Understanding the Ryobi Miter Saw Parts Diagram for Efficient Repairs

When engaging in woodworking or construction tasks, familiarity with the essential elements of cutting equipment is crucial. A clear grasp of these components not only enhances efficiency but also ensures safety and longevity of the tool. Whether you’re a seasoned professional or a hobbyist, understanding the intricacies of your device can ultimately improve your craftsmanship.

In this section, we will delve into the various sections of a cutting instrument, focusing on their functionality and interrelationships. Recognizing how each element contributes to the overall performance will empower users to make informed decisions during maintenance and repairs.

Moreover, exploring the layout of these components can demystify any potential issues that may arise. With proper knowledge, troubleshooting becomes more straightforward, paving the way for smoother operations and successful projects.

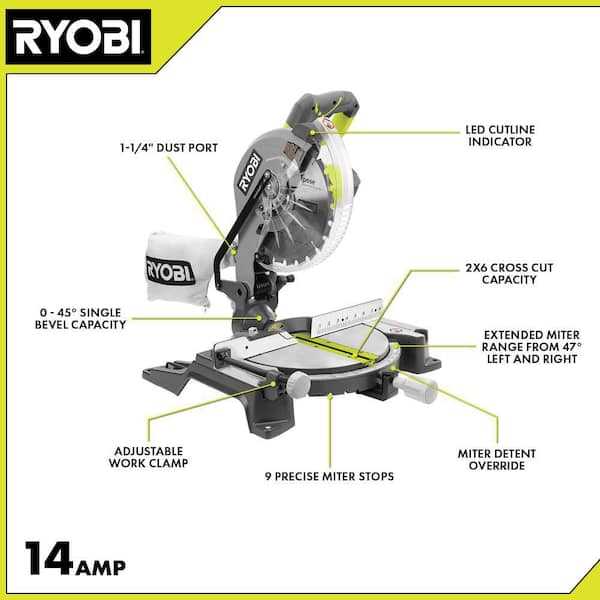

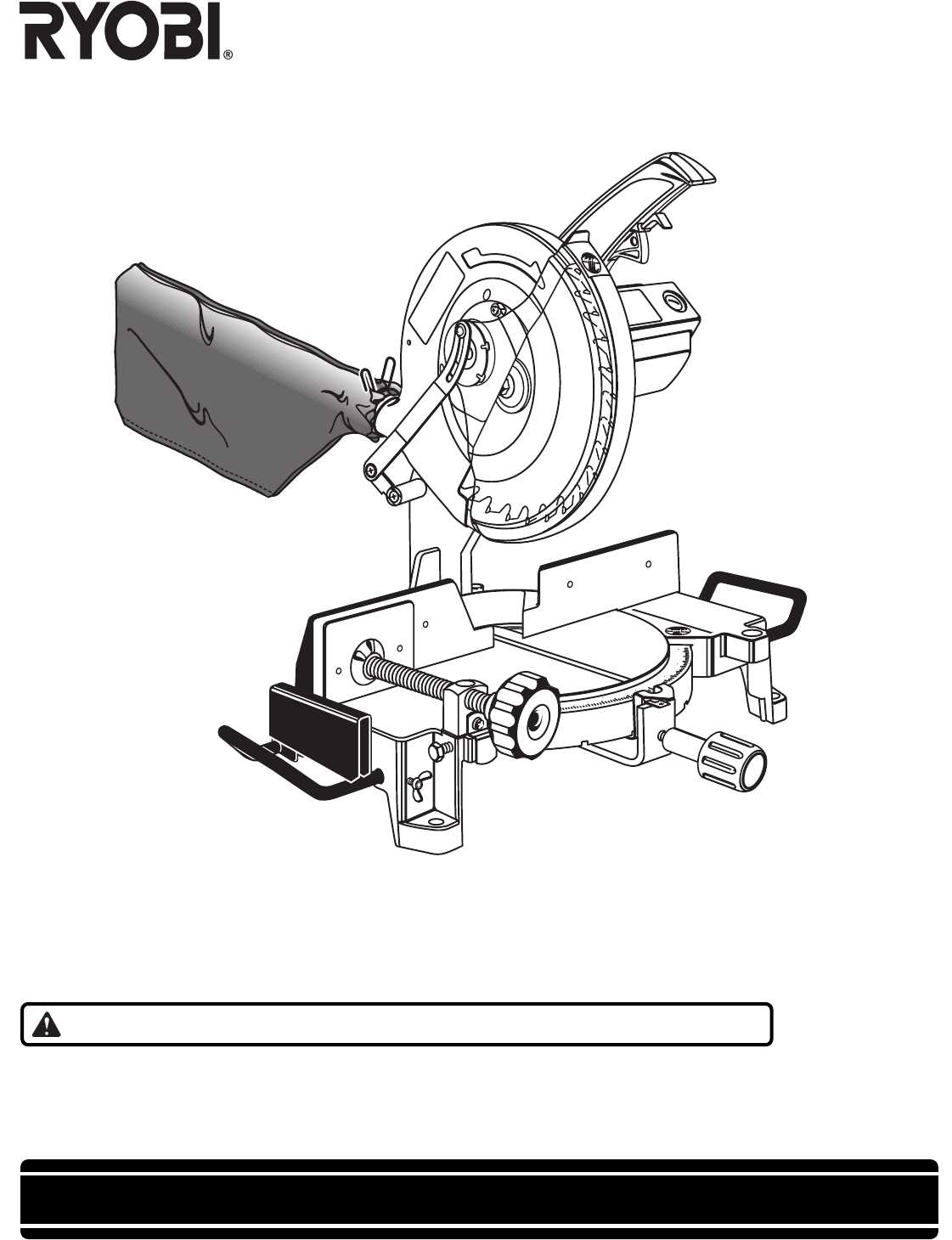

Understanding Ryobi Miter Saw Components

Grasping the essential elements of a cutting tool is crucial for both effective operation and maintenance. Each component plays a significant role in ensuring precision and safety, contributing to the overall performance of the machine. Familiarity with these parts allows users to troubleshoot issues and enhance their woodworking experience.

| Component | Description |

|---|---|

| Base | The foundation that supports the entire assembly, providing stability during use. |

| Arm | This part allows for the vertical movement, essential for making angled cuts. |

| Blade | Designed for cutting through various materials, its type and sharpness affect performance. |

| Fence | Ensures accuracy by guiding the material being cut, keeping it aligned. |

| Handle | Provides control during operation, contributing to user safety and precision. |

