Parts Diagram for Ryobi AP1305

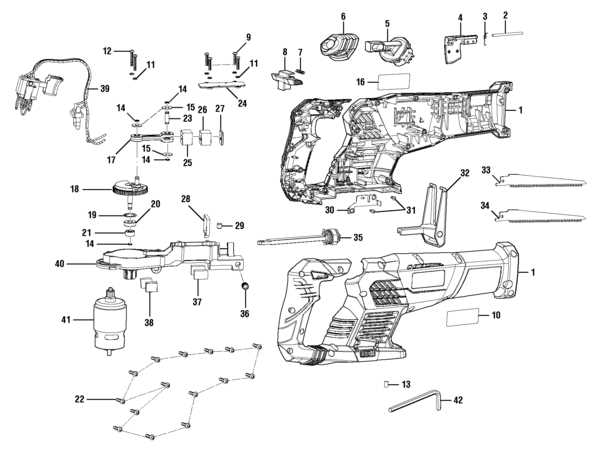

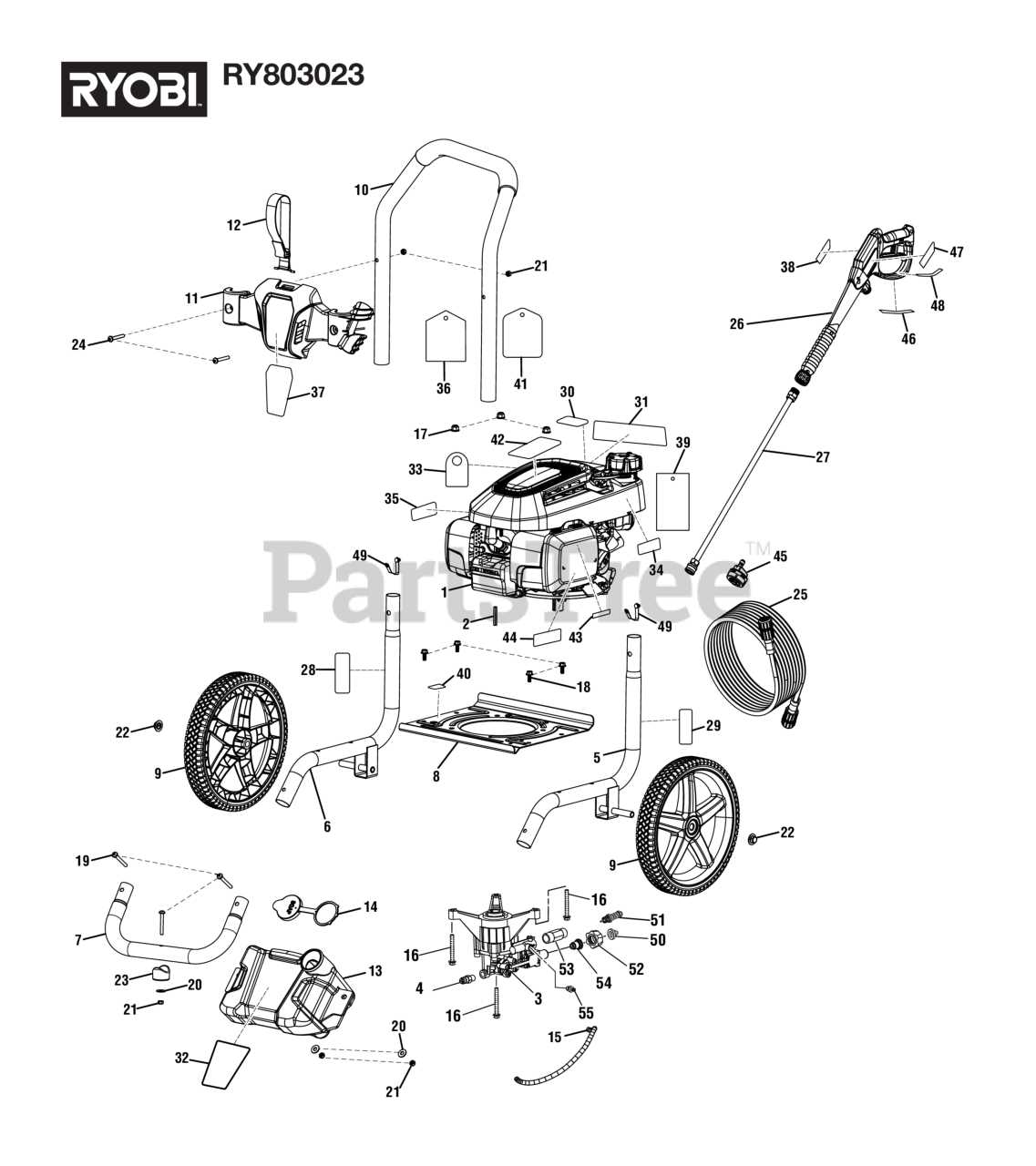

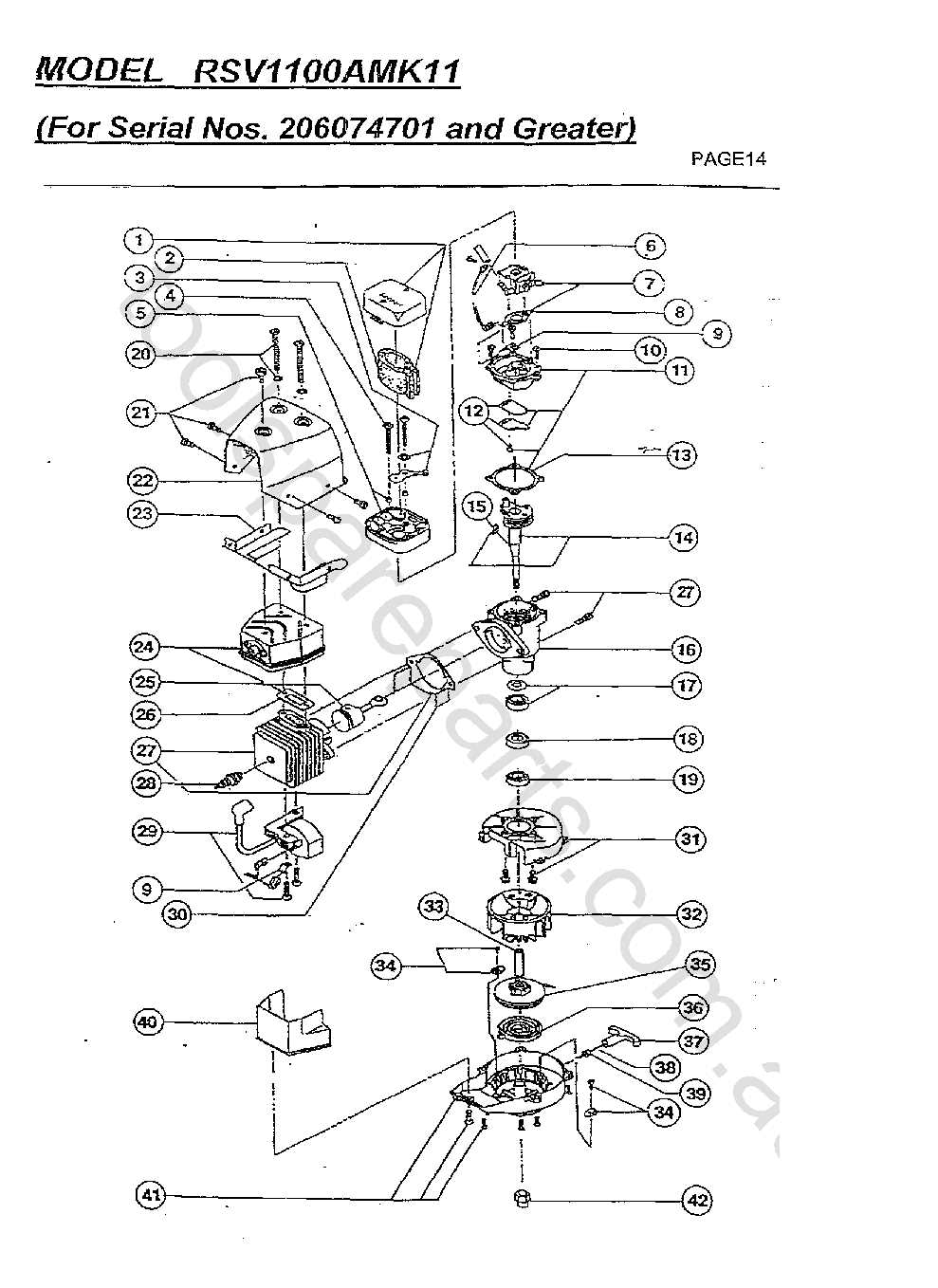

When it comes to maintaining and repairing equipment, having a clear overview of its individual elements is crucial. A well-structured representation of these components not only aids in identifying parts but also simplifies the assembly and disassembly process. Such illustrations serve as valuable guides, ensuring users can effectively manage their devices without unnecessary complications.

