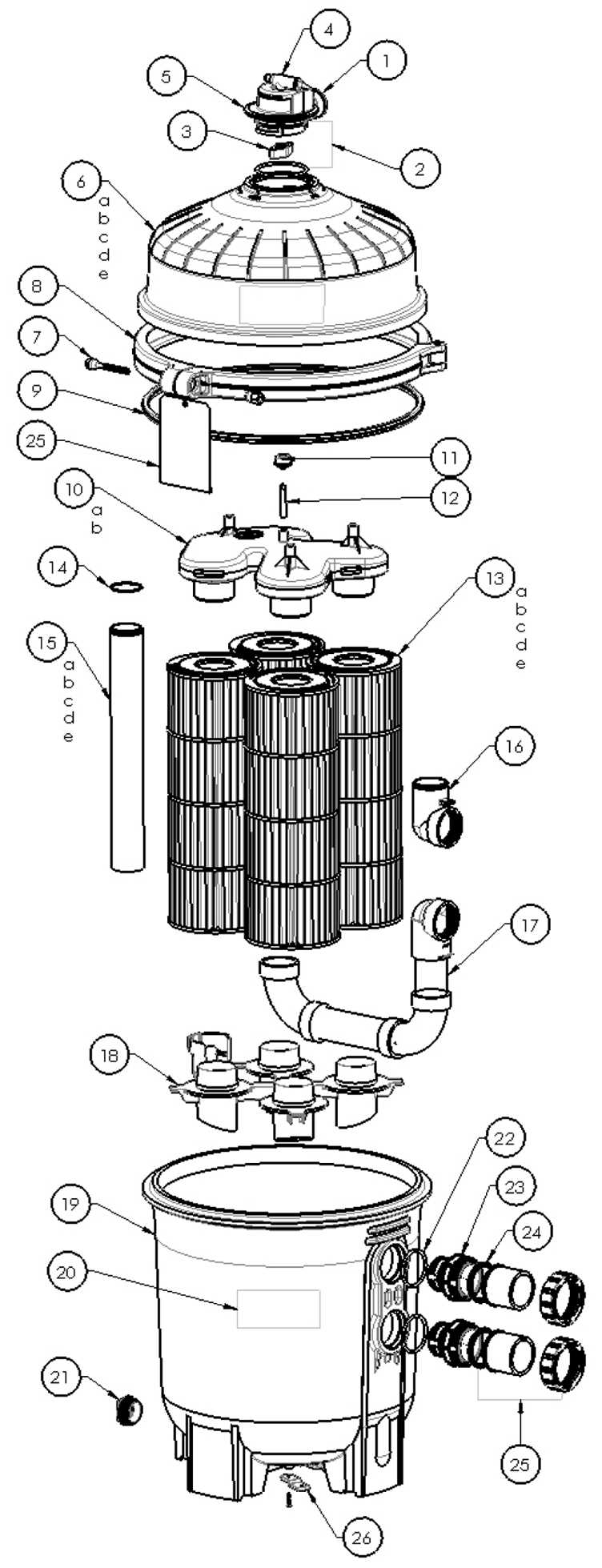

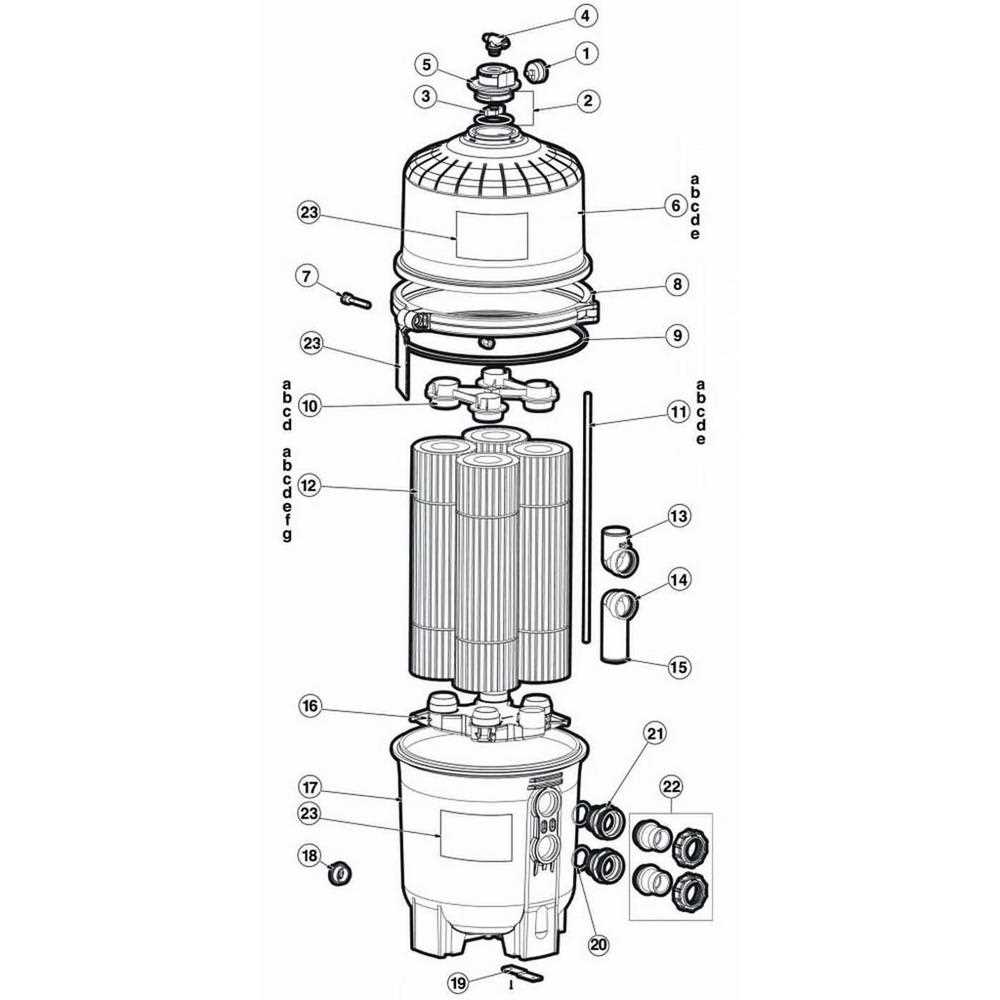

Understanding the Hayward Pro Series Sand Filter Parts Diagram

Maintaining a clean and inviting aquatic environment is essential for any pool owner. A crucial aspect of achieving this goal lies in comprehending the various elements that make up a reliable purification mechanism. This article delves into the intricate details of the essential components involved in the filtration process, ensuring optimal functionality and longevity.

Each element plays a vital role in enhancing performance and efficiency. Recognizing how these components interact with one another allows users to troubleshoot potential issues effectively. This understanding not only aids in regular maintenance but also empowers owners to make informed decisions regarding upgrades and replacements.

In this exploration, we will present a detailed visual representation of the key elements within the system, highlighting their specific functions and interconnections. By familiarizing yourself with these components, you can ensure that your aquatic oasis remains pristine and enjoyable throughout the seasons.

Understanding Hayward Pro Series Filters

This section provides a comprehensive overview of a popular type of water purification system designed for maintaining cleanliness and clarity in swimming pools. By exploring its components and functionality, users can better appreciate how this equipment ensures efficient operation and longevity.

Key Components

The essential elements of this water management system include various components that work in unison to deliver optimal performance. Understanding these parts is crucial for effective maintenance and operation.

- Tank: The main body that houses the filtration medium.

