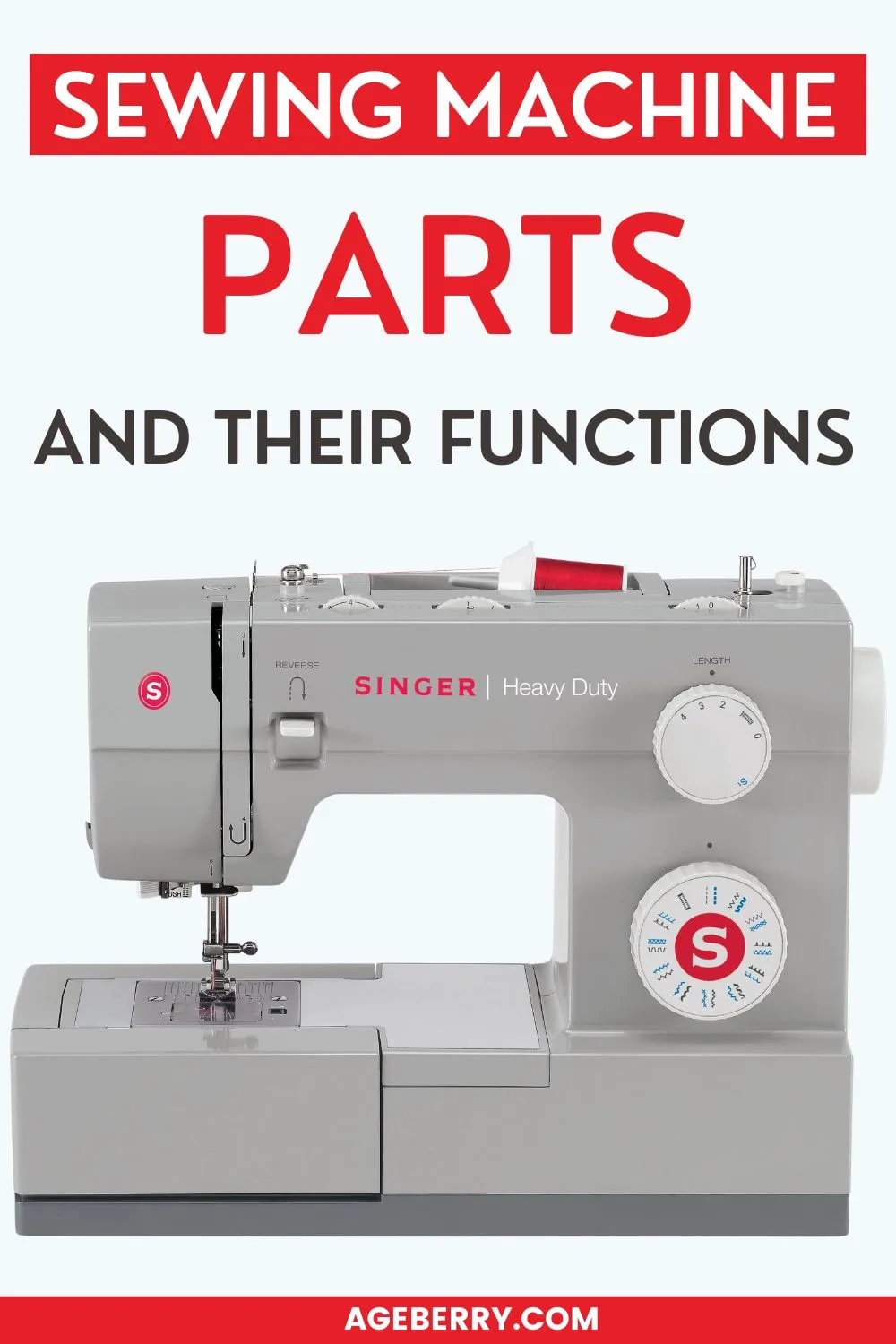

Understanding the Key Components of a Singer Sewing Machine Diagram

In the world of textile crafting, the functionality and design of an intricate tool play a crucial role in achieving desired results. A comprehensive grasp of the various elements that constitute this creative apparatus enhances the user experience and boosts efficiency. Each section of the device is carefully engineered to work in harmony, allowing for precision in the crafting process.

