Comprehensive Guide to Labeled Parts of a Sewing Machine

In the realm of textile creation, a key instrument plays a vital role in transforming fabric into various forms. Mastery of this tool requires familiarity with its intricate structure and functionalities, enabling artisans to unleash their creativity effectively. Each element is designed to serve a specific purpose, contributing to the overall performance and efficiency of the device.

Exploring the individual elements reveals not only their names but also their significance in the crafting process. By delving into the features and capabilities of each segment, users can enhance their skills and optimize their workflow. This knowledge empowers crafters to tackle projects with confidence, ensuring precision and quality in their creations.

Whether one is a novice or a seasoned expert, understanding these essential components fosters a deeper connection with the craft. As artisans become more acquainted with the functionalities, they can innovate and experiment, pushing the boundaries of their artistic endeavors.

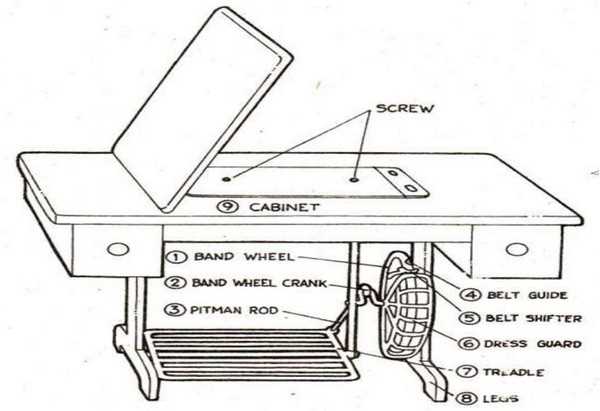

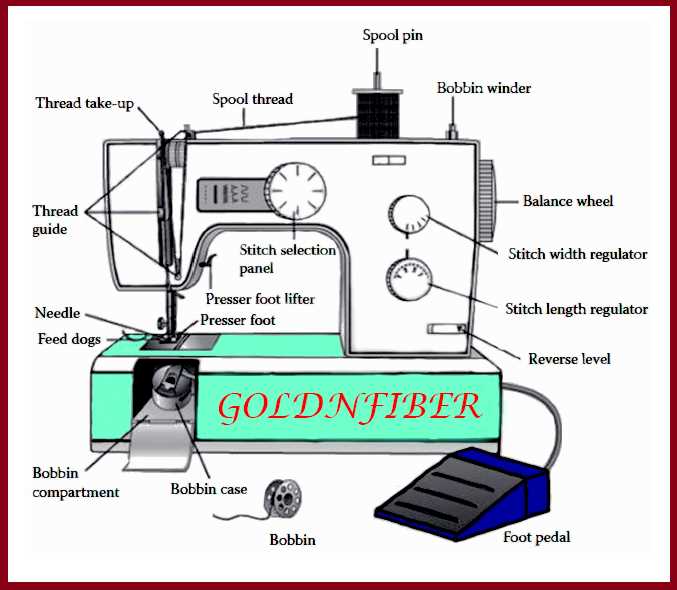

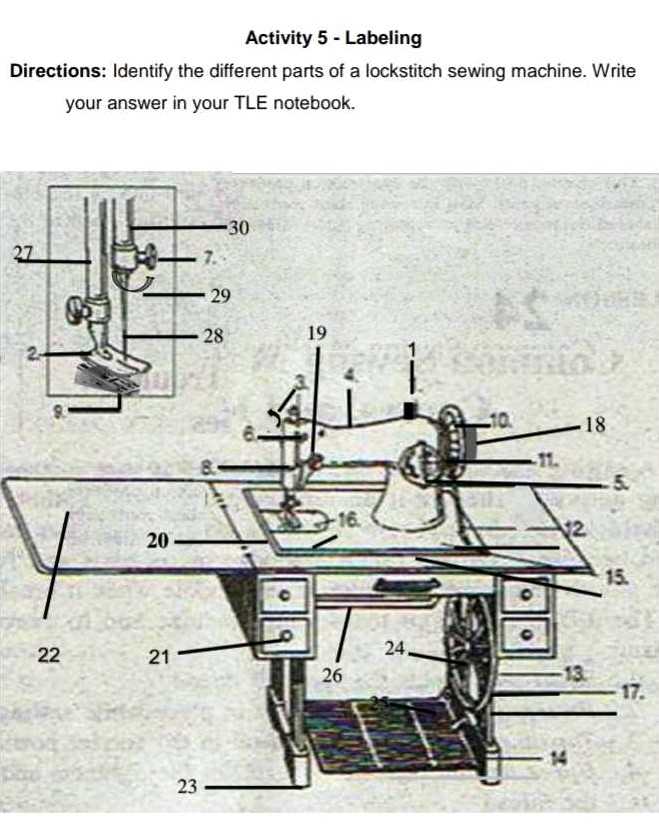

Sewing Machine Basics Explained

Understanding the fundamentals of textile crafting tools is essential for any enthusiast. Each component plays a critical role in the overall functionality, enabling users to create intricate designs and practical items with ease.

