Understanding the Juki Sewing Machine Parts Diagram

When it comes to enhancing your creative projects, a thorough comprehension of the inner workings of your favorite crafting device is essential. Each component plays a vital role, contributing to the overall performance and functionality. Gaining insights into these elements not only aids in effective usage but also fosters a deeper appreciation for the artistry involved in crafting.

As you embark on this journey to explore the intricacies of your apparatus, you’ll uncover the ultimate connections between various sections. Recognizing how these elements interrelate can empower you to troubleshoot issues and optimize your crafting experience. Whether you’re a novice or an experienced artisan, understanding these components can elevate your skills and inspire new possibilities.

Join us as we delve into the essential features and functions that make up your device, providing you with a roadmap to mastery. By familiarizing yourself with these aspects, you’ll be well-equipped to harness its full potential and take your creative endeavors to new heights.

Understanding Juki Sewing Machines

This section explores the intricacies and functionalities of advanced textile crafting devices. A thorough understanding of these tools can enhance the user experience and improve project outcomes.

Key components play a crucial role in the efficiency and effectiveness of these devices. Familiarizing oneself with their functions can significantly elevate crafting skills.

- Needle Assembly: Essential for various stitch types.

- Thread Tension: Controls the tightness and looseness of the thread for optimal performance.

- Feed Mechanism: Determines the movement of fabric during operation.

- Bobbin Holder: Stores the lower thread, crucial for seamless stitching.

- Stitch Selector: Allows users to choose from multiple stitch styles.

Each element is designed to work harmoniously, contributing to the overall functionality of the equipment. Understanding how these components interact is key to mastering the craft.

- Start by reviewing the user manual for detailed information on each feature.

- Experiment with different settings to find the optimal configuration for your projects.

- Regular maintenance will prolong the life of the device and ensure consistent performance.

With this knowledge, users can approach their creative endeavors with confidence, making the most of these sophisticated tools.

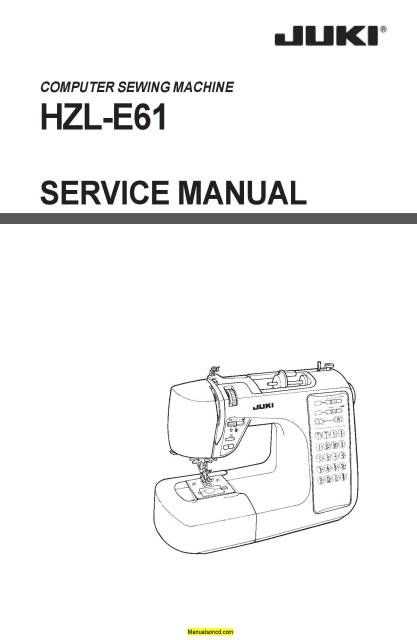

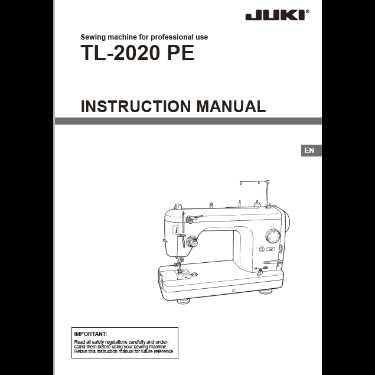

Overview of Juki Models

This section provides insights into various offerings from a renowned brand known for its excellence in fabric manipulation tools. Each variant caters to specific user needs, ensuring a wide range of functionalities and performance levels.

Popular Variants

- Entry-Level Options: Designed for beginners, these models offer simplicity and ease of use.

- Intermediate Choices: Balancing features and affordability, they suit hobbyists and semi-professionals.

- Professional Series: High-end variants designed for extensive use in commercial settings.

Key Features

- Stitching Precision: Ensures accuracy in every project.

- Durability: Built to withstand regular use without compromising performance.

