Understanding the Briggs and Stratton 1150 Snow Series Parts Diagram

The operation of any cold-weather machine hinges on the seamless interplay of its various elements. An intricate understanding of these components is essential for optimal performance and maintenance. Whether you’re preparing for the season or addressing a specific issue, knowledge of the intricate layout and functionality of each part can make a significant difference.

In this exploration, we will delve into the essential elements that contribute to the efficiency and reliability of your engine during harsh conditions. From the power system to the ignition components, each aspect plays a vital role in ensuring that your equipment operates smoothly when you need it most.

By familiarizing yourself with the configuration and function of these integral parts, you will empower yourself to tackle repairs and enhancements with confidence. This comprehensive overview aims to equip you with the insights needed to keep your machinery running at peak performance throughout the winter months.

Understanding Briggs and Stratton 1150 Snow Series

This section provides insights into a specific engine model designed for harsh winter conditions. These power units are known for their reliability and efficiency, making them ideal for managing snow-related tasks. Understanding the components and their functionalities can significantly enhance the user experience and maintenance practices.

Key Features

The engine is equipped with several notable characteristics that contribute to its performance. Here are some of the primary aspects:

| Feature | Description |

|---|---|

| Power Output | Designed to deliver robust energy, ensuring effective snow removal. |

| Durability | Constructed with high-quality materials to withstand extreme conditions. |

| Easy Maintenance | Components are accessible for straightforward upkeep and servicing. |

Components Overview

Familiarizing oneself with the individual elements is crucial for optimal operation. Each part plays a vital role in the overall functionality, contributing to the engine’s efficiency and longevity. Regular inspection and understanding of these components can prevent issues and extend the lifespan of the machinery.

Overview of Snow Series Engines

The engines designed for winter applications are crafted to withstand harsh conditions while providing reliable performance. These power units are essential for effective snow removal, ensuring that users can maintain clear pathways and driveways during inclement weather. With a focus on durability and efficiency, these machines are built to tackle heavy snowfall with ease.

Key Features

Winter engines typically incorporate several noteworthy characteristics. They are equipped with enhanced starting mechanisms that ensure quick ignition, even in low temperatures. Additionally, the design includes improved fuel systems that reduce the likelihood of gelling, allowing for smooth operation in frigid climates.

Maintenance Considerations

Proper upkeep is crucial for the longevity of these power units. Regular checks on components such as spark plugs and air filters can significantly impact performance. Users should also be attentive to oil levels, as optimal lubrication is vital for engine health. By adhering to these maintenance practices, one can ensure that the machine remains dependable throughout the snowy months.

Key Features of the 1150 Model

This section explores the distinctive characteristics of a highly efficient winter engine, focusing on its innovative design and performance enhancements that ensure reliability during challenging weather conditions.

| Feature | Description |

|---|---|

| Power Output | Delivers exceptional torque, providing ample power for heavy snow removal tasks. |

| Starting Mechanism | Equipped with an effortless start system, making operation seamless even in frigid temperatures. |

| Durability | Constructed with robust materials, ensuring long-lasting performance and resistance to wear. |

| Fuel Efficiency | Designed for optimal fuel consumption, allowing for extended use without frequent refueling. |

| Maintenance | Features user-friendly components, simplifying upkeep and enhancing longevity. |

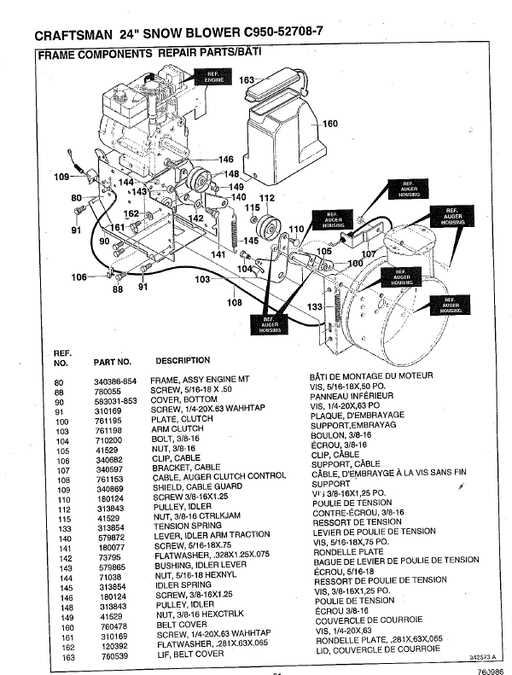

Common Applications of Snow Engines

Engines designed for cold weather applications serve a vital role in various equipment, ensuring efficient operation in challenging conditions. These power sources are engineered to handle heavy-duty tasks, making them essential for winter maintenance and outdoor activities.