Comprehending the layout of a machine can significantly enhance your troubleshooting skills. Whether you’re looking to replace a worn-out section or just want to familiarize yourself with the inner workings, a visual reference provides clarity. With a detailed breakdown of the structure, you can navigate through the various sections with ease.

Ultimately, having access to a thorough reference empowers you to make informed decisions regarding repairs and upgrades. Understanding how each component fits together fosters confidence in handling your equipment, leading to improved performance and longevity.

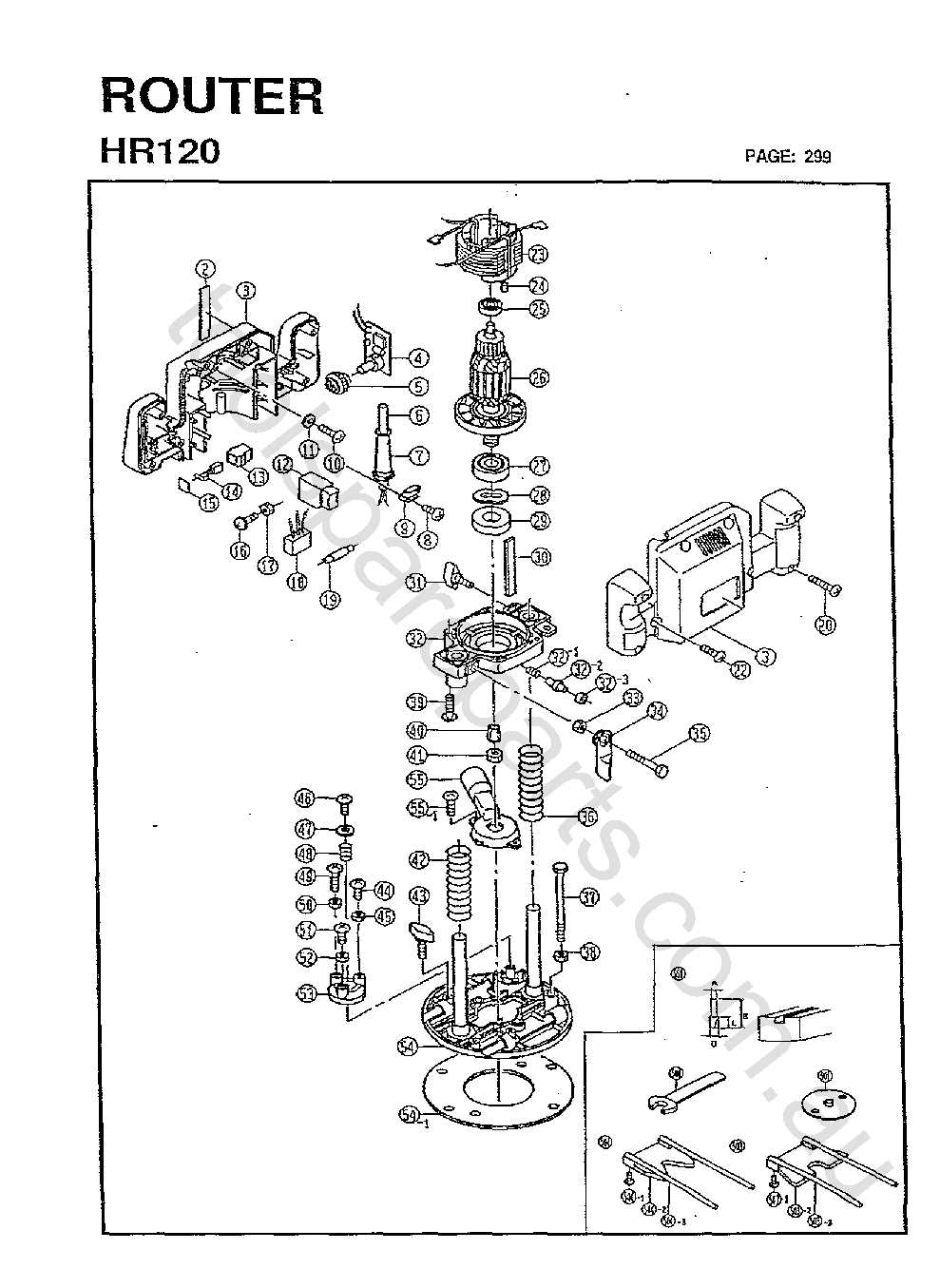

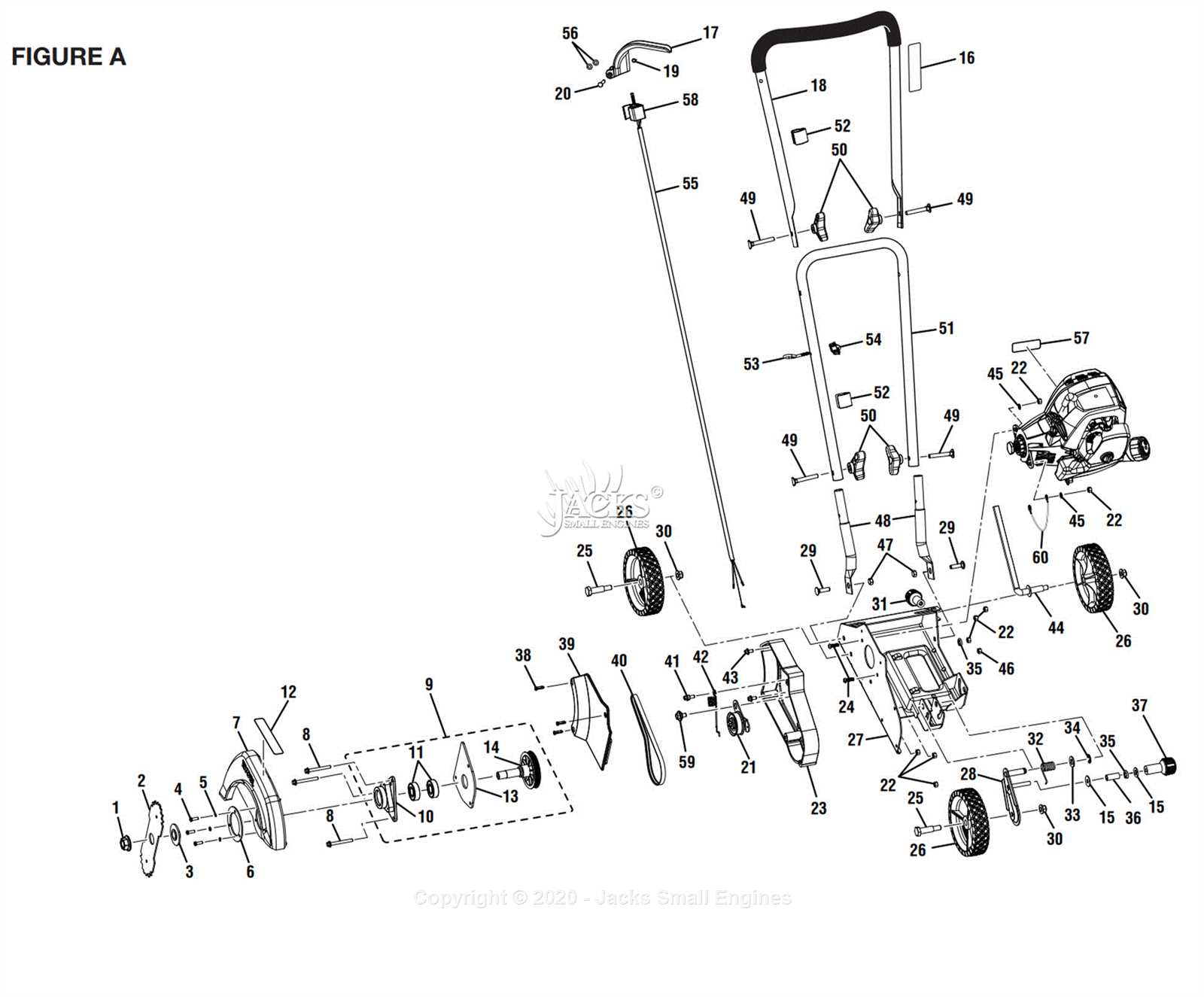

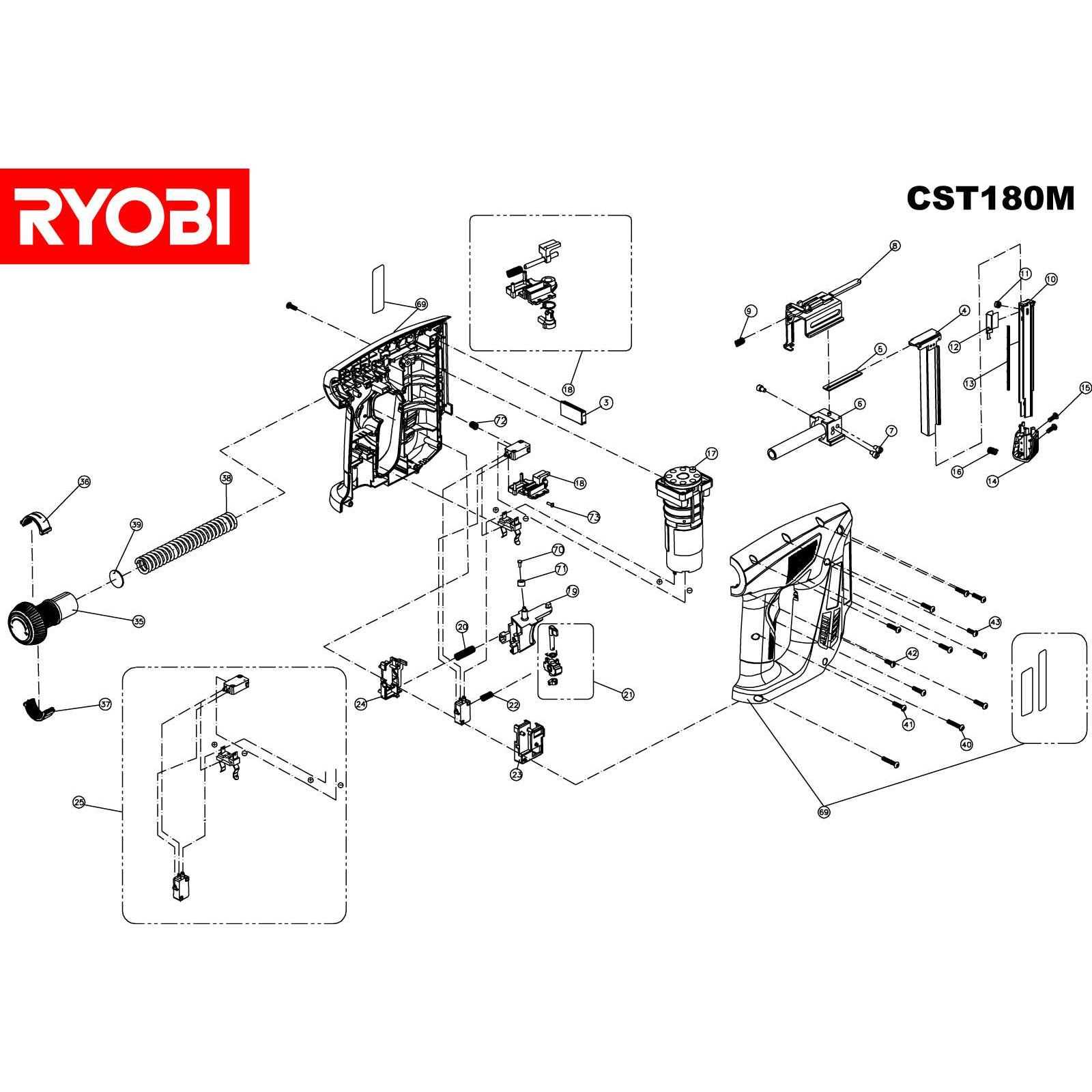

Having a clear visual representation of the components involved in a device is crucial for effective maintenance and repair. This illustration serves as a valuable reference tool, enabling users to identify each element’s position and function. It simplifies the process of locating specific pieces, understanding their roles, and recognizing how they interact with one another.