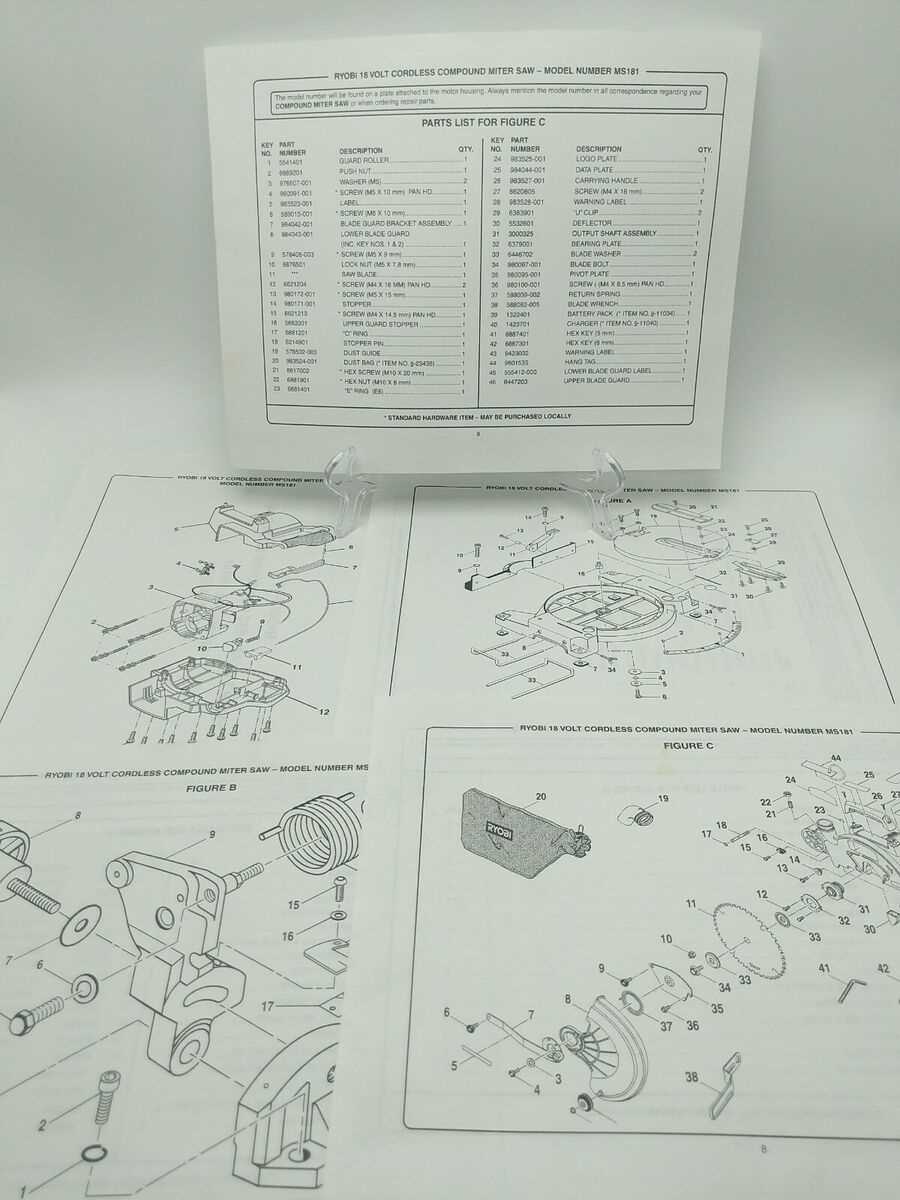

Importance of Miter Saw Parts Diagram

Understanding the components of any cutting tool is crucial for effective operation and maintenance. A visual representation of its elements aids users in identifying each section, ensuring smoother functionality and enhanced safety during use.

Maintenance becomes significantly easier when one has access to a clear representation of all components. This knowledge not only facilitates timely replacements but also helps in avoiding potential hazards associated with malfunctioning parts.

Moreover, a well-organized reference can enhance efficiency during assembly and disassembly, allowing users to delve deeper into the mechanics of the tool. Familiarity with individual sections leads to a better understanding of overall performance.

In conclusion, a comprehensive visual guide is the ultimate resource for anyone looking to optimize their experience with cutting equipment. It promotes safety, efficiency, and longevity, making it an invaluable tool for both amateurs and professionals alike.

Identifying Key Parts of Ryobi Saws

Understanding the essential components of cutting tools is crucial for effective operation and maintenance. Each element plays a vital role in ensuring precision and efficiency during use. Familiarity with these components enhances performance and prolongs the tool’s lifespan.

Motor: The powerhouse of the tool, responsible for driving the cutting action.

Blade: The primary element for cutting, available in various sizes and types for different applications.

Fence: A guiding structure that ensures accurate alignment and stability during cutting tasks.

Base: The foundation that supports the entire assembly, providing balance and preventing movement.

Bevel and Angle Adjustments: Mechanisms that allow for precise angle settings, facilitating diverse cutting techniques.

Recognizing these key components will enable users to operate their tools more effectively and address any maintenance needs that may arise.

Common Issues with Miter Saw Parts

Tools that rely on precise cutting mechanisms often encounter various challenges that can affect their performance. Understanding these frequent problems is essential for maintaining optimal functionality and ensuring safe operation. By identifying issues early, users can enhance the longevity of their equipment and improve accuracy.

Blade Misalignment is a prevalent concern, leading to inaccurate cuts. Regular checks can help ensure that the cutting edge is properly positioned.

Motor Overheating can occur due to prolonged use or lack of maintenance. This can result in reduced efficiency and potential damage to internal components.

Wear and Tear on critical components, such as bearings or bushings, can lead to decreased performance. Regular inspections can help spot these issues before they escalate.

Dust Accumulation within the housing can hinder performance and pose safety risks. Implementing a routine cleaning schedule is crucial to maintaining functionality.

Addressing these common concerns can ultimately improve the tool’s reliability and performance, ensuring that it meets the demands of any project.

