Complete Guide to Ryobi TSS103 Parts Diagram

In the world of power equipment, familiarity with the intricate parts of your machinery is essential for optimal performance and maintenance. Each element plays a vital role in ensuring that your device operates smoothly and efficiently. By exploring the layout and functions of these components, users can significantly enhance their understanding and care for their tools.

Gaining insight into the specific pieces that make up your device allows for more effective troubleshooting and repair. Whether you’re looking to replace a worn part or simply want to familiarize yourself with the overall structure, having a visual representation can be incredibly helpful. This knowledge empowers you to address issues swiftly and confidently, ultimately prolonging the lifespan of your equipment.

Moreover, diving into the various segments not only aids in maintenance but also encourages users to explore modifications or upgrades. With a clearer picture of how everything fits together, you can make informed decisions on improvements that can elevate your tool’s performance. Engaging with this knowledge transforms the user experience, turning routine tasks into opportunities for innovation.

Understanding the Ryobi TSS103 Diagram

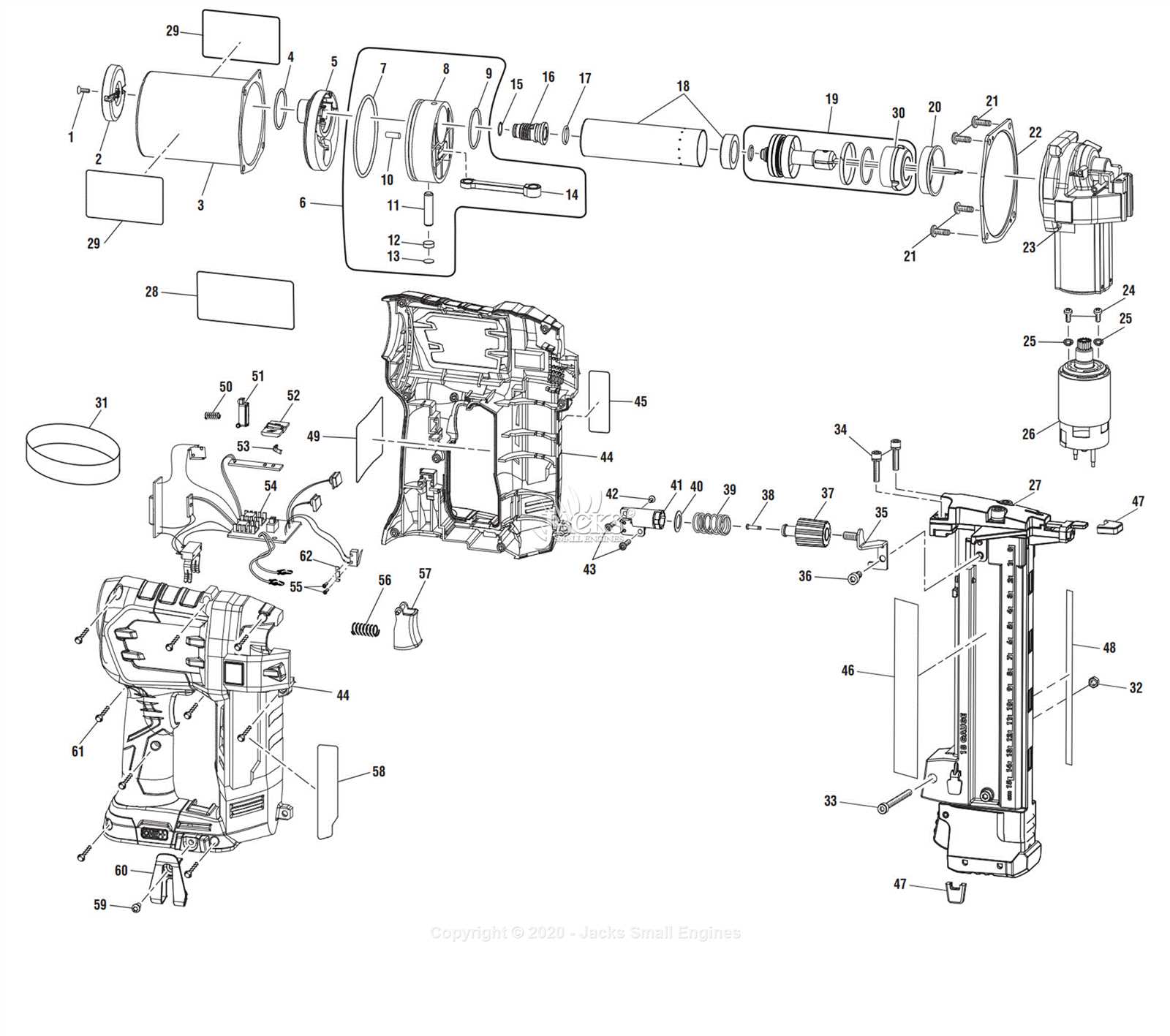

Grasping the layout of a tool can significantly enhance your maintenance and repair efforts. A comprehensive representation of the components not only aids in identifying individual parts but also streamlines the assembly process. Familiarity with this visual guide is essential for anyone looking to optimize their equipment’s functionality.

Components Overview

Each section of the illustration corresponds to a specific aspect of the machine. Here are some critical elements to note:

- Base Assembly: The foundation that supports all other components.

- Cutting Mechanism: This includes blades and gears responsible for the actual cutting action.

- Safety Features: Elements designed to protect the user during operation.

- Adjustment Systems: Parts that allow for fine-tuning of settings to ensure precision.

Benefits of Familiarization

Understanding this visual representation brings several advantages:

- Facilitates easier troubleshooting by pinpointing potential issues.

- Aids in locating specific components for replacement or upgrades.

- Enhances user confidence during operation and maintenance.

By investing time in learning the configuration, users can ensure their tools remain in peak condition, thereby maximizing performance and longevity.