Exploring the anatomy of this essential tool reveals a fascinating interplay of mechanics and artistry. From the driving elements that enable motion to the guiding structures that ensure accuracy, each component contributes to the overall performance. This intricate relationship not only facilitates smooth operation but also empowers users to unleash their creativity.

As we delve into the specifics, it becomes evident that understanding each segment’s function provides invaluable insights. Whether you are a novice eager to learn or an experienced artisan refining your skills, familiarizing yourself with these crucial components will undoubtedly elevate your craftsmanship and inspire new projects.

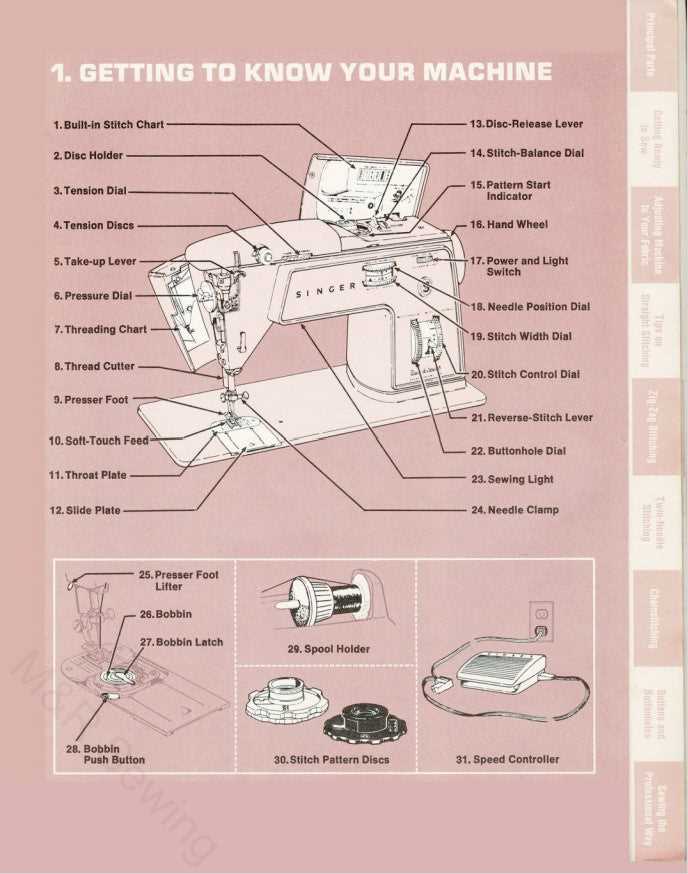

Understanding the Singer Sewing Machine

Exploring the intricate components of a textile creation device enhances our appreciation for its functionality and craftsmanship. Each element plays a crucial role in transforming fabric into beautifully crafted items, ensuring precision and ease of use for both novices and experts.

| Component | Description |

|---|---|

| Needle | Essential for piercing fabric to create stitches. |

| Bobbin | Holds the thread used in the lower stitching. |

| Foot Pedal | Controls the speed and operation of the device. |

| Thread Tension Dial | Adjusts the tightness of the thread for optimal results. |