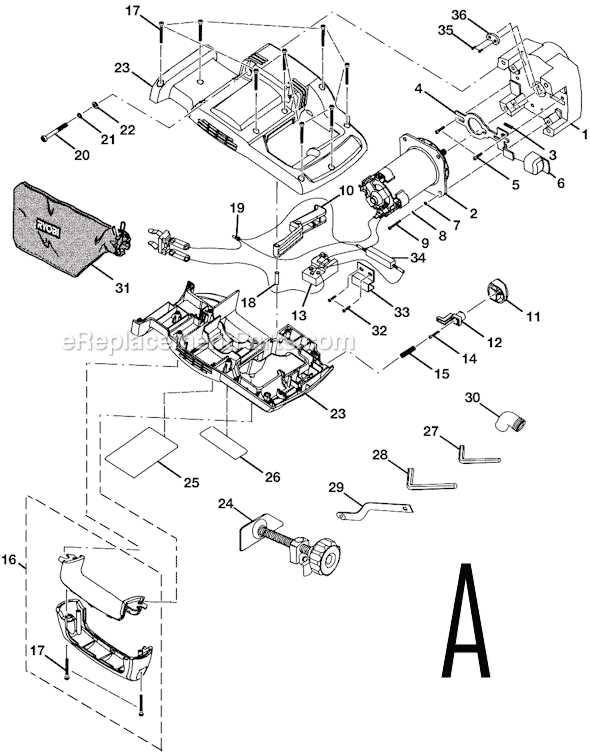

How to Use the Diagram Effectively

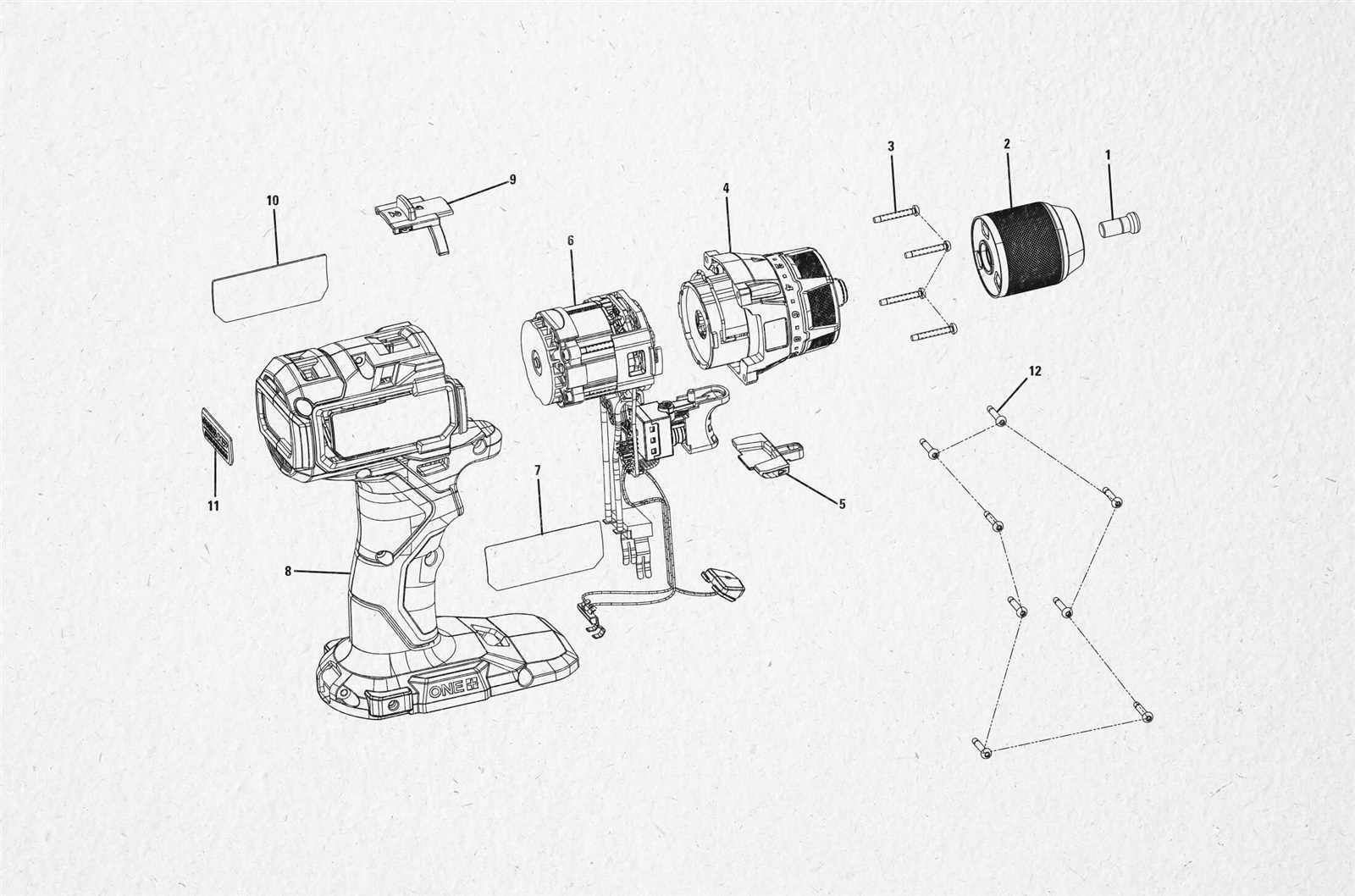

Understanding the visual representation of components is crucial for anyone looking to perform maintenance or repairs. This guide will help you navigate the illustration to identify and utilize various elements efficiently, ensuring you have all necessary information at your fingertips.

Identifying Key Components

Begin by familiarizing yourself with the layout. Each section typically corresponds to specific functionalities, making it easier to pinpoint what you need. Look for labels and annotations that provide context about each part.

Utilizing the Information for Repairs

Once you’ve identified the components, use the illustration to assist in troubleshooting. Cross-reference any issues you encounter with the corresponding elements in the representation, allowing for a systematic approach to resolving problems.

| Component | Description |

|---|---|

| Base | The foundation that supports the assembly. |

| Blade | The cutting tool essential for functionality. |

| Handle | The part used for maneuvering the device. |

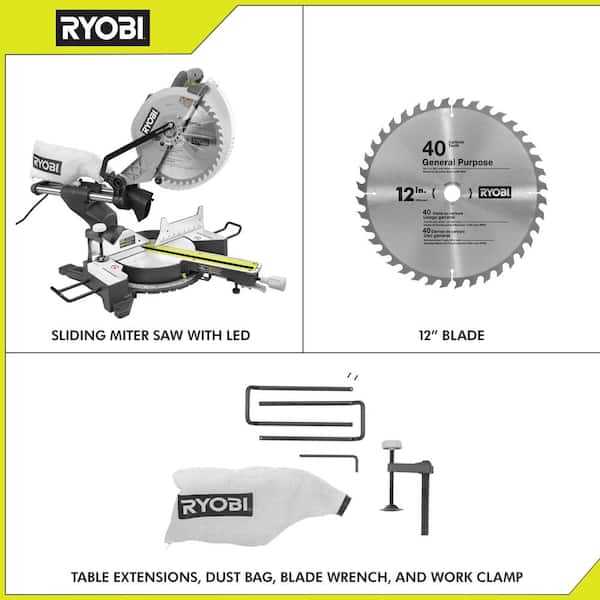

Replacement Parts for Ryobi Miter Saws

Ensuring your cutting tool operates smoothly often requires finding the right components when replacements are needed. Understanding the available options and maintaining the device’s efficiency is crucial for both professionals and DIY enthusiasts alike. This section delves into the various alternatives that can enhance the longevity and performance of your equipment.

Common Components to Consider

When looking for replacements, several key elements are essential to keep in mind. Each plays a vital role in the functionality of the tool, and knowing which to replace can make a significant difference.

| Component | Description |

|---|---|

| Blade | Critical for precision cuts, available in various sizes and types. |

| Motor | Powers the tool; ensure compatibility for optimal performance. |

| Base | Provides stability; can wear out over time, affecting accuracy. |

| Fences | Help in guiding the material; essential for precise cuts. |

Finding the Right Alternatives

Locating suitable replacements can be streamlined by consulting product manuals or manufacturer websites. Additionally, engaging with user communities can provide insights and recommendations, ensuring that the right choices are made for sustained performance.

