Comprehensive Guide to Quicksilver 3000 Parts Diagram

The intricacies of marine machinery often require a thorough exploration of their individual elements and how they interconnect. Gaining insight into these assemblies can significantly enhance both maintenance and operational efficiency. Knowledge of each unit’s function is crucial for anyone involved in the upkeep or usage of these complex systems.

When delving into the structure of these essential systems, one can uncover valuable information regarding the various components that contribute to optimal performance. An organized representation of these elements can serve as a vital tool for technicians and enthusiasts alike, ensuring that every piece is accounted for and understood.

In this discussion, we will examine a comprehensive visual reference that illustrates the configuration of components within marine engines. This resource will facilitate a better understanding of how each part interacts, ultimately leading to improved troubleshooting skills and maintenance practices.

Understanding the Quicksilver 3000 System

This section delves into the intricacies of a sophisticated marine control mechanism designed for enhanced navigation and operational efficiency. By breaking down its components and functionality, users can gain a clearer perspective on how this system operates within a vessel’s framework.

Key Features

- Streamlined interface for user-friendly navigation

- Integrated safety mechanisms to prevent malfunction

- Responsive feedback system for real-time performance monitoring

Core Components

- Control Unit: Central hub for managing operations.

- Sensor Array: Collects critical data for decision-making.

- Power Supply: Ensures reliable energy flow to all elements.

- Communication Link: Facilitates interaction with other onboard systems.

Understanding these elements is essential for efficient operation and troubleshooting, empowering users to maintain optimal performance while navigating the waters.

Components Overview of Quicksilver 3000

This section provides a comprehensive look at the essential elements that make up a particular system. Understanding these components is crucial for effective maintenance and optimal performance. Each element plays a significant role, contributing to the overall functionality and reliability.

Key Elements

Among the primary components, the engine stands out as the powerhouse of the system. It is responsible for converting fuel into mechanical energy, driving the entire operation. Additionally, the transmission ensures smooth power delivery, allowing for efficient movement and control.

Supporting Features

In addition to the main components, various accessories enhance performance and user experience. These include the cooling system, which prevents overheating, and the electrical system, ensuring reliable operation of all electronic features. Together, these supporting elements create a harmonious and effective assembly.

