Understanding the Delta 1700 Series Parts Diagram

In the realm of mechanical assemblies, having a clear representation of individual elements is crucial for effective maintenance and troubleshooting. A comprehensive overview of these components allows users to grasp the intricate relationships and functionalities within the system. This knowledge not only enhances repair efforts but also aids in the optimization of overall performance.

As enthusiasts and professionals alike delve into their projects, familiarity with the specific arrangement of pieces becomes essential. Each element plays a significant role in ensuring the functionality and efficiency of the entire unit. By examining a detailed layout, one can easily identify potential issues and plan for necessary interventions.

Moreover, understanding the visual representation of components fosters a deeper appreciation for engineering design. It highlights the importance of each part in contributing to the larger mechanism, reinforcing the idea that every detail matters. This insight encourages a more informed approach to both usage and upkeep, ultimately leading to enhanced longevity and reliability.

Understanding Delta 1700 Series Components

In this section, we will explore the essential elements that constitute a particular line of fixtures. Each component plays a vital role in ensuring optimal functionality and user satisfaction. By gaining insights into these individual pieces, one can appreciate the overall design and efficiency of the entire system.

Key Elements: The primary components include various fittings, valves, and controls that contribute to performance and ease of use. Understanding their specific functions can help users make informed decisions when it comes to installation and maintenance.

Maintenance Tips: Regular checks and timely replacements of these parts are crucial for prolonging the life of the fixtures. Familiarity with these elements not only enhances user experience but also facilitates troubleshooting when issues arise.