Among the primary uses of these engines are:

| Application | Description |

|---|---|

| Snow Blowers | Powerful machines that clear driveways and sidewalks of accumulated snow, often featuring augers and impellers for effective snow removal. |

| Ice Augers | Specialized tools used for drilling holes in ice, typically for fishing or other outdoor activities during winter months. |

| Tractors | Used for snow plowing and landscaping tasks, these vehicles can be fitted with attachments to manage snow effectively. |

| ATVs | All-terrain vehicles equipped with snow plows or tracks, allowing for versatile use in snowy conditions. |

| Utility Vehicles | Versatile machines that can be used for various tasks, including snow removal, often featuring customizable attachments. |

These applications highlight the versatility and necessity of reliable engines in winter environments, ensuring safety and accessibility throughout the colder months.

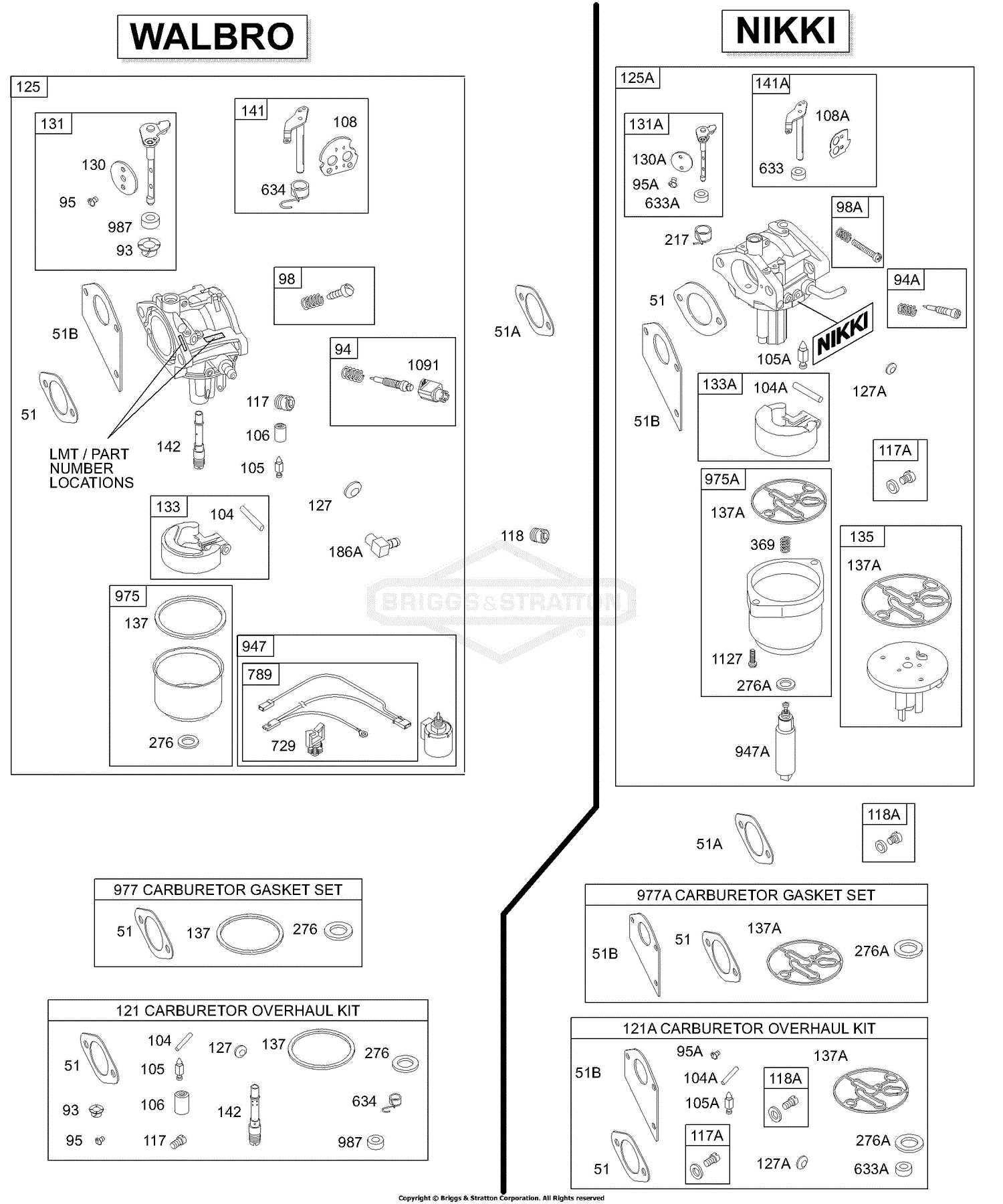

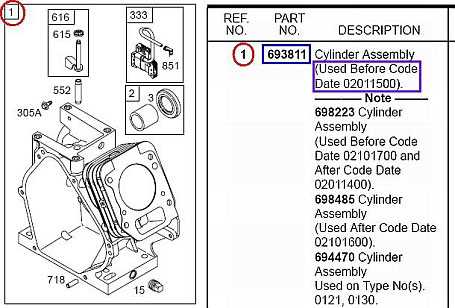

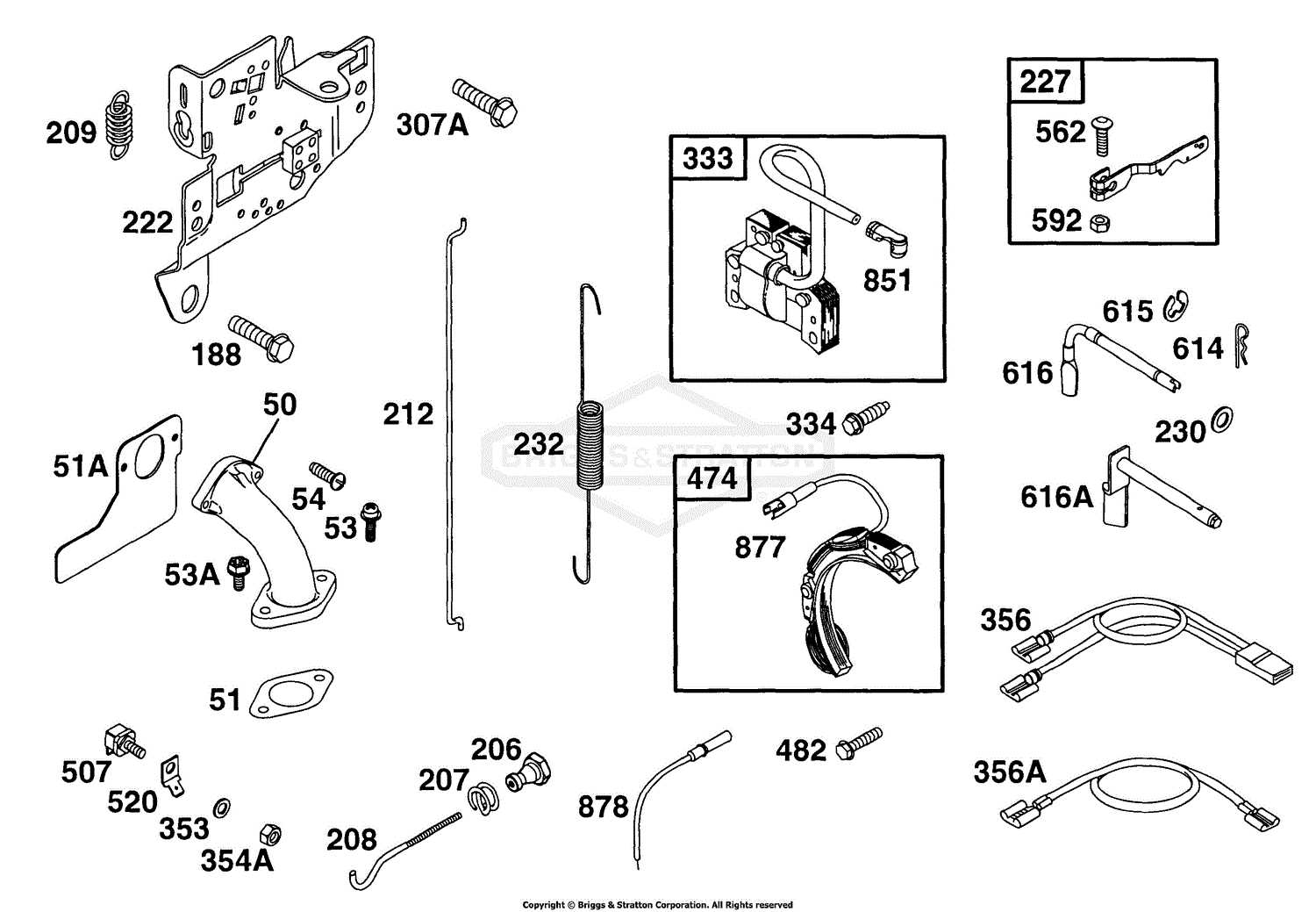

Parts Identification for Maintenance

Understanding the components of your equipment is crucial for effective upkeep and performance. Proper identification of each element ensures that maintenance tasks are executed efficiently, reducing the risk of damage and extending the lifespan of your machine. Familiarity with these elements allows you to address issues promptly and maintain optimal functioning.

