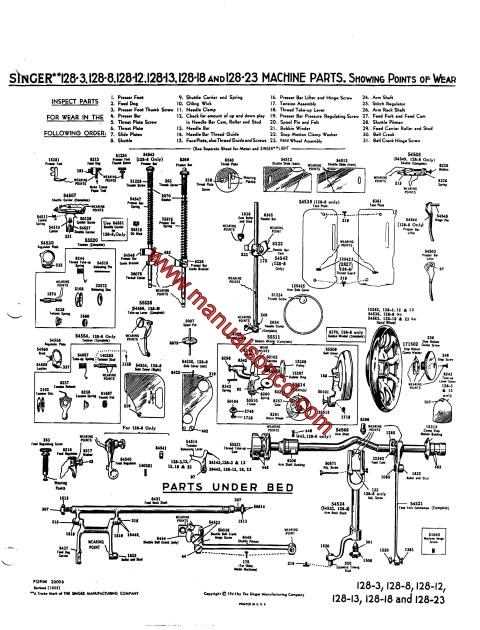

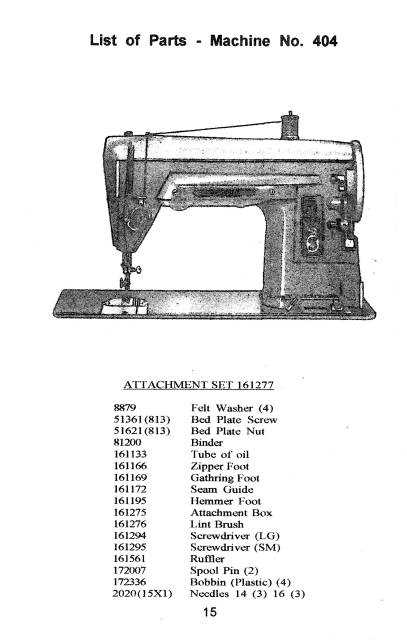

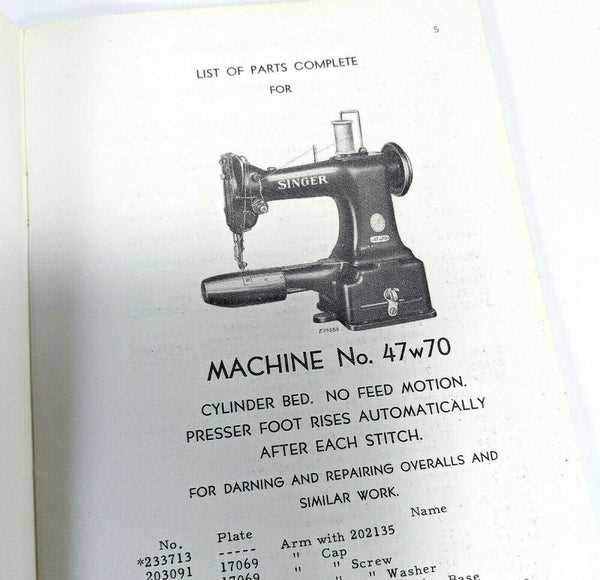

Singer Sewing Machine Parts Diagram

In the realm of fabric manipulation, various tools and implements play a crucial role in achieving precision and creativity. A thorough comprehension of these tools and their specific functionalities enhances the overall crafting experience. Each element serves a unique purpose, contributing to the seamless operation and versatility of the entire setup.

The intricate assembly of these instruments comprises numerous sections, each designed for specific tasks. Familiarity with these segments allows enthusiasts to troubleshoot issues effectively and optimize their crafting processes. By delving into the detailed layout and organization of these components, users can gain valuable insights into improving their skills and techniques.

Furthermore, understanding the arrangement and interrelation of these elements can lead to more efficient workflows. Whether for hobbyists or professionals, knowledge of the various components is essential for maintaining the quality and longevity of the tools. This exploration provides a solid foundation for anyone looking to enhance their crafting capabilities.

This section highlights essential elements that contribute to the overall functionality and efficiency of the device. Understanding these components is crucial for effective operation and maintenance.

- Needle: A critical element that penetrates the fabric, allowing for the creation of stitches.

- Bobbin: A small spool that holds the thread used for the underside of stitches, ensuring a seamless finish.

- Foot Pedal: The control mechanism that regulates the speed of the device, enabling precise operation.

- Thread Tension Dial: This component adjusts the tightness of the thread, affecting stitch quality.