- Framework: The sturdy base that provides stability.

- Needle: The essential element for piercing fabric and forming stitches.

- Bobbin: A crucial part that holds the thread used for stitching.

- Foot Pedal: Controls the speed and operation of the device.

- Thread Tension: Regulates the tightness of the thread for consistent stitching.

Each of these components contributes to the ultimate goal of transforming fabric into finished products. Mastery of these basics lays the groundwork for more advanced techniques.

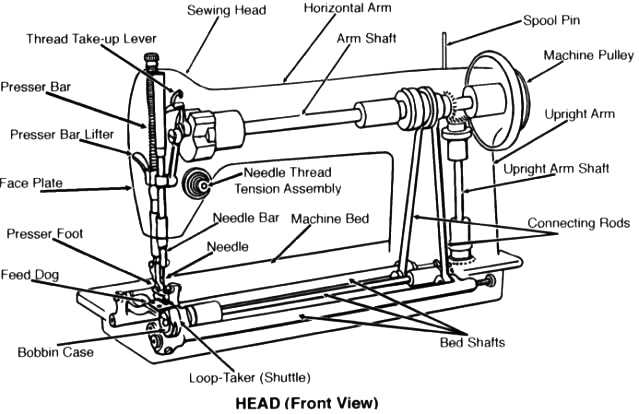

Understanding the Anatomy of Machines

Exploring the fundamental components of devices reveals how they function harmoniously. Each segment plays a critical role, contributing to the overall efficiency and effectiveness of the system.

- Structure: The framework that provides stability and support.

- Power Source: The element that supplies energy necessary for operation.

- Control Mechanism: The interface that allows users to direct the device’s actions.

- Movement System: The parts that enable motion and facilitate tasks.

- Output Section: The area responsible for delivering results or products.

Understanding these components allows users to appreciate the ultimate intricacies of design and functionality.

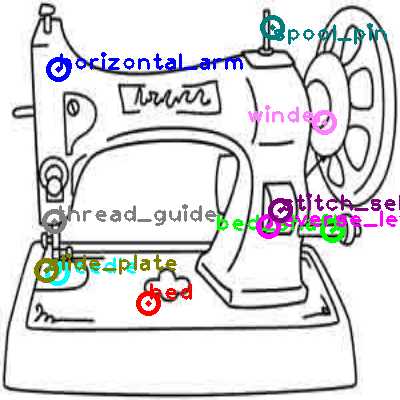

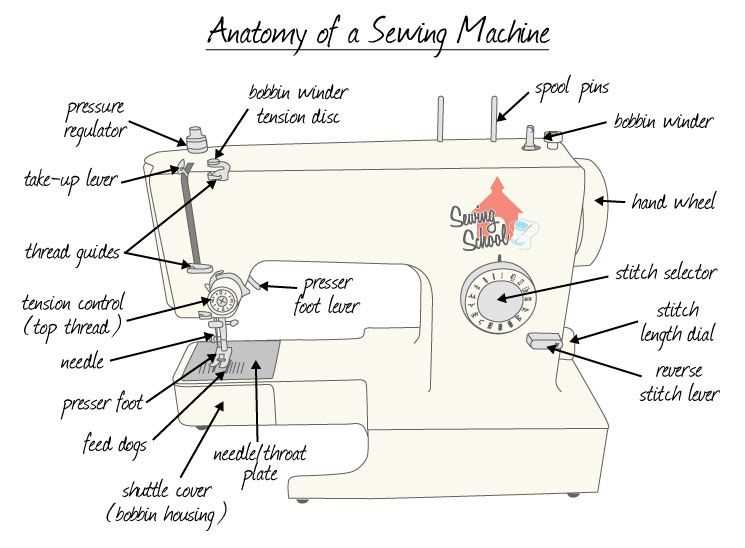

Key Components of a Sewing Machine

Understanding the essential elements of a stitching device is crucial for both beginners and experienced enthusiasts. Each component plays a significant role in achieving precise and effective results. Familiarity with these elements enhances the overall sewing experience and ensures successful projects.

Upper Mechanism

The upper mechanism includes the needle, which pierces the fabric to create stitches. This part works in conjunction with the presser foot, which holds the fabric in place while stitching occurs. Additionally, the thread tension dial regulates the tightness of the upper thread, impacting the quality of the finished work.