- Versatility: Capable of handling a variety of fabrics and techniques.

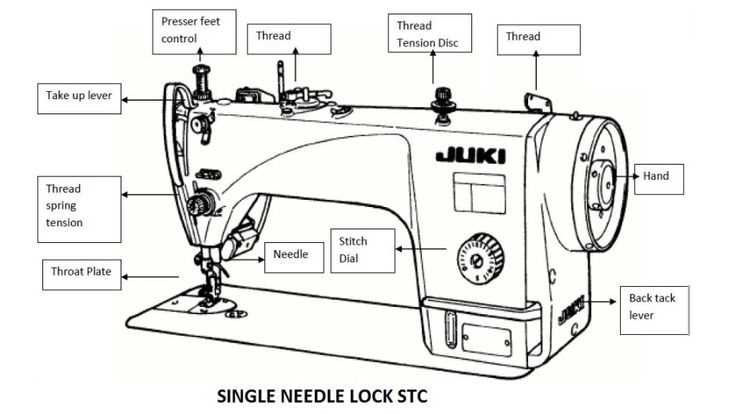

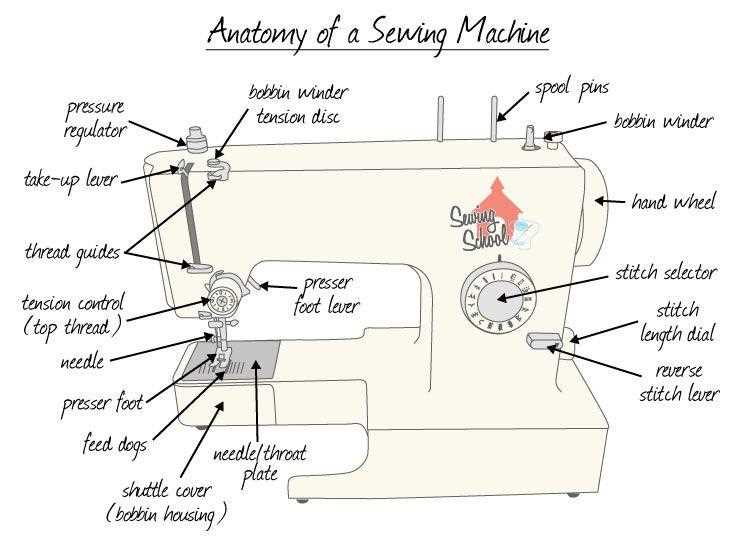

Essential Components of Sewing Machines

Understanding the fundamental elements of textile equipment is crucial for effective use and maintenance. Each component plays a significant role in ensuring optimal performance and achieving desired results in various projects.

Needle: The primary tool for creating stitches, its type and size directly influence the fabric handling and stitch quality. Choosing the right needle is essential for achieving the best results.

Bobbin: This small but vital component holds the lower thread. Proper winding and placement of the bobbin are necessary for smooth operation and consistent stitching.

Presser Foot: This part controls the fabric’s movement during the stitching process. Different styles of presser feet are available for specific tasks, enhancing versatility.

Feed Dogs: Located beneath the needle plate, these teeth help move the fabric forward as you sew. Their functionality is key to maintaining an even and controlled stitch line.

Thread Tension Mechanism: This system regulates the tightness of the thread, affecting the stitch appearance and fabric handling. Proper adjustment is vital for preventing issues like bunching or puckering.

Motor: The driving force behind the entire operation, it powers the movement of the needle and other components. A reliable motor ensures consistent performance during extended use.

Stitch Selector: This feature allows users to choose from various stitch styles, accommodating different techniques and design requirements. Familiarity with the stitch options enhances creative possibilities.

Each of these elements contributes to the overall functionality of the equipment, making knowledge of their roles indispensable for any enthusiast or professional. Proper care and understanding can lead to enhanced creativity and efficiency in crafting.