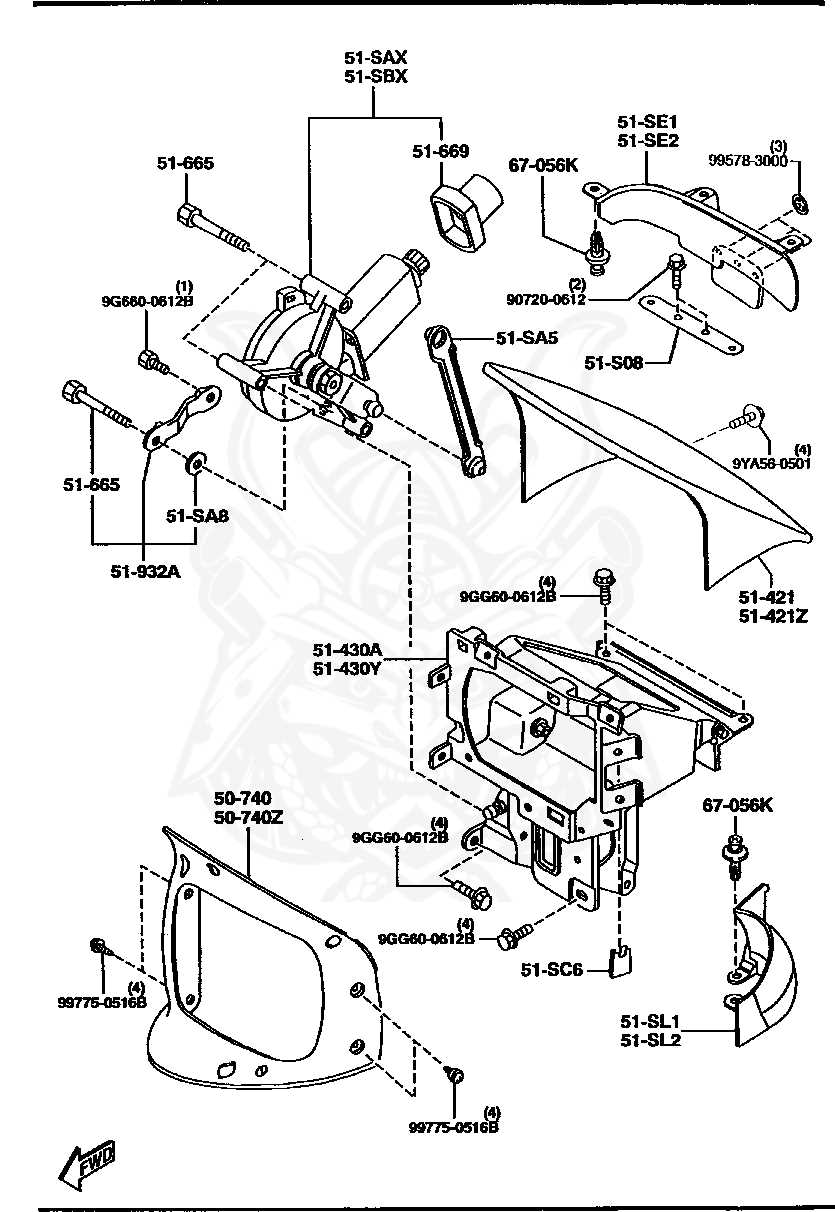

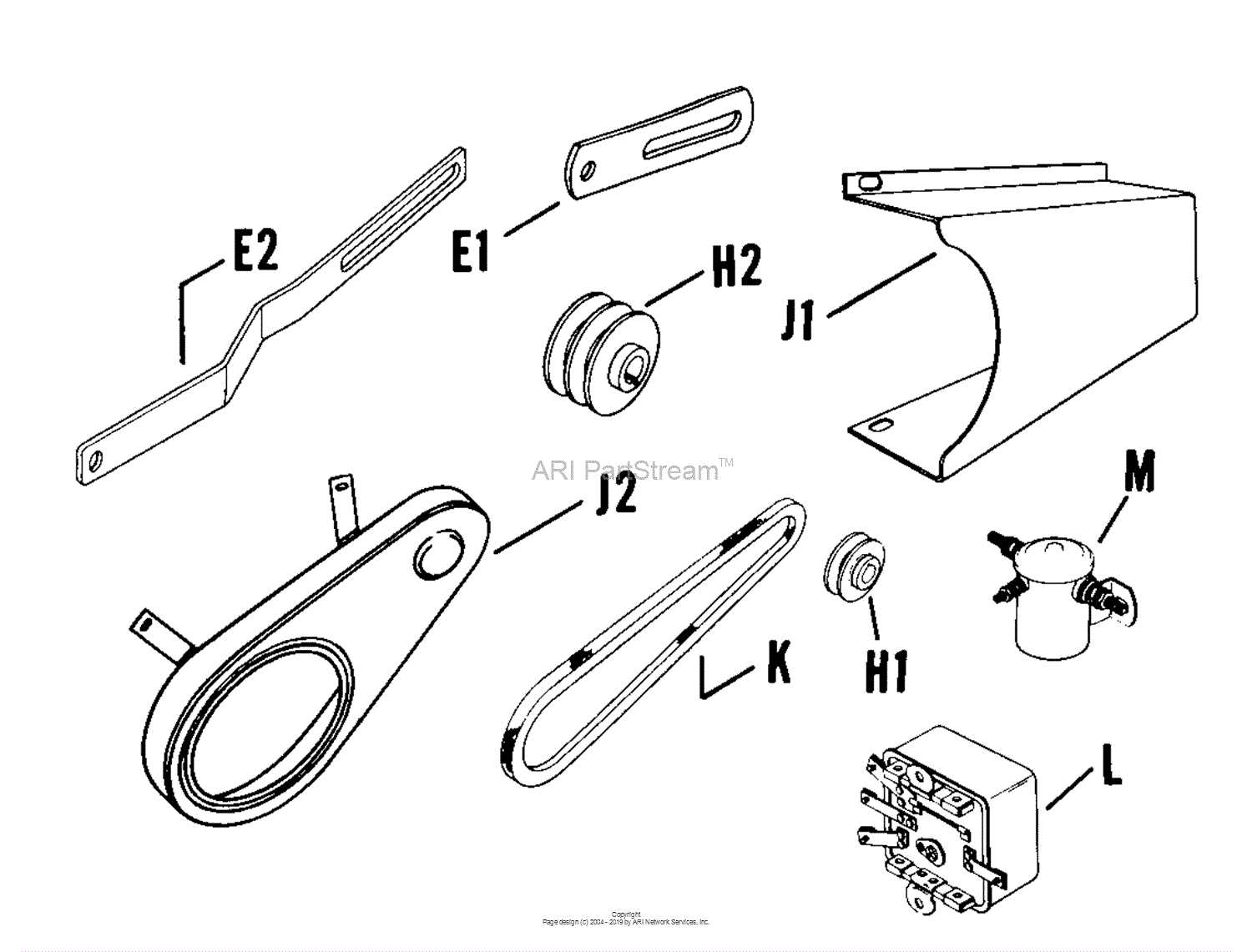

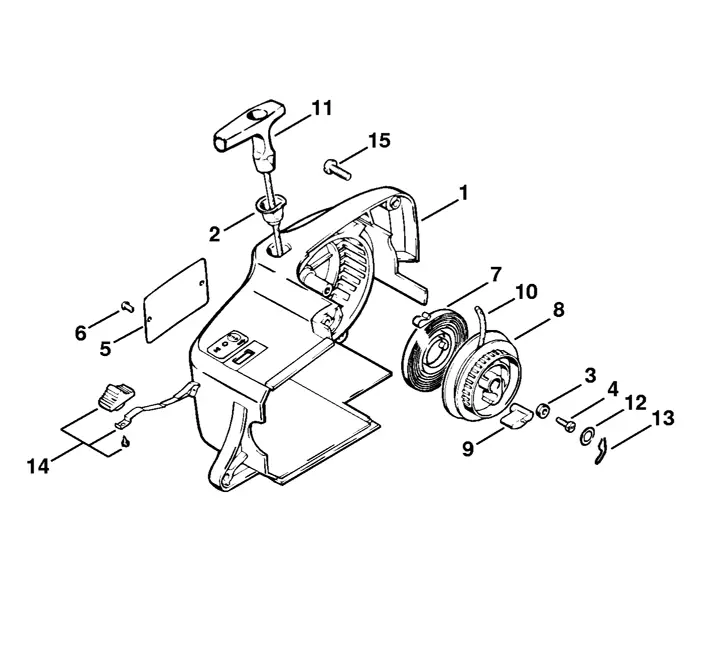

Importance of Parts Diagrams

Understanding the assembly and functionality of mechanical components is crucial for maintenance and repair tasks. Visual representations of these elements provide invaluable assistance in identifying individual pieces, their relationships, and roles within a larger system. Such illustrations serve as a guide for both novice and experienced technicians, ensuring efficiency and accuracy during servicing operations.

Enhanced Clarity and Understanding

Visual aids simplify complex systems, allowing users to quickly grasp the arrangement and interconnectivity of various elements. This clarity helps prevent errors during repairs, as technicians can accurately locate and assess each component.

Facilitating Communication

Illustrations also enhance communication among team members, as they provide a common reference point. This shared understanding promotes collaboration and reduces the likelihood of misunderstandings, ultimately leading to more effective problem-solving.

| Benefit | Description |

|---|---|

| Improved Accuracy | Minimizes the risk of misidentifying components. |

| Time Efficiency | Speeds up the repair process by providing clear guidance. |

| Cost-Effectiveness | Reduces the likelihood of costly mistakes. |

| Training Aid | Serves as a valuable resource for new technicians. |

Common Issues with Quicksilver 3000 Parts

When dealing with mechanical components in aquatic machinery, users often encounter a variety of challenges that can hinder performance and reliability. Understanding these common difficulties can help in diagnosing issues and ensuring optimal functionality.

