Kenmore 385 Sewing Machine Parts Overview

In the realm of crafting and fabric manipulation, having a clear grasp of the various components that constitute a popular textile tool is essential for both beginners and seasoned enthusiasts. This knowledge not only enhances the user experience but also facilitates effective maintenance and troubleshooting. A comprehensive exploration of these elements offers valuable insights into their functions and interactions, ensuring optimal performance in creative endeavors.

Within this section, we will delve into the intricate layout of this widely-used instrument, breaking down its essential features and functionalities. By familiarizing yourself with the arrangement of each element, you will gain a deeper appreciation for how they contribute to the overall efficiency and effectiveness of the device. Understanding these intricacies empowers users to maximize their skills and unleash their creativity.

Whether you are embarking on a new project or seeking to resolve a specific issue, having access to detailed information about the structure of this essential tool can make all the difference. This guide aims to illuminate the various sections and components, providing a solid foundation for your crafting journey.

Understanding Kenmore Sewing Machine Models

This section explores the various variations of a renowned brand known for its reliability and performance in the realm of crafting and textile projects. Each version boasts distinct features tailored to meet diverse needs and preferences, ensuring a seamless experience for users at all skill levels.

Key Features of Different Models

When selecting a particular variant, it’s essential to consider several key characteristics:

- Stitch Options: Variations in stitch types allow for creative possibilities, from basic utility stitches to intricate decorative patterns.

- Ease of Use: Some models are designed with user-friendly interfaces, making them ideal for beginners.

- Portability: Certain designs are lightweight and compact, perfect for those who attend workshops or need to store their equipment easily.

Choosing the Right Variant

Selecting the most suitable option involves evaluating personal needs and project requirements. Here are some factors to consider:

- Project Type: Identify the primary tasks, whether they involve quilting, garment construction, or decorative stitching.

- Budget: Determine the price range that aligns with your financial plan, as options vary significantly in cost.

- Accessories: Look for models that come with essential add-ons, such as presser feet and bobbins, to enhance functionality.

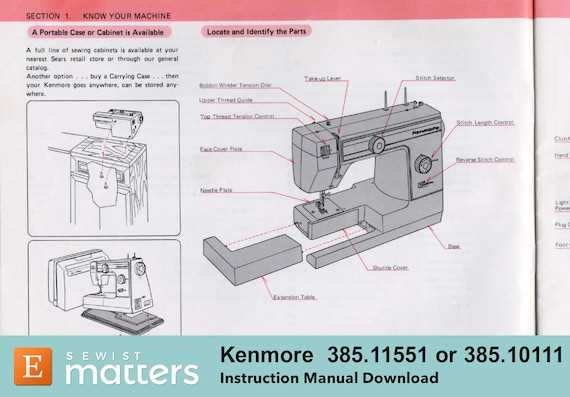

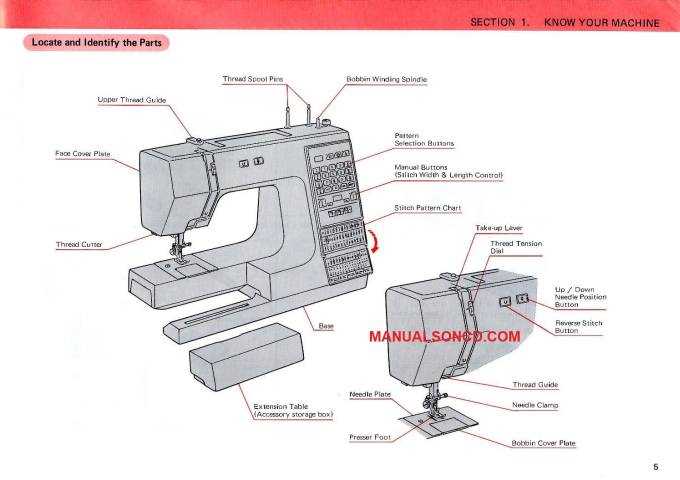

Key Components of Kenmore Machines

Understanding the essential elements of these devices is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, contributing to both performance and user experience. Familiarizing oneself with these vital parts can enhance one’s ability to troubleshoot issues and ensure optimal use.

Main Functional Elements

The primary functional elements include the needle system, feed dogs, and presser foot. The needle is responsible for creating stitches, while the feed dogs move the fabric through the device. The presser foot holds the material in place during the sewing process, ensuring accurate and consistent stitching.