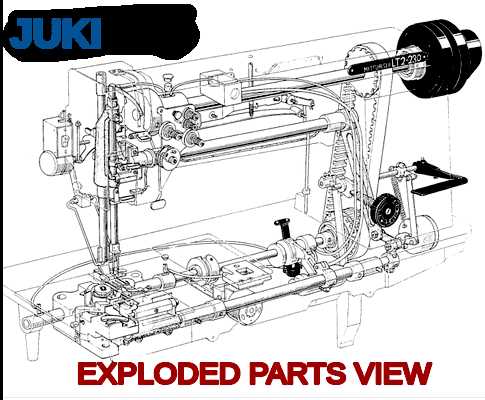

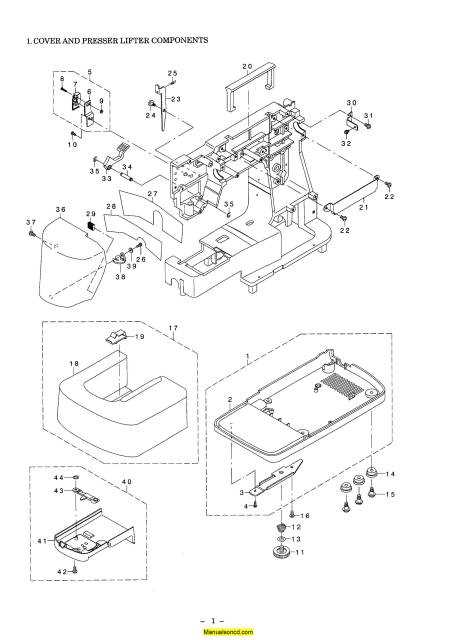

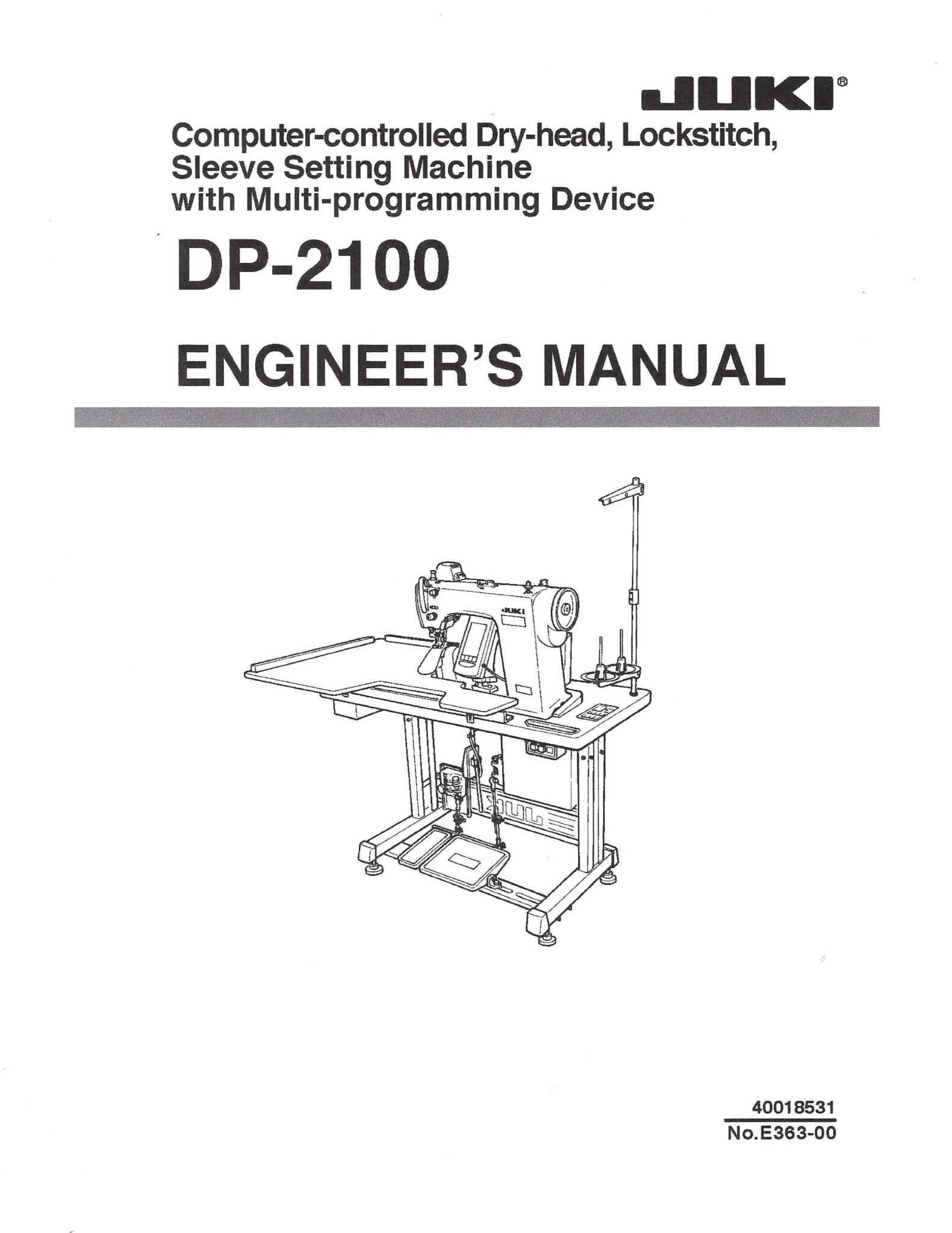

Importance of a Parts Diagram

A comprehensive visual representation of components is crucial for anyone working with complex machinery. It serves as an invaluable resource for understanding how each element interacts within the system, ultimately leading to improved functionality and maintenance. Without this guide, troubleshooting and repairs become significantly more challenging.

Enhanced Understanding

Having a detailed illustration allows users to quickly identify and locate individual elements, fostering a deeper comprehension of the entire system. This knowledge is essential for efficient operation and timely repairs.

Facilitating Repairs

When issues arise, a clear schematic simplifies the process of diagnosing and resolving problems. This not only saves time but also minimizes the risk of further damage during repair efforts.

| Component | Function |

|---|---|

| Drive Mechanism | Transmits power to various functions |

| Tension Adjuster | Regulates thread tightness |

| Feed Dogs | Controls fabric movement |

Key Parts in Juki Machines

Understanding the essential components of these devices is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring efficiency and precision during operation.

Main Components