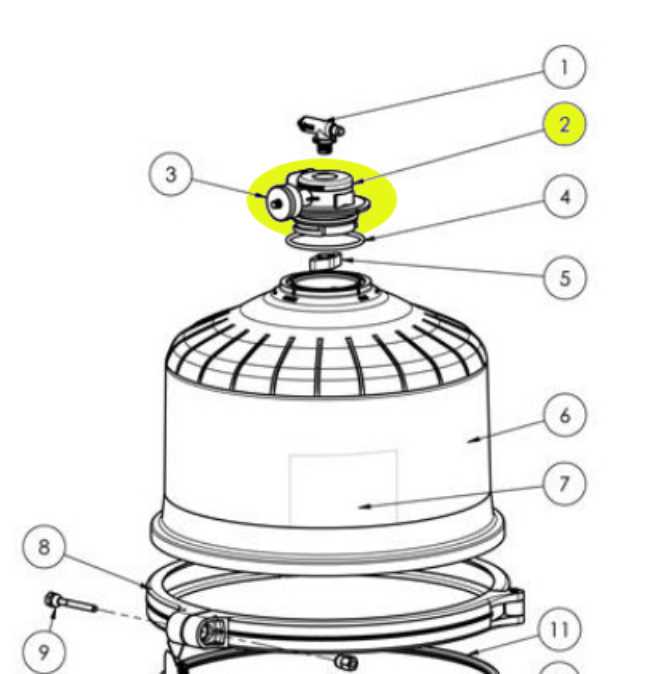

- Multiport Valve: A device that allows users to select different functions such as filtering, backwashing, and rinsing.

- Pressure Gauge: Monitors the pressure within the system, indicating when maintenance is needed.

- Drain Plug: Used for emptying the tank during maintenance procedures.

- Filter Media: The material inside the tank that captures debris and contaminants.

Maintenance Tips

To ensure optimal performance and extend the lifespan of this water treatment equipment, regular upkeep is necessary. Here are some essential maintenance practices:

- Check and clean the pressure gauge regularly.

- Perform backwashing as recommended to clear trapped particles.

- Inspect the multiport valve for any leaks or damage.

- Replace the filtration medium as needed, based on usage and manufacturer guidelines.

- Ensure the drain plug is functioning properly to facilitate maintenance.

By understanding the components and following maintenance tips, users can enjoy clear and clean water throughout the swimming season.

Components of Sand Filter Systems

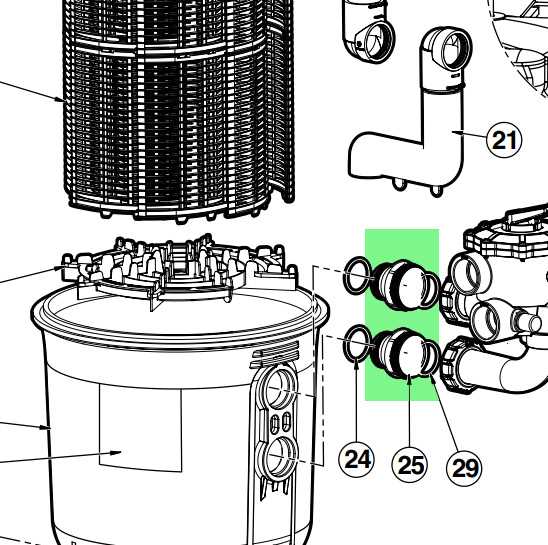

Understanding the essential elements of a filtration system is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring that water remains clean and free from impurities. Below are the key elements typically found in these systems.

- Tank: The primary structure that holds the filtering medium and water.

- Valve: A mechanism that controls water flow, allowing for various operational modes.

- Media: The material responsible for trapping particles and debris, often made of specific granules.

- Pump: A device that circulates water through the system, ensuring even distribution and effective cleaning.

- Pressure Gauge: An instrument that monitors the pressure within the tank, indicating when maintenance is required.

- Drain Valve: A feature that facilitates the removal of water from the tank for cleaning or maintenance purposes.

Each of these components must work in harmony to achieve the desired clarity and purity of the water. Regular checks and maintenance of these elements are essential for longevity and efficiency.

Importance of Filter Maintenance

Regular upkeep of your water purification system is crucial for optimal performance and longevity. Neglecting this aspect can lead to various issues that ultimately compromise the quality of the water.

- Ensures efficient operation, reducing energy consumption.

- Prevents the buildup of debris, which can cause malfunctions.

- Enhances the lifespan of the equipment, saving on replacement costs.

- Improves water clarity and sanitation, promoting a healthier environment.

To achieve these benefits, consider the following maintenance practices:

- Regularly check and clean the components.

- Replace worn or damaged elements promptly.

- Monitor pressure levels to identify potential problems.

- Keep a maintenance log for tracking issues and solutions.

Ultimately, investing time in maintenance is key to ensuring your system operates at its best for years to come.

