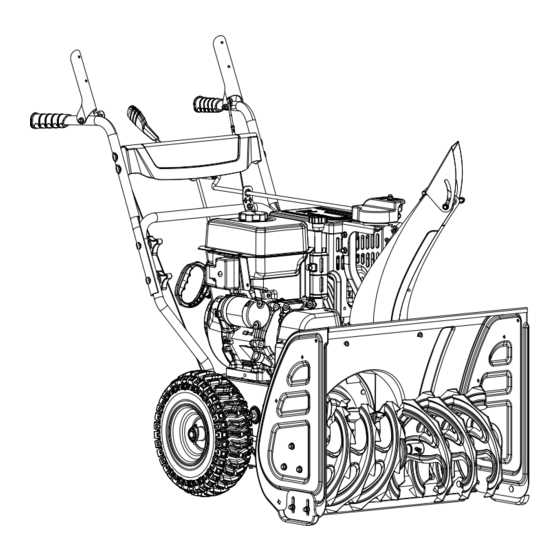

Understanding the Certified Snowblower Parts Diagram for Optimal Maintenance

When it comes to maintaining outdoor machinery, having a clear grasp of its elements is essential. A thorough comprehension of how each segment contributes to the overall functionality can significantly enhance performance and longevity. This guide aims to illuminate the various components of a specific type of winter equipment, enabling users to troubleshoot issues effectively.

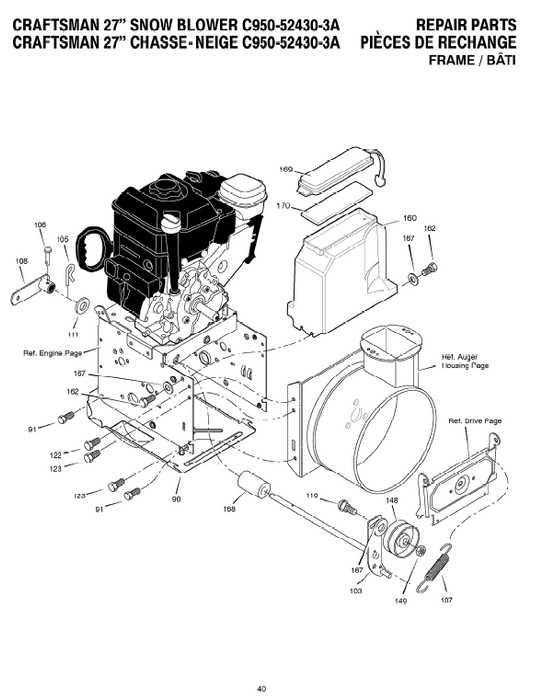

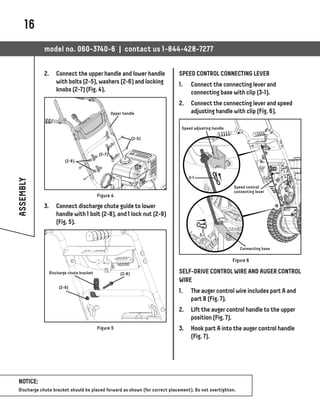

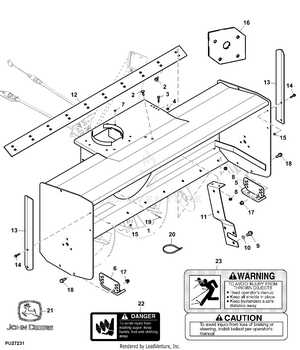

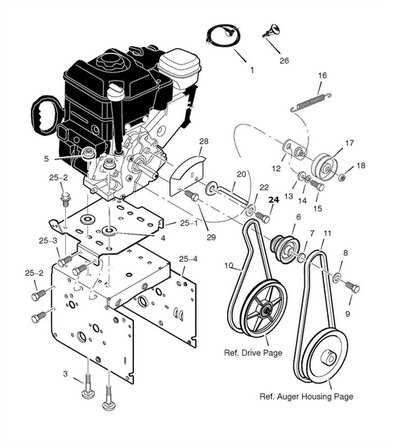

Visual aids can be invaluable in the quest for knowledge. By utilizing clear illustrations, users can easily identify and understand the role of each element, simplifying the maintenance process. This resource serves not just as a reference but as a tool to empower users in their upkeep endeavors.

