Juki Sewing Machine Parts Diagram and Names

When dealing with intricate devices that are composed of numerous elements, it is essential to familiarize oneself with the core components and their individual functions. Each element plays a crucial role in ensuring the device operates smoothly and efficiently.

Grasping the purpose of various elements within such devices not only aids in better usage but also simplifies the maintenance process. Identifying and understanding the roles of these individual components helps in troubleshooting and extends the longevity of the system.

Clear knowledge of these elements contributes significantly to improved efficiency and enhanced performance, making it easier to manage repairs and adjustments when necessary.

Juki Sewing Machine Components Overview

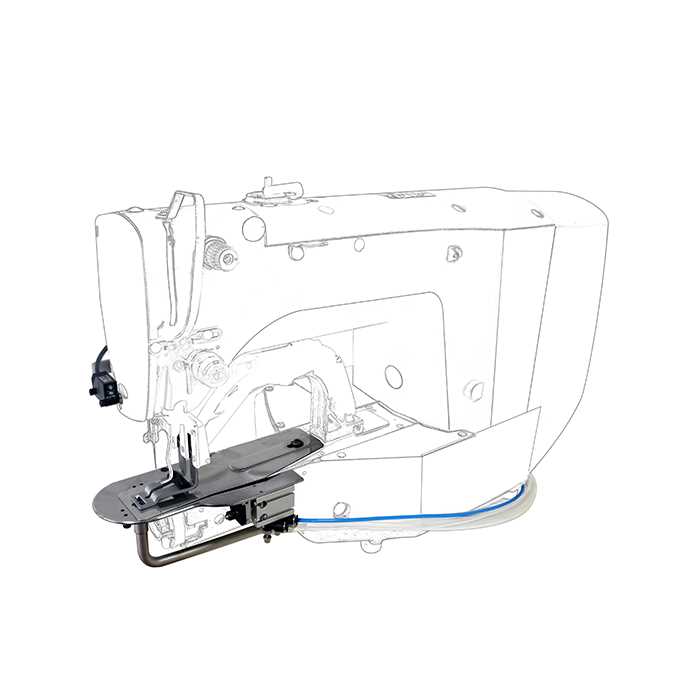

The design of modern stitching devices includes a variety of critical elements that work together to deliver smooth and efficient operation. Each of these components plays a unique role in ensuring precise and reliable stitching performance. Understanding the key mechanisms can help users operate and maintain their equipment more effectively.

Core Mechanical Elements are responsible for the essential movements and adjustments required during fabric processing. These include levers, tension regulators, and drive systems that ensure consistent performance.