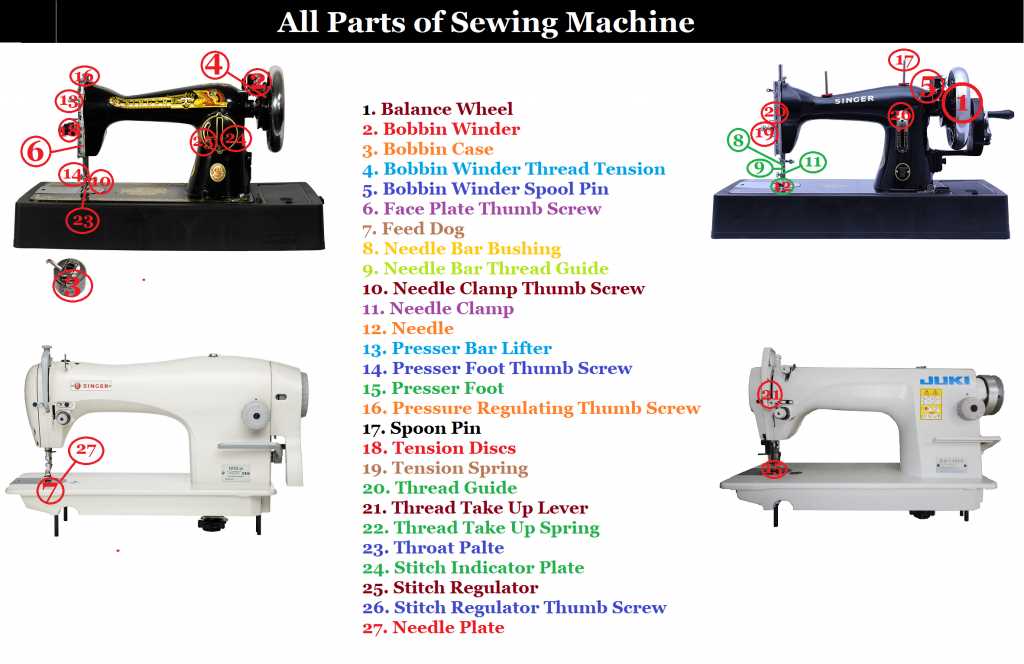

Key Components of the Machine

This section highlights essential elements that contribute to the overall functionality and performance of the equipment. Understanding these vital components is crucial for effective operation and maintenance.

Essential Elements

Among the key elements are the motor, which powers the unit, and the needle, responsible for creating stitches. Each component plays a specific role in ensuring smooth and efficient performance.

Support Structures

Additionally, features such as the thread tension mechanism and feed dogs are integral in controlling the movement of fabric. These mechanisms work together to provide the ultimate experience in crafting textiles.

Functionality of the Needle Assembly

The needle assembly plays a crucial role in the overall operation of fabric manipulation and stitching. This component ensures that the thread is precisely inserted into the fabric, creating secure and durable seams. Understanding its functions can greatly enhance the quality of the final product.

Precision and Control

One of the primary functions of the needle assembly is to maintain accuracy during the stitching process. The needle moves up and down, allowing for controlled penetration into the fabric layers. This action is vital for achieving consistent stitch length and quality. A well-functioning assembly ensures that the needle aligns perfectly with the threading mechanism, preventing issues like skipped stitches or uneven seams.

Thread Management

Another important aspect of the needle assembly is its role in thread management. As the needle penetrates the fabric, it carries the upper thread down to interact with the bobbin thread. This interlocking mechanism creates the stitches that hold the fabric pieces together. Proper alignment and functionality of this assembly are essential for preventing thread jams and ensuring smooth operation.

Role of the Bobbin System

The bobbin mechanism is crucial for the functionality of any textile tool designed for stitching fabrics. It serves as a foundation for creating strong and durable seams, providing the necessary thread supply that works in harmony with the upper thread. Understanding its significance helps users appreciate the intricate interplay of components that contribute to the overall performance.

At its core, the bobbin system serves several essential functions:

- Thread Storage: It holds the lower thread, which is essential for forming stitches.

- Stitch Formation: Works in conjunction with the needle to interlock threads, ensuring secure seams.

- Tension Regulation: Maintains consistent tension on the thread, preventing puckering or uneven stitching.

- Easy Replacement: Designed for quick access, allowing for efficient reloading of thread when needed.

In summary, the bobbin system is integral to achieving high-quality results in textile crafting. Its ability to seamlessly integrate with other components enhances the overall effectiveness, making it a vital element for any sewing enthusiast.

Importance of the Presser Foot

The presser foot plays a crucial role in ensuring the precision and quality of stitching during textile projects. Its primary function is to hold the fabric in place, allowing for consistent and even sewing. This component significantly influences the outcome of various techniques, making it an essential tool for both novice and experienced crafters.

Functions of the Presser Foot

- Stabilization: It secures the fabric, preventing slipping and misalignment.

- Fabric Handling: Different types of feet are designed to accommodate various materials, enhancing versatility.

- Technique Enhancement: Specialized feet can assist in executing techniques such as quilting, zippers, or hemming.

Choosing the Right Presser Foot

Selecting an appropriate foot is vital for achieving desired results. Consider the following factors:

- Project Type: Identify the technique or fabric type to determine the best foot.

