Comprehensive Guide to Ryobi 2000 PSI Pressure Washer Parts Diagram

The functionality of a high-pressure cleaning machine relies on various essential elements working in harmony. Recognizing these individual components is crucial for both effective operation and maintenance. This section aims to provide a comprehensive overview of the layout and interconnection of these vital parts.

Each component plays a significant role in ensuring the equipment delivers optimal performance. From the motor to the nozzle, understanding how these parts interact can enhance user efficiency and extend the life of the device. Additionally, a clear representation of the assembly allows for easier troubleshooting and repairs.

By familiarizing yourself with the structure of the cleaning apparatus, you can gain valuable insights into its operation. This knowledge will empower you to tackle common issues and make informed decisions when it comes to repairs or replacements.

Understanding the essential elements of a high-pressure cleaning device is crucial for both effective operation and maintenance. Each component plays a vital role in delivering optimal performance, ensuring that the equipment operates smoothly and efficiently during use.

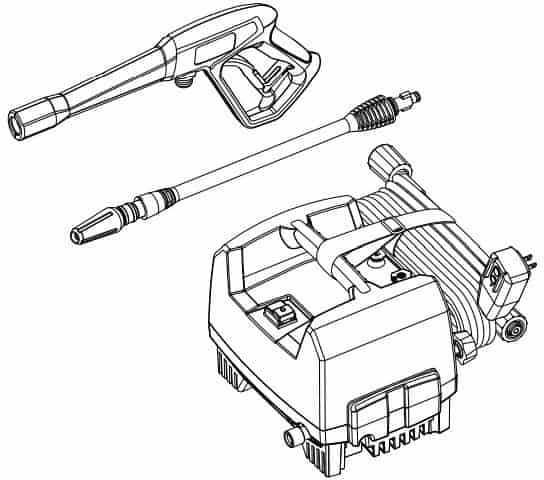

The primary elements of these cleaning machines include:

- Motor: The heart of the device, responsible for providing the necessary power to drive the pump.

- Pump: This part generates the force needed to expel water at high speeds, crucial for effective cleaning.

- Nozzle: The end attachment that controls the flow and direction of the water stream, allowing for various spray patterns.

- Hoses: Flexible tubes that transport water from the source to the cleaning tool, designed to withstand high pressure.

- Handle: The ergonomic grip that facilitates maneuverability and control during operation.

- Wheels: These provide mobility, making it easier to transport the equipment across different surfaces.

Each of these components contributes to the overall functionality and effectiveness of the cleaning apparatus. Familiarity with these elements can help users optimize their cleaning tasks and address any potential issues that may arise.

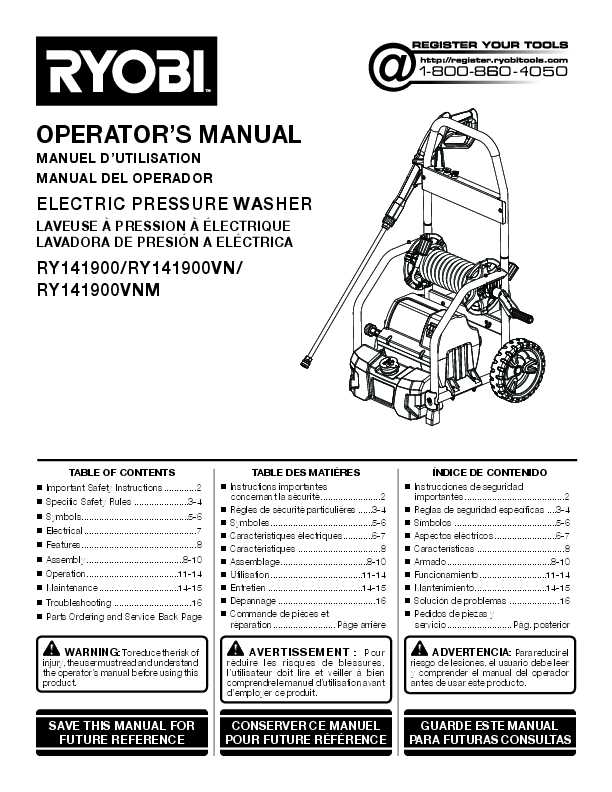

Understanding the Parts Diagram

Comprehending the visual representation of components is essential for efficient maintenance and troubleshooting of any cleaning equipment. This schematic serves as a guide, illustrating the relationship between various elements, ensuring users can identify and locate each section with ease.