- Feed Dogs: A set of teeth that moves the fabric through the unit, allowing for consistent stitching.

- Stitch Selector: A control that allows users to choose different stitching patterns based on their project requirements.

- Presser Foot: This holds the fabric in place while stitching, ensuring accuracy and even tension.

- Take-Up Lever: A part that controls the thread’s movement, ensuring proper feeding and tension during operation.

Familiarity with these crucial components enhances the user’s ability to troubleshoot and perform maintenance effectively, ultimately leading to improved results in their projects.

Understanding the Needle Assembly

The needle assembly is a crucial component in the functionality of various fabric crafting devices. It plays a vital role in the precision and efficiency of stitching, directly influencing the quality of the finished product. Understanding its structure and operation can greatly enhance your crafting experience.

This assembly typically consists of several key elements, including the needle itself, which pierces the material, and the holder that secures it in place. Additionally, there are various mechanisms that allow for the adjustment of needle position, accommodating different fabric types and stitch styles. Familiarity with these components enables users to troubleshoot issues and make necessary adjustments for optimal performance.

Proper maintenance of the needle assembly is essential for achieving consistent results. Regularly checking for wear and tear, as well as ensuring that the needle is correctly installed, can prevent complications during operation. This attention to detail can lead to smoother and more efficient crafting, ultimately enhancing the overall enjoyment of the process.

Importance of the Feed Dogs

The feed dogs play a crucial role in the operation of textile equipment, ensuring smooth and efficient movement of fabric during the stitching process. Their functionality is essential for achieving consistent results and maintaining the overall performance of the device.

Functionality of Feed Dogs

These components are designed to grip and transport material as it passes under the needle. Their movement is synchronized with the needle’s action, providing a seamless flow that is vital for various stitching techniques. Understanding their operation helps in troubleshooting common issues that may arise.

- Ensure consistent fabric advancement.

- Facilitate various stitching patterns.

- Support different fabric types and thicknesses.

Maintenance Tips

To keep the feed dogs functioning optimally, regular maintenance is necessary. Here are some essential practices:

- Clean the feed dogs frequently to remove lint and debris.

- Check for any signs of wear or damage and replace as needed.

- Ensure proper alignment to prevent skipping or uneven feeding.

By prioritizing the care of these components, users can enhance the longevity and efficiency of their equipment.

Threading Mechanism Explained

The process of guiding and managing the thread within a textile apparatus is essential for achieving precise stitching. Understanding this component is crucial for ensuring the smooth operation and functionality of the apparatus. The threading mechanism facilitates the controlled movement of the thread from the spool to the needle, creating the foundation for effective textile creation.

Key Components of the Threading System

- Spool Holder: Supports the thread spool, allowing for easy access and unwinding.

- Tension Regulator: Maintains the appropriate tension on the thread, preventing slack or breakage.

- Thread Guides: Direct the thread along its path to the needle, ensuring accurate placement.

- Needle Bar: Holds and moves the needle, enabling the penetration of the fabric with the threaded point.

- Take-up Lever: Adjusts the thread tension as the needle moves up and down during operation.

Understanding the Thread Path

- The thread is placed on the spool holder, ensuring it unwinds smoothly.

- The thread travels through the tension regulator, where tension is adjusted.

- It moves along the designated guides to reach the needle bar.

- Finally, the thread passes through the needle’s eye, ready for use in fabric manipulation.

By familiarizing oneself with the threading mechanism, users can troubleshoot issues, optimize performance, and enhance their overall experience with the apparatus.

Functions of the Bobbin Case

The bobbin case plays a crucial role in the functionality of textile creation tools. This component is responsible for holding the bobbin securely in place, allowing for the smooth operation of thread feeding during the stitching process. Understanding its various functions helps users appreciate its importance in achieving high-quality results.

Key Functions

- Thread Control: The bobbin case regulates the amount of thread that is released from the bobbin. This ensures a consistent feed, preventing tangles or slack.

- Stitch Quality: A properly functioning bobbin case contributes significantly to the overall stitch quality. It influences tension and alignment, which are essential for even stitching.

- Durability: The material and design of the bobbin case enhance its longevity, allowing it to withstand the wear and tear associated with frequent use.

Maintenance Tips

- Regularly clean the bobbin case to remove lint and debris, which can affect performance.

- Check for any signs of damage or wear that may require replacement.

- Ensure the bobbin is correctly inserted to avoid operational issues.