Each section of the representation is typically labeled with unique identifiers, making it easier to locate and order replacements when necessary. This visual guide not only aids in assembling or disassembling the unit but also enhances the overall understanding of its functionality.

| Component | Description | Function |

|---|---|---|

| Motor | Main power source | Drives the operational mechanisms |

| Handle | Grip area | Provides control and maneuverability |

| Base Plate | Bottom support | Stabilizes the entire assembly |

| Blade | Cutting edge | Facilitates the cutting action |

Main Components of the AP1305

This section explores the key elements that contribute to the functionality and efficiency of the device in question. Each part plays a crucial role in ensuring optimal performance, enhancing usability, and extending the overall lifespan of the equipment. Understanding these essential components can help users appreciate the intricate design and engineering behind the tool.

Power System

The power system serves as the heart of the equipment, providing the necessary energy to operate all functions effectively. It typically consists of a battery or an electrical input system, ensuring that the device runs smoothly and reliably during use.

Cutting Mechanism

Central to the functionality of this tool is the cutting mechanism, which enables precise and efficient operation. This assembly may include blades, motors, and guides that work together to facilitate smooth cutting, making it easier for users to achieve their desired results.

Identifying Replacement Parts

Understanding the various components of your equipment is crucial for effective maintenance and repair. By familiarizing yourself with these elements, you can ensure that your machine operates smoothly and efficiently. This section provides a guide to recognizing essential components, enabling you to make informed decisions when seeking replacements.

| Component Name | Description | Common Issues |

|---|---|---|

| Motor Assembly | The part responsible for powering the device. | Overheating, unusual noises. |

| Blade | The cutting element that performs the main function. | Dullness, chipping, or bending. |

| Housing | The outer shell that protects internal components. | Cracks, dents, or wear. |

| Switch | The control mechanism for powering the unit on and off. | Failure to engage, intermittent operation. |

| Handle | The part that allows for easy maneuverability. | Loose fittings or breaks. |

Maintenance Tips for Longevity

To ensure the durability and optimal performance of your equipment, regular maintenance is crucial. By following a few simple guidelines, you can extend its lifespan and enhance its efficiency. Implementing preventive care not only saves money in the long run but also improves the overall user experience.

Here are some essential practices to consider:

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the device clean from dust and debris. Use a soft cloth to wipe surfaces and ensure that vents are unobstructed. |

| Inspection | Frequently check for signs of wear or damage. Address any issues immediately to prevent further complications. |

| Lubrication | Apply lubricant to moving parts as recommended. This reduces friction and helps in smooth operation. |

| Storage | Store the equipment in a dry, cool place when not in use. Avoid exposing it to extreme temperatures or moisture. |

| Follow Guidelines | Adhere to the manufacturer’s instructions for maintenance. This ensures that you are performing the correct procedures for care. |

Common Issues and Solutions

This section addresses frequent problems encountered with the equipment and offers practical solutions to resolve them effectively. Understanding these common challenges can help users maintain optimal performance and extend the lifespan of their devices.

1. Performance Degradation

Users may notice a decline in efficiency over time. This can manifest as reduced power output or sluggish operation. Here are some common reasons and their solutions:

- Clogged Filters: Regularly check and clean or replace air and fuel filters to ensure proper airflow and fuel delivery.

- Worn Components: Inspect belts and blades for wear and replace them if they appear damaged or worn out.

- Improper Fuel Mixture: Ensure the correct fuel-to-oil ratio is used to maintain engine performance.

2. Electrical Issues

Electrical problems can disrupt operation and lead to frustration. Common electrical issues include:

- Dead Battery: Check battery connections and charge or replace the battery if necessary.

- Faulty Switch: If the equipment fails to start, inspect the power switch for damage and replace it if required.

- Loose Connections: Ensure all electrical connections are secure to prevent intermittent power loss.

Where to Purchase Spare Parts

Finding reliable sources for replacement components is crucial for maintaining the functionality of your equipment. Various options are available to ensure you can acquire the necessary items quickly and efficiently. Here are some effective ways to locate these essential materials.

Online Retailers

- Numerous websites specialize in selling various components, offering a wide selection at competitive prices.

- Major online marketplaces often provide customer reviews, helping you gauge the quality and reliability of the items.

- Utilize search filters to narrow down your options based on specific criteria, such as compatibility and price range.

