Comprehensive Parts Diagram for 2005 GMC Sierra 1500

When it comes to maintaining and repairing your vehicle, having a clear visualization of its elements is essential. Each component plays a crucial role in the overall functionality and performance. This section aims to provide a comprehensive overview of the essential elements that contribute to your truck’s operation.

Visual aids are invaluable tools for both enthusiasts and professionals alike. They help in identifying individual parts, understanding their placement, and recognizing how they interact within the system. By examining these layouts, you can gain insight into the intricacies of your vehicle’s construction.

Whether you are planning to undertake a DIY project or simply wish to expand your knowledge, familiarizing yourself with the various components will empower you. This information not only enhances your ability to perform repairs but also increases your confidence in understanding your truck’s capabilities and limitations.

Understanding the 2005 GMC Sierra 1500

This section aims to provide a comprehensive overview of a popular model known for its durability and performance. By exploring its key components and systems, readers can gain insights into its design and functionality, enhancing their knowledge of this vehicle.

The vehicle’s robust construction and advanced features contribute to its reputation as a reliable option for both work and leisure. Familiarity with its critical elements can empower owners and enthusiasts to make informed decisions regarding maintenance and upgrades.

In examining the various assemblies, one can appreciate how each plays a role in the overall operation. Understanding these components not only aids in troubleshooting but also highlights the engineering that enhances driving experiences.

Ultimately, grasping the intricacies of this model equips individuals with the knowledge needed to navigate repairs and modifications effectively, ensuring optimal performance for years to come.

Overview of Key Components

This section provides a comprehensive look at the essential elements that contribute to the overall functionality and performance of the vehicle. Understanding these components is crucial for maintenance and repair, ensuring optimal operation on the road.

The primary parts can be categorized into several critical groups:

- Powertrain: This includes the engine, transmission, and related systems that work together to provide power and movement.

- Suspension: Essential for ride comfort and handling, the suspension system absorbs shocks and maintains vehicle stability.

- Braking System: Comprising various components that ensure safe stopping capabilities, this system is vital for vehicle safety.

- Electrical System: This encompasses the battery, wiring, and electronic control units that manage various functions and systems.

- Body and Frame: The structural components that provide durability and support, housing all other elements securely.

Each of these categories contains specific elements that play distinct roles, contributing to the vehicle’s overall efficiency and reliability. Familiarity with these parts can aid in troubleshooting and enhance the understanding of how the vehicle operates as a cohesive unit.

Importance of Parts Diagrams

Understanding the intricate assembly of any vehicle is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling mechanics and enthusiasts to identify components and their relationships. These illustrations not only simplify the repair process but also enhance overall efficiency.

Clear guidance is provided by these visual aids, allowing users to locate specific items quickly. This clarity minimizes the risk of errors during assembly and disassembly. Furthermore, comprehensive illustrations promote better understanding, facilitating smoother troubleshooting and enhancing the longevity of the vehicle.

Ultimately, having access to detailed visual references empowers individuals to perform repairs with confidence, ensuring that every component is correctly installed and functioning as intended.

Common Issues with Sierra 1500 Parts

When it comes to vehicle maintenance, certain components tend to exhibit recurring problems over time. Understanding these common issues can help owners take preventive measures and ensure the longevity of their vehicles. Below are some prevalent challenges faced with various elements.

Frequent Problems

- Electrical Failures: Wiring and connectors often experience corrosion or disconnection, leading to malfunctioning systems.

- Brake Wear: Brake pads and rotors may wear out unevenly, causing reduced stopping power and increased noise.

- Suspension Concerns: Shocks and struts can deteriorate, resulting in a rough ride and compromised handling.

- Engine Performance: Components such as spark plugs and fuel injectors may become clogged, affecting fuel efficiency and acceleration.

Prevention and Maintenance Tips

- Regularly inspect electrical connections for signs of wear.

- Schedule brake inspections at recommended intervals.

- Monitor suspension components for any signs of leakage or damage.

- Conduct routine engine tune-ups to maintain optimal performance.

By addressing these common issues proactively, owners can enhance their vehicle’s reliability and performance over time.

Where to Find OEM Parts

Locating original equipment manufacturer components can be a straightforward process when you know where to look. These authentic replacements ensure compatibility and quality, making them essential for maintaining vehicle performance.

Online Retailers: Numerous websites specialize in OEM components, offering a vast selection with detailed descriptions. Reputable online platforms allow users to search by vehicle specifications to find exactly what they need.