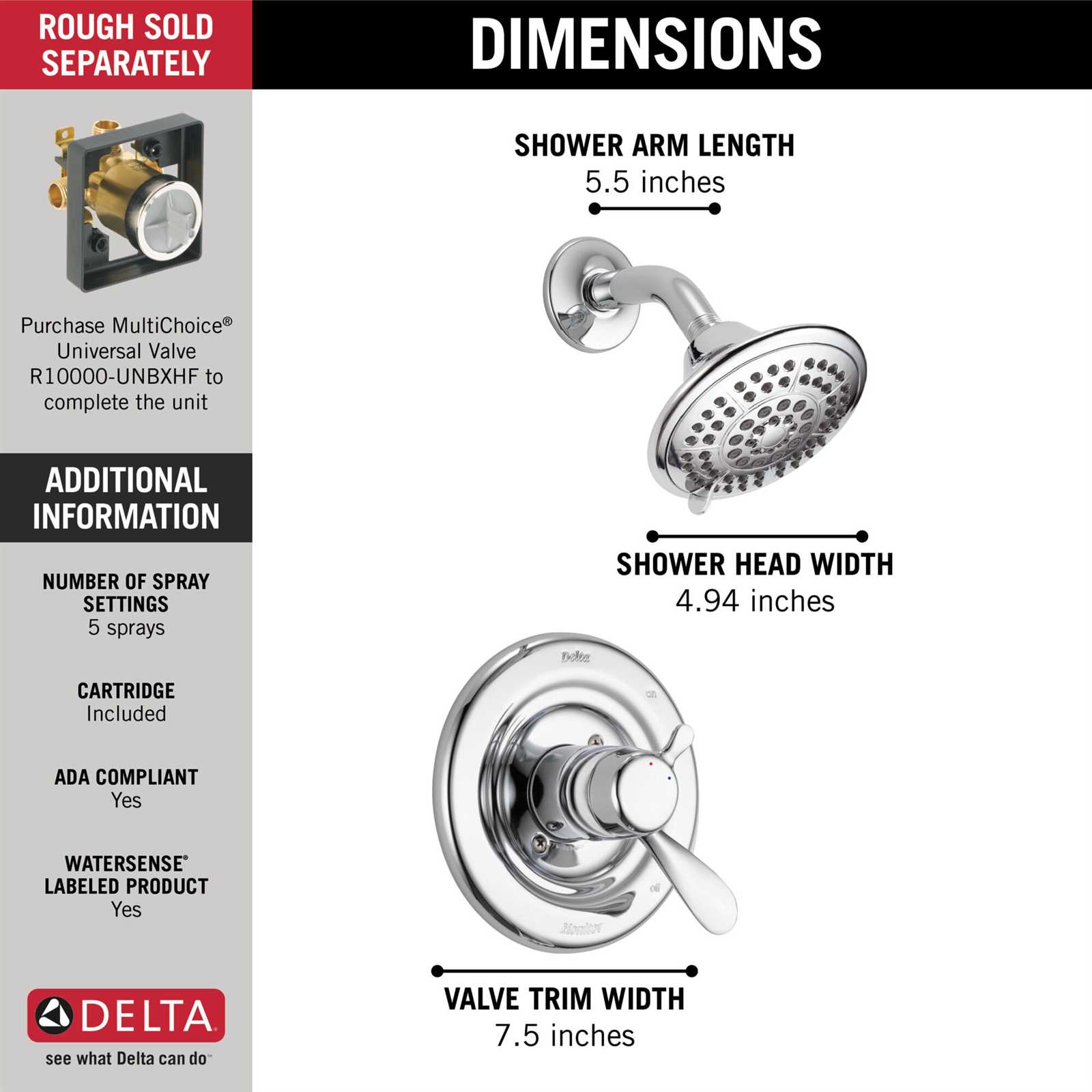

Overview of Delta 1700 Series Models

This section provides a comprehensive look at a popular line of products known for their reliability and innovative design. These models are widely recognized for their exceptional performance and versatility, making them suitable for various applications. Users appreciate the combination of durability and efficiency that these products deliver.

Each model within this range is crafted with attention to detail, ensuring that they meet the diverse needs of consumers. The functionality and ease of use have made them a favorite among both professionals and DIY enthusiasts. Furthermore, the availability of compatible accessories enhances their adaptability, allowing for tailored solutions in different settings.

As you explore the specifications and features of these models, you’ll discover a commitment to quality that stands out in the market. From robust construction to innovative functionalities, each variant brings unique advantages, contributing to a well-rounded selection for every user’s requirements.

Key Features of Delta 1700 Parts

This section explores the essential attributes of components from a well-known plumbing brand, highlighting their significance in enhancing performance and reliability. Understanding these characteristics helps users make informed decisions when selecting fixtures and accessories for their systems.

Durability and Reliability

Quality materials ensure longevity and dependability, making these components suitable for both residential and commercial applications. With an emphasis on resistance to wear and corrosion, users can trust that these items will withstand daily use.

Innovative Design

The cutting-edge technology integrated into these components not only improves functionality but also enhances user experience. Ergonomic features and modern aesthetics provide both comfort and visual appeal, allowing for seamless integration into any setting.

Importance of Accurate Diagrams

Precise visual representations play a crucial role in understanding complex machinery and equipment. They facilitate clarity, ensuring that each component is easily identifiable, thus aiding in maintenance and assembly tasks. A well-crafted illustration can significantly reduce the likelihood of errors during repair or installation processes.

Enhancing Efficiency

Accurate illustrations streamline workflows, allowing technicians to quickly locate and address issues. This efficiency minimizes downtime and enhances overall productivity, making it essential for businesses that rely on timely repairs.

Supporting Training and Education

High-quality visual guides serve as valuable educational tools. They assist new employees in grasping the intricacies of machinery, fostering a deeper understanding that ultimately leads to better performance and safety.

| Benefits | Description |

|---|---|

| Reduced Errors | Clear visuals minimize mistakes during assembly and repairs. |

| Time-Saving | Quick identification of components accelerates maintenance tasks. |

| Improved Training | Visual aids enhance comprehension for new staff. |

Common Replacement Parts Explained

In any system, certain components are more prone to wear and tear over time. Understanding these elements is crucial for maintenance and ensuring optimal performance. This section delves into the most frequently needed components, their functions, and why they may require replacement.