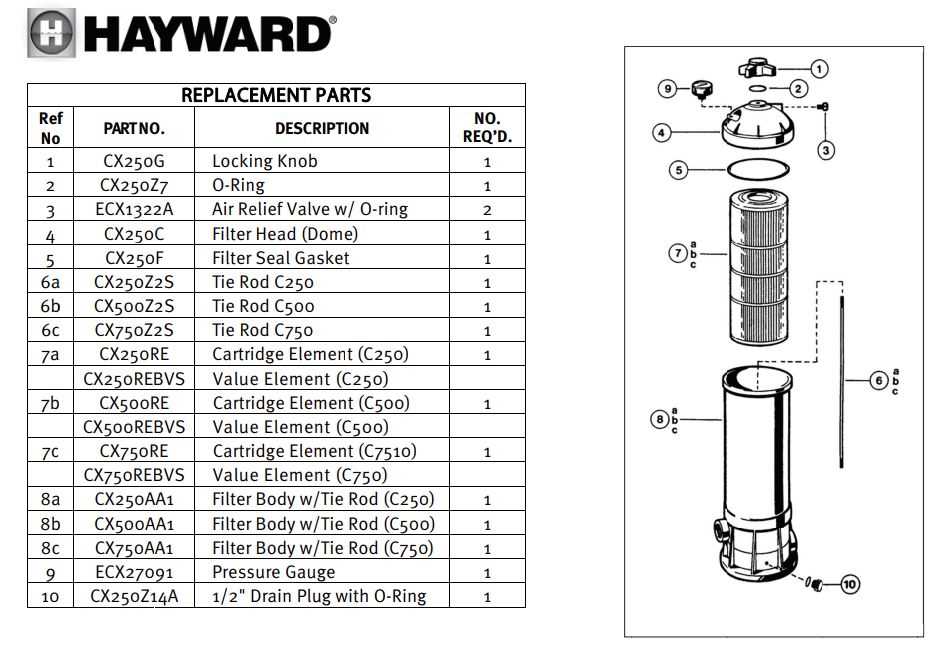

Identifying Common Replacement Parts

Understanding the essential components of your water circulation system is crucial for maintenance and efficient operation. Recognizing the common elements that may require substitution can help ensure longevity and optimal performance.

Key Components to Monitor

Regular inspection of valves, seals, and hoses is essential, as these parts often experience wear over time. Addressing issues with these elements promptly can prevent more significant problems down the line.

Signs of Wear and Tear

Look for signs such as leaks, unusual noises, or reduced performance. These indicators often suggest that specific components need to be replaced to restore efficiency and functionality.