Moreover, recognizing the intricate relationships between different components can lead to more efficient repairs and replacements. An informed approach can transform daunting tasks into manageable ones, ensuring your machinery remains reliable even in the harshest conditions. Understanding the layout and function of each piece will provide confidence and clarity in your maintenance routine.

Understanding Snowblower Components

When tackling winter challenges, it’s essential to comprehend the various elements that contribute to the efficiency of your machine. Each component plays a crucial role in ensuring optimal performance and reliability during snowy conditions. A solid grasp of these components not only aids in maintenance but also enhances troubleshooting skills.

Main Elements

The primary features of this machinery include mechanisms responsible for movement, power generation, and snow management. Knowing how each part interacts helps in making informed decisions regarding repairs or upgrades.

Functionality Overview

| Component | Function |

|---|---|

| Engine | Drives the entire system and generates power. |

| Auger | Collects and moves snow toward the discharge chute. |

| Chassis | Provides structural support and houses other components. |

| Discharge Chute | Directs snow away from the pathway. |

Importance of Certified Parts

Using high-quality components in machinery is crucial for ensuring optimal performance and longevity. Genuine items, often produced by the original manufacturer, offer a guarantee of reliability that generic alternatives cannot match. Investing in these superior elements not only enhances functionality but also minimizes the risk of breakdowns and costly repairs.

When machinery operates with authentic components, users can expect smoother operation and improved efficiency. These elements are designed specifically for the equipment, ensuring a perfect fit and compatibility. This precision reduces wear and tear, extending the lifespan of the overall system and ultimately saving money in the long run.

Furthermore, utilizing reputable items often comes with warranties and support from manufacturers, providing peace of mind for users. This backing can be invaluable in case of any issues, making it easier to resolve problems quickly and effectively. In an environment where performance and safety are paramount, choosing high-quality components is an essential decision.

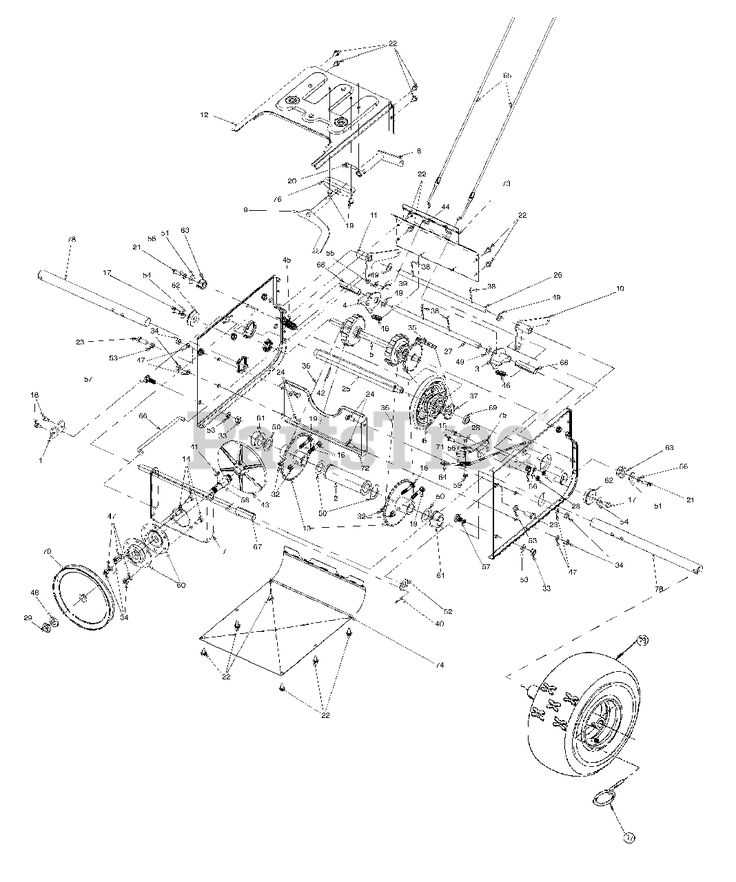

How to Read Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair tasks. These visual representations simplify complex information, allowing users to grasp the relationships and functions of various components. By familiarizing yourself with their layout and symbols, you can enhance your ability to interpret these guides effectively.