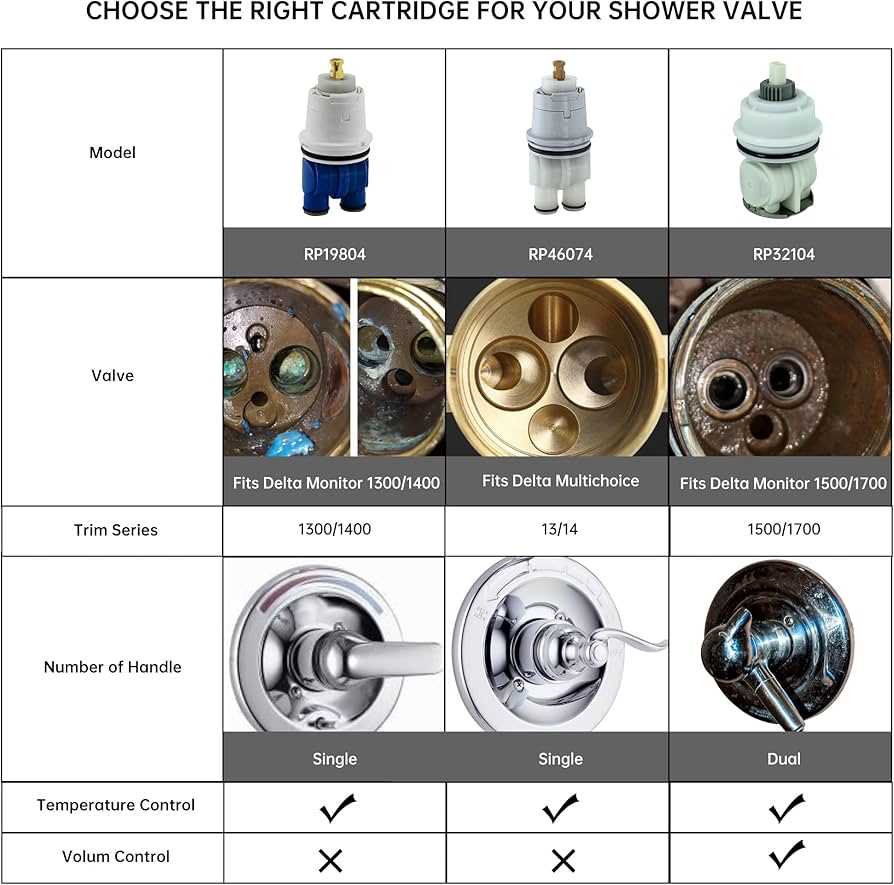

- Cartridges: These vital units regulate water flow and temperature. Over time, they may become less efficient, leading to leaks or inconsistent temperature control.

- Handles: Often the first point of contact, handles can become loose or break, affecting usability. Replacement ensures a comfortable grip and ease of operation.

- O-Rings: Small yet significant, these seals prevent leaks. They can degrade due to age or exposure to harsh elements, necessitating their replacement to maintain a watertight seal.

- Sprayers: Frequently used in kitchen settings, sprayers can wear out or clog. Regular checks can help identify when a replacement is necessary for proper function.

- Hoses: These components transport water and may become damaged or kinked. Replacing them ensures efficient flow and prevents potential leaks.

Regular maintenance and timely replacement of these components can greatly enhance the longevity and performance of the system, ensuring a smooth operation for years to come.

