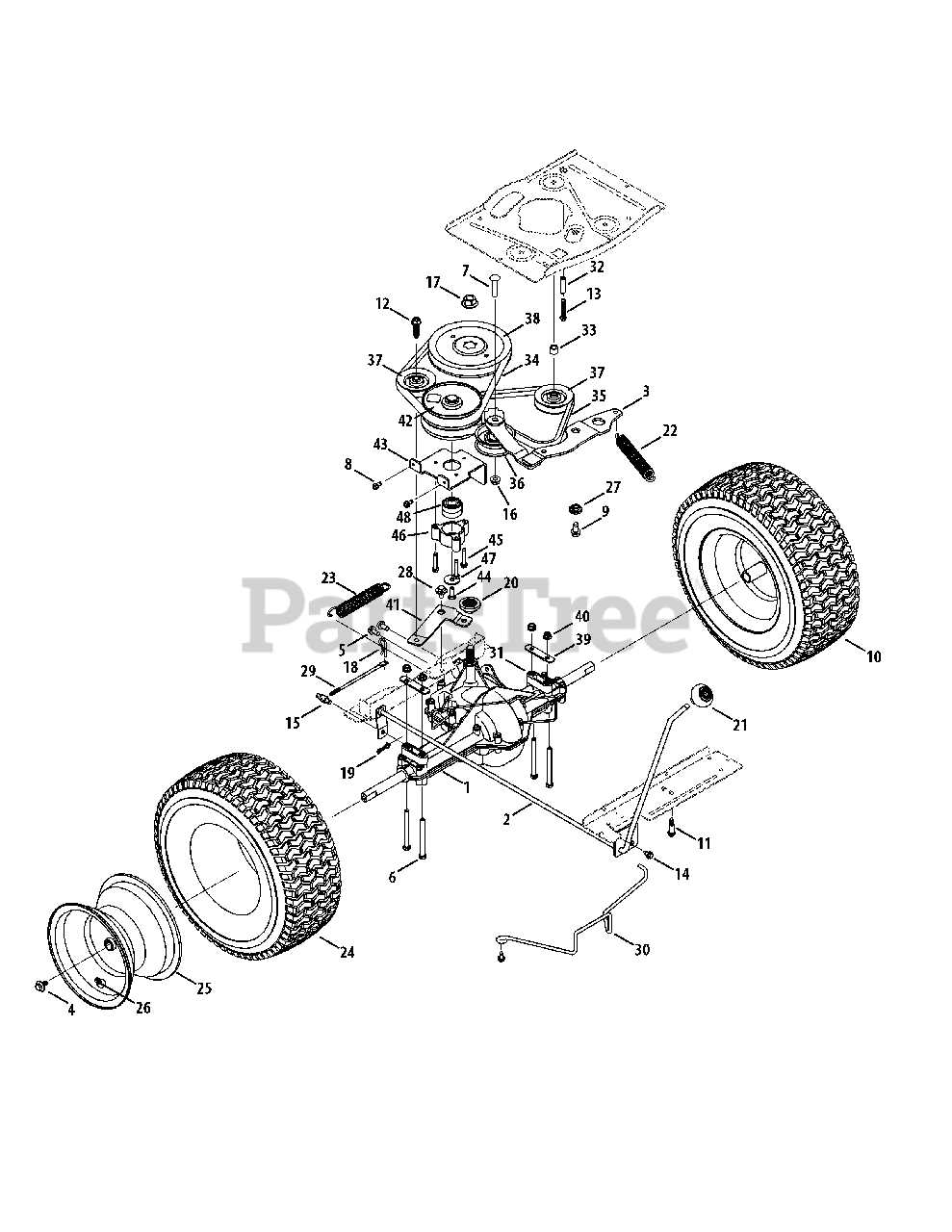

Key Components of LT1000 Mowers

Understanding the fundamental elements of lawn care machines is essential for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency, durability, and user satisfaction.

Engine: The heart of the machine, the engine provides the necessary power to operate various functions, influencing speed and cutting capabilities.

Transmission: This element transfers power from the engine to the wheels, allowing for smooth movement and control over terrain.

Deck: The deck houses the cutting blades and determines the width of the cut, impacting the overall mowing experience.

Blades: Sharp and robust, these components ensure a clean cut, promoting healthy grass growth and an attractive lawn appearance.

Wheels: Designed for traction and maneuverability, the wheels enable efficient navigation across different surfaces and slopes.

Battery: A crucial element for electric start models, the battery provides the energy needed for ignition and accessory functions.

Chassis: The framework that supports all components, the chassis contributes to the machine’s stability and durability during operation.

By delving into these key components, users can achieve the ultimate understanding of their equipment and ensure its longevity through proper care and maintenance.

Maintenance Tips for Longevity

Proper care is essential for extending the lifespan of your equipment. Regular maintenance not only enhances performance but also prevents costly repairs down the line. Here are some key practices to ensure your machine remains in top condition.

Regular Inspections

- Check for wear and tear on belts and blades.

- Inspect tires for proper inflation and tread wear.

- Examine fluid levels, including oil and coolant.

Routine Cleaning

- Remove debris from undercarriage to prevent rust.

- Clean air filters to ensure efficient airflow.

- Wipe down exterior surfaces to prevent corrosion.

Following these guidelines will help maintain efficiency and ensure reliable operation for years to come.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of the assembly, making it easier to identify individual elements and their relationships.

To navigate these illustrations, consider the following steps:

- Familiarize Yourself with Symbols: Each diagram uses specific icons to represent different parts. Make sure to refer to the legend for clarification.

- Identify Key Sections: Diagrams are often divided into segments. Focus on one section at a time for clarity.

- Cross-Reference with Manuals: Use your service manual alongside the illustration for detailed descriptions and specifications.

- Take Notes: Jot down important information about each component to keep track of your findings.

By mastering these techniques, you’ll enhance your ability to assess and manage mechanical assemblies effectively.

Identifying Faulty Parts Quickly

Efficiently recognizing malfunctioning components can significantly enhance maintenance routines and prolong the lifespan of your equipment. By understanding key indicators of wear and failure, users can take prompt action to address issues before they escalate.

Common Signs of Malfunction

- Unusual noises during operation

- Reduced performance or efficiency

- Visible wear or damage on components

- Inconsistent operation or stalling

Steps for Quick Identification

- Perform regular visual inspections.

- Listen for abnormal sounds during use.

- Check for leaks or unusual vibrations.

- Refer to manuals for troubleshooting guidance.

Upgrading vs. Replacing Components

When maintaining outdoor machinery, users often face the choice between upgrading existing components and outright replacement. Both options have their advantages and drawbacks, making it essential to consider several factors before making a decision.

Benefits of Upgrading

- Cost Efficiency: Upgrading typically requires less financial investment than replacing entire systems.

- Enhanced Performance: Improvements can lead to better efficiency and functionality without needing a complete overhaul.

- Less Downtime: Upgrades can often be implemented quickly, reducing the time machinery is out of service.

- Compatibility: Many upgrades are designed to work seamlessly with existing components, minimizing compatibility issues.

When Replacement Makes Sense

- Severe Wear: Components that are extensively worn or damaged may need to be replaced to ensure safety and reliability.

- Outdated Technology: In some cases, older parts may not be compatible with newer technology or advancements.

- Long-Term Savings: Replacing an outdated component may ultimately be more cost-effective in the long run if it significantly improves overall performance.

- Warranty Considerations: New components may come with warranties, providing peace of mind for the user.

Evaluating the specific situation, budget, and long-term goals will guide the decision between upgrading and replacing. Each approach can contribute to the optimal performance of outdoor machinery.