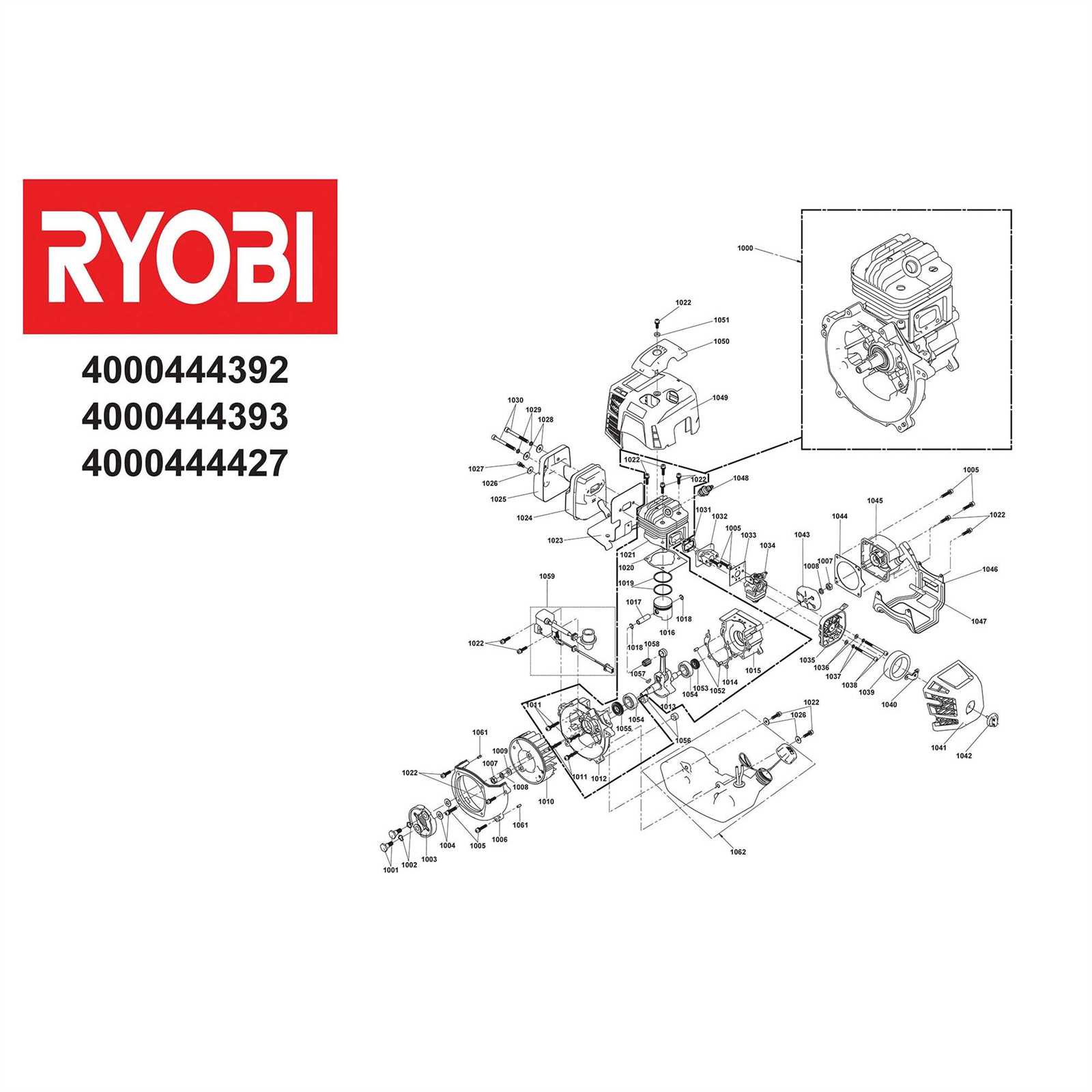

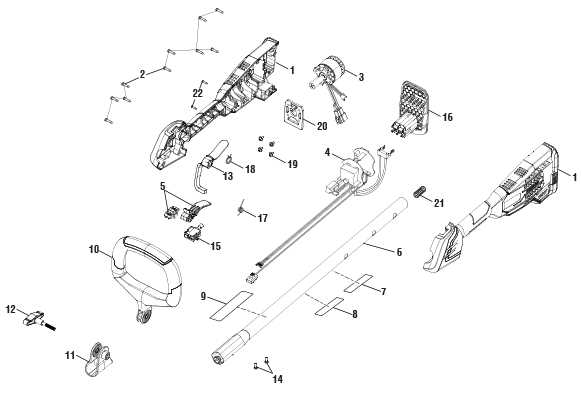

Key Components of Ryobi TSS103

This section delves into the essential elements that contribute to the functionality and efficiency of a cutting tool designed for precision. Understanding these components is vital for both maintenance and optimal performance, ensuring that users can achieve their desired results with ease.

Base Platform: The foundation of the equipment provides stability and support during operation. A robust base minimizes vibrations, allowing for smoother cuts and enhanced accuracy.

Blade Assembly: Central to the cutting process, the blade is engineered for various materials. Its sharpness and design are crucial for achieving clean, precise edges.

Adjustment Mechanisms: Features such as bevel and miter adjustments enable users to customize the cutting angles. This flexibility is essential for tackling different projects with precision.

Motor Unit: The powerhouse of the device, the motor drives the blade at varying speeds. A high-performance motor ensures efficiency and can handle tougher materials with ease.

Safety Features: Incorporating safeguards is essential for user protection. Elements like blade guards and automatic shut-off systems are designed to enhance safety during operation.

Table Surface: The surface area where the material is placed must be durable and flat. A quality table enhances support and ensures accurate cuts, reducing the likelihood of errors.