Frequent Wear and Tear

One of the most prevalent problems is the degradation of essential components due to regular use in harsh environments. Exposure to water, salt, and varying temperatures can lead to corrosion and physical wear, resulting in decreased efficiency and potential failures. Regular maintenance and timely replacements are crucial to mitigating these effects.

Compatibility Concerns

Another issue arises from the integration of different components. Users may find that certain elements do not fit or function well together, leading to misalignments or operational inefficiencies. Ensuring that all parts are compatible and suited for specific applications is vital for maintaining the overall integrity of the system.

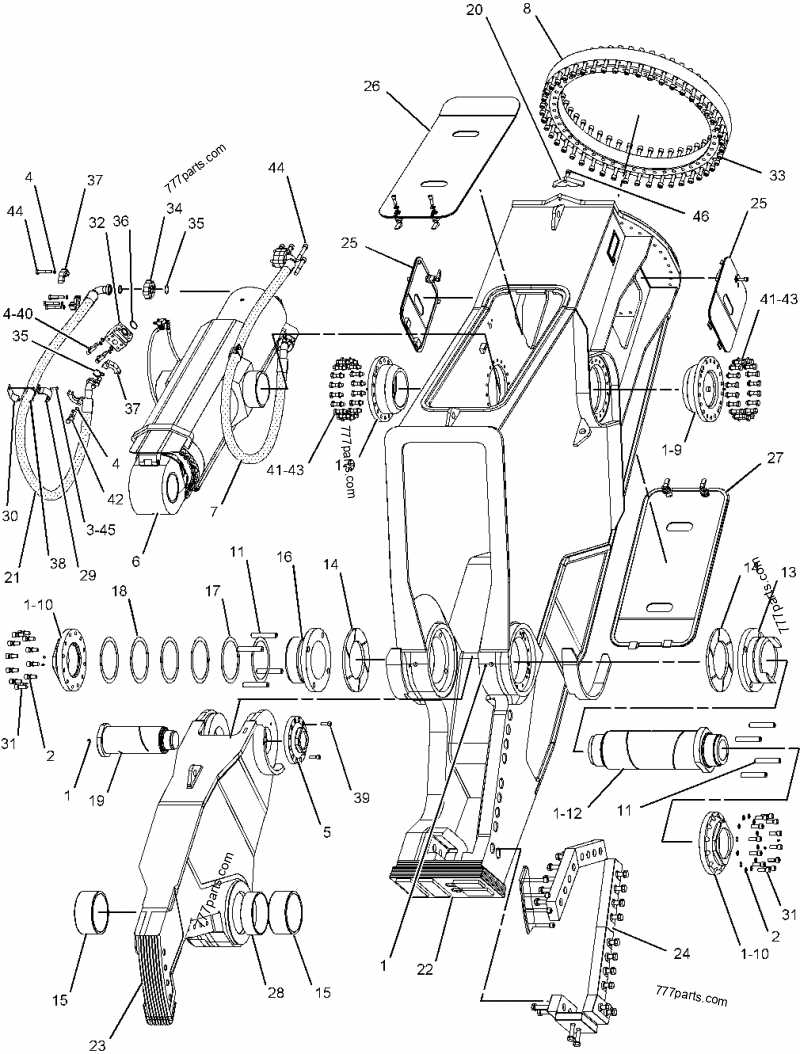

How to Read the Diagram

Understanding a schematic representation is crucial for effective maintenance and repair tasks. These illustrations serve as visual guides, helping users to identify components, their connections, and functionalities. Grasping the layout and symbols used can significantly enhance your ability to troubleshoot and assemble mechanical systems.

Familiarize Yourself with Symbols

Each representation contains specific icons that denote various elements. Familiarizing yourself with these symbols is essential for accurate interpretation. Pay attention to the legends or keys provided, as they will clarify what each symbol signifies, allowing you to decode the information more efficiently.

