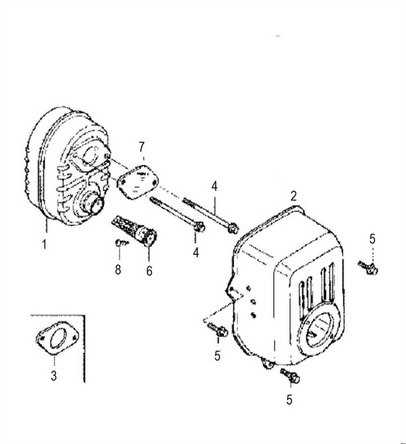

Briggs and Stratton Professional Series 175cc Parts Diagram Overview

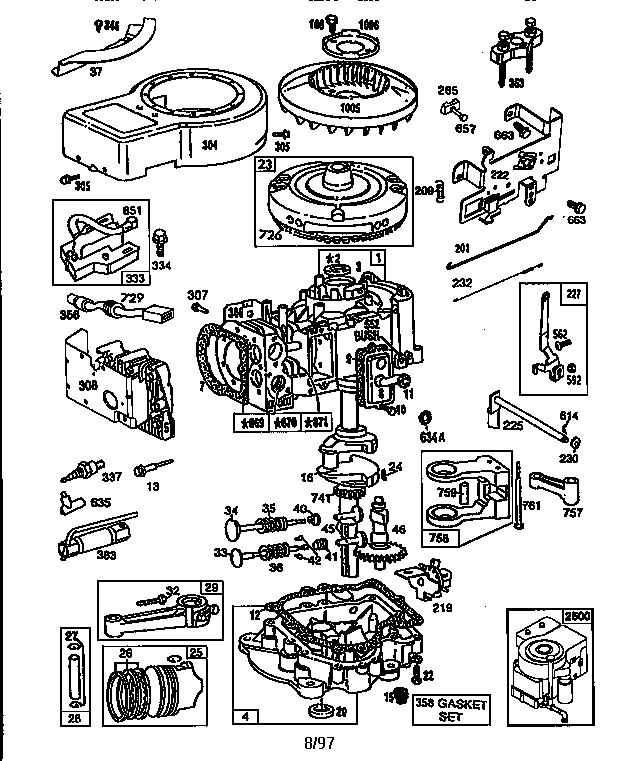

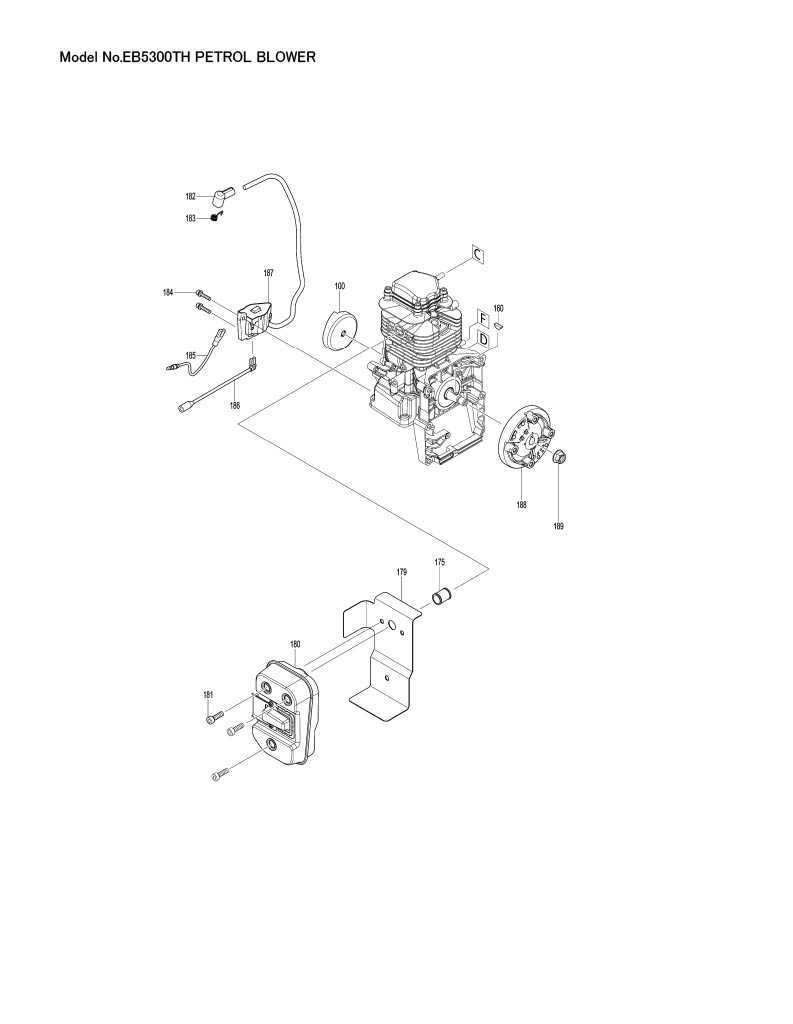

In the realm of small engine maintenance, having a clear visual reference is essential for efficient repairs and replacements. Such illustrations provide insight into the intricate relationships between various components, enabling enthusiasts and professionals alike to navigate the complexities of engine assembly.

These detailed schematics serve as a roadmap, allowing users to identify specific elements and their functions within the mechanical framework. Grasping this layout not only simplifies the repair process but also enhances overall understanding of engine mechanics.

Whether for routine upkeep or major overhauls, leveraging these resources empowers individuals to tackle challenges with confidence. With the right knowledge, even the most daunting tasks can become manageable, ensuring longevity and optimal performance of the equipment.

Understanding Briggs and Stratton Engines

Engines are the heart of many outdoor power equipment, providing the necessary force to perform various tasks efficiently. Familiarity with these machines allows users to appreciate their functionality, maintenance needs, and troubleshooting processes.

Key Components

To grasp the workings of these engines, it’s essential to recognize their fundamental components:

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber.

- Ignition System: Initiates the combustion process, ensuring the engine starts smoothly.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Lubrication System: Reduces friction between moving parts, prolonging engine life.

Maintenance Tips

Regular upkeep is crucial for optimal performance. Here are some essential practices:

- Check and change the oil periodically to ensure smooth operation.

- Inspect air filters and clean or replace them as needed to maintain airflow.

- Examine spark plugs for wear and replace them if necessary.

- Keep the fuel system clean and free from debris to prevent clogs.

By understanding these essential elements, users can enhance the longevity and efficiency of their outdoor machinery.

Overview of Professional Series 175cc

This section provides a comprehensive look at a specific line of powerful engines designed for various outdoor applications. Known for their reliability and efficiency, these units are tailored to meet the demands of both professionals and enthusiasts alike.

Key Features

These engines boast a range of attributes that enhance their performance and usability. From improved fuel efficiency to advanced starting mechanisms, each component is engineered to provide optimal results.