Local Dealerships: Authorized dealerships provide genuine components directly from the manufacturer. Visiting a nearby location allows you to obtain the right items and seek expert advice on installation and compatibility.

Automotive Forums: Engaging with online communities can lead to valuable insights and recommendations for sourcing authentic components. Enthusiasts often share experiences and can guide you to trustworthy vendors.

Salvage Yards: For those looking for cost-effective solutions, salvage yards can be treasure troves of OEM items. Inspecting used components in good condition can save money while maintaining quality.

Ultimately, whether you prefer shopping online, visiting a dealership, or exploring local options, several avenues are available for finding authentic components tailored to your needs.

Aftermarket vs. OEM Components

The choice between alternative and original equipment parts can significantly influence vehicle performance and longevity. Each type offers distinct advantages and drawbacks, impacting maintenance decisions and overall costs.

Original equipment manufacturer (OEM) components are designed by the vehicle’s manufacturer, ensuring compatibility and quality. These items typically come with warranties, providing peace of mind for the owner.

On the other hand, aftermarket alternatives often come at a lower price point and can enhance customization options. While some may lack the same level of quality assurance, many aftermarket parts are engineered to meet or exceed original specifications.

When deciding between these options, it’s essential to consider factors such as budget, intended use, and desired performance. Delving into user reviews and expert opinions can further guide your ultimate choice in maintaining your vehicle.

Step-by-Step Repair Process

This section outlines a comprehensive method for addressing mechanical issues. By following a structured approach, you can effectively identify problems and implement solutions, ensuring a smoother repair experience.

Preparation Phase

- Gather necessary tools and materials.

- Review the vehicle’s manual for specifications.

- Ensure a clean and organized workspace.

Execution Steps

- Diagnose the issue by inspecting all related components.

- Remove any obstructive parts for better access.

- Replace or repair damaged components as needed.

- Reassemble all parts, ensuring proper alignment and fit.

- Test the system to confirm successful repair.

Tools Required for Repairs

When undertaking vehicle maintenance or repair tasks, having the right tools is crucial for achieving effective results. The selection of tools not only enhances the efficiency of the job but also ensures safety and precision during the process.

Essential Tools

- Wrenches and Sockets

- Ratchet Set

- Torque Wrench

- Flathead and Phillips Screwdrivers

- Pliers and Wire Cutters

Specialized Equipment

- Jack and Jack Stands

- Oil Drain Pan

- Diagnostic Scanner

- Multimeter

- Brake Bleeder Kit

Having these tools readily available can significantly streamline the repair process, allowing for timely completion and reducing the likelihood of errors.

Maintenance Tips for Longevity

Ensuring the enduring performance of your vehicle requires consistent care and attention. By following a few essential maintenance practices, you can enhance the lifespan of your automobile and keep it operating smoothly.

- Regular Oil Changes: Frequent oil changes help maintain engine health.

- Tire Maintenance: Check tire pressure regularly and rotate them to promote even wear.

- Fluid Checks: Monitor coolant, brake fluid, and transmission fluid levels to prevent overheating and ensure optimal performance.

- Brake Inspections: Regularly inspect brake pads and rotors to ensure safety and effectiveness.

- Battery Care: Clean terminals and check for corrosion to ensure reliable starts.

By incorporating these practices into your routine, you can significantly prolong the life of your vehicle and enjoy a dependable ride for years to come.

Understanding Electrical Systems Layout

Electrical systems in vehicles are intricate networks that govern the operation of various components, ensuring functionality and efficiency. A comprehensive understanding of this layout is essential for troubleshooting and repairs, as it reveals how power flows throughout the system.

Wiring diagrams are invaluable tools that illustrate the connections and pathways of electrical circuits. They depict not only the components but also the relationships between them, allowing technicians to identify potential issues swiftly. Understanding these layouts empowers individuals to tackle repairs confidently, ensuring that each electrical element operates harmoniously within the vehicle.

Moreover, familiarity with the electrical architecture can lead to improved performance and safety. As one delves into the specifics, recognizing the significance of each part becomes clearer, ultimately enhancing the overall knowledge of vehicle maintenance.

