Understanding the Exmark Radius E Series Parts Diagram

In the realm of outdoor maintenance, the efficiency and performance of a lawn care machine hinge on its intricate assembly. Each element plays a vital role in ensuring optimal functionality, enabling users to achieve their landscaping goals with ease.

The exploration of these components offers valuable insights into how they interact and contribute to the overall effectiveness of the equipment. By understanding the layout and relationships among various parts, operators can enhance their maintenance practices and troubleshoot potential issues more effectively.

Moreover, gaining familiarity with the mechanical structure not only empowers users but also aids in making informed decisions when it comes to repairs or upgrades. Whether you’re a seasoned professional or a dedicated hobbyist, delving into this knowledge is essential for maximizing your machine’s potential.

Understanding Exmark Radius E Series

This section explores the intricacies of a particular line of high-performance mowing equipment, focusing on its design, functionality, and key components. By examining the unique features that set this machinery apart, users can appreciate its engineering excellence and operational efficiency.

The models in this range are crafted for superior maneuverability and reliability, making them ideal for both commercial and residential use. Their robust construction and thoughtful design elements ensure a seamless mowing experience, catering to various turf conditions.

Maintenance is crucial for longevity, and understanding the essential components will help users keep their machines in top condition. Familiarizing oneself with the structure and assembly of this equipment enables better care and enhances overall performance.

Key Features of Radius E Series

This section highlights the essential characteristics of a premier lawn care equipment model designed for efficiency and user comfort. Its innovative design elements set it apart, making it a top choice for professionals and enthusiasts alike.

Performance Enhancements

- Powerful engine options for robust performance.

- Enhanced cutting technology for a precise finish.

- Improved fuel efficiency for longer operational time.

User Comfort and Control

- Ergonomic seating designed for prolonged use.

- Intuitive controls for effortless maneuverability.

- Adjustable cutting height for versatile mowing options.