Lower Mechanism

On the flip side, the lower mechanism features the bobbin, which houses the thread used for the underside of the stitch. The feed dogs help move the fabric through the device, allowing for even stitching. Together, these components work harmoniously to create durable seams and beautiful finishes.

Functionality of the Needle Assembly

The needle assembly plays a crucial role in the operation of fabric manipulation devices, serving as the primary tool for creating stitches. This essential component is responsible for penetrating the material and interlocking threads, thereby ensuring the integrity of the finished product. Understanding its functionality is key to mastering the art of stitching.

At its core, the needle assembly consists of several elements that work in unison to achieve precise results. Each component contributes to the overall effectiveness, from the needle itself to the threading mechanisms involved. The following table outlines the main components and their specific functions:

| Component | Function |

|---|---|

| Needle | Penetrates the fabric, creating a hole for the thread to pass through. |

| Needle Bar | Holds the needle in place and moves it up and down to facilitate stitching. |

| Thread Guide | Directs the thread from the spool to the needle, ensuring proper tension and alignment. |

| Needle Plate | Provides a stable surface for the fabric and assists in guiding the material as it moves through. |

Each of these components must function harmoniously to produce consistent and reliable results. A well-maintained needle assembly is essential for achieving high-quality outcomes in any fabric-related project.

Role of the Bobbin System

The bobbin system plays a crucial role in the functionality of fabric stitching tools, ensuring that the creation of seams is both efficient and precise. It serves as a reservoir for the lower thread, enabling the interlocking of threads to form sturdy stitches. This system is essential for maintaining consistent tension and facilitating smooth operation during the stitching process.

Mechanics of the Bobbin

At the heart of the bobbin system is the bobbin itself, a small spool that holds the thread. When the upper thread is fed through the needle, it interacts with the lower thread wound on the bobbin, forming a secure bond. The synchronization between these two threads is vital; any discrepancy can lead to issues such as uneven stitching or thread breaks.

Importance in Stitch Quality

Effective functioning of the bobbin system significantly impacts the overall quality of the finished product. Proper winding and placement of the bobbin ensure that tension is maintained throughout the process, contributing to neat and durable seams. Regular maintenance and correct adjustments are key to optimizing performance and achieving professional results.

Importance of the Feed Mechanism

The feed mechanism plays a crucial role in the functioning of any textile crafting apparatus. It ensures that the fabric moves smoothly through the system, allowing for precise stitching and consistent results. Without an effective feed mechanism, the quality of the finished product would be compromised, leading to uneven seams and frustration for the user.

Key Functions of the Feed Mechanism

- Fabric Movement: It regulates the forward motion of the material, enabling uniform stitching.

- Tension Control: Helps maintain the right amount of tension on the fabric, preventing bunching or distortion.

- Compatibility: Works with various fabric types, accommodating different thicknesses and textures.

Impact on Crafting Quality

A well-designed feed mechanism significantly enhances the overall quality of the crafted item. It provides the following benefits:

- Ensures straight and even seams.

- Reduces the likelihood of puckering.

- Improves overall efficiency, allowing for faster project completion.

In conclusion, the feed mechanism is integral to achieving high-quality results in textile projects, making it a vital component for both hobbyists and professionals alike.

Overview of Tension Control

Tension management is a crucial aspect of achieving high-quality results in textile crafting. Proper control of this aspect ensures that the thread flows smoothly, preventing issues such as puckering or uneven stitches. Understanding the mechanics behind this process allows for better adjustments and enhances the overall outcome of fabric manipulation.

Importance of Proper Tension

Maintaining the correct degree of tension is essential for producing neat and durable seams. When the balance is off, it can lead to a range of problems, including thread breakage and fraying. By learning how to adjust the tension appropriately, crafters can enhance their skillset and ensure that their creations withstand the test of time.

Common Adjustments and Techniques

Various techniques can be employed to modify the tension. For instance, adjusting the tension dial or using specific settings based on fabric types can yield better results. Familiarity with these adjustments enables practitioners to handle different materials effectively, ensuring versatility and precision in their work.

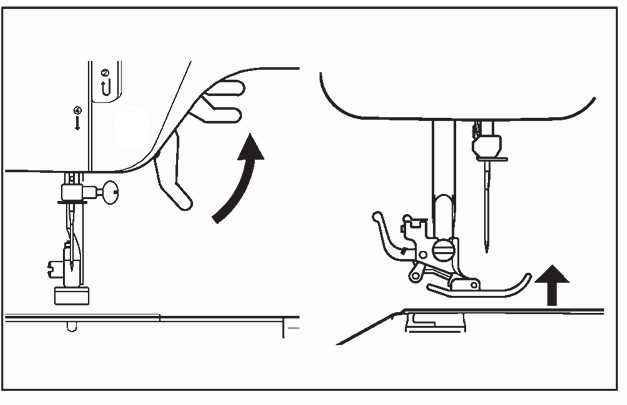

Examining the Presser Foot Types

The choice of foot attachments can significantly influence the quality and versatility of fabric manipulation. Understanding the various designs available helps in achieving specific techniques and finishes, enhancing the overall crafting experience.