- Compatibility: Ensure the foot fits well with your equipment for optimal performance.

- Personal Preference: Experiment with various options to find what works best for your style.

Understanding the significance of this component can elevate your crafting experience and improve the overall quality of your work.

How the Feed Dogs Work

The feed mechanism plays a crucial role in guiding fabric through the stitching process. Understanding its functionality helps users achieve better control and precision in their creative endeavors.

Here’s how the feed mechanism operates:

- Movement: The feed dogs move up and down in a rhythmic pattern, gripping the fabric as they rise.

- Advancement: As they descend, the teeth push the fabric forward, allowing for even feeding.

- Synchronization: The mechanism is synchronized with the needle’s movement, ensuring that the fabric advances at the right moment.

Additionally, there are several important factors to consider:

- Fabric Type: Different materials require varying feed settings for optimal results.

- Tension: Proper tension adjustments help maintain smooth feeding and avoid snags.

- Height Adjustment: Some models allow for height adjustment to accommodate thicker layers or delicate fabrics.

By mastering the intricacies of this feeding system, users can enhance their skills and achieve a variety of sewing techniques with confidence.

Exploring the Tension Mechanism

The tension system plays a crucial role in ensuring precise and consistent stitching in fabric manipulation processes. By regulating the tightness of threads, it directly influences the quality and appearance of the final output. A well-functioning mechanism can enhance performance and reduce errors, making it essential for effective textile craftsmanship.

Understanding Its Functionality

This intricate assembly works by balancing the upper and lower threads, providing the necessary resistance for smooth operation. Adjusting the tension allows users to accommodate various materials, enabling the creation of diverse projects. Proper calibration is vital for achieving the ultimate results.

Common Issues and Solutions

Problems such as thread breakage or uneven stitches often arise from incorrect tension settings. Identifying these issues can involve examining thread alignment and making necessary adjustments. Regular maintenance and careful observation can help in ensuring optimal functionality, ultimately leading to a more satisfying crafting experience.

