Samsung WF50K7500AV Parts Diagram Overview

Understanding the inner workings of home appliances can significantly enhance their efficiency and longevity. By familiarizing oneself with the internal structure, users gain a better grasp of how each element contributes to the overall operation. This insight can be especially helpful in maintaining smooth performance and addressing potential issues more effectively.

Knowing the arrangement of internal mechanisms helps in identifying the essential elements that ensure optimal functionality. Each section within the device plays a unique role, from managing water flow to ensuring stable rotation. A clear understanding of these elements can lead to more accurate troubleshooting and adjustments.

Moreover, visualizing how different segments connect and interact allows for a more thorough grasp of the overall assembly. This knowledge can simplify regular upkeep and make it easier to pinpoint where attention is needed, thus reducing the likelihood of unexpected issues. A well-maintained appliance ensures not only better performance but also a

Overview of Key Components

In this section, we explore the essential elements that make up this household appliance. Each part plays a critical role in ensuring smooth operation, contributing to the overall functionality and durability. Understanding these components helps in maintaining and optimizing the performance of the device over time.

Main Structural Elements

The core framework consists of a durable exterior shell, which houses various mechanical and electronic parts. Inside, key elements like the drum and support system ensure proper movement and stability. These structural parts work together to manage the physical aspects of operation, providing balance and durability.

Internal Mechanisms

Within the unit, the internal mechanisms include a motor, pump, and various control modules. The motor drives the core functions, while the pump manages the flow of water through different cycles. Control modules regulate temperature, speed, and timing, ensuring the right conditions for different types of loads. These internal systems are essential for maintaining efficiency and performance throughout the usage cycle.

Main Features and Functions

The device combines advanced capabilities to ensure an efficient and user-friendly experience. It integrates a variety of functionalities designed to meet everyday needs, offering both convenience and reliability. This model stands out with its ability to adapt to different conditions, providing a seamless and effective operation for a wide range of tasks.

| Feature | Description |

|---|---|

| Enhanced Efficiency | Optimized for quick performance, reducing energy consumption while maintaining high productivity. |

| Adaptive Settings | Automatically adjusts functions to suit various requirements, ensuring versatile use. |

| Intuitive Control Panel | Simplifies user interaction with easy-to-navigate options, improving overall usability. |

| Quiet Operation | Minimizes noise levels during use, providing a peaceful environment without sacrificing efficiency. |

Internal Mechanisms Explained

The inner workings of a modern washing machine are designed to provide efficient and reliable performance. These systems ensure that each cycle runs smoothly, delivering clean results every time. Understanding the way these components interact can offer valuable insight into the overall function of the device.

Core Functional Components

At the heart of the unit, a motor drives the rotation of the drum, ensuring consistent agitation. This motor, connected to various belts and pulleys, allows for precise control over speed and direction. A control module regulates these movements, ensuring proper operation during each phase of the cycle.

Water Flow and Control

The valves and pumps work together to manage water intake and drainage. The valves open to allow the correct amount of water into the drum, while the pumps remove excess water once the washing is complete. These mechanisms operate in harmony to maintain an optimal balance, ensuring thorough rinsing and spinning processes

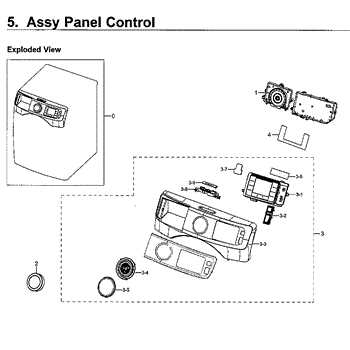

Understanding the Control Panel Layout

The control panel of a modern washing machine offers a user-friendly interface for managing various functions and settings. It includes different buttons and indicators that help users navigate through options and customize cycles to meet specific laundry needs. Knowing the arrangement of these elements is essential for efficient use and optimal performance.

Main Buttons and Their Functions

At the center of the control panel, users will find the primary control dial and essential buttons. This dial allows the selection of different washing programs, while additional buttons let users adjust temperature, spin speed, and other settings. Understanding these controls ensures a smoother operation and better results for different fabric types.

Indicator Lights and Displays

The panel also features indicator lights and a display screen that provide information about the current status of the machine. These indicators can show remaining time, cycle progress, and alerts for any necessary actions, such as cleaning filters or adjusting settings. Familiarity with these visual cues helps users address issues promptly and maintain optimal functionality.

Water Inlet System Details

The water inlet mechanism is designed to ensure a steady and efficient flow of water into the washing unit. It incorporates various elements that collaborate to manage the water supply, allowing for optimal performance. This system is crucial for regulating water levels and temperature, ensuring the right conditions for different cycles.

Key Components and Their Roles: The water intake structure consists of valves and filters that work together to control the flow and purity of the water. The valves adjust the intake according to the selected wash cycle, while filters ensure that any impurities are removed before entering the system.

The flow control elements are carefully calibrated to maintain consistent water pressure. These parts help to minimize fluctuations, ensuring the washing process proceeds smoothly. Additionally, sensors within the system monitor water levels, adjusting the intake as needed for each cycle.