Specifications

| Feature | Description |

|---|---|

| Power Output | Up to 6.75 ft-lbs of torque |

| Starting System | Easy start recoil mechanism |

| Fuel Type | Unleaded gasoline |

| Cooling System | Air-cooled design |

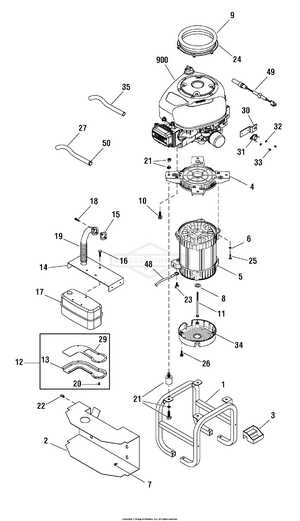

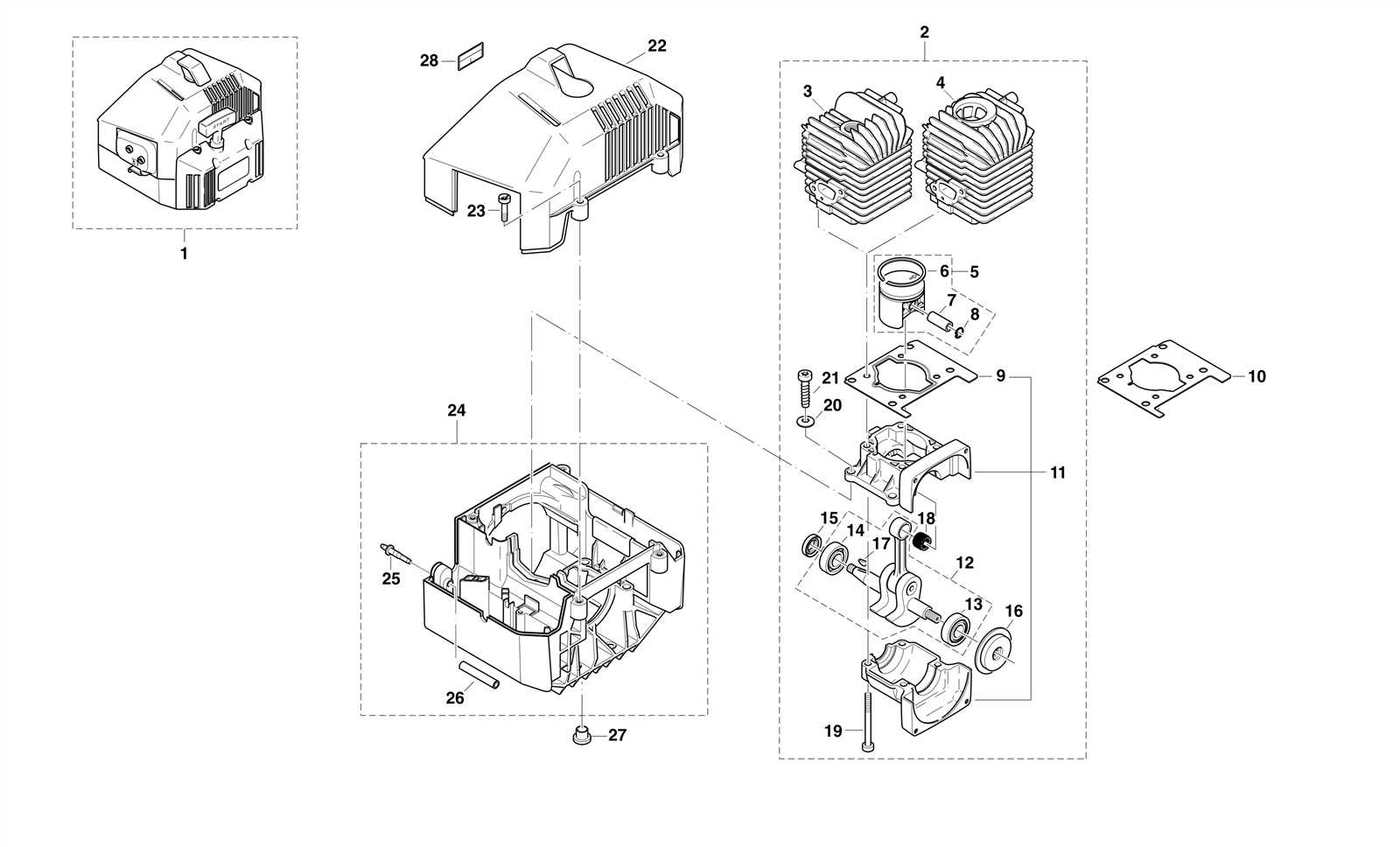

Key Components of 175cc Engines

Understanding the essential elements of small engines is crucial for maintenance and performance. Each component plays a vital role in ensuring efficiency and durability.

- Cylinder: Houses the piston and is integral to the combustion process.