Supporting Features

Supporting features such as the bobbin case, tension control, and stitch selector greatly influence the quality of the output. The bobbin case holds the thread that forms the lower stitches, while the tension control adjusts the tightness of the thread to prevent puckering or bunching. The stitch selector allows users to choose from various stitching patterns, adding versatility to their projects.

Common Issues with Kenmore Parts

When working with various components of textile devices, users may encounter several prevalent challenges that can affect functionality and performance. Recognizing these issues early can help prevent further complications and ensure a smooth operation. This section highlights frequent concerns that arise with these mechanisms, providing insights into troubleshooting and resolution.

One common problem is misalignment, which can lead to improper feeding of fabric. This misalignment often results from worn gears or incorrectly positioned elements. Regular maintenance and adjustments are crucial in preventing this issue.

An additional concern involves the accumulation of lint and debris within the assembly, which can hinder performance. Cleaning the internal mechanisms regularly helps maintain optimal function and prolongs the lifespan of the device.

Moreover, wear and tear on specific components, such as needles and bobbins, can cause inconsistent stitching. It’s essential to replace these items periodically to maintain the quality of the work produced. Users should also be aware of the compatibility of replacements to ensure seamless operation.

Finally, electronic issues may arise, especially in models that incorporate advanced features. Troubleshooting the electrical connections and ensuring the firmware is updated can resolve many operational glitches.

How to Identify Missing Parts

Recognizing absent components in your equipment can be a challenging task, yet it is crucial for ensuring optimal functionality. Whether you are attempting to troubleshoot or refurbish, knowing how to effectively identify what is missing will streamline the process. Here are some practical strategies to assist you in this endeavor.

1. Review the User Manual

Your initial step should be to consult the user manual that accompanied your device. This document often contains detailed illustrations and lists of components that can guide you in recognizing which items are required for complete operation.

2. Utilize Online Resources

Numerous online platforms offer resources, such as instructional videos and community forums, where you can find information on common components and their functions. Engaging with these resources can enhance your understanding of what you may be lacking.

| Component Name | Description | Function |

|---|---|---|

| Foot Control | A pedal used to operate the equipment | Regulates speed and starts the process |

| Needle Holder | Secures the needle in place | Holds the needle for proper functioning |

| Bobbins | Small spools that hold thread | Provide thread for stitching |

Exploring Kenmore Maintenance Tips

Proper upkeep is essential for ensuring the longevity and optimal performance of your textile crafting equipment. By following a few simple guidelines, you can enhance the functionality and reliability of your device, keeping it in excellent working condition for years to come.

Regular maintenance involves inspecting and cleaning various components to prevent issues that may arise from dirt and wear. Below are key recommendations for effective upkeep:

| Task | Frequency | Description |

|---|---|---|

| Clean the exterior | Weekly | Wipe down the outer surfaces to remove dust and lint. |

| Oil moving parts | Monthly | Apply appropriate lubricant to maintain smooth operation. |

| Check tension settings | As needed | Ensure that the tension is set correctly for various fabrics. |

| Replace needles | After 8 hours of use | Change needles regularly to prevent fabric damage. |

| Inspect the belt | Every 6 months | Look for signs of wear and replace if necessary. |

By implementing these straightforward maintenance practices, you can maximize the lifespan and performance of your crafting equipment, ensuring enjoyable and successful projects ahead.

Replacement Parts: What to Consider

When it comes to maintaining your equipment, selecting appropriate components is crucial for optimal performance. Understanding what to look for can significantly enhance the longevity and functionality of your device. Here are key factors to keep in mind when seeking out replacements.

Compatibility

Ensuring that the new components fit seamlessly with your existing setup is essential. Consider the following:

- Check the model specifications to find suitable alternatives.

- Verify dimensions and functionality to avoid mismatches.

- Consult product manuals or manufacturer websites for guidance.

Quality and Durability

Investing in high-quality replacements can prevent future issues and improve overall performance. Keep these points in mind:

- Look for reputable brands known for their reliability.

- Read customer reviews to gauge performance over time.

- Consider warranty options that provide additional security.

Where to Find Kenmore Diagrams

Locating detailed illustrations for various models can greatly assist in understanding and maintaining your appliance. These resources provide valuable insights into the components and their arrangement, which can be crucial for troubleshooting or repairs.