Common Components to Identify

Various key components play significant roles in the operation of your equipment. Recognizing these parts will help you manage repairs and replacements effectively.

| Component Name | Function |

|---|---|

| Engine | Provides power for operation. |

| Carburetor | Mixes fuel and air for combustion. |

| Spark Plug | Ignites the fuel-air mixture. |

| Fuel Tank | Stores fuel for the engine. |

| Blade Assembly | Performs cutting or clearing tasks. |

Tips for Effective Maintenance

To ensure your equipment remains in top condition, regular checks of these components are recommended. Replace worn or damaged items promptly to prevent further complications. Keeping a record of maintenance activities will aid in tracking performance and identifying recurring issues.

How to Access the Parts Diagram

Accessing a detailed schematic for your engine components can greatly enhance maintenance and repair efforts. Understanding where to locate this information is essential for efficient troubleshooting and part replacement.

Online Resources

- Visit the manufacturer’s official website.

- Utilize online forums and communities for user-shared resources.

- Search for authorized dealers that provide downloadable schematics.

Printed Manuals

- Check if a physical manual came with your device.

- Purchase a service manual for comprehensive information.

- Contact customer support for access to printed resources.

Importance of Genuine Replacement Parts

Using authentic components for repairs is crucial for maintaining the performance and longevity of machinery. While aftermarket options may seem appealing due to their lower price, they often compromise quality and reliability, leading to potential issues down the line.

Benefits of Authentic Components

- Quality Assurance: Genuine parts are manufactured to meet strict standards, ensuring optimal performance.

- Perfect Fit: These components are designed specifically for your equipment, reducing the risk of installation errors.

- Warranty Protection: Using authentic parts helps maintain warranty coverage, safeguarding your investment.

- Safety: Quality parts reduce the risk of malfunctions, which can lead to accidents or injuries.

Long-Term Cost Efficiency

Investing in genuine components can save money over time. Although the initial cost may be higher, the reliability and durability of authentic parts minimize the need for frequent replacements and repairs.

- Reduced downtime due to fewer breakdowns.

- Lower maintenance costs, as quality parts last longer.

- Enhanced resale value of your equipment.

Choosing authentic components is a smart decision that ensures your machinery operates smoothly and efficiently for years to come.

Step-by-Step Repair Process

This section outlines a comprehensive approach to tackling repair tasks effectively. Following these steps will ensure a smooth restoration of functionality, allowing for optimal performance once completed.