- Piston: Moves within the cylinder, creating pressure for fuel combustion.

- Crankshaft: Converts the piston’s linear motion into rotational energy.

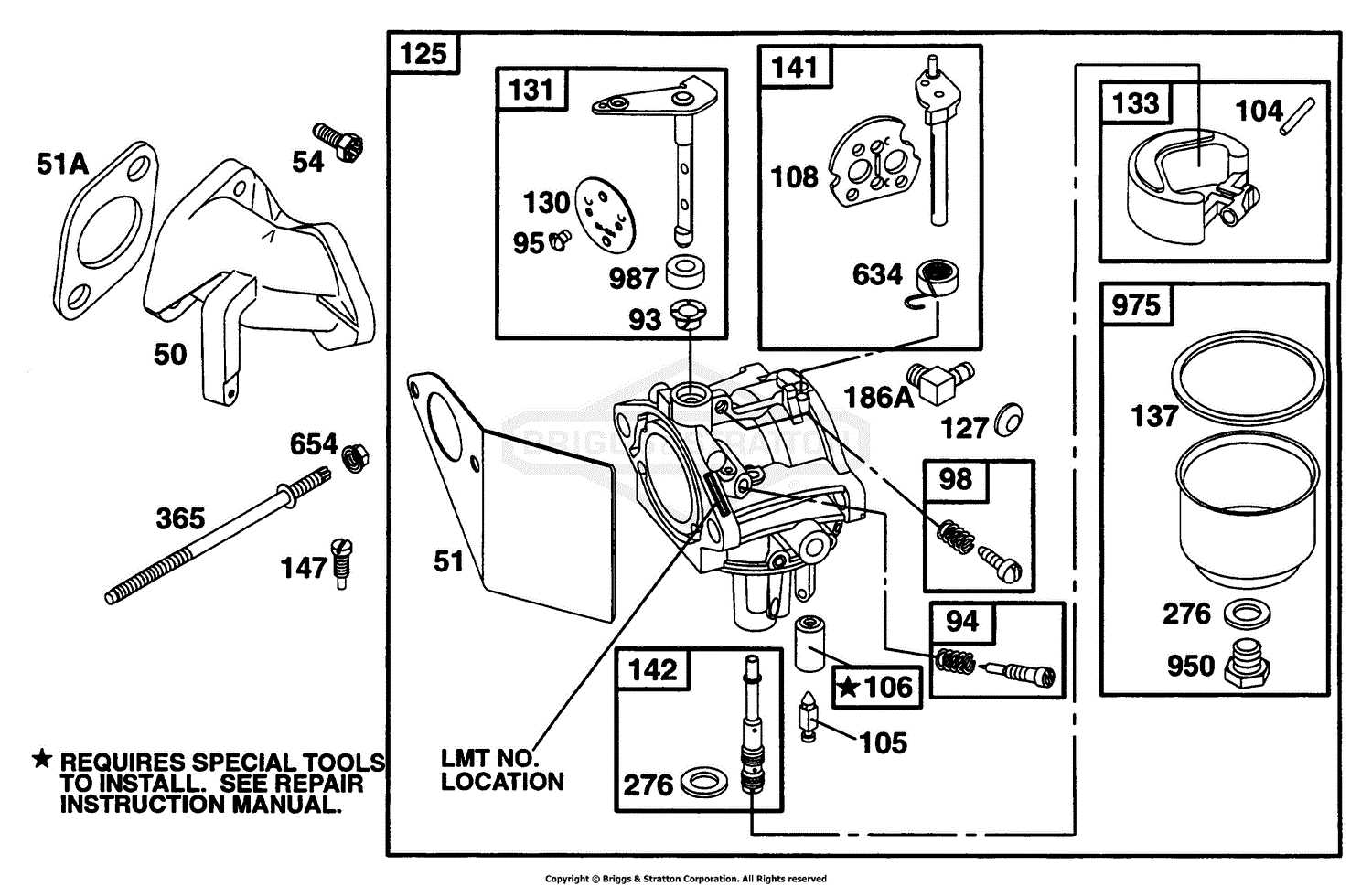

- Carburetor: Mixes air and fuel for optimal combustion.