Several key elements are fundamental to the functionality of these devices. Knowing their names and functions can enhance your ability to troubleshoot and perform routine maintenance effectively.

| Component | Function |

|---|---|

| Needle | Creates stitches by piercing through the fabric. |

| Feed Dogs | Move the fabric through the device during stitching. |

| Bobbin | Holds the thread that forms the lower part of the stitch. |

Additional Elements

Beyond the main components, various other elements contribute to the overall functionality. Familiarity with these can aid in achieving the desired results in your projects.

| Component | Function |

|---|---|

| Presser Foot | Holds the fabric in place while stitching. |

| Tension Regulator | Controls the tightness of the thread for consistent stitching. |

| Hand Wheel | Manually raises and lowers the needle for precision work. |

Common Juki Sewing Machine Issues

Every enthusiast may encounter certain challenges while operating their equipment. Understanding these common problems can help in maintaining optimal performance and extending the lifespan of the device.

Frequent Challenges

- Thread Bunching: Often caused by improper threading or incorrect tension settings.

- Skipped Stitches: This can occur due to a dull needle, incorrect needle type, or insufficient tension.

- Fabric Not Feeding: Usually a result of feed dog issues or incorrect presser foot pressure.

- Unusual Noises: Grinding or clunking sounds may indicate a need for lubrication or mechanical inspection.

