Understanding the Components of a Sewing Machine Diagram

In the realm of textile creation, various elements play a crucial role in transforming raw fabric into beautifully crafted garments. A comprehensive overview of these components reveals the intricate workings behind every stitch. Each segment contributes uniquely, ensuring smooth operation and precision in crafting.

Delving deeper into the mechanics, one uncovers how every element interacts with others, forming a harmonious system. This interplay not only enhances functionality but also enriches the overall user experience, enabling both amateurs and professionals to bring their creative visions to life.

Moreover, understanding these fundamental aspects is essential for anyone aiming to maintain, troubleshoot, or optimize their equipment. By familiarizing oneself with these critical features, users can ensure longevity and efficiency, allowing for endless possibilities in textile artistry.

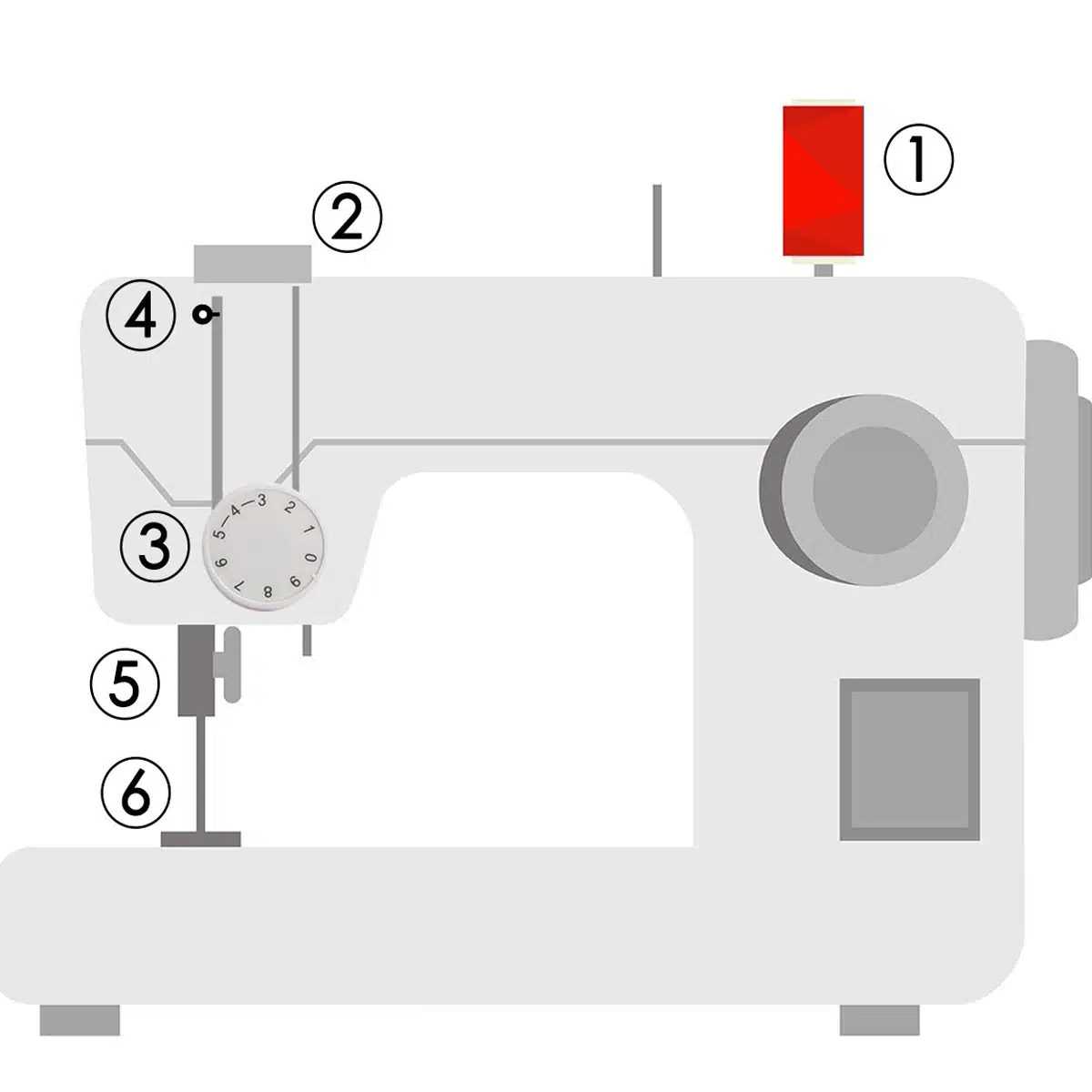

Understanding the Sewing Machine Components

This section explores essential elements found in modern stitching devices, highlighting their functions and significance in the crafting process.

- Needle: Vital for piercing fabric and creating stitches.

- Foot: Holds material in place while allowing smooth movement.

- Bobbin: Supplies lower thread, working in tandem with the needle.

- Feed dogs: Grips fabric to ensure even feeding during operation.

Understanding these components enhances skills, allowing for greater creativity and efficiency in projects.

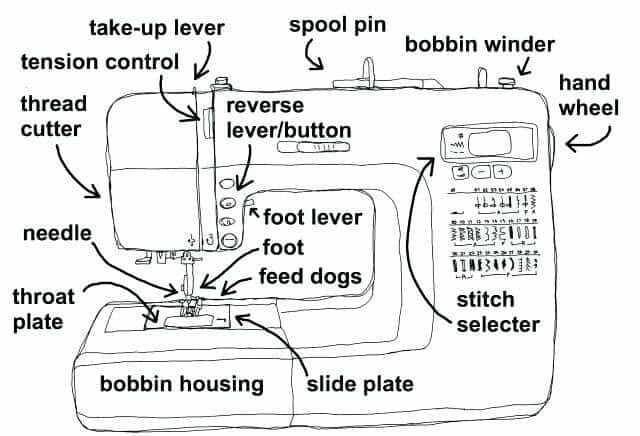

Overview of Machine Parts

This section explores key components essential for functionality and performance in textile creation. Understanding these elements enhances appreciation for craftsmanship and efficiency.