- Ignition System: Responsible for initiating the combustion cycle.

- Cooling System: Maintains the engine’s temperature to prevent overheating.

Familiarity with these key parts enables users to delve deeper into performance tuning and troubleshooting, enhancing the overall engine experience.

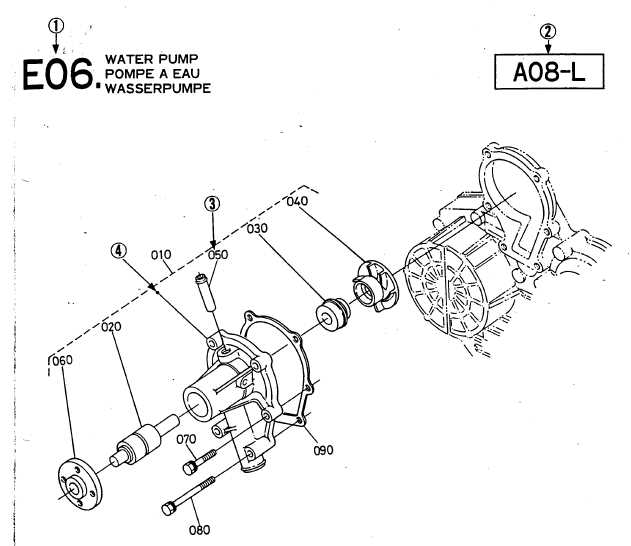

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for efficient maintenance and repairs. Visual representations provide crucial insights into how various elements interact within a system. These illustrations serve as a guide for both novices and experienced users, streamlining the troubleshooting process and enhancing overall functionality.

Benefits of Visual References

- Facilitates easy identification of components.

- Assists in locating specific parts during repairs.

- Improves comprehension of assembly and disassembly procedures.

- Reduces the risk of errors during maintenance tasks.

Enhanced Efficiency in Repairs

- Allows for quicker diagnosis of issues.

- Enables users to gather necessary tools and replacements in advance.

- Provides clarity on the order of operations for repairs.

Overall, having access to these visual aids significantly enhances the repair experience, leading to more effective and efficient maintenance practices.

How to Read Engine Diagrams

Understanding engine schematics is essential for anyone involved in maintenance or repair tasks. These illustrations provide a visual representation of components, helping users identify parts and their relationships within the system. Familiarity with these diagrams can simplify troubleshooting and enhance efficiency in repairs.

Key Components

When examining an engine schematic, start by identifying major elements such as the cylinder, carburetor, and ignition system. Each component is typically labeled, allowing you to quickly locate specific parts. Pay attention to the lines connecting these components, which represent pathways for fuel, air, and electrical signals.

Interpreting Symbols

Diagrams often use standardized symbols to represent various mechanical and electrical parts. Familiarizing yourself with these symbols is crucial for accurate interpretation. Many diagrams include a legend that defines each symbol, aiding in comprehension. Additionally, recognizing common color codes can provide insight into the function and connectivity of different elements.

Common Parts and Their Functions

Understanding the key components of a small engine is essential for maintenance and troubleshooting. Each part plays a specific role in ensuring optimal performance, contributing to the overall efficiency and functionality of the machine. Below is a breakdown of some crucial elements commonly found in these engines and their respective functions.

Essential Components

| Component | Function |

|---|---|

| Cylinder | Houses the piston, creating the space for combustion. |

| Piston | Moves up and down within the cylinder, compressing the air-fuel mixture. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Camshaft | Controls the opening and closing of the engine valves. |

| Fuel Tank | Stores fuel needed for combustion. |

Supporting Elements

| Component | Function |

|---|---|

| Ignition System | Ignites the air-fuel mixture for combustion. |

| Exhaust System | Channels away combustion gases from the engine. |

| Air Filter | Prevents dirt and debris from entering the engine. |

| Oil System | Lubricates moving parts to reduce friction and wear. |

Maintenance Tips for 175cc Engines

Regular upkeep is essential for ensuring optimal performance and longevity of small engines. By following a few simple guidelines, you can enhance efficiency and reduce the likelihood of mechanical failures.