The significance of this illustration lies in its ability to simplify complex machinery. By breaking down the unit into identifiable sections, users can approach repairs and maintenance tasks with confidence. Each labeled component aids in understanding the overall functionality, promoting a smoother workflow.

Additionally, familiarity with the schematic enhances the user’s ability to communicate effectively with support services. Whether ordering replacements or seeking assistance, knowing the terminology and layout empowers users to articulate their needs accurately.

Overall, mastering the components depicted in this visual reference not only streamlines maintenance tasks but also fosters a deeper appreciation for the machinery’s design and functionality.

How to Read the Diagram

Understanding the visual representation of components is essential for effective maintenance and troubleshooting of your cleaning equipment. This section will guide you through the key aspects of interpreting the illustration, ensuring you can easily identify each element and its function.

Here are some important points to consider when examining the illustration:

- Labels and Symbols: Pay attention to the markings associated with each component. They often indicate the specific function or role of that part in the overall system.

- Numbering System: Many illustrations employ a numbering system to correspond with a legend or key. This allows for quick identification and reference.

- Color Coding: Colors may be used to differentiate between various types of components, such as electrical parts, mechanical elements, or fluid pathways.

- Connections and Layout: Observe how the components are interconnected. Understanding the layout can help you grasp how the system operates as a whole.

By familiarizing yourself with these elements, you will enhance your ability to interpret the visual representation effectively and carry out necessary tasks with confidence.

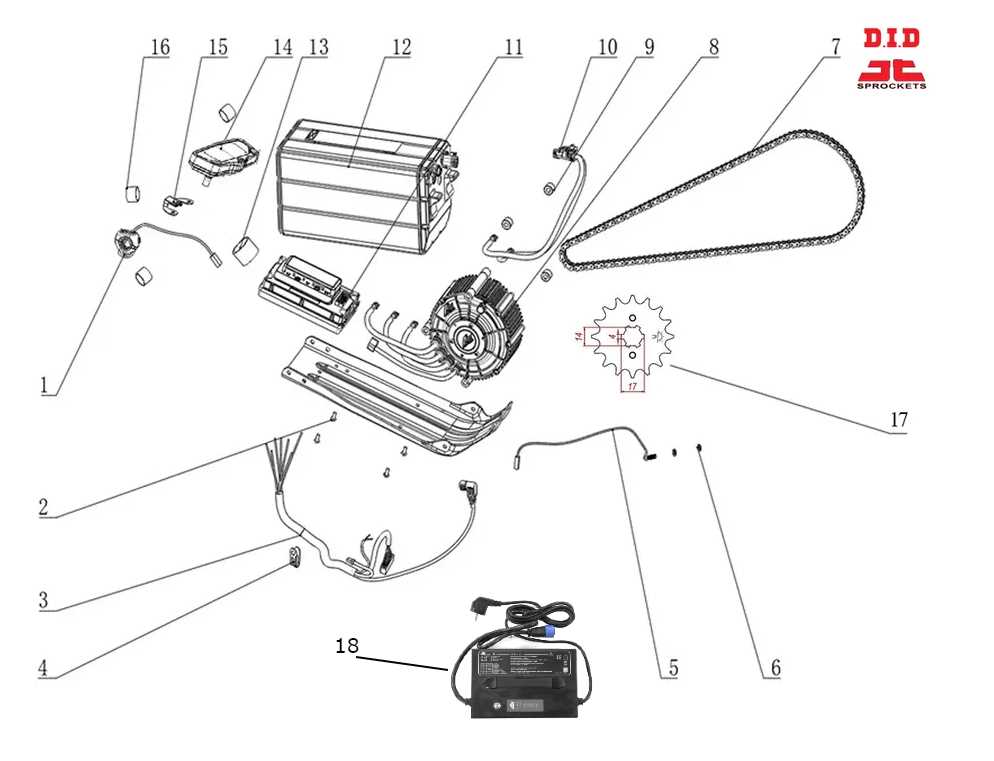

Identifying Common Replacement Parts

Understanding the key components of your cleaning device is essential for maintaining its efficiency and performance. Familiarizing yourself with these crucial elements can significantly enhance your ability to address common issues and ensure optimal functionality.