Local Stores and Distributors

- Visiting nearby hardware or specialized tool shops can be beneficial for immediate needs.

- Local distributors often have knowledgeable staff who can assist in identifying the correct items for your requirements.

- Check if they offer order services for components that are not readily available in-store.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right tools is crucial for ensuring a smooth and effective repair process. Utilizing appropriate equipment not only simplifies the job but also enhances safety and efficiency. Below is a list of essential tools commonly needed for various repair tasks.

Essential Hand Tools

- Wrenches: A set of adjustable and fixed wrenches for loosening or tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers in different sizes for handling screws of various types.

- Pliers: Needle-nose and regular pliers for gripping and manipulating components.

- Hex Keys: Also known as Allen wrenches, useful for fastening hexagonal socket screws.

Power Tools

- Drill: A versatile tool for creating holes and driving screws efficiently.

- Impact Driver: Ideal for loosening stubborn fasteners and driving screws into tough materials.

- Reciprocating Saw: Effective for cutting through materials quickly and easily during disassembly.

Having these tools at hand will make the repair process much more manageable, enabling you to complete tasks effectively and with confidence.

Step-by-Step Repair Process

This section outlines a systematic approach to fixing common issues encountered with your equipment. Following these steps will ensure a thorough examination and effective resolution of the problems at hand.

1. Gather Necessary Tools and Materials

Before starting the repair, assemble all essential tools and replacement components. Having everything on hand will streamline the process and minimize interruptions. Common tools include screwdrivers, wrenches, and pliers.

2. Disassemble the Equipment

Carefully take apart the unit, starting with the outer casing. Take note of the arrangement of parts as you remove them. Using a labeling system can help keep track of each component’s original position, making reassembly easier.

Safety Precautions During Maintenance

When performing maintenance on equipment, it is essential to adhere to specific safety measures to ensure a secure working environment. Proper precautions help prevent accidents and injuries, protecting both the technician and the equipment. Always prioritize safety by following established guidelines before, during, and after any maintenance tasks.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes items such as gloves, safety glasses, and ear protection. Each piece of equipment serves a distinct purpose, minimizing the risk of injury from sharp edges, flying debris, or loud noise. Ensure that all PPE is in good condition and fits properly before beginning any work.

Work Environment and Tools

Maintaining a clean and organized workspace significantly contributes to safety. Clear away any unnecessary tools or materials that could cause tripping hazards. Additionally, inspect all tools for damage before use. Using well-maintained tools reduces the likelihood of malfunctions or accidents during maintenance. Properly store equipment when not in use to keep the area tidy and prevent unauthorized access.

Comparing with Other Models

When evaluating various tools in the same category, it’s essential to consider their features, performance, and overall design. Each model brings unique specifications that can cater to different user needs and preferences. This comparison highlights how certain options stack up against others, providing insights that can assist in making an informed choice.

One key aspect to examine is the power and efficiency of each tool. While some models may offer higher wattage or enhanced battery life, others may excel in lightweight design or portability. Here are a few points of comparison:

- Performance: Analyze the output and reliability during operation.

- Durability: Consider the materials used and their resistance to wear over time.

- Ease of Use: Look into ergonomic designs and intuitive controls.

Additionally, price points and warranty options can significantly influence the decision-making process. Users often weigh their budget against the desired features and the longevity of the tool.

In summary, comparing different models allows potential buyers to find the right fit for their specific tasks, whether they prioritize power, comfort, or affordability. Careful consideration of these factors can lead to a more satisfactory purchase.

Customer Reviews and Feedback

This section provides insights into user experiences and impressions regarding the product. It aims to highlight the strengths and weaknesses as reported by those who have utilized it, offering potential buyers a clearer perspective on what to expect.

Positive feedback often focuses on the reliability and ease of use of the equipment. Many users appreciate the intuitive design, which simplifies operation and maintenance. Customers frequently mention the efficiency of the device in various applications, noting its performance exceeds expectations.

On the other hand, some constructive criticisms point out areas for improvement. Issues such as the availability of replacement components or specific operational challenges are noted. Users have expressed a desire for better customer support options, particularly in resolving minor issues that may arise during use.

Overall, the collective feedback serves as a valuable resource for prospective buyers, ensuring they make informed decisions based on real-world experiences.