Troubleshooting Tips

- Check and adjust the thread tension to see if it resolves any bunching issues.

- Replace the needle and ensure it is compatible with the fabric type being used.

- Inspect the feed dogs for obstructions and adjust the presser foot pressure accordingly.

- Regularly clean and oil the moving parts to minimize noise and friction.

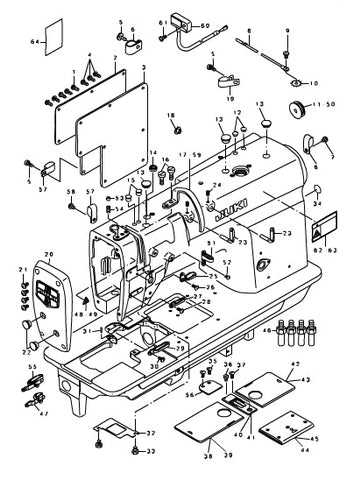

Identifying Parts by Number

Understanding the components of your device is essential for effective maintenance and repair. Each element plays a vital role, and recognizing them by their numerical identifiers simplifies the process of sourcing replacements and ensures compatibility.

Utilizing Numerical Codes

Numerical codes often serve as unique identifiers for each component, making it easier to locate specific items in manuals or catalogs. Familiarizing yourself with these codes can save time and enhance accuracy during your search for replacements.

Resources for Identification

Many online resources, including manufacturer websites and forums, offer comprehensive guides to help you decode these numerical identifiers. Engaging with these platforms can further enhance your understanding and assist in the ultimate goal of effective repair.

Maintaining Your Juki Sewing Machine

Proper upkeep is essential for ensuring the longevity and optimal performance of your equipment. Regular attention not only enhances functionality but also prevents potential issues that could disrupt your creative process. Understanding how to care for your apparatus will lead to smoother operation and improved results in your projects.

Cleaning your device should be a priority. Dust and fabric lint can accumulate, affecting performance. Make it a habit to clean the interior and exterior regularly. Utilize a soft brush or cloth to remove debris, ensuring that all areas are accessible and well-maintained.

Lubrication is another crucial aspect. Periodic oiling of designated components helps reduce friction and wear, contributing to a quieter and more efficient experience. Refer to the user guide to identify the specific areas that require lubrication and the type of oil recommended.

Inspection of the various elements is vital. Check for any signs of wear, such as frayed belts or dull needles. Addressing these issues promptly can prevent larger problems down the line. Replace any worn-out items as necessary to maintain peak functionality.

Finally, consulting the manual regularly provides valuable insights into best practices and specific maintenance guidelines. Familiarize yourself with the recommendations to ensure your equipment remains in excellent condition for years to come.

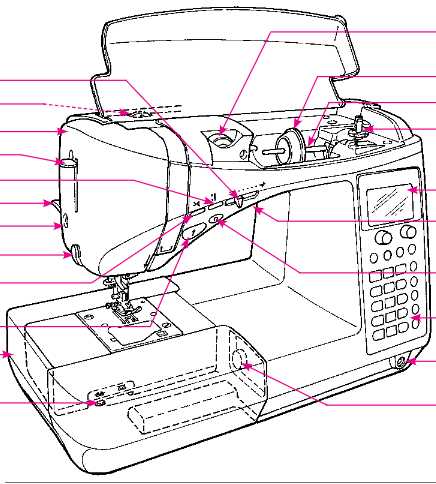

How to Read a Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. Familiarity with the layout and symbols can significantly enhance your ability to troubleshoot and identify necessary replacements.

Follow these steps to grasp the essentials:

- Identify Sections: Look for labeled areas that group similar components together.

- Recognize Symbols: Familiarize yourself with the common icons representing different elements.

- Note Numbers: Pay attention to numerical references that correspond to a parts list.

- Check Orientation: Understand the perspective from which the components are illustrated, as it can affect how you interpret their arrangement.