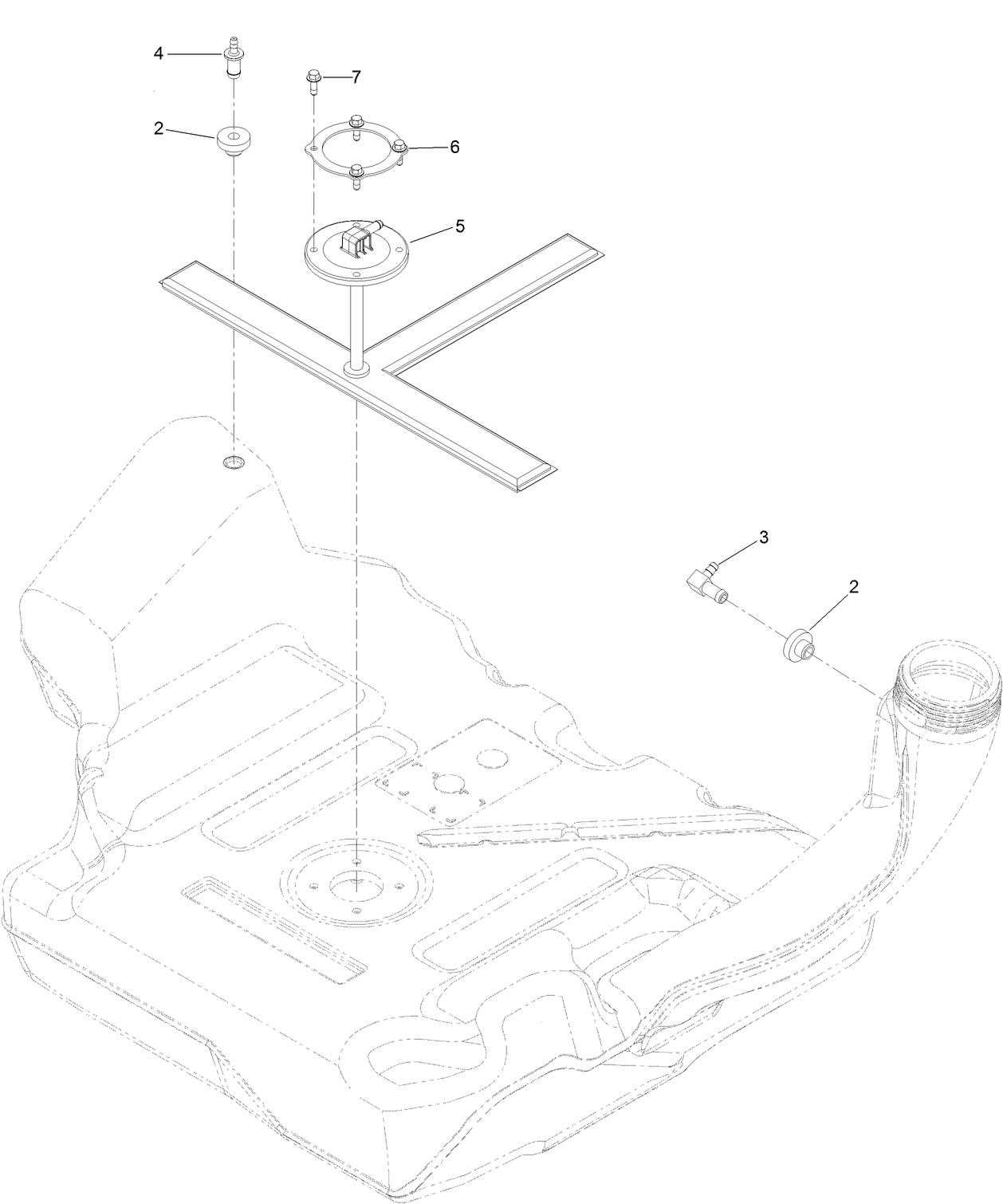

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify each element with ease and precision. These illustrations not only enhance comprehension but also facilitate smoother workflows, ensuring that every task is approached systematically.

Clarity is one of the primary benefits of these visual aids. By breaking down complex structures into manageable sections, they help users to grasp the functionality and interrelation of each part. This clarity significantly reduces the risk of errors during assembly or repairs.

Moreover, such illustrations serve as a valuable reference for both novice and experienced users. They provide a quick way to locate necessary components, which ultimately saves time and enhances efficiency in any maintenance task. Ultimately, the effective use of these resources fosters greater confidence in handling machinery.

Common Replacement Parts Explained

In the maintenance of outdoor power equipment, understanding frequently needed components is crucial for ensuring optimal performance and longevity. Familiarity with these essential items allows users to efficiently manage repairs and replacements, ultimately enhancing the equipment’s reliability.

Here are some of the most commonly replaced components:

- Blades: Sharp blades are vital for achieving a clean cut. Regular replacement ensures efficient grass trimming and prevents unnecessary strain on the motor.

- Filters: Air and fuel filters keep contaminants out of the engine, promoting better performance and fuel efficiency. Replacing them periodically is essential for engine health.

- Batteries: A reliable battery is crucial for starting the engine. Over time, batteries may lose their ability to hold a charge, necessitating replacement.

- Belts: These components transfer power from the engine to the blades. Worn or damaged belts can lead to performance issues and should be checked regularly.

- Spark Plugs: Spark plugs ignite the fuel-air mixture, and worn plugs can cause starting difficulties and reduce engine efficiency. Regular checks and replacements can prevent such issues.

By staying informed about these key elements, users can perform timely maintenance and ensure their equipment operates smoothly and efficiently.

How to Interpret Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed overview of the various elements within a machine, aiding in identification and replacement tasks. Here’s how to navigate these useful resources.

- Familiarize Yourself with the Layout: Each illustration typically follows a structured format, often organized into sections that represent different parts of the machine.

- Identify Key Labels: Look for labels and numbers that correspond to specific components. These annotations are crucial for locating the correct items in a parts catalog.

- Refer to the Legend: Many visuals include a legend or key that explains symbols and color codes used throughout the illustration.

- Cross-Reference with Manuals: Consult the accompanying manuals to gain context on the components’ functions and assembly.

- Take Note of Assembly Order: If applicable, pay attention to how parts fit together, as this will be vital during reassembly.

By mastering these elements, you can efficiently interpret these illustrations, ensuring you have the correct components for any project.

Finding Authentic Exmark Parts

When maintaining outdoor equipment, sourcing genuine components is crucial for optimal performance and longevity. Authentic pieces ensure that machinery operates at its best, reducing the risk of malfunctions and enhancing overall efficiency. This guide will explore effective methods for locating reliable sources that provide these essential items.

Start by researching reputable dealers or authorized distributors who specialize in outdoor machinery. These providers often carry a wide selection of original components, ensuring compatibility with your equipment. Additionally, visiting official websites can yield valuable information regarding certified sellers.

Another effective strategy involves engaging with local service centers that are recognized for their expertise. These establishments can offer insights into where to find genuine components and may even have them available on-site. Establishing a relationship with knowledgeable technicians can prove invaluable in your search.

Lastly, consider exploring online marketplaces, but exercise caution. Look for sellers with positive reviews and those who clearly state that their offerings are authentic. Comparing prices and verifying the authenticity of items can save both time and resources while ensuring you obtain the best quality.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and performance of your outdoor equipment. Regular maintenance not only enhances efficiency but also extends the lifespan of your machinery. Following a systematic approach can prevent costly repairs and downtime.