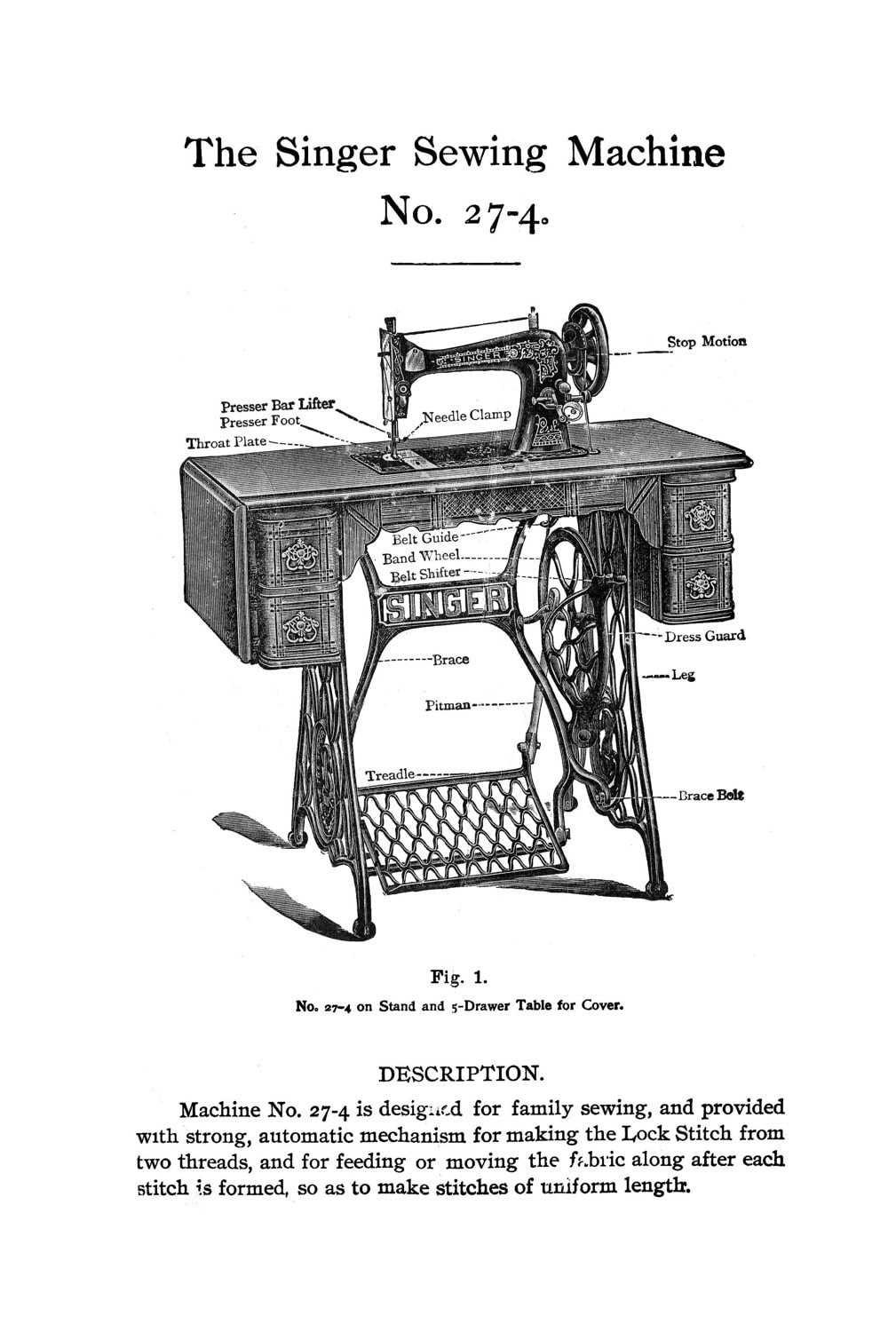

Insights into the Throat Plate

The throat plate serves as a crucial component, playing a significant role in the overall functionality of the device. It provides a stable surface for the fabric to rest upon, allowing for smoother movement and precise stitching. Understanding its features can enhance your experience and improve the quality of your work.

Functionality and Design

Designed with precision, the throat plate often includes various markings and guidelines that assist in aligning materials accurately. These markings can indicate seam allowances, helping to ensure consistent results. Additionally, the plate may feature slots for the needle and feed dogs, facilitating the smooth transport of the fabric.

Maintenance Tips

To maintain optimal performance, it’s essential to keep this component clean and free from lint or debris. Regular inspection can prevent issues such as skipped stitches or uneven tension. A gentle cleaning routine can prolong the life of the plate and contribute to better overall performance.

Understanding the Stitch Selector

The stitch selector is a crucial feature that empowers users to create a variety of designs and patterns effortlessly. It allows for customization, ensuring that each project meets specific aesthetic and functional needs. By choosing different options, one can achieve everything from simple straight lines to intricate decorative motifs.

Functionality is at the heart of the stitch selector’s design. It enables the user to easily switch between different stitching styles, which is essential for achieving desired results in various fabrics. This tool not only enhances creativity but also improves efficiency, allowing for quicker adjustments during the crafting process.

Moreover, understanding the settings associated with the stitch selector can significantly elevate the overall quality of the finished product. Each option is tailored for specific tasks, making it vital for users to delve into the features available to them. Mastering this component ultimately leads to a more satisfying crafting experience.

Significance of the Hand Wheel

The hand wheel serves as a crucial component in the operation of textile crafting equipment, allowing users to exert manual control over various functions. This feature is essential for enhancing precision and ensuring seamless execution during the stitching process.

Control and Precision

By turning the wheel, individuals can accurately position the needle and adjust the fabric tension, facilitating meticulous work on intricate designs. This level of control is particularly beneficial when dealing with delicate materials or detailed patterns.

Ease of Use

The hand wheel provides an intuitive method for beginners to familiarize themselves with the fundamentals of fabric manipulation. Its straightforward functionality contributes to a smoother learning curve, empowering users to develop their skills effectively.

Overview of the Power Source

The energy supply is a crucial component that enables the operation of various devices. It provides the necessary electrical power, ensuring that the mechanisms function efficiently and effectively. Understanding how this source interacts with other elements can enhance performance and durability.