- Needle: Vital for piercing fabric and creating stitches.

- Bobbin: Stores lower thread, working in conjunction with needle.

- Feed dogs: Move fabric during stitching, ensuring even progression.

- Tension discs: Regulate thread tightness for optimal stitching results.

- Presser foot: Holds fabric in place, allowing for controlled movement.

By familiarizing oneself with these critical components, users can delve into troubleshooting and maintenance, ultimately leading to improved outcomes in their projects.

Key Functions of Each Part

Understanding essential roles within this intricate device is crucial for effective operation. Each component contributes to overall functionality, ensuring smooth and precise stitching. Below, we delve into specific duties fulfilled by various sections, highlighting their significance in achieving desired results.

Driving Mechanisms

- Feed Dog: Engages with fabric to move it forward during stitching.

- Motor: Powers the entire unit, controlling speed and direction.

- Belt: Connects motor to mechanisms, transferring energy efficiently.

Stitching Elements

- Needle: Penetrates fabric to create stitches, available in various sizes and types.

- Presser Foot: Holds fabric in place, allowing for consistent feeding.

- Bobbin: Supplies thread from underneath, essential for completing stitches.

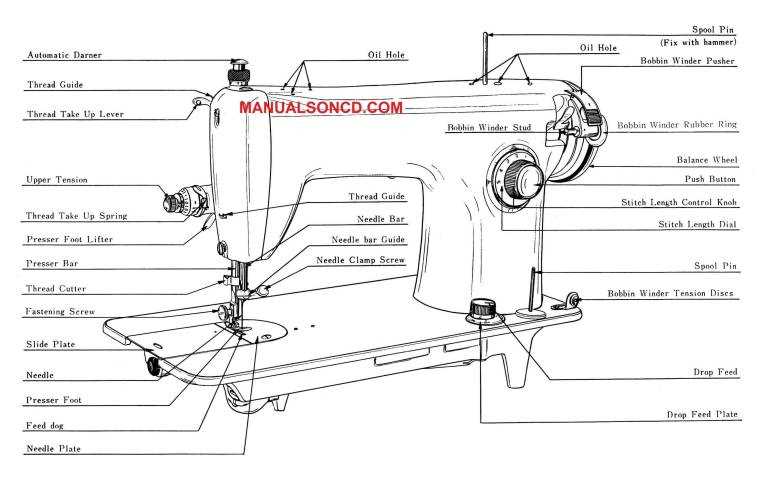

Importance of the Needle System

A critical component in any stitching apparatus, the needle system plays a vital role in determining overall performance and quality of output. Its design directly influences efficiency and precision during fabric manipulation.