Here are some effective methods to obtain these helpful resources:

- Official Manufacturer Website: Visit the brand’s official site to explore available manuals and guides specific to different models.

- Online Retailers: Many online stores that sell accessories may also provide links to user manuals or reference images related to their products.

- User Forums: Engaging with community forums can yield shared diagrams and tips from other users who have encountered similar needs.

- Library Resources: Local libraries may house repair manuals or guides that include the illustrations you require.

- Specialty Repair Shops: Contacting repair technicians or shops that specialize in your type of equipment might lead to useful information or access to diagrams.

Using these resources can enhance your understanding and ensure efficient maintenance of your appliance.

Importance of Parts Compatibility

Ensuring the compatibility of components is crucial for the seamless operation of any device. When elements fit together correctly, they not only enhance performance but also prolong the lifespan of the equipment. Compatibility minimizes the risk of damage and malfunctions, which can lead to costly repairs or replacements.

Enhancing Performance

Using compatible components allows for optimal functionality. Each element is designed to work in harmony with others, promoting efficient operation. When components are mismatched, it can result in decreased efficiency, leading to frustration and reduced productivity.

Reducing Repair Costs

When all components are compatible, the likelihood of wear and tear diminishes significantly. This alignment helps avoid frequent breakdowns and repairs, which can be financially burdensome. Additionally, it simplifies the maintenance process, as knowing which parts are suitable eliminates guesswork.

Upgrading Kenmore Sewing Equipment

Enhancing your crafting apparatus can significantly improve your overall experience and results. Whether you’re looking to increase functionality, efficiency, or simply modernize your tools, there are several aspects to consider. This section explores various upgrades that can transform your setup into a more versatile and enjoyable environment.

Here are some potential improvements to think about:

- Enhanced Accessories: Consider investing in high-quality attachments that can expand your capabilities. These may include specialty feet for different tasks, such as quilting or zipper installation.

- Upgraded Needles: Utilizing the right needle type can make a substantial difference. Opt for needles designed for specific fabrics or techniques to achieve better results.

- Better Thread: Switching to superior threads can enhance both the quality of your stitches and the durability of your projects. Explore options that suit your fabric choices.

- Stitching Software: Modernizing your setup with software that allows for custom stitch creation can elevate your craftsmanship. Many applications offer a variety of design options and tutorials.

- Lighting Solutions: Improved illumination is essential for detailed work. Adding dedicated lighting can reduce strain on your eyes and help you see fine details more clearly.

Taking the time to enhance your equipment can lead to a more enjoyable and productive crafting experience. Explore these options to find the perfect upgrades that meet your specific needs and preferences.

Tools for DIY Repair Projects

Engaging in repair tasks can be both rewarding and cost-effective. Having the right instruments on hand can significantly streamline the process, making it easier to tackle a variety of issues that may arise. This section explores essential tools that every DIY enthusiast should consider for successful repair endeavors.

Essential Hand Tools

Having a solid selection of hand tools is crucial for any repair project. These tools allow for precision and flexibility, enabling you to handle different tasks with ease.

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for tightening or loosening screws in various applications. |

| Wrenches | Ideal for gripping, turning, and loosening nuts and bolts. |

| Pliers | Useful for gripping, bending, and cutting materials. |

| Utility Knife | Perfect for cutting and trimming various materials. |

Power Tools to Consider

In addition to hand tools, power tools can enhance your efficiency, especially for larger tasks that require more force.

| Tool | Purpose |

|---|---|

| Drill | Used for creating holes in different materials, including wood and metal. |

| Saw | Ideal for cutting through various materials, including wood and plastic. |

| Sanders | Used for smoothing surfaces by abrasion. |

| Multitool | Versatile tool for various applications, combining several functions in one device. |

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components of various fabric handling devices. Understanding these elements can enhance your experience and ensure optimal functionality.

What should I consider when selecting components?

When choosing components for your device, it is crucial to consider compatibility, quality, and functionality. Always refer to the specifications and guidelines provided by the manufacturer to ensure that the selected item meets the necessary requirements for performance.

How can I troubleshoot issues with my components?

If you encounter problems with your components, start by checking for any visible damage or wear. Ensure that all connections are secure and clean. If the issue persists, consult the user manual or reach out to a professional for assistance. Regular maintenance can also prevent common issues from arising.