Among the most frequently needed elements are the nozzle, which regulates the flow of water and impacts the cleaning power, and the pump, responsible for generating the necessary pressure for effective operation. Additionally, the hose plays a vital role, delivering water from the source to the nozzle. Recognizing these essential components will allow users to quickly identify when a replacement is necessary.

Furthermore, elements like the filter and spray wand are critical for maintaining cleanliness and enhancing the user experience. By regularly checking and replacing these parts as needed, you can extend the lifespan of your cleaning equipment and improve its overall performance.

Tools Needed for Maintenance

Proper upkeep of your cleaning equipment is essential for optimal performance and longevity. Having the right tools at your disposal can make maintenance tasks more efficient and effective. Below is a list of essential instruments to consider when caring for your unit.

Wrenches: Adjustable or socket wrenches are crucial for loosening and tightening various components. These tools ensure that connections remain secure and leak-free.

Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for accessing different sections of your machine. They allow for easy removal of covers and attachments.

Cleaning Solutions: Using appropriate cleaning agents will help maintain the integrity of your equipment. Look for products specifically designed for the type of machinery you own.

Protective Gear: Safety should always come first. Gloves and goggles are recommended to protect yourself from any debris or cleaning solutions during maintenance tasks.

Brushes: Soft-bristled brushes are effective for removing dirt and grime from sensitive areas without causing damage. Regular brushing can enhance performance and prevent buildup.

Having these essential tools readily available will facilitate a smoother maintenance process, ensuring your cleaning equipment operates efficiently for years to come.