Follow the Connections

Once you understand the symbols, focus on the connections between components. Trace the lines and arrows to comprehend how different parts interact. This will provide insights into the flow of operations and potential points of failure. By following these connections, you can formulate a clearer picture of the system’s overall functionality.

Maintenance Tips for Quicksilver 3000

Regular upkeep is essential for ensuring the longevity and optimal performance of your marine equipment. By following a few key practices, you can enhance reliability and reduce the risk of unexpected issues.

Here are some effective maintenance strategies:

- Routine Inspections: Check all components regularly for signs of wear or damage. Look for frayed wires, corrosion, and leaks.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear. Follow manufacturer recommendations for specific products.

- Fluid Levels: Regularly monitor oil and coolant levels. Top up as necessary to prevent overheating and ensure smooth operation.

- Cleaning: Keep the equipment clean from dirt, salt, and debris. Use freshwater to rinse after use in saltwater to avoid corrosion.

- Electrical Connections: Inspect and clean electrical terminals. Ensure connections are secure to prevent malfunctions.

By adhering to these guidelines, you can help maintain peak functionality and extend the lifespan of your equipment, ensuring safe and enjoyable experiences on the water.

Identifying Spare Parts Easily

Recognizing components for your equipment can often be a daunting task. However, a systematic approach can streamline the process, making it more efficient and less stressful. By leveraging visual aids and organized resources, you can quickly pinpoint the specific elements you need for maintenance or replacement.

One effective method is to utilize a structured reference chart that categorizes each element based on its functionality and placement within the system. Below is an example of how such a chart could be organized:

| Component Name | Description | Function | Location |

|---|---|---|---|

| Element A | Primary drive unit | Transmits power | Base assembly |

| Element B | Control panel | Interface for operation | Front casing |

| Element C | Power supply module | Supplies energy | Side compartment |

| Element D | Cooling fan | Regulates temperature | Top assembly |

By consulting such a reference, you can easily identify what you are looking for, ensuring that you acquire the correct replacements with minimal hassle. This approach not only saves time but also enhances overall efficiency during repairs or upgrades.

Where to Find Replacement Parts

When seeking components for your machinery, identifying reliable sources is crucial. Various avenues can be explored to obtain the necessary items, ensuring that you maintain optimal performance and longevity.

Online Retailers: Numerous e-commerce platforms specialize in equipment and accessories. These websites often provide a vast selection and detailed descriptions, making it easier to locate the specific items you need.

Manufacturer Websites: Visiting the official site of your equipment’s manufacturer is a smart move. They typically offer original components and sometimes provide helpful resources like installation guides or customer support.

Local Dealers: Many local distributors stock a range of essential items. Building a relationship with them can lead to valuable insights and personalized service, ensuring you find exactly what you require.

Online Marketplaces: Platforms that facilitate peer-to-peer sales can be treasure troves for used or hard-to-find items. However, it’s essential to verify the credibility of sellers to avoid low-quality products.

Repair Shops: Professionals who specialize in repairing similar machinery often have access to a variety of components. They might also offer advice on where to find the right replacements for your specific needs.

By exploring these diverse options, you can efficiently source the necessary items to keep your equipment running smoothly.

Comparing Quicksilver Models

This section aims to explore the various iterations of a well-known brand in the marine industry, focusing on the unique features and specifications that differentiate each version. By analyzing the attributes of these models, enthusiasts can better understand their options and make informed decisions when choosing the right one for their needs.

Key Features Overview

| Model | Engine Power | Fuel Capacity | Weight |

|---|---|---|---|

| Model A | 150 HP | 50 liters | 400 kg |

| Model B | 200 HP | 60 liters | 450 kg |

| Model C | 250 HP | 70 liters | 500 kg |

Performance Analysis

Each variant offers distinct performance metrics that cater to different user preferences. For instance, while one model may excel in fuel efficiency, another might be tailored for high-speed pursuits. Understanding these variations allows potential buyers to align their choices with their intended usage, whether it’s leisurely cruising or high-performance adventures on the water.