- Check and change the oil regularly to keep the engine lubricated.

- Inspect air filters and replace them if they become dirty to maintain airflow.

- Clean or replace spark plugs to ensure reliable ignition.

- Examine fuel lines for cracks or leaks, replacing them as needed.

- Keep the engine clean by removing debris and dirt buildup.

Implementing these strategies can significantly improve the reliability of your engine, allowing it to perform at its best for years to come.

Where to Find Replacement Parts

Finding the right components for your outdoor equipment can be essential for maintaining optimal performance. Various sources provide options for acquiring necessary items, ensuring you can keep your machinery in top shape without hassle.

Online Retailers

Numerous websites specialize in outdoor equipment parts, offering a wide selection of items. Shopping online often allows for convenient comparison of prices and availability.

Local Dealers

Your local dealers can be a valuable resource. They usually carry a range of components and can assist in identifying the right ones for your specific model.

| Source | Description | Advantages |

|---|---|---|

| Online Retailers | Websites offering various components for outdoor machinery. | Convenient, often lower prices, extensive selection. |

| Local Dealers | Brick-and-mortar stores specializing in equipment. | Personal assistance, immediate availability, expert advice. |

Identifying Engine Issues Using Diagrams

Recognizing problems in machinery can be a complex task, but utilizing visual representations significantly simplifies the process. These illustrations serve as valuable tools, enabling users to pinpoint potential faults and understand the intricate workings of their engines. By examining detailed visuals, one can diagnose issues more effectively and undertake appropriate maintenance measures.

Common Problems and Their Visual Indicators

- Overheating: Look for signs of discoloration or warping in the components.

- Fuel Leaks: Identify any irregularities or stains around fuel lines and connections.

- No Start Condition: Check for disconnected wires or worn-out ignition parts.

- Unusual Noises: Refer to sections highlighting moving parts to trace the source of the sound.

Using Diagrams for Troubleshooting

- Start with a comprehensive overview of the engine layout.

- Follow the flow of fuel and air through the system to identify blockages.

- Refer to specific sections for detailed views of electrical components.

- Cross-reference symptoms with the corresponding parts to ascertain issues.

By leveraging these visual aids, users can enhance their understanding and tackle engine dilemmas with greater confidence and precision.

DIY Repairs with Parts Reference

Engaging in self-repairs can be a rewarding experience, empowering individuals to tackle maintenance tasks with confidence. Understanding the components involved is crucial for effective troubleshooting and restoration of equipment. This guide aims to simplify the repair process by providing a clear reference for essential elements.

Essential Tools for Repair

- Screwdrivers (various sizes)

- Wrenches and pliers

- Replacement components

- Cleaning supplies

- Safety gear

Common Repair Procedures

- Identify the issue by observing the equipment’s performance.

- Refer to the component guide for necessary parts.

- Gather tools and prepare a clean workspace.

- Follow step-by-step instructions to replace or repair the identified parts.

- Test the equipment to ensure proper function before concluding the repair.

Upgrades for Enhanced Engine Performance

Boosting engine efficiency can significantly enhance overall functionality. By implementing specific enhancements, users can experience improved power output, increased durability, and better fuel efficiency. Below are some popular modifications that can help achieve these benefits.

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Air Filter | Replaces standard filters with ones that allow for better airflow. | Improved combustion and horsepower. |

| Performance Carburetor | Enhances fuel delivery for optimal combustion. | Increased throttle response and efficiency. |

| Modified Exhaust System | Reduces back pressure and improves exhaust flow. | Boosted power and reduced engine strain. |

| Upgrade Spark Plug | Utilizes plugs that provide a more efficient spark. | Better ignition and smoother operation. |