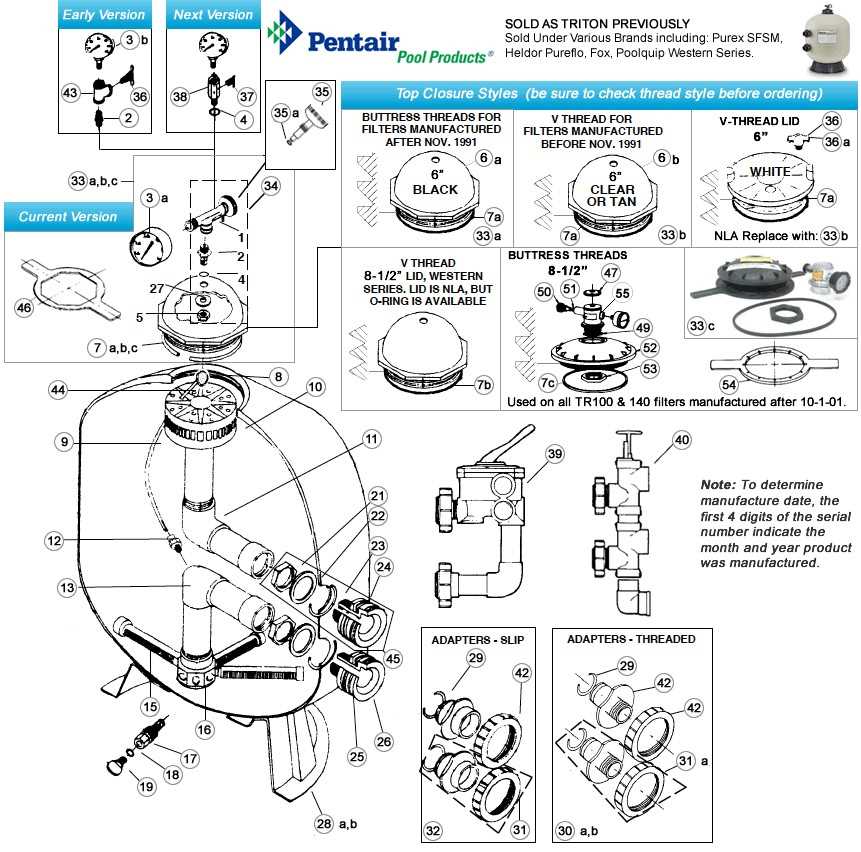

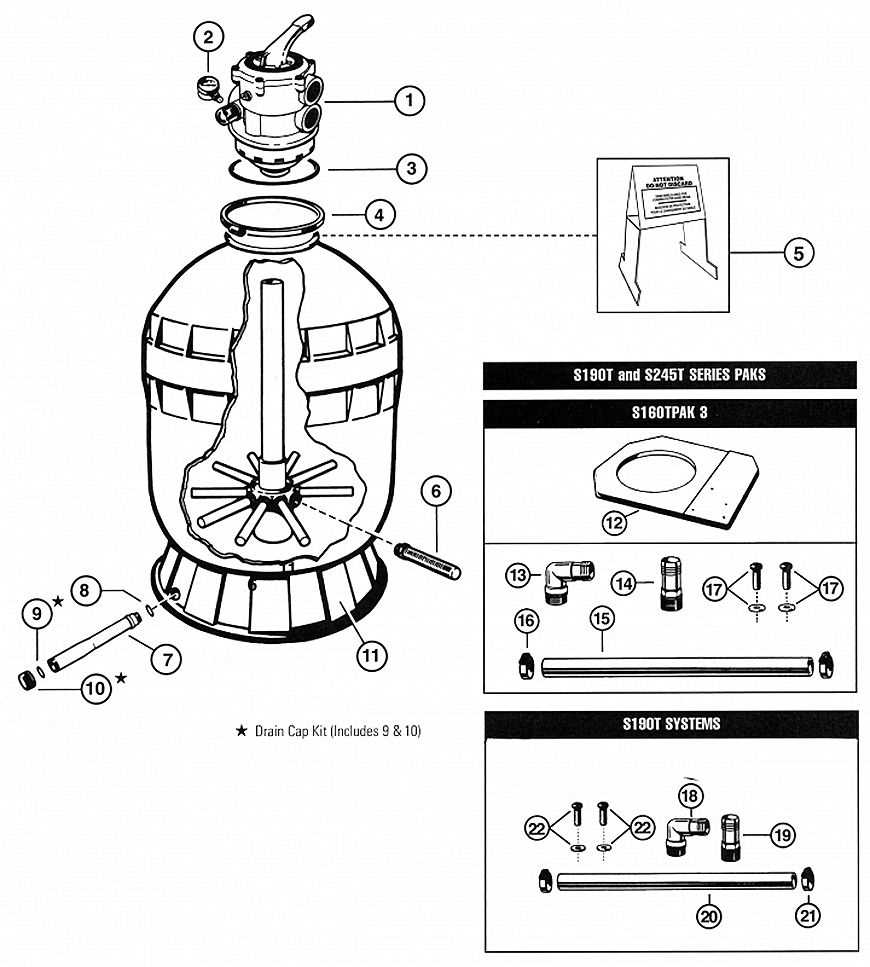

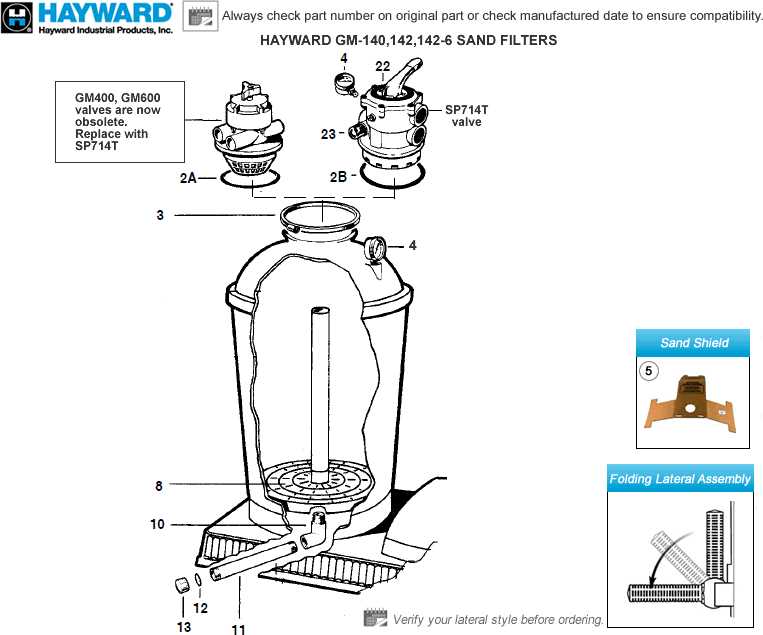

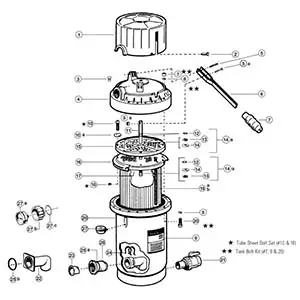

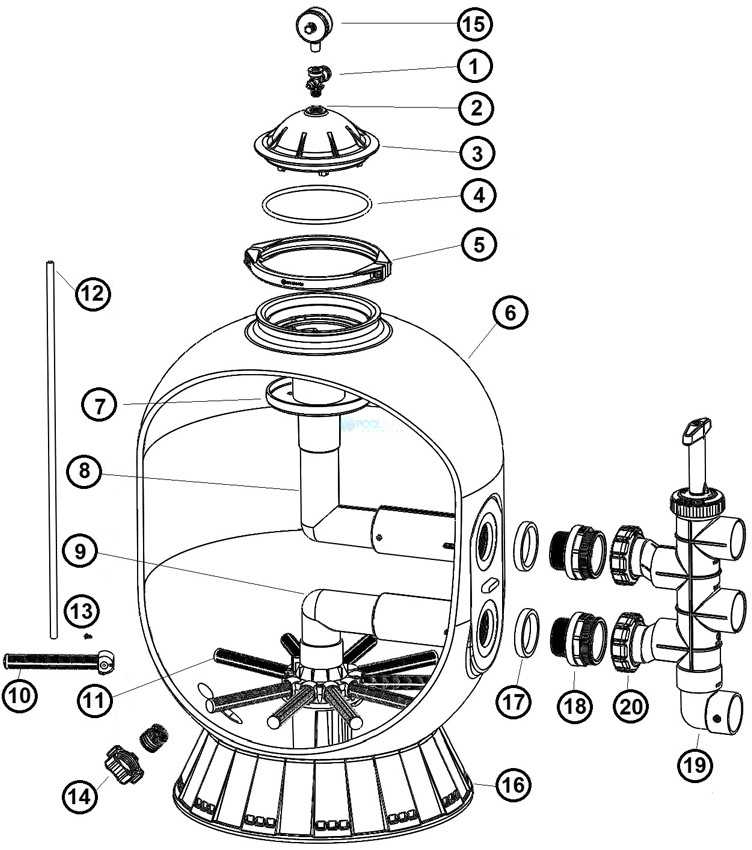

How to Read Parts Diagrams

Understanding visual representations of components can significantly enhance your ability to troubleshoot and maintain equipment. These illustrations often provide crucial insights into the assembly and functionality of various mechanisms, making it essential to grasp how to interpret them effectively.

Here are some key points to consider when analyzing these visuals:

- Familiarize Yourself with Symbols: Different symbols may represent various components. Take time to learn what each icon denotes.

- Identify Main Sections: Most illustrations are divided into distinct segments. Recognizing these areas can help you navigate the entire layout.

- Read Labels and Annotations: Descriptive labels often accompany the illustrations. Pay attention to these details, as they provide additional context.

- Note the Orientation: Some diagrams are oriented in specific ways. Understanding the perspective can be crucial for correct assembly.