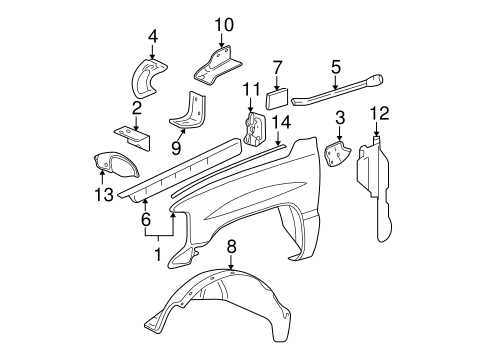

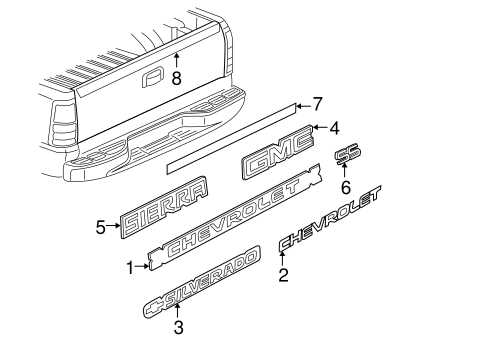

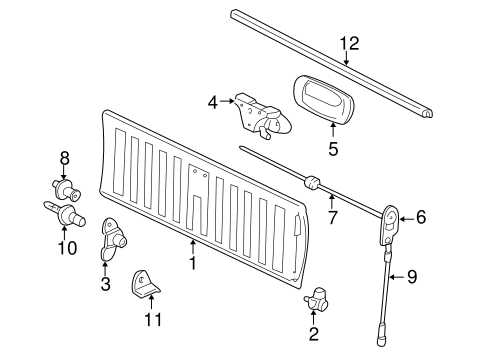

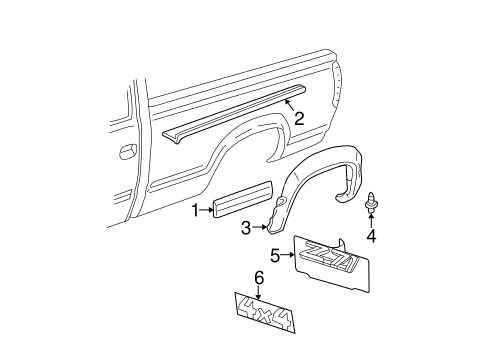

Body Parts and Specifications

This section explores the essential components of a vehicle’s exterior structure, detailing their functions and design elements. Understanding these features is crucial for maintenance and performance enhancement.

Key Components

The main elements of the vehicle’s body contribute significantly to its overall strength and aesthetics. Each component is engineered to provide safety and durability while enhancing the visual appeal.

Specifications Overview

| Component | Material | Dimensions |

|---|---|---|

| Fenders | Steel/Aluminum | Standard size varies |

| Doors | Steel/Composite | Standard size varies |

| Hood | Steel/Aluminum | Standard size varies |

| Grille | Plastic/Metal | Standard size varies |

Engine Parts and Their Functions

The internal combustion mechanism comprises various components, each playing a crucial role in ensuring optimal performance and efficiency. Understanding these elements can enhance knowledge of how the system operates and how to maintain it effectively.

Block: The main structure that houses the cylinders and provides the foundation for the engine.

Cylinders: These are the chambers where fuel and air mix and combust, generating power.

Pistons: Moving within the cylinders, they convert the energy from combustion into mechanical motion.

Crankshaft: This component transforms the linear motion of the pistons into rotational energy to power the drivetrain.

Camshaft: Responsible for opening and closing the valves at the appropriate times, it controls the airflow into and out of the combustion chambers.

Valves: These regulate the intake of air-fuel mixture and the expulsion of exhaust gases, critical for maintaining engine efficiency.

Timing Belt/Chain: This ensures the synchronization of the crankshaft and camshaft, maintaining proper timing in the engine cycle.

Oil Pan: It stores oil necessary for lubrication, helping to reduce friction between moving parts and prevent overheating.

Each of these components interacts intricately, contributing to the ultimate performance of the engine. Understanding their functions allows for better maintenance and troubleshooting practices.

Suspension and Chassis Components

The suspension and chassis elements are crucial for maintaining vehicle stability, comfort, and handling. These components work together to absorb shocks, provide support, and ensure a smooth ride, ultimately enhancing overall performance.

| Component | Function |

|---|---|

| Shock Absorbers | Dampen the impact of road irregularities and improve ride quality. |

| Control Arms | Connect the chassis to the wheels, allowing for controlled movement. |

| Springs | Support the vehicle’s weight and absorb bumps for a smoother ride. |

| Sway Bar | Minimize body roll during turns, enhancing stability. |

| Frame | Provide structural support and house various components. |