- Cross-Reference: Use the visual guide alongside written documentation for clarity.

By mastering these techniques, you will be better equipped to delve into any project confidently and efficiently.

Where to Find Replacement Parts

Locating suitable components for your equipment can often be a challenging task. However, with the right resources, you can easily acquire what you need to ensure optimal performance. This section aims to guide you through the various avenues available for sourcing these essential items.

Authorized Retailers: One of the most reliable options is to check with official dealers. These retailers often stock a wide range of components and can provide the assurance of quality and compatibility. Visiting their websites or physical stores can yield positive results.

Online Marketplaces: E-commerce platforms have become increasingly popular for finding specialized items. Websites such as Amazon, eBay, and dedicated parts suppliers can offer an extensive selection, often at competitive prices. Be sure to read reviews and check seller ratings to ensure a satisfactory purchase.

Local Repair Shops: Sometimes, the best resources are right in your community. Local repair shops often have connections and can either provide the required components or guide you to trusted suppliers. They might also have used items at a lower cost, which can be a budget-friendly option.

Forums and Online Communities: Engaging with fellow enthusiasts through forums and social media groups can be incredibly helpful. Members often share their experiences and can recommend reliable sources for obtaining specific components. Networking in these spaces can also lead to discovering rare items.

Manufacturer’s Website: Checking the manufacturer’s official website is always a prudent choice. They usually offer a catalog of available components, along with detailed information on compatibility and usage. This ensures you are getting the right fit for your needs.

Upgrading Juki Machine Components

Enhancing the functionality and performance of your equipment can significantly improve your crafting experience. By focusing on key elements within the setup, you can achieve greater precision, speed, and efficiency. Whether you are a hobbyist or a professional, exploring upgrades will ultimately elevate your projects to new heights.

Identifying Essential Upgrades

Begin by evaluating the current features of your setup. Upgrades such as a high-quality needle, advanced presser feet, or improved feed mechanisms can make a substantial difference. Investing in quality components is essential for achieving superior results.

Installation and Maintenance Tips

When integrating new components, ensure proper installation to avoid complications. Regular maintenance of these enhancements is equally important; keep them clean and well-lubricated for optimal performance. Delve into user manuals and online resources for the best practices to guarantee longevity and efficiency.

Repairing Your Juki Sewing Machine

Maintaining your crafting device is essential for optimal performance and longevity. Understanding its components can help troubleshoot common issues, ensuring you can continue your creative projects without interruption.

Common Issues and Solutions

Frequent problems include thread breakage, uneven stitching, and motor malfunction. Thread tension is often the culprit; adjusting it can resolve many issues. If you encounter uneven stitches, check the needle and ensure it’s suitable for your fabric. For motor-related concerns, a thorough cleaning and lubrication might restore functionality.

When to Seek Professional Help

If your device exhibits persistent problems despite your best efforts, it may be time to consult a professional. Expert technicians possess the knowledge and tools necessary for in-depth repairs that you may not be equipped to handle. Prioritizing your device’s health will ultimately enhance your crafting experience.

Resources for Juki Users

For enthusiasts and professionals alike, having access to reliable information and tools can significantly enhance the crafting experience. This section aims to provide valuable resources that support users in their creative endeavors, ensuring they can make the most of their equipment.

Numerous online platforms offer extensive guides, tutorials, and forums where individuals can share insights and seek assistance. These communities foster collaboration and knowledge sharing, allowing users to troubleshoot issues and discover innovative techniques.

In addition, official documentation and instructional materials are essential for understanding functionality and maintenance. Users can find comprehensive manuals that outline operating procedures, maintenance tips, and troubleshooting steps to ensure longevity and optimal performance.

Lastly, various suppliers and retailers provide a wide range of accessories and enhancements, enabling users to customize their setups. By exploring these resources, individuals can elevate their projects and achieve their desired results more effectively.