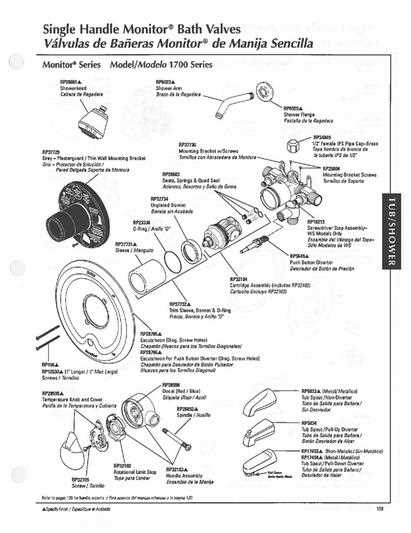

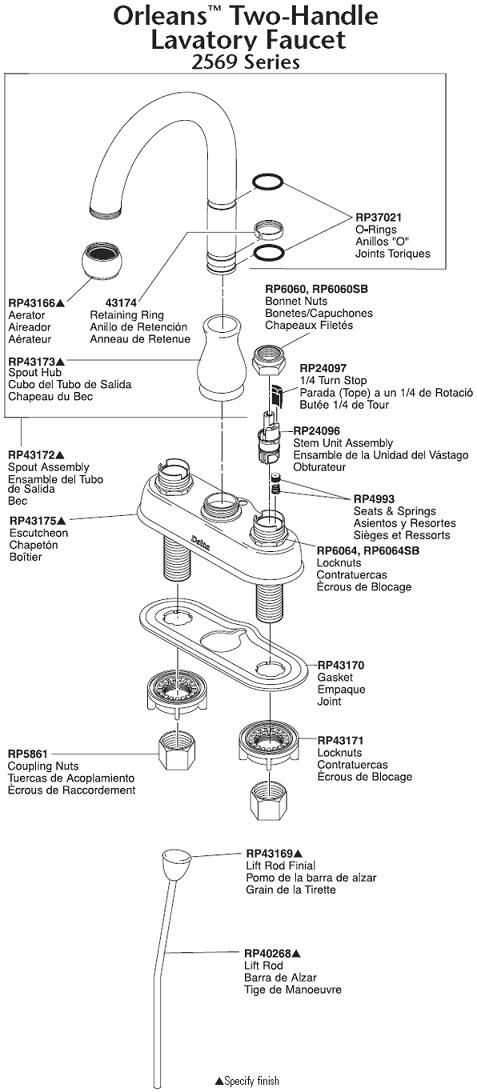

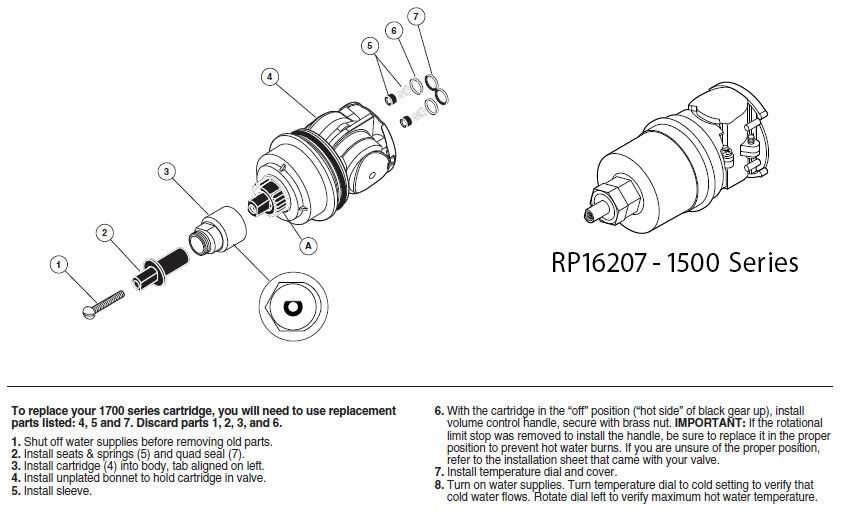

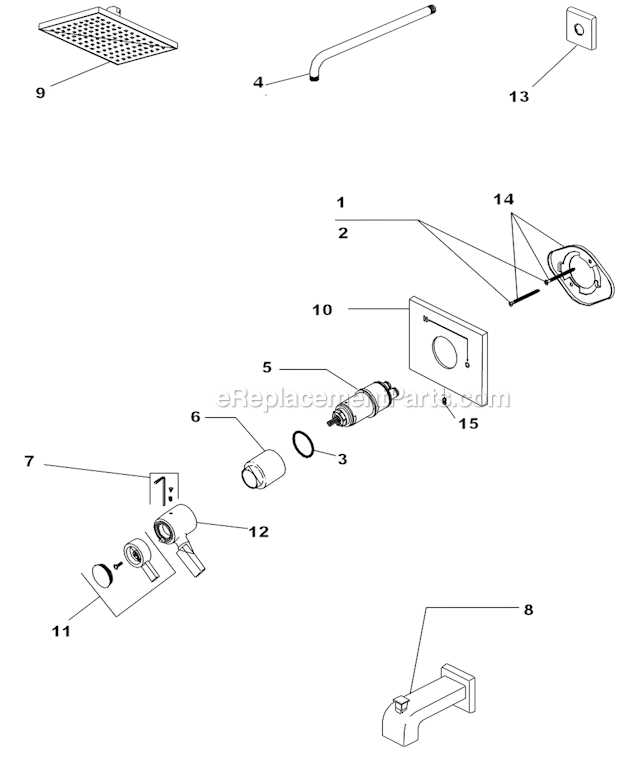

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective assembly and maintenance. These illustrations provide a clear overview of individual elements, their arrangement, and how they interact within a larger system. Mastering the interpretation of these images can significantly enhance your ability to troubleshoot and repair machinery.

Begin by familiarizing yourself with the key symbols and labels used in the visuals. Each icon or drawing represents a specific piece, often accompanied by numerical references or letters that correlate with a parts list. This allows for easy identification and ordering of the required components.

Next, pay attention to the layout. Components are usually organized in a logical manner that reflects their physical placement within the machinery. Understanding this spatial relationship can aid in visualizing the assembly process and pinpointing areas that may require attention or replacement.