- Gather Necessary Tools:

- Screwdrivers

- Wrenches

- Replacement components

- Review the Manual:

Familiarize yourself with the device’s specifications and recommended procedures.

- Disassemble the Unit:

Carefully remove outer casings to access internal parts. Keep track of screws and components.

- Inspect for Damage:

Look for wear, cracks, or broken elements that may require replacement.

- Replace Defective Parts:

Install new components as needed, ensuring proper alignment and fitting.

- Reassemble the Device:

Put all parts back together securely, following the reverse order of disassembly.

- Test Functionality:

Start the unit to ensure all repairs were successful and everything operates correctly.

Troubleshooting Common Issues

Maintaining a reliable engine during winter conditions is essential for optimal performance. Various challenges may arise, but identifying and addressing them promptly can ensure smooth operation. Below are common problems along with potential solutions.

Engine Won’t Start

- Check the fuel level; ensure it’s fresh and not contaminated.

- Inspect the ignition system for proper functionality.

- Examine the battery connections for corrosion or looseness.

- Verify that the choke is in the correct position.

Loss of Power

- Clear any obstructions in the air intake or exhaust.

- Examine the fuel filter for clogs or dirt.

- Ensure the spark plug is clean and properly gapped.

- Look for signs of wear in the drive belts or chains.

Essential Tools for Maintenance Tasks

Proper upkeep of machinery requires a selection of crucial implements that ensure efficiency and longevity. These instruments not only facilitate the repair process but also enhance overall performance by addressing wear and tear effectively.

Basic Tools

A well-equipped toolkit typically includes a variety of wrenches, screwdrivers, and pliers. These essentials are vital for tackling common adjustments and replacements. Having a reliable set allows for seamless operations during maintenance routines.

Specialized Equipment

In addition to standard tools, some tasks may necessitate specialized devices. Oil filters, spark plug wrenches, and cleaning brushes are invaluable for thorough servicing. Investing in these items ultimately leads to improved machinery reliability.

Safety Tips When Working on Engines

Engaging in maintenance or repair tasks on machinery requires careful consideration of safety practices to prevent accidents and injuries. Understanding potential hazards and implementing protective measures is essential for a secure working environment.

Wear Protective Gear

Always equip yourself with appropriate personal protective equipment. This includes safety goggles, gloves, and sturdy footwear to safeguard against debris and sharp objects. Additionally, ensure that your clothing is fitted and free from loose ends that could get caught in moving parts.

Work in a Well-Ventilated Area

Conduct all tasks in a space with adequate airflow to reduce the risk of inhaling harmful fumes or vapors. Proper ventilation helps maintain a safer atmosphere, especially when dealing with fuel or oil. Always be mindful of your surroundings and keep flammable materials away from ignition sources.

Where to Find Replacement Parts

When your equipment needs new components, locating the right replacements can be a challenge. Fortunately, there are several reliable sources that cater to your needs, ensuring your machinery continues to operate smoothly. Whether you’re looking for OEM or aftermarket options, the following avenues are worth exploring.

| Source | Description |

|---|---|

| Manufacturer’s Website | Direct access to original components, complete with diagrams and specifications. |

| Authorized Dealers | Local retailers specializing in machinery, often providing expert advice and assistance. |

| Online Marketplaces | Popular e-commerce platforms that offer a wide variety of components at competitive prices. |

| Repair Shops | Professionals who can source parts directly or suggest trusted suppliers for your needs. |

| Community Forums | Online groups where enthusiasts share recommendations and experiences with specific replacements. |

Warranty Information and Support Resources

This section aims to provide essential insights regarding guarantees and assistance for your equipment. Understanding the terms of your warranty can enhance your ownership experience and ensure you receive the best support available.

Warranty Coverage: Typically, warranties cover manufacturing defects and offer repairs or replacements within a specified period. It’s crucial to review the terms to understand what is included.

Support Channels: For any inquiries or issues, numerous support resources are available. You can access online manuals, customer service hotlines, and authorized service centers that are ready to assist.

Claim Process: Should you need to make a warranty claim, follow the outlined steps in your documentation. Gather necessary information, such as purchase receipts and serial numbers, to facilitate the process.

Being informed about your warranty and support options empowers you to address any challenges effectively.