Role of the Tension Control

The mechanism responsible for regulating thread tightness plays a crucial role in achieving optimal results in fabric manipulation. Proper tension ensures that stitches are uniform and secure, allowing for smooth operation during the crafting process.

This element is essential for maintaining balance between the upper and lower threads. If the tension is too loose, stitches may appear uneven or puckered, while excessive tightness can lead to breakage or skipped stitches. By adjusting this control, users can adapt to different fabrics and thread types, ensuring consistent quality in their projects.

Understanding how to properly manage thread tension empowers creators to troubleshoot common stitching issues effectively. With practice, one can master the art of tension adjustment, enhancing both the durability and aesthetics of their final creations.

Benefits of a Stitch Selector

A stitch selector is a valuable feature that enhances the versatility and functionality of textile crafting tools. By providing users with the ability to easily choose from a variety of stitch patterns, this component simplifies the process of customizing projects and achieving desired results.

Utilizing a stitch selector can lead to numerous advantages, including:

| Benefit | Description |

|---|---|

| Versatility | Enables the user to create a wide range of designs, from simple straight stitches to intricate decorative patterns, catering to various crafting needs. |

| Efficiency | Streamlines the selection process, allowing crafters to switch between stitches quickly, thus saving time and effort during projects. |

| Precision | Improves accuracy in stitching by providing clear options, reducing the chances of errors and enhancing the overall quality of the work. |

| Creativity | Encourages experimentation with different stitch styles, fostering innovation and unique creations in textile projects. |

Incorporating a stitch selector into your crafting toolkit not only enhances functionality but also opens up new possibilities for creative expression.

Maintenance Tips for Key Parts

Proper care and regular upkeep of essential components play a vital role in ensuring the longevity and efficiency of your fabric crafting tool. By focusing on a few critical areas, you can significantly enhance performance and prevent common issues. This section outlines best practices for maintaining these important elements, helping you achieve consistent results and minimize wear and tear.

Regular Cleaning

Keeping the critical elements free from dust and debris is crucial for optimal performance. Use a soft brush or a lint-free cloth to remove any particles that may accumulate over time. Pay special attention to areas where fabric and thread may gather, as buildup can lead to operational difficulties.

Lubrication and Adjustment

Applying the right lubricant to moving components ensures smooth operation and reduces friction. Consult the user manual for recommendations on suitable products and application frequency. Additionally, periodic adjustments to tension settings and alignments can help maintain accuracy and improve functionality, enabling a seamless crafting experience.

Common Issues with Machine Parts

When operating a textile fabrication tool, users often encounter various challenges related to its components. Understanding these common obstacles can significantly enhance performance and extend the life of the equipment.

- Thread Bunching: This issue frequently arises when the thread gets tangled, leading to uneven stitching and potential damage.

- Skipping Stitches: When the needle fails to penetrate the fabric correctly, it can result in gaps in the stitching.

- Tension Problems: Improper tension settings can cause the thread to either be too tight or too loose, affecting the overall quality of the seams.

- Noise During Operation: Unusual sounds may indicate that certain components are worn or not aligned correctly, requiring immediate attention.

- Difficulty in Feeding Fabric: If the fabric does not move smoothly, it can lead to inconsistent stitches and frustration for the user.

Addressing these challenges promptly not only improves functionality but also ensures a more enjoyable experience for users.

Resources for Repair and Support

When it comes to maintaining and troubleshooting your textile apparatus, having access to reliable resources is essential. Various platforms provide valuable information that can assist users in resolving issues effectively and efficiently.

Online Forums: Engaging with community-driven online forums can be a great way to connect with other enthusiasts and experts. These platforms often feature discussions, tips, and shared experiences that can guide you in your repair endeavors.

Instruction Manuals: Referring to the original instruction guides can provide critical insights into the functionality and maintenance of your equipment. These manuals typically contain troubleshooting tips and detailed guidance for assembly and disassembly.

Video Tutorials: Numerous online video resources demonstrate step-by-step repair processes. These visual aids can be particularly beneficial for those who prefer a hands-on approach to learning.

Local Repair Shops: Visiting local repair shops can offer personalized assistance and professional insights. Skilled technicians can diagnose issues and provide expert recommendations tailored to your specific needs.

Parts Suppliers: Reliable suppliers offer the necessary components for repairs, ensuring you can restore your equipment to optimal working condition. Many of these suppliers also provide customer support for inquiries related to compatibility and installation.

Utilizing these resources can empower you to tackle challenges confidently, ensuring the longevity and efficiency of your device.