Precision is essential; the right needle ensures clean, accurate stitches that enhance appearance and durability. Different materials require specific needles to achieve optimal results, making choice crucial.

Versatility is another key factor. A well-designed needle system accommodates various techniques and fabric types, allowing users to explore creative possibilities while maintaining quality.

In conclusion, understanding and selecting appropriate needles is fundamental for anyone seeking to achieve excellence in their stitching endeavors.

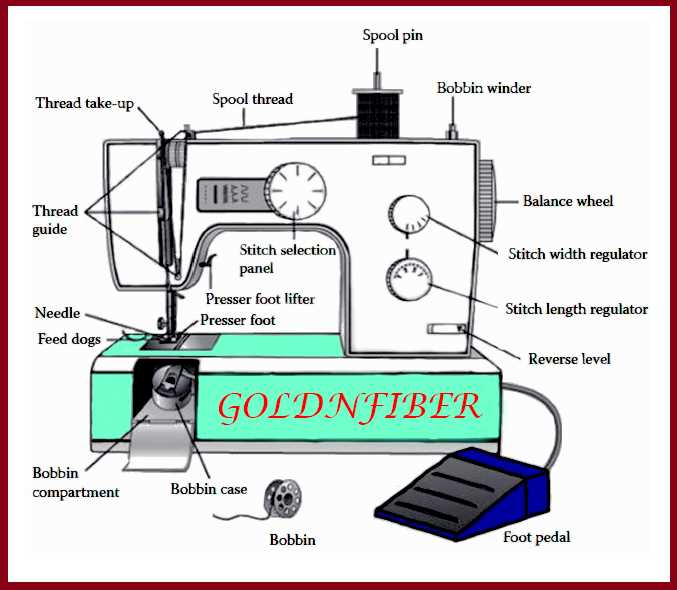

Role of the Bobbin and Case

The interaction between a bobbin and its housing is essential for achieving smooth, consistent stitching. This dynamic duo works together to ensure that upper and lower threads intertwine seamlessly, creating a strong seam.

Bobbin serves as a vital reservoir for thread, providing the necessary supply during operation. When correctly placed within its case, it enables efficient feeding and tension control, crucial for various fabric types.

Moreover, the design of both components significantly impacts performance. An improperly positioned bobbin can lead to complications such as thread jams or uneven tension, highlighting their importance in overall functionality.

In summary, understanding the roles of these elements allows users to delve deeper into enhancing their crafting experience, ultimately leading to higher quality results.

Threading Mechanism Explained

This section delves into the intricate system responsible for guiding and controlling the filament used in textile creation. Understanding this mechanism is crucial for achieving optimal results in fabric manipulation and design.

At its core, this assembly facilitates the flow of the thread from the spool to the needle, ensuring a smooth and consistent operation. Each component plays a vital role in maintaining tension and preventing tangling, which can hinder performance.

Various elements, such as guides and tension discs, work harmoniously to secure the filament in place. Properly adjusting these features can significantly impact the quality of stitching, making it essential for users to familiarize themselves with their functions.

Ultimately, mastering this intricate system empowers creators to enhance their craft, leading to more refined and precise outcomes in their textile projects.

Impact of Tension Adjustments

Adjusting tension is crucial for achieving optimal results in fabric manipulation. Proper control of this factor can significantly affect the quality of stitches, influencing both appearance and durability. An understanding of how these modifications work can lead to improved outcomes in various projects.

Effects on Stitch Quality

Inconsistent or incorrect tension can result in a range of issues, from puckering to thread breakage. Identifying the right balance ensures smooth operation and enhances overall performance.