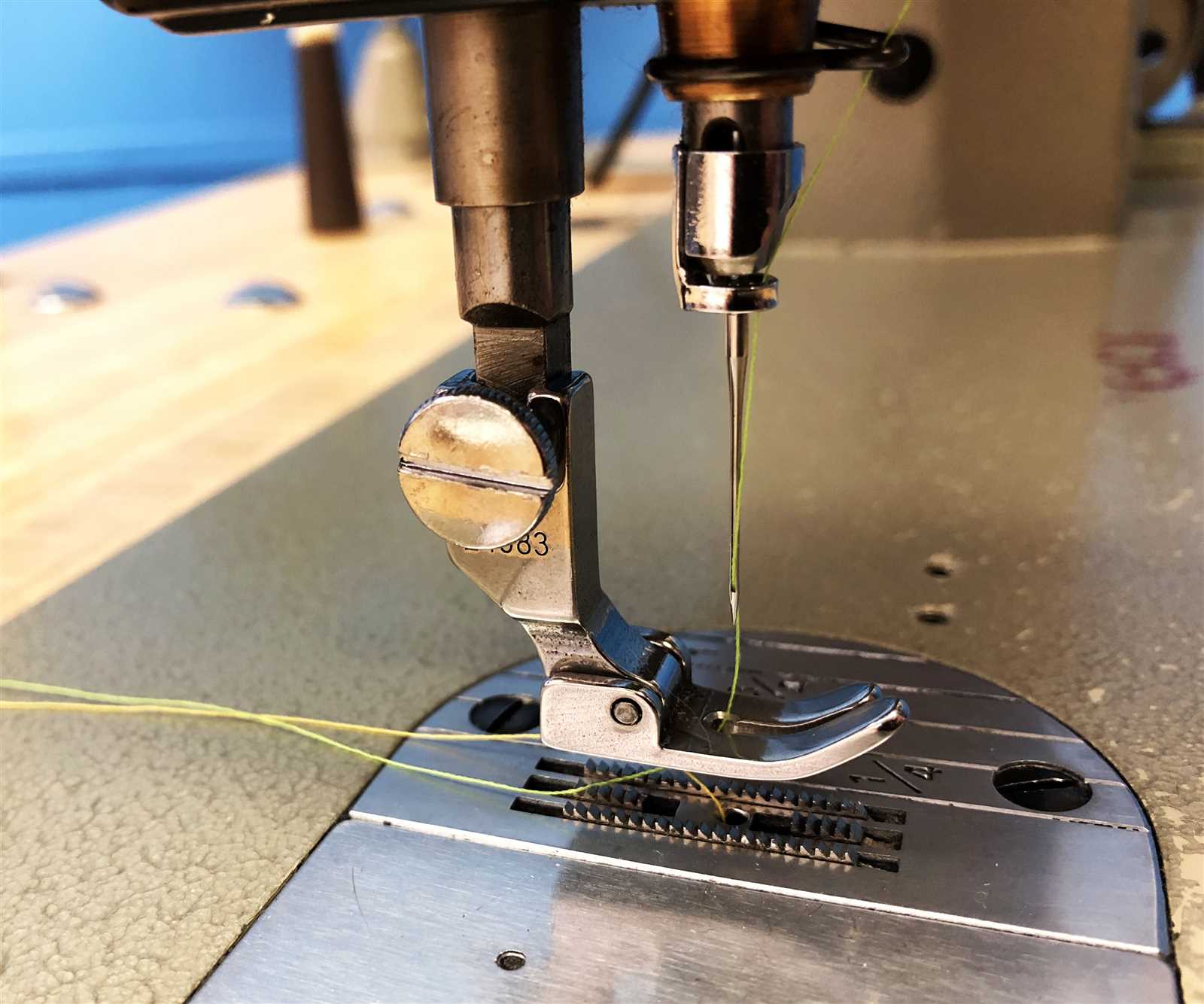

Needle and Thread Interaction is at the heart of every stitching device. The precision of these interactions is crucial to achieving perfect stitches. Adjusting these components correctly is essential for avoiding thread breaks and ensuring fabric integrity.

The supportive structure provides stability and houses the intricate internal mechanisms, helping to maintain balance and durability during operation. Proper maintenance of this structure is key to ensuring long-lasting

Main Functions of Juki Machine Parts

The functionality of various elements in a stitching system is essential for achieving high-quality performance and smooth operation. Each component works together to ensure precision, speed, and durability, making the overall process more efficient and reliable. Understanding how these components function can help users optimize their setup and maintain the equipment in good condition.

Core Functional Elements

Among the key components, the driving mechanism plays a crucial role in ensuring seamless motion and consistent speed during the process. It is designed to manage the movement of the needle and other vital elements, guaranteeing accuracy with each stitch.

Supportive Elements

Another critical area is the tension control system, which helps manage the thread flow, preventing breaks or uneven stitching. Additionally, the presser foot provides stability by holding the fabric in place, ensuring smooth material handling and even distribution.

| Component | Main Function |

|---|

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Regulator | Controls the tension and smooth flow of the thread during operation. | ||||||||||||

| Drive System | Transfers power from the motor to the needle, ensuring consistent stitching motion. | ||||||||||||

| Needle Mechanism | Handles the movement and precision of the needle to form each stitch. |

| Component | Function | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control Mechanism | Regulates motion and coordination between different elements, ensuring balanced movement. | ||||||||||||

| Drive Unit | Generates the necessary force to initiate and sustain operation, powering the entire process. | ||||||||||||

| Operating Arm | Facilitates the movement of crucial sections, allowing precise and steady control during use. |

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Thread Tension Problems | Incorrect threading, worn tension discs | Re-thread the unit, adjust tension settings |

| Needle Breakage | Wrong needle type, incorrect installation | Use the correct needle, ensure proper insertion |

| Skipping Stitches | Dull needle, incorrect foot pressure | Replace the needle, adjust pressure settings |

Preventive Measures

To minimize the need for repairs, regular inspections and maintenance are recommended. Keeping the unit clean and well-lubricated, along with using appropriate materials, can significantly enhance its performance and reduce the likelihood of issues arising.