Types of Feet Attachments

- Standard Foot: Ideal for general stitching, providing stability and control.

- Zipper Foot: Allows for close stitching next to zippers and piping, enabling a clean finish.

- Designed specifically for creating uniform buttonholes with ease.

- Walking Foot: Helps in managing multiple layers of fabric by evenly feeding them through.

- Appliqué Foot: Perfect for detailed decorative work and precision when layering fabrics.

Choosing the Right Foot

When selecting an attachment, consider the fabric type and the desired technique. Different designs offer unique advantages:

- For intricate designs, an appliqué foot is recommended.

- For heavier materials, a walking foot is essential to prevent slipping.

- Standard tasks can be accomplished with a basic foot attachment.

By familiarizing yourself with these variations, you can enhance your crafting capabilities and achieve professional results in your projects.

Significance of Stitch Selector Dial

The stitch selector dial is a crucial component that enhances the versatility and functionality of any textile crafting tool. It allows users to effortlessly choose from various stitch types, catering to diverse projects and fabric requirements. Mastering this element can greatly influence the quality and appearance of finished items.

Benefits of Using the Selector Dial

- Customization: Offers a range of options for unique designs.

- Efficiency: Streamlines the process of selecting appropriate stitches.

- Creativity: Encourages experimentation with different stitch patterns.

How to Effectively Use the Dial

- Familiarize yourself with available stitch options.

- Choose the stitch that suits your fabric type and project style.

- Adjust settings as needed for optimal results.

Power Supply and Motor Basics

This section explores the essential components that provide energy and facilitate movement in textile apparatus. Understanding these elements is crucial for optimal functionality and performance.

Power Source Functionality

The primary energy source transforms electrical energy into mechanical force. It ensures consistent operation and responds to various user commands, enhancing the overall experience.

Motor Types

Different types of motors serve distinct purposes within the apparatus. Each type varies in efficiency, speed, and torque, catering to diverse sewing tasks.

| Motor Type | Efficiency | Common Use |

|---|---|---|

| AC Motor | High | Continuous operation |

| DC Motor | Moderate | Variable speed applications |

| Stepper Motor | High | Precision tasks |

Accessories and Attachments Overview

This section explores the various tools and enhancements that can significantly improve your crafting experience. Understanding these additions not only boosts functionality but also allows for greater creativity and precision in your projects. Each component plays a unique role, ensuring that your endeavors yield professional results with ease.

Common Enhancements

Among the most frequently used tools are specialized feet, which cater to different stitching techniques. For example, a zipper foot enables seamless insertion of zippers, while a walking foot is perfect for handling multiple layers of fabric without slipping. These enhancements streamline processes and help achieve flawless outcomes.

Storage and Organization Tools

Effective organization is crucial for maintaining an efficient workspace. Storage solutions, such as tool boxes and dedicated caddies, help keep accessories in order, ensuring that everything is easily accessible. A well-arranged setup minimizes distractions, allowing you to focus entirely on your creative pursuits.

Common Issues with Machine Parts

Understanding the frequent challenges associated with various components is crucial for maintaining optimal functionality. Problems can arise due to wear and tear, improper use, or lack of maintenance, leading to decreased efficiency and performance. Below are some typical issues encountered with essential elements and their potential solutions.

| Component | Common Issue | Potential Solution |

|---|---|---|

| Needle | Breaking or bending | Ensure correct needle type and size, and replace regularly. |

| Bobbin | Jamming | Check for proper threading and alignment. |

| Thread | Snapping | Use quality thread and verify tension settings. |

| Foot | Sticking or not moving | Clean and lubricate as needed, and ensure correct attachment. |

| Tension Discs | Improper tension | Adjust settings according to fabric type and thickness. |

Maintenance Tips for Longevity

Ensuring the durability of your textile apparatus requires consistent care and attention. Implementing a few simple practices can significantly enhance its lifespan and performance.

- Regular Cleaning: Remove dust and lint after each session to prevent buildup.

- Lubrication: Apply appropriate oils to moving components periodically to maintain smooth operation.

- Check Tension: Verify and adjust thread tension settings to avoid strain on the system.

- Use Quality Materials: Opt for high-quality threads and fabrics to minimize wear and tear.

- Store Properly: Keep your device in a dry, dust-free environment when not in use.

By following these guidelines, you can help ensure your equipment remains efficient and reliable over time.