Types of Power Sources

Typically, energy can be sourced from electrical outlets or batteries. AC power is commonly used for stationary devices, while DC power is preferred for portable alternatives. Each type has its own set of advantages, influencing the overall usability and convenience.

Importance of a Reliable Power Source

A dependable energy supply is essential for optimal performance. Inconsistent power can lead to interruptions, affecting the device’s functionality and longevity. Ensuring a stable connection contributes to a seamless experience, making the operation more efficient.

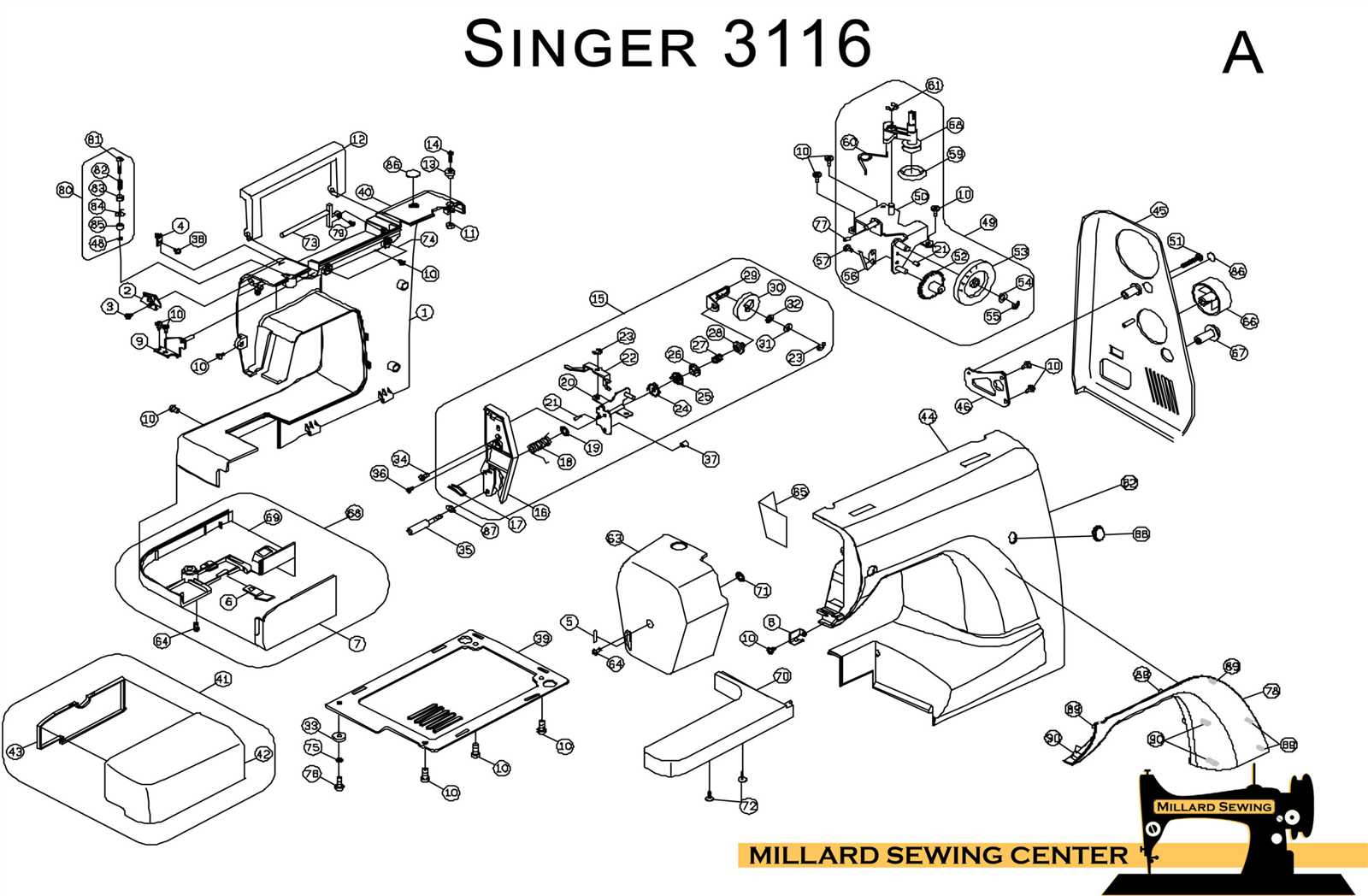

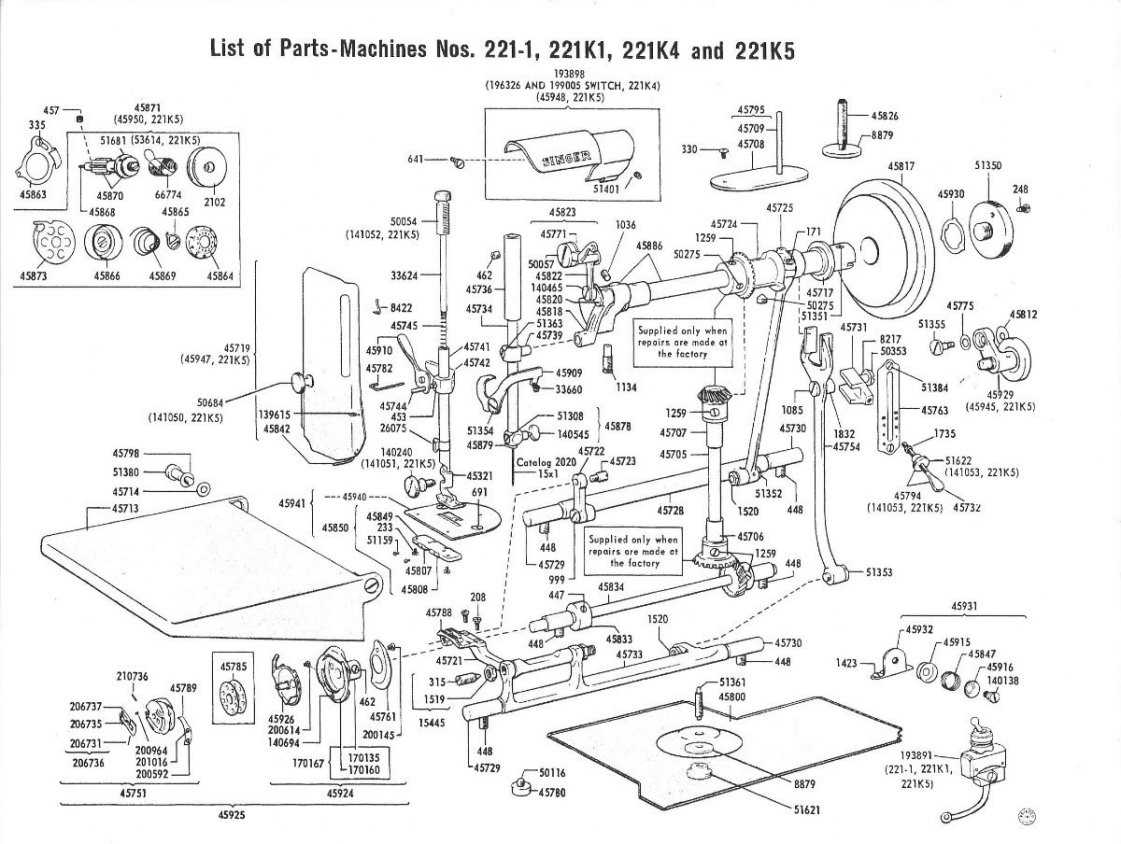

Maintenance of Internal Parts

Proper upkeep of internal components is crucial for optimal performance and longevity. Regular attention can prevent wear and tear, ensuring seamless operation.

Here are some essential practices for maintaining these elements:

- Regular Cleaning: Dust and debris can accumulate, affecting functionality. Clean components frequently with a soft brush or cloth.

- Lubrication: Use appropriate oils or lubricants to reduce friction. Apply sparingly to designated areas as per guidelines.

- Inspection: Regularly examine for any signs of damage or misalignment. Early detection can prevent further issues.

- Calibration: Ensure components are correctly aligned and calibrated to maintain accuracy during use.

- Replacement: Identify parts that show excessive wear and replace them promptly to avoid operational disruptions.

Following these steps will help prolong the life and efficiency of the internal mechanisms.