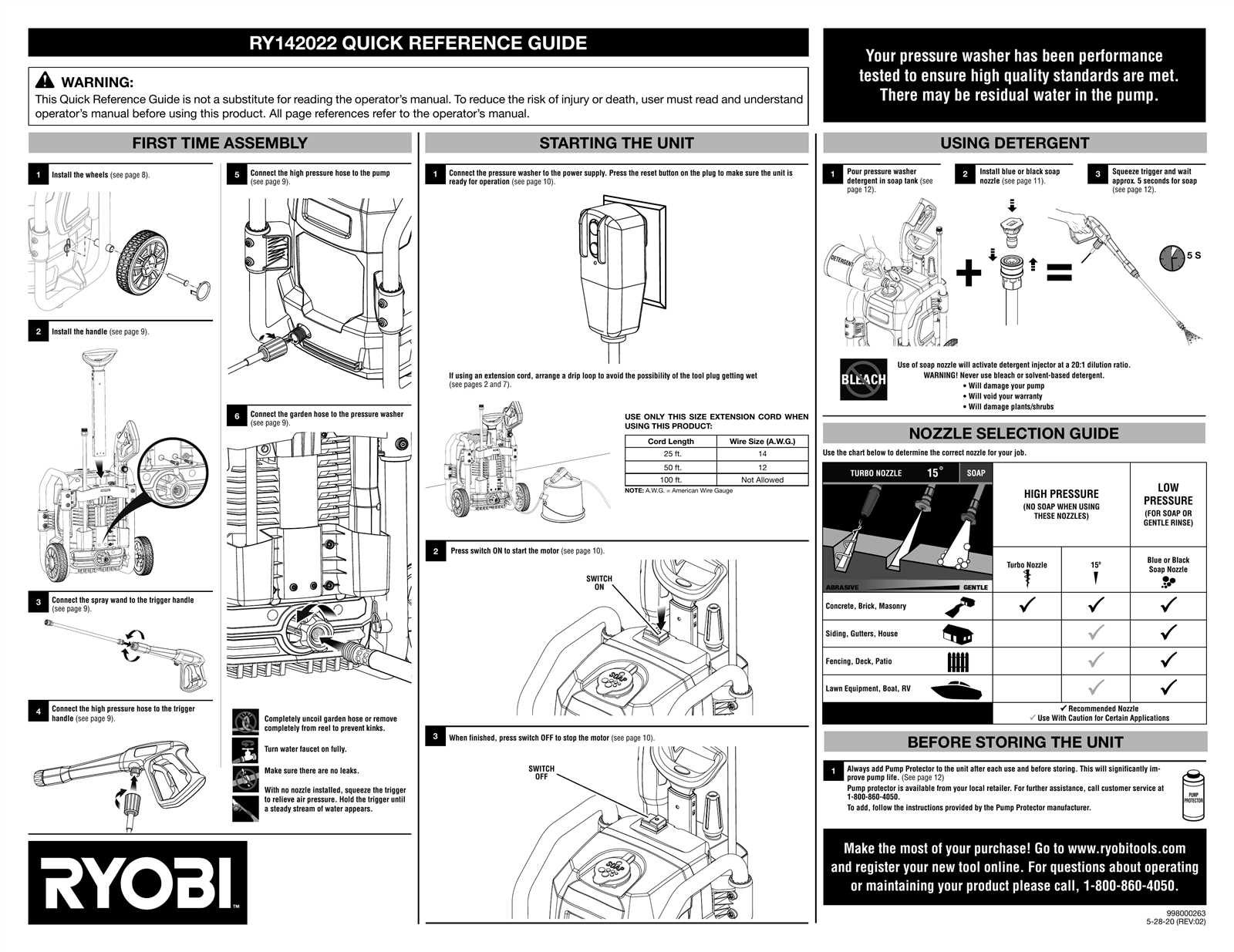

Assembly Instructions for Key Parts

Understanding the assembly of essential components is crucial for ensuring the efficient operation of your cleaning device. Each element plays a significant role in its overall functionality, and proper assembly guarantees optimal performance. This section will guide you through the assembly process, focusing on the most vital parts that contribute to the effective use of your equipment.

To begin, ensure that all necessary components are gathered and easily accessible. Carefully align each piece according to the specified arrangement, following the provided instructions. Pay close attention to the connections, ensuring that they fit snugly and securely. Use appropriate tools for fastening to avoid any damage to the components.

Next, verify that all seals and gaskets are properly positioned to prevent leaks during operation. It is essential to check for any signs of wear or damage to these elements, as they are critical for maintaining efficiency. Once everything is in place, perform a thorough inspection to confirm that all connections are tight and secure.

Finally, refer to the manufacturer’s recommendations for any additional steps specific to your model. By following these guidelines, you can ensure that your equipment is assembled correctly, providing reliable performance for all your cleaning tasks.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on any equipment is essential for preventing accidents and injuries. Adhering to specific guidelines can significantly reduce risks and create a safer working environment. It is crucial to familiarize yourself with these precautions before beginning any repair work.

Here are some important safety measures to consider:

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, safety goggles, and sturdy footwear to protect yourself from potential hazards. |

| Disconnect Power Source | Before starting any repairs, ensure that the power source is completely disconnected to prevent accidental activation. |

| Work in a Well-Ventilated Area | Ensure your workspace is adequately ventilated to avoid inhaling harmful fumes that may be released during repairs. |

| Use Proper Tools | Utilize the correct tools for the task at hand. This minimizes the risk of injury and ensures effective repair work. |

| Read Manufacturer Guidelines | Refer to the manufacturer’s instructions for specific safety recommendations related to your equipment model. |

Following these safety protocols will help ensure a smooth and hazard-free repair process. Prioritizing safety not only protects you but also enhances the longevity of the equipment being serviced.

Troubleshooting Common Issues

Maintaining optimal performance of your cleaning device can sometimes present challenges. This section aims to address typical problems users may encounter, providing practical solutions to enhance the efficiency and longevity of your equipment.

Insufficient Cleaning Power

If your equipment isn’t delivering the expected cleaning results, several factors could be at play. First, ensure that the nozzle is appropriately selected for the task at hand. Additionally, check for any blockages in the spray tip or hose that may restrict water flow. Regular maintenance, such as descaling and cleaning filters, can also significantly improve performance.

Engine Starting Issues

Encountering difficulty in starting the engine can be frustrating. Begin by confirming that there is sufficient fuel in the tank. Examine the spark plug for any signs of wear or damage; replacing it may resolve ignition issues. Furthermore, ensure that the choke is set correctly and that the device is on a stable, level surface during startup.

Where to Purchase Replacement Parts

Finding the right components for your cleaning equipment is crucial for maintaining its performance. There are various reliable sources to consider when looking for new items to ensure your device operates efficiently.

Online Retailers

The internet offers a wide array of options for sourcing replacement components. Here are some popular choices:

- Specialized websites dedicated to cleaning equipment

- General online marketplaces with a diverse inventory

- Manufacturer’s official online store

Local Stores

Visiting physical stores can provide immediate access to what you need. Consider these locations:

- Home improvement centers with dedicated sections for maintenance supplies

- Local hardware shops that may carry a selection of necessary items

- Specialized repair shops with expertise in cleaning machinery