By following these guidelines, you can enhance your comprehension of the visuals, ultimately improving your maintenance and repair tasks.

Types of Sand Used in Filters

Understanding the various materials utilized for filtration is crucial for achieving optimal water clarity and cleanliness. Each type of granulate offers unique properties that enhance the effectiveness of the purification process. Selecting the appropriate medium can significantly impact the performance and longevity of the entire system.

Natural Quartz Granules

Natural quartz granules are among the most common choices for filtration applications. Their durability and ability to trap debris make them highly effective. The angular shape of these particles aids in creating a labyrinth effect, which improves the filtration capacity and ensures long-lasting performance.

Zeolite Media

Zeolite media is a synthetic alternative that offers superior absorption capabilities. This material not only captures particles but also reduces ammonia levels in the water, contributing to overall water quality. Its unique molecular structure allows for effective ion exchange, enhancing the filtration process even further.

Common Issues and Solutions

Maintaining a reliable water circulation system is essential for optimal performance. However, various complications may arise, leading to inefficiencies. Understanding these common issues and their corresponding remedies can help ensure your equipment operates smoothly.

Frequent Complications

- Clogging: Debris accumulation can obstruct flow, reducing efficiency.

- Leaks: Unwanted water escape can indicate seal wear or connection issues.

- Noisy Operation: Unusual sounds may suggest mechanical problems or air entrapment.

- Poor Water Quality: Ineffective purification can lead to cloudy or dirty water.

Effective Solutions

- Addressing Clogs: Regularly check and clean the system to prevent blockages.

- Fixing Leaks: Inspect seals and connections; replace any worn parts promptly.

- Minimizing Noise: Ensure proper installation and check for air leaks in the system.

- Improving Water Quality: Monitor chemical levels and ensure the purification unit is functioning correctly.

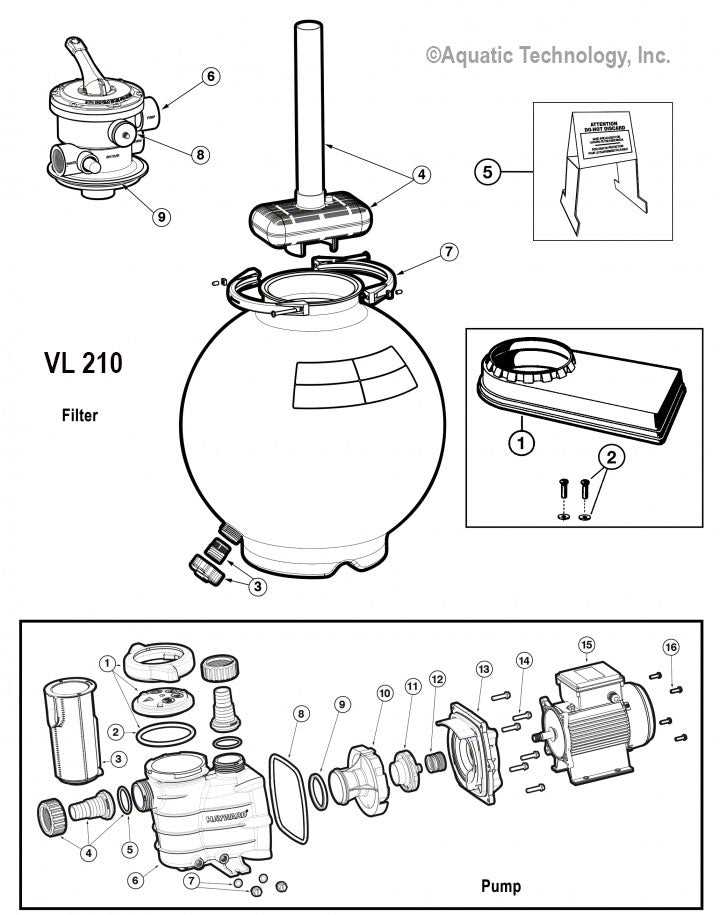

Step-by-Step Installation Guide

This guide provides a comprehensive overview of the installation process for a water purification system, ensuring you can set it up efficiently and effectively. Follow the outlined steps carefully to achieve optimal performance and longevity of your equipment.