Additionally, note any annotations or notes included in the illustration. These can provide valuable insights into installation techniques, maintenance tips, or specific configurations necessary for optimal performance. Taking the time to read these details can save you time and prevent potential issues.

Finally, practice is key. Regularly reviewing and working with these visuals will build your confidence and proficiency. Over time, you will find it easier to navigate and interpret these essential tools, leading to more efficient repairs and improvements.

Maintenance Tips for Delta 1700 Series

Regular upkeep is essential to ensure the longevity and optimal performance of your equipment. Following a systematic maintenance routine can help prevent issues and enhance efficiency.

Here are some key recommendations to keep your system in top condition:

- Routine Inspection: Regularly examine all components for signs of wear or damage. This includes checking seals, connections, and any moving parts.

- Cleanliness: Keep the unit free from debris and buildup. Use appropriate cleaning agents that won’t harm the surfaces.

- Lubrication: Apply lubricant to moving parts as specified by the manufacturer. This will reduce friction and wear.

- Fluid Levels: Monitor and maintain correct fluid levels. Replace fluids as necessary to ensure optimal operation.

Additionally, consider the following steps:

- Schedule regular maintenance checks at least twice a year.

- Document any repairs or replacements for future reference.

- Keep all necessary tools and replacement items on hand for quick access.

By adhering to these maintenance practices, you can significantly extend the lifespan of your equipment and maintain its efficiency. Stay proactive to avoid larger issues down the line.

Where to Find Parts Diagrams

Finding visual representations for various components is essential for maintenance and repairs. These illustrations can guide users in identifying and acquiring the correct elements needed for their projects.

- Manufacturer Websites: Most manufacturers provide official resources that include detailed visuals of their products.

- Online Retailers: E-commerce platforms often feature schematics in product listings to assist buyers.

- User Forums: Communities dedicated to specific brands may share resources and diagrams uploaded by fellow enthusiasts.

- Repair Manuals: Comprehensive guides typically contain detailed illustrations and descriptions for reference.

- Technical Support: Contacting customer service can yield access to specialized diagrams not readily available online.

Utilizing these resources will ensure a thorough understanding of component layouts, leading to effective repairs and enhancements.

Installation Procedures for Replacement Parts

This section outlines essential guidelines for properly installing new components in a system. Following these procedures ensures optimal functionality and longevity of the equipment while minimizing the risk of issues during and after the installation process.

Preparation Steps

Before starting the installation, gather all necessary tools and components. Review the user manual for specific instructions related to the equipment. Ensure the work area is clean and free of obstructions to facilitate a smooth process.

Installation Process

Begin by carefully removing the existing component, taking note of the orientation and connections. Install the new item, ensuring a secure fit and proper alignment. Reconnect any wiring or fixtures, then test the system to confirm successful installation.

Frequently Asked Questions on Delta 1700

This section addresses common inquiries regarding a specific line of products, focusing on components and their functionality. Here, you will find answers that clarify various aspects, ensuring users gain a deeper understanding of their maintenance and operational needs.

What are the main components of this product line?

The primary elements include various fixtures, controls, and attachments designed to enhance usability and performance.

How can I identify a specific component?

Where can I find replacement parts?

Replacement items are available through authorized retailers, online marketplaces, or directly from the manufacturer’s website, ensuring compatibility and quality.

Are there any maintenance tips I should follow?

Regular cleaning, inspection for wear, and timely replacements are essential for longevity. Following the user manual’s guidelines can greatly enhance the product’s lifespan.

Can I upgrade components for better performance?

Many users opt for upgrades to improve efficiency or add features. However, it’s important to ensure that any upgrades are compatible with the existing setup.

Resources for Delta 1700 Users

This section aims to provide essential materials and support for users seeking to enhance their experience with specific equipment. Whether you’re looking for troubleshooting guides, maintenance tips, or community forums, the following resources will prove invaluable in maximizing your setup’s performance.

Online Communities

Joining dedicated forums and discussion boards can connect you with fellow enthusiasts and experts. Platforms like Reddit and specialized groups on social media offer spaces to share experiences, ask questions, and gain insights into effective usage and modifications.

Official Manuals and Guides

Accessing user manuals and maintenance guides is crucial for understanding the operational intricacies of your equipment. These documents often include diagrams, troubleshooting steps, and maintenance schedules that can significantly improve functionality and longevity.