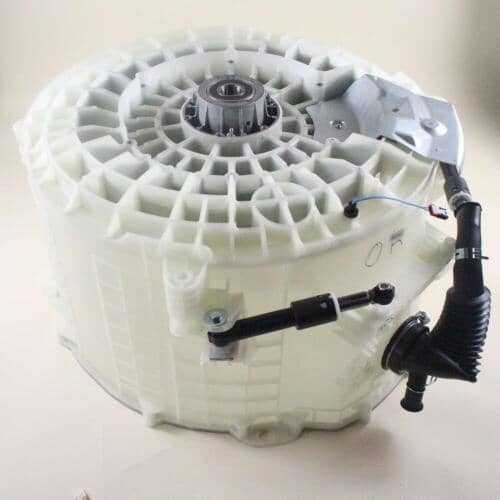

Drum Assembly and Maintenance

The drum assembly of a washing machine plays a crucial role in ensuring optimal performance and longevity. Understanding its components and proper care techniques can significantly enhance the efficiency of the appliance. Regular maintenance not only prolongs the life of the drum but also prevents potential issues that could disrupt laundry processes.

Components of the Drum Assembly

The drum assembly comprises several key components, each contributing to its functionality:

- Drum Cylinder: The main body where clothes are placed for washing.

- Drum Bearings: These support the drum and facilitate smooth rotation.

- Drive Belt: Connects the motor to the drum, enabling movement.

- Suspension Springs: Help absorb vibrations during operation.

- Seals: Prevent water leaks and maintain internal pressure.

Maintenance Tips

Proper upkeep of the drum assembly is essential for optimal operation. Here are some tips to consider:

- Regular Cleaning: Clean the drum and seals to remove residue and prevent odors.

- Inspect for Wear: Regularly check bearings and seals for signs of wear and replace as needed.

- Monitor for Unusual Noises: Listen for any strange sounds during operation, which may indicate issues with the drum or motor.

- Balance Loads: Avoid overloading the drum to prevent strain on components and ensure effective cleaning.

- Check Drive Belt: Periodically inspect the drive belt for any signs of fraying or damage.

Pump and Drainage System Insights

The efficiency of any washing appliance relies heavily on its water management components. Understanding how these systems function can significantly enhance performance and longevity.

At the core of effective water circulation are the pump and drainage mechanisms. These components play a crucial role in ensuring that water is effectively moved in and out of the appliance during cycles. Below are some key aspects of these systems:

- Functionality: The pump is responsible for transferring water from the tub to the drainage system, facilitating the removal of dirty water after washing.

- Types of Pumps: Different models may utilize varying pump types, each designed for specific performance characteristics.

- Drainage Pathways: Proper drainage pathways prevent water backup and ensure efficient water expulsion, which is vital for optimal operation.

- Maintenance: Regular inspection and maintenance of the pump and drainage components are essential to avoid clogs and ensure smooth operation.

In summary, a thorough understanding of the water management systems within a washing appliance can lead to improved functionality and reduce the likelihood of malfunctions. Adopting proactive maintenance practices can significantly enhance the lifespan and efficiency of these critical components.

Electronic Circuit and Wiring Overview

This section provides a comprehensive examination of the electronic circuitry and wiring utilized in modern laundry appliances. Understanding these components is crucial for effective troubleshooting, maintenance, and repair. A well-designed circuit ensures the proper functioning of various features, enhancing the overall efficiency and longevity of the machine.

Key Components

The electronic circuitry is composed of several essential elements, each playing a significant role in the operational efficiency of the appliance:

- Control Board: Acts as the brain, processing user inputs and managing various functions.

- Sensors: Detect conditions such as water level and temperature, providing feedback to the control board.

- Power Supply: Converts electrical energy from the outlet to usable power for the machine’s components.

- Wiring Harness: Connects various components, ensuring that signals and power are efficiently transmitted.

Wiring Configuration

The configuration of wires is critical for the seamless operation of the device. Proper wiring ensures that signals flow without interruption, preventing malfunctions:

- Identify the different wire colors used for specific functions.

- Trace connections between the control board and sensors.

- Inspect the integrity of the wiring harness for signs of wear or damage.

Door Seal and Lock Mechanism

The door seal and locking system play a crucial role in maintaining the efficiency and safety of washing machines. This section provides insights into the components and functions that ensure a secure closure, preventing leaks and ensuring optimal performance during operation.

At the heart of this mechanism lies the rubber seal, designed to create a watertight barrier between the door and the main body of the appliance. It is essential for preventing water from escaping during the wash cycle. Over time, wear and tear can affect its performance, making regular inspection important for proper functionality.

| Component | Description |

|---|---|

| Door Seal | Provides a watertight closure, preventing leaks. |

| Locking Mechanism | Ensures the door remains securely closed during operation. |

| Hinges | Allows the door to pivot open and closed smoothly. |

| Latch | Engages the lock to secure the door in place. |

Regular maintenance of these components is essential for extending the lifespan of the washing appliance. Identifying signs of wear or damage early can prevent larger issues and enhance overall efficiency.

Dispenser Unit Structure

The dispenser unit serves as a vital component within the washing appliance, facilitating the efficient distribution of cleaning agents during various cycles. Its design is crucial for ensuring that detergents and softeners are released at the appropriate times for optimal cleaning performance.

Typically, the dispenser unit consists of several key components:

- Main Compartment: The primary section where cleaning agents are stored prior to release.

- Separator: A barrier that ensures different types of detergents do not mix, preserving their efficacy.

- Inlet Valve: Controls the flow of water into the dispenser, triggering the release of the cleaning agents.

- Dispensing Channels: Pathways that guide the cleaning solutions from the compartment to the drum, ensuring proper distribution.

- Cleaning Mechanism: A feature that helps to flush out residual detergent, preventing buildup over time.

Understanding the structure of the dispenser unit is essential for troubleshooting and maintenance. Regular inspection of these components can enhance the longevity of the appliance and improve its cleaning efficiency.