Maintenance Tips for Miter Saw Longevity

Ensuring the long-lasting performance of your cutting tool involves regular upkeep and attention to detail. A well-maintained machine not only operates more efficiently but also enhances safety during use. By following a few straightforward practices, you can extend the life of your equipment and improve its overall effectiveness.

Regular Cleaning

Keeping your device clean is essential for optimal performance. After each use, remove any dust and debris that accumulates on the surface and within the mechanisms. Utilize a soft brush or compressed air to reach tight spots. Regular cleaning prevents buildup that can hinder operation and cause premature wear.

Lubrication and Inspection

Periodic lubrication of moving parts is crucial for smooth operation. Check the manufacturer’s recommendations for suitable lubricants and apply them as needed. Additionally, regularly inspect components for signs of wear or damage. Early detection of issues can save you from costly repairs and downtime.

Tools Needed for Repairs

When it comes to maintaining and fixing cutting equipment, having the right tools is essential for a successful and efficient repair process. Each task may require specific instruments to ensure that everything functions smoothly and safely. Below is a comprehensive list of tools that will aid in carrying out repairs effectively.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening various bolts and screws. |

| Screwdriver Set | Essential for removing and securing screws in different components. |

| Replacement Blades | Needed to replace dull or damaged cutting edges for optimal performance. |

| Safety Goggles | Protects eyes from debris during disassembly and maintenance. |

| Measuring Tape | Useful for ensuring accurate measurements for component alignment. |

| Lubricant | Applied to moving parts to reduce friction and wear. |

Equipping yourself with these essential tools will facilitate a smoother repair process and help maintain the longevity of your equipment.

Where to Find Official Diagrams

Finding accurate visual representations of your equipment can greatly enhance your repair and maintenance efforts. These resources are crucial for understanding how components fit together and for identifying the specific parts you need.

Official Manufacturer Websites

The most reliable source for authentic visuals is the manufacturer’s website. They typically provide comprehensive resources for their products, including detailed illustrations and specifications.

Authorized Retailers

Many certified retailers also host product manuals and diagrams on their websites. These can be valuable for locating specific components and understanding their configurations.

| Source Type | Advantages |

|---|---|

| Manufacturer Websites | Official resources, updated information |

| Authorized Retailers | Easy access, additional product support |

Comparing Different Ryobi Models

When selecting tools from a specific brand, it’s essential to evaluate various models to find the perfect fit for your needs. Each option comes with unique features and specifications, making it crucial to understand their differences.

Here are key factors to consider when comparing models:

- Power and Performance: Assess the motor capacity and cutting capabilities.

- Design and Build Quality: Look for durability and ergonomic features.

- Portability: Consider weight and ease of transportation.

- Price Point: Compare costs to ensure you’re getting value for your investment.

- Accessories and Compatibility: Check what additional tools or attachments are available.

By examining these aspects, you can make an informed decision that aligns with your project requirements and preferences.

DIY Repairs: Step-by-Step Guide

Engaging in home repairs can be a rewarding experience, allowing you to save money and gain valuable skills. This guide will walk you through essential steps to troubleshoot and fix common issues with your cutting equipment effectively. Follow these instructions to ensure a successful repair process.

- Identify the Problem

Start by observing the tool closely. Look for any unusual sounds, movements, or performance issues. Common problems may include:

- Inconsistent cutting

- Excessive vibrations

- Difficulty in adjusting angles

- Gather Necessary Tools and Materials

Before you begin, make sure you have the right tools on hand. Some essentials include:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Replacement components

- Lubricants

- Disassemble the Equipment

Carefully take apart the device, keeping track of all screws and small parts. Organize them in a manner that makes reassembly straightforward.

- Inspect Components

Examine each part for wear and damage. Look for:

- Cracks or breaks

- Rust or corrosion

- Loose fittings

- Replace or Repair Parts

If you find any damaged components, replace them with new ones. For minor issues, consider applying lubricants or tightening loose screws.

- Reassemble the Equipment

Once repairs are completed, carefully put the tool back together, ensuring that all parts fit correctly and securely.

- Test the Tool

Finally, conduct a test run to ensure everything operates smoothly. Monitor the tool for any lingering issues and address them as needed.

lessCopy code

By following this guide, you can enhance your repair skills and keep your cutting equipment in top condition, ensuring efficient performance for your projects.