Here are some key practices to consider:

| Task | Frequency | Tips |

|---|---|---|

| Oil Change | Every 50 hours | Use high-quality oil and replace the filter. |

| Air Filter Check | Every 25 hours | Clean or replace filters to ensure proper airflow. |

| Blade Sharpening | After every 8 hours of use | Keep blades sharp for a cleaner cut and less strain. |

| Battery Inspection | Monthly | Check terminals for corrosion and ensure a full charge. |

| Fuel System Maintenance | Before storage | Stabilize fuel and run the engine to prevent clogging. |

By adhering to these guidelines, you can significantly improve the reliability and lifespan of your machinery, ensuring it performs at its best season after season.

Tools Needed for Parts Replacement

Proper maintenance and repair require a set of essential instruments to ensure efficient and safe replacement of components. Having the right tools at your disposal can significantly streamline the process and minimize potential issues.

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips to accommodate different screws.

- Pliers: For gripping and manipulating smaller components.

- Socket Set: Ideal for reaching tight spaces and providing leverage.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Utility Knife: Useful for cutting through materials as needed.

- Safety Gear: Goggles and gloves to protect yourself during the process.

Equipping yourself with these tools will provide the ultimate support for any maintenance or repair task you undertake.

Step-by-Step Replacement Process

When it comes to maintaining your equipment, replacing worn or damaged components is crucial for optimal performance. This guide will provide a clear, concise method for carrying out replacements, ensuring that you can complete the task efficiently and effectively.

Preparation

Before beginning the replacement, gather all necessary tools and new components. Make sure to read through the manufacturer’s instructions to understand the specific requirements for your model. Additionally, ensure that the equipment is turned off and disconnected from any power source to prevent accidents during the process.

Replacement Steps

1. Remove the old component: Carefully detach the damaged part by following the manufacturer’s guidelines. Use appropriate tools to avoid any unnecessary strain on surrounding elements.

2. Inspect surrounding areas: Once the old part is removed, examine the area for any debris or damage. Clean the space as needed to ensure a proper fit for the new component.

3. Install the new component: Align the new piece according to the specifications and securely fasten it in place. Ensure that all connections are tight and that there are no loose ends.

4. Test the equipment: Once the installation is complete, reconnect the power source and test the equipment to confirm that the new part functions correctly. Listen for any unusual noises and check for proper operation.

By following these steps, you can ensure that the replacement process is smooth and that your equipment continues to operate at its best.

Troubleshooting Common Issues

When dealing with outdoor power equipment, encountering operational challenges is not uncommon. Identifying and resolving these issues quickly can enhance performance and prolong the lifespan of your machine. Here are some frequent problems and solutions to consider.

Engine Won’t Start

If the engine fails to ignite, check the fuel level and ensure that fresh fuel is being used. Additionally, inspect the battery connections and spark plug for any signs of wear or corrosion. Cleaning these components may restore functionality.

Uneven Cutting Performance

When your equipment does not provide a uniform cut, it might be due to a dull blade or improper height settings. Regularly sharpening the blades and adjusting the cutting height can significantly improve results. Inspecting the tires for equal pressure is also advisable.

Where to Buy Exmark Parts

Finding quality components for your lawn care equipment can significantly enhance its performance and longevity. Whether you need replacement items or upgrades, knowing where to purchase reliable supplies is essential for maintaining your machinery. This guide will explore various options for sourcing these essential elements.

| Source | Description |

|---|---|

| Authorized Dealers | These retailers offer genuine components and knowledgeable staff to assist with your needs. |

| Online Marketplaces | Websites like Amazon and eBay provide a wide selection, often at competitive prices. |

| Local Hardware Stores | Many local shops stock essential components and can often place special orders for specific items. |

| Manufacturer’s Website | Direct purchasing from the manufacturer’s site ensures authenticity and often includes detailed specifications. |

| Specialty Suppliers | These companies focus on lawn and garden equipment, often providing expert advice and hard-to-find items. |

Customer Support and Resources

Access to reliable assistance and valuable materials is essential for users seeking to enhance their experience with outdoor equipment. Comprehensive support services and informational resources ensure that customers can maintain their machinery effectively, resolve issues promptly, and optimize performance over time.

Customers can benefit from a variety of support options, including dedicated helplines, online chat services, and email support. These channels provide direct access to knowledgeable representatives who can assist with inquiries, troubleshoot problems, and offer guidance on maintenance and repairs.

In addition to direct support, a wealth of online resources is available. Official websites often host extensive libraries of manuals, maintenance guides, and instructional videos, making it easier for users to find the information they need. Furthermore, community forums and user groups foster a collaborative environment where individuals can share tips, advice, and personal experiences.

For those in need of replacement components, accessing a reliable source for quality parts is crucial. Many manufacturers provide online catalogs, allowing customers to easily identify and order the necessary items to keep their equipment in optimal condition. By utilizing these resources, users can ensure longevity and performance from their machines.