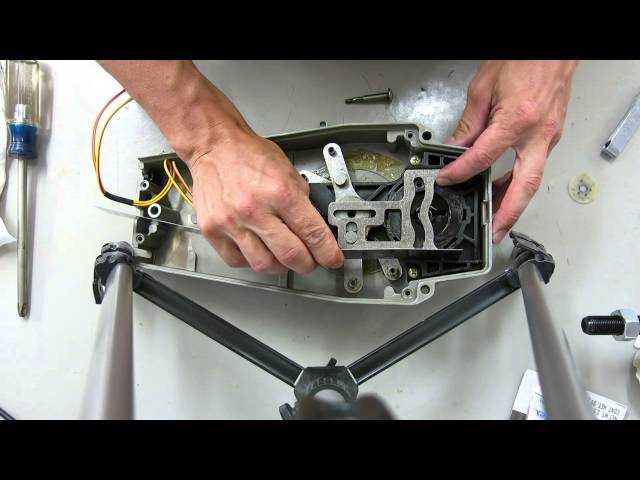

DIY Repairs Using the Diagram

Understanding how to maintain and fix equipment can empower users to take control of their tools and extend their lifespan. By utilizing visual guides, individuals can identify components and learn the intricacies of their machines, making repairs more accessible and less daunting.

Identifying Components

Before embarking on a repair journey, it’s crucial to familiarize oneself with the various elements involved. Visual aids can serve as a roadmap, helping to pinpoint each part’s location and function. This knowledge not only streamlines the repair process but also fosters a deeper understanding of the machinery.

Step-by-Step Guidance

Following a structured approach is essential for effective repairs. Start by consulting the visual reference to locate the problematic section. Next, gather the necessary tools and materials. With careful attention to detail, follow each step methodically to ensure accuracy. Documenting the process can be beneficial, especially for future reference or if further issues arise.

In conclusion, engaging with visual references can significantly enhance the DIY repair experience, making it easier to tackle challenges and maintain equipment efficiently.

Upgrading Your Quicksilver 3000

Enhancing your watercraft can significantly improve its performance and longevity. This process involves selecting high-quality components and accessories that align with your specific needs and preferences. Whether you’re aiming for better speed, efficiency, or comfort, thoughtful upgrades can transform your vessel into a more enjoyable and capable machine.

Consider starting with the engine system, where optimizing power output can make a noticeable difference. Upgrading to a more efficient fuel system or incorporating a performance exhaust can enhance both responsiveness and fuel efficiency. Additionally, examining the electronics can lead to improved navigation and safety features, ensuring a more reliable experience on the water.

Don’t overlook the importance of hull enhancements. Upgrading the materials or adding protective coatings can increase durability and reduce maintenance. Furthermore, incorporating advanced propulsion technologies can boost overall performance, making your rides smoother and faster.

Lastly, prioritize comfort and usability. Upgrading seating, storage solutions, and accessories can create a more enjoyable environment for both you and your passengers. By carefully considering each of these areas, you can create a truly personalized and optimized watercraft that meets all your adventure needs.

Customer Support for Quicksilver Products

Ensuring satisfaction and resolving inquiries is a fundamental aspect of any brand’s commitment to its customers. Effective assistance enhances user experience and fosters loyalty. This section outlines the various avenues available for obtaining help and information regarding your favorite products.

Support Channels

- Email Support: Reach out via email for detailed inquiries. A dedicated team typically responds within 24-48 hours.

- Phone Assistance: Speak directly with a representative to receive immediate help. Customer service numbers are usually listed on the official website.

- Live Chat: Many brands offer real-time chat support on their website, providing quick answers and solutions.

Resources for Users

- Online FAQs: A comprehensive list of frequently asked questions can help users find quick solutions.

- Community Forums: Engage with other users and share experiences in dedicated discussion boards.

- User Manuals: Downloadable guides and manuals provide valuable insights on product use and maintenance.

Accessing support through these various channels ensures that you can fully enjoy your purchases and address any issues that may arise effectively.