How to Read Parts Diagrams

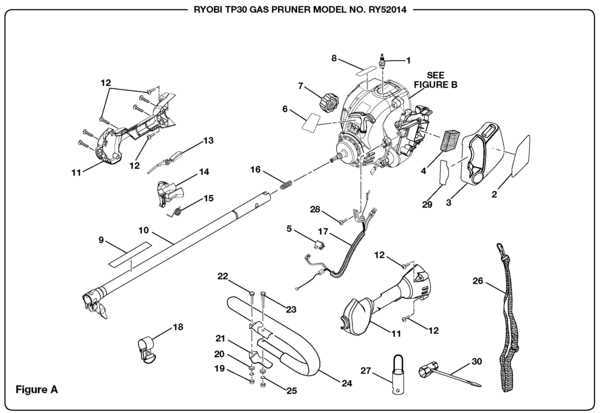

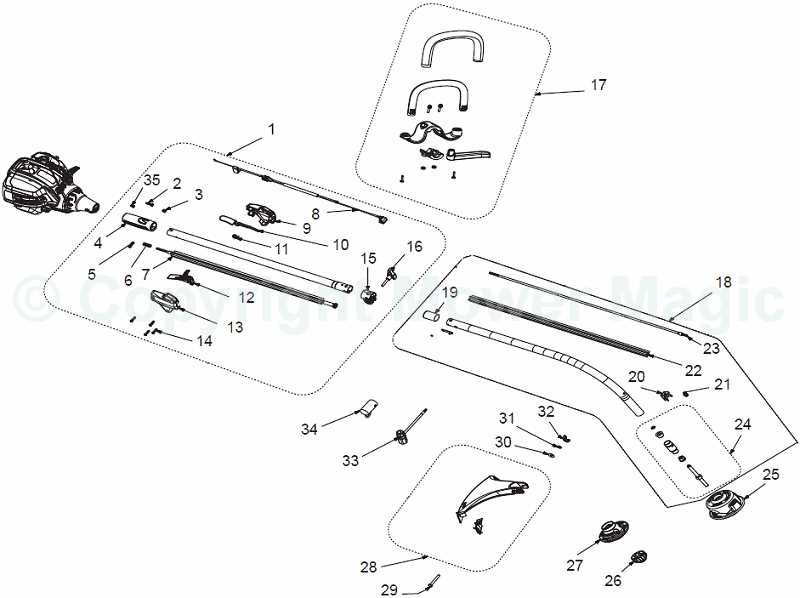

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations serve as guides, helping users identify individual elements and their relationships within a larger assembly. Familiarity with these visuals can streamline the repair process and enhance overall efficiency.

Key Elements to Consider

When examining these visual guides, focus on several critical aspects that will aid in your comprehension:

| Element | Description |

|---|---|

| Labels | Look for annotations that indicate part numbers and names, which help in identifying each component. |

| Connections | Observe how different elements are linked together, as this can reveal assembly order and functional relationships. |

| Legend | A legend may explain symbols used in the illustration, providing clarity on various components. |

Steps for Effective Interpretation

To effectively interpret these visual guides, follow these steps:

- Begin by reviewing the legend and any accompanying notes.

- Identify key components and their corresponding identifiers.

- Trace connections between elements to understand their arrangement and functionality.

- Refer to any additional documentation for further clarification on specific parts.

Identifying Replacement Parts Easily

When it comes to maintaining tools and machinery, understanding how to find suitable components is essential. Whether you’re repairing equipment or upgrading features, knowing where to look and how to identify what you need can save time and frustration.

Key Steps to Identify Components

Follow these simple guidelines to streamline your search for the right items:

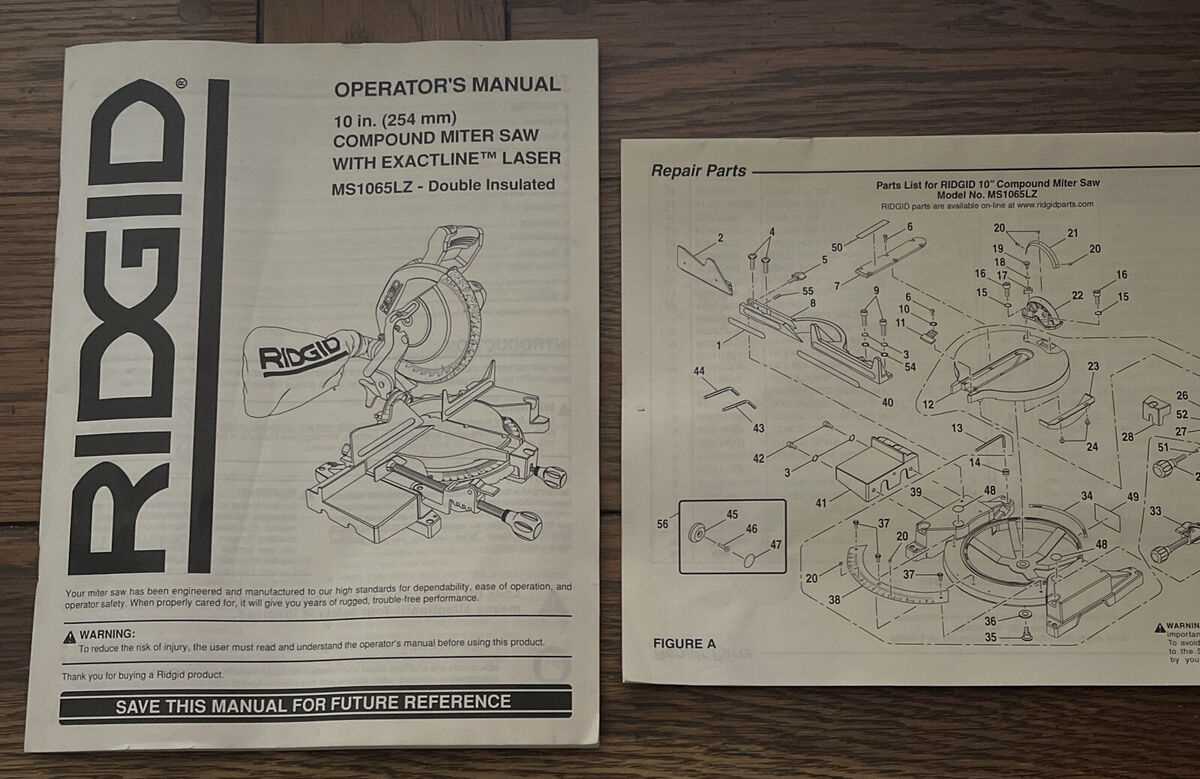

- Check the Manual: Start with the product manual, which often includes a list of necessary items and specifications.

- Model Number Reference: Always note the model number, as it helps narrow down options to the correct versions.

- Visual Inspection: Examine the tool closely for any markings or part numbers that may assist in identification.

- Online Resources: Utilize manufacturer websites or reputable retailers to explore inventory and specifications.

Using Resources Effectively

Make the most of available resources to ensure you find the exact replacements:

- Forums and Communities: Engage with online forums where users share experiences and recommendations.

- Videos and Tutorials: Look for instructional videos that demonstrate disassembly and reassembly, highlighting component locations.

- Customer Support: Don’t hesitate to contact customer service for assistance in locating the necessary items.

Common Issues and Solutions

When working with power tools, encountering problems is not uncommon. Understanding frequent challenges and their remedies can enhance efficiency and prolong the tool’s lifespan.

- Tool Not Starting:

- Check the power source for issues.

- Inspect the on/off switch for faults.

- Inconsistent Performance:

- Ensure the blades are sharp and properly installed.

- Examine the motor for potential malfunctions.

- Excessive Vibration:

- Verify that the tool is securely mounted.

- Look for any worn components that need replacement.

- Overheating:

- Allow the tool to cool down regularly during use.

- Check for blockages in ventilation areas.

Maintenance Tips for Longevity

To ensure the extended life of your equipment, regular upkeep is essential. Implementing simple maintenance practices can significantly enhance performance and reliability, minimizing the likelihood of unexpected failures.

Routine Cleaning

Keeping the machinery free from debris and dust is crucial. Regularly wipe down surfaces and ensure that moving parts are clear of any buildup.