Common Tension Problems

| Issue | Cause | Solution |

|---|---|---|

| Puckering | Too much tension | Loosen tension settings |

| Thread Breakage | Too little tension | Tighten tension settings |

| Skipped Stitches | Incorrect needle size | Replace with appropriate needle |

| Uneven Stitching | Improper threading | Re-thread correctly |

By understanding these dynamics, individuals can refine their techniques, leading to enhanced creativity and satisfaction in their textile endeavors.

Types of Sewing Machine Feet

Different attachments play a crucial role in enhancing functionality and versatility. Each variant is designed for specific tasks, allowing for creative possibilities and efficiency.

- All-Purpose Foot: Ideal for most tasks, providing a balanced approach for various fabrics.

- Zipper Foot: Facilitates the easy installation of zippers, ensuring a neat finish.

- Buttonhole Foot: Allows for creating uniform buttonholes with precision.

- Walking Foot: Helps in feeding multiple layers evenly, great for quilting.

- Overlock Foot: Perfect for finishing edges, preventing fraying.

Choosing the right attachment can ultimately enhance the sewing experience and lead to professional results.

Feed Dogs and Their Functionality

Feed dogs play a crucial role in the fabric handling process, ensuring smooth movement during stitching. Their design allows for precise advancement, which is essential for achieving consistent results in various projects.

How Feed Dogs Work

These components function by gripping and moving material through the needle area. They operate in a coordinated manner, contributing to the overall efficiency of the stitching operation.

- Engagement with fabric

- Synchronization with needle action

- Adjustment for different thicknesses

Importance of Proper Maintenance

Regular upkeep is vital for optimal performance. Neglect can lead to issues such as uneven feeding or skipped stitches.

- Clean regularly to remove lint and debris.

- Inspect for wear and tear.

- Adjust height as needed for specific materials.

Understanding the Presser Foot

The presser foot plays a crucial role in ensuring precise and controlled fabric handling during the stitching process. Its design and function significantly impact the quality of results achieved in various projects, allowing for greater versatility and creativity.

| Type | Description |

|---|---|

| Standard | Ideal for general stitching tasks, providing consistent pressure. |

| Zipper | Facilitates easy installation of zippers with specialized grooves. |

| Walking | Ensures even feeding of multiple layers, preventing puckering. |

| Buttonhole | Designed for creating professional-looking buttonholes effortlessly. |

How the Stitch Selector Works

The stitch selector is a crucial feature that allows users to customize their crafting experience by choosing various stitch patterns. This functionality enables creativity and precision, making projects more versatile and enjoyable.

Understanding Functionality

When you adjust the selector, it communicates with internal mechanisms to change the stitch formation. Each setting corresponds to a unique design, allowing for an array of options from simple to intricate.

Importance of Customization

Customization enhances the outcome of any project, ensuring that each piece is tailored to specific needs. With various choices available, enthusiasts can delve into unique designs, achieving ultimate satisfaction in their creations.

Electric Components in Modern Machines

In contemporary devices, various electrical elements play a crucial role in enhancing functionality and efficiency. These components work together to ensure seamless operation, offering users a more intuitive experience.

- Motors: Drive mechanisms that provide power and movement.

- Control Panels: User interfaces that allow for adjustments and settings.

- Sensors: Devices that monitor performance and provide feedback.

- Power Supply Units: Convert electrical energy for optimal usage.

Integrating these components not only boosts performance but also allows for innovative features that cater to diverse needs.

Maintenance Tips for Longevity

Ensuring optimal performance and extended lifespan of your equipment requires consistent care and attention. Simple practices can significantly enhance durability and functionality, allowing you to enjoy a seamless experience.

Regular Cleaning

Dust and debris can accumulate over time, affecting performance. Regularly wipe surfaces and remove lint to prevent buildup. Use a soft brush or cloth for delicate areas.

Proper Lubrication

Utilizing the right lubricants is essential for smooth operation. Apply oil to designated spots as recommended in the manual to minimize wear and tear on moving components.