Tools and Materials Required

Before starting, gather all necessary tools and materials to streamline the process. Below is a list of essential items:

| Tool/Material | Purpose |

|---|---|

| Wrench | For tightening connections |

| Screwdriver | For securing brackets |

| PVC Pipes | For water flow connections |

| Sealant Tape | To prevent leaks |

| Level | To ensure proper alignment |

Installation Steps

Follow these steps to install your water purification system successfully:

- Choose an appropriate location that provides easy access to water and power sources.

- Ensure the ground is level and stable. Use the level tool to verify alignment.

- Connect the inlet and outlet pipes according to the specifications, ensuring all connections are tight.

- Apply sealant tape on threaded connections to prevent leaks.

- Install any necessary brackets or supports to secure the unit in place.

- Once everything is in position, turn on the water supply to check for leaks and proper operation.

- Run the system for a few minutes and observe to ensure everything is functioning correctly.

By following this guide, you can set up your water treatment equipment confidently, paving the way for clean and clear results.

Tools Needed for Repairs

When it comes to maintenance and fixing equipment, having the right tools at your disposal is essential for effective and efficient work. A well-equipped toolkit not only streamlines the repair process but also ensures that tasks are completed safely and accurately. Below is a list of necessary instruments that will aid in conducting repairs effectively.

| Tool | Description |

|---|---|

| Wrench Set | Essential for loosening and tightening various fasteners. |

| Screwdriver Set | Includes various types and sizes for handling different screws. |

| Plumber’s Tape | Useful for sealing threaded connections to prevent leaks. |

| Replacement Parts | Specific components that may need to be swapped out during repairs. |

| Safety Gear | Includes gloves and goggles to ensure personal protection during repairs. |

Advantages of Hayward Filter Systems

When it comes to maintaining pristine water quality in aquatic environments, certain systems stand out for their efficiency and reliability. These advanced solutions provide numerous benefits, ensuring clarity and cleanliness for both residential and commercial settings.

Efficiency and Performance

These systems are designed to optimize water circulation, reducing energy consumption while enhancing overall performance. With innovative technology, they effectively remove debris and impurities, ensuring a sparkling clean environment.

Durability and Maintenance

Constructed from robust materials, these solutions offer long-lasting performance with minimal upkeep. Regular maintenance is straightforward, allowing users to enjoy hassle-free operation over extended periods.

| Benefit | Description |

|---|---|

| Energy Efficiency | Lower energy costs through optimized water flow. |

| High Filtration | Superior debris removal for crystal-clear water. |

| Durable Construction | Long-lasting materials ensuring reliability. |

| Easy Maintenance | Simplified upkeep for user convenience. |

Comparing Different Filter Models

When evaluating various models of filtration systems, it’s essential to consider their distinct features, performance metrics, and suitability for different environments. Each variant presents unique advantages and potential drawbacks, influencing the decision-making process for consumers and professionals alike.

Performance and Efficiency

Different filtration systems exhibit varying levels of efficiency in removing contaminants. Some designs prioritize speed, while others focus on thoroughness. Understanding how each model manages flow rate and the size of particles it can capture is crucial for selecting the right option for your needs.

Maintenance and Durability

The ease of maintenance and the longevity of each unit can significantly impact overall satisfaction. Some models require regular upkeep and replacement of components, while others are engineered for resilience and minimal intervention. Assessing the long-term investment versus initial cost can guide users toward the most practical choice.

Finding Quality Replacement Parts

When it comes to maintaining and repairing your equipment, sourcing high-quality components is essential for optimal performance and longevity. Ensuring that you invest in reliable replacements can prevent future issues and enhance overall efficiency.

Here are some tips for identifying superior components:

- Research Brands: Look for reputable manufacturers known for their durability and performance. Reading reviews can provide insight into the reliability of various brands.

- Check Compatibility: Always verify that the replacement matches the specifications of your existing unit. Incompatibility can lead to further complications.

- Purchase from Authorized Dealers: Authorized retailers often guarantee the authenticity and quality of their offerings, reducing the risk of subpar products.

- Examine Materials: High-quality components are typically made from robust materials. Check for certifications or warranties that reflect quality standards.

Taking the time to find the right replacements can save you both money and hassle in the long run. Consider these strategies to ensure you select the best options available.