Regular Inspections

Performing consistent evaluations can help identify potential issues early. Look for wear and tear, ensuring that all components are functioning properly.

| Maintenance Task | Frequency |

|---|---|

| Clean surfaces | Weekly |

| Check for wear | Monthly |

| Lubricate moving parts | Every 3 months |

| Inspect electrical components | Every 6 months |

Where to Find Authentic Parts

When it comes to maintaining your equipment, sourcing genuine components is essential for ensuring optimal performance and longevity. Authentic items not only guarantee compatibility but also uphold the integrity of the machine, preventing potential malfunctions that can arise from substandard replacements.

Official Retailers

One of the most reliable avenues for obtaining genuine components is through official retailers. These stores often provide a comprehensive selection and knowledgeable staff who can assist with any inquiries.

Online Marketplaces

Another option is to explore reputable online platforms. Many of these sites have dedicated sections for original components, making it easy to locate what you need.

| Source Type | Benefits |

|---|---|

| Official Retailers | Guaranteed authenticity, expert support |

| Online Marketplaces | Convenient access, wide selection |

| Authorized Dealers | Specialized knowledge, quality assurance |

Assembly Instructions for Beginners

Understanding how to piece together tools can be daunting for newcomers. This guide aims to simplify the assembly process by breaking it down into manageable steps, making it accessible for those unfamiliar with such tasks. Each stage will be clearly outlined to enhance your confidence as you progress.

Essential Tools Required

Before beginning the assembly, gather the necessary tools to ensure a smooth process. Below is a list of items you will need:

| Tool | Purpose |

|---|---|

| Screwdriver | To secure screws |

| Wrench | For tightening bolts |

| Allen Key | To adjust specific fittings |

| Measuring Tape | For accurate measurements |

Step-by-Step Assembly Process

Follow these steps to assemble your tool effectively. Start by laying out all components and ensuring you have everything needed. Refer to the included instructions for precise guidance on connecting parts. Take your time to double-check each connection, ensuring everything is secure before moving to the next step. Patience is key in achieving the ultimate assembly.

Comparing Ryobi TSS103 with Other Models

When evaluating a specific cutting tool, it’s essential to consider how it stacks up against other available options. By examining various features, performance metrics, and overall usability, users can make informed decisions that best suit their needs. This analysis will highlight key differences and similarities, providing a clearer picture of what to expect from each model.

Performance and Features

One of the primary factors in assessing any cutting tool is its performance. The model in question offers robust cutting capabilities and precision, often favored for its efficiency in handling various materials. Comparatively, other brands may prioritize versatility, featuring multiple cutting modes or additional attachments. While some may excel in cutting speed, others might offer enhanced accuracy, catering to different user preferences.

Build Quality and Durability

Build quality plays a significant role in the longevity of a tool. The discussed model is recognized for its sturdy construction, designed to withstand rigorous use. In contrast, alternatives might focus on lightweight materials for ease of transport, which can impact durability. Users should assess how these design choices align with their intended applications, weighing portability against resilience.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right instruments is essential for ensuring efficiency and accuracy. This section outlines the key equipment necessary to perform repairs effectively, allowing for a smoother process and better results.

Essential Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | For removing and tightening screws. |

| Wrench | To loosen or tighten nuts and bolts. |

| Pliers | For gripping and bending materials. |

| Measuring Tape | To ensure accurate measurements. |

Optional Tools

| Tool | Purpose |

|---|---|

| Level | To check for evenness in surfaces. |

| Drill | For creating holes or driving screws. |

| Safety Goggles | To protect eyes during work. |

Customer Reviews and Feedback

This section provides insights into user experiences and evaluations regarding the product’s performance, quality, and reliability. Analyzing feedback from consumers can help potential buyers make informed decisions and understand what to expect.

Overall Satisfaction

Many users express high levels of satisfaction, praising the ease of use and efficiency of the tool. Positive remarks often highlight its durability and effectiveness in various tasks, making it a favored choice among DIY enthusiasts and professionals alike.

Areas for Improvement

While most feedback is favorable, some customers point out specific areas where enhancements could be beneficial. Common suggestions include better instruction manuals and additional accessory options to maximize functionality. These insights provide valuable perspectives for future improvements.