Key Elements to Consider

- Legend: Often found at the bottom or side, this section explains the symbols used in the illustration.

- Labels: Each component is typically marked with a label that identifies its function or part number.

- Connections: Pay attention to lines or arrows indicating how different elements interact or connect with each other.

- Scale: Some illustrations may provide a scale to help you understand the relative sizes of the components.

Steps to Effectively Read Illustrations

- Start with the legend to familiarize yourself with the symbols and terminology.

- Identify key components by reading the labels and noting their positions.

- Trace the connections between parts to understand how they work together.

- Refer back to the legend if any symbols are unclear as you analyze the illustration.

Common Snowblower Issues

During the winter months, many users encounter a range of challenges with their outdoor clearing equipment. Understanding these typical problems can help in maintaining efficiency and ensuring that the machinery operates smoothly when needed most. Here are some of the frequent issues that may arise.

Frequent Mechanical Problems

Mechanical difficulties often stem from wear and tear or improper maintenance. Identifying these issues early can prevent further complications and costly repairs.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Fuel issues, battery failure, or spark plug problems | Check fuel levels, inspect the battery, and replace the spark plug if necessary |

| Insufficient Clearing Power | Dull blades, clogged intake, or engine problems | Sharpen blades, clear debris, and check engine performance |

| Stalling During Operation | Fuel blockages or overheating | Clean fuel lines and ensure proper ventilation |

Operational Concerns

Aside from mechanical failures, users may experience operational issues that affect performance. Recognizing and addressing these can enhance usability and efficiency.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Vibration Excess | Loose components or uneven surfaces | Tighten bolts and operate on stable ground |

| Snow Sticking | Improper auger speed or wet snow | Adjust speed settings and clear the chute regularly |

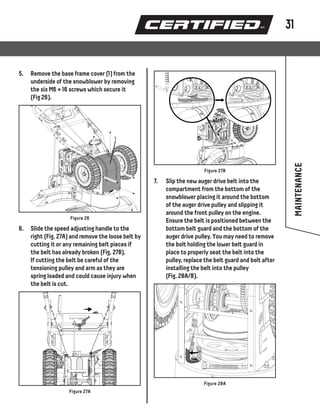

Identifying Replacement Parts

Understanding the components of your equipment is essential for effective maintenance and repair. Knowing how to accurately recognize and source the necessary elements can significantly enhance the longevity and performance of your machine. This process involves familiarizing yourself with the various sections and functions of the assembly.

Visual references play a crucial role in identifying components. Utilizing manuals or online resources can provide clear illustrations that simplify the recognition process. These tools often highlight key features and specifications, enabling users to make informed decisions when seeking substitutes.

Another important aspect is compatibility. Ensure that the replacements align with the specific model and year of your equipment. Cross-referencing with original documentation or trusted retailers can help avoid mismatches that may lead to further complications.

Finally, consulting with experts can provide invaluable insights. Whether through forums, local dealers, or repair shops, engaging with knowledgeable individuals can clarify uncertainties and enhance your understanding of what is needed for optimal functionality.

Maintaining Your Snowblower

Proper upkeep of your winter equipment is essential to ensure optimal performance and longevity. Regular attention to key components can prevent breakdowns during critical times and enhance efficiency.

Routine checks should include examining belts, blades, and fuel systems. Keeping these elements in top condition minimizes wear and tear, ultimately improving functionality.

Lubrication is also crucial. Applying the right oils to moving parts reduces friction and extends the lifespan of your machine. Make it a habit to refer to your manual for specific maintenance guidelines tailored to your model.

Additionally, cleaning after each use helps prevent the buildup of snow and ice, which can affect performance. A well-maintained unit not only operates better but also provides peace of mind during harsh conditions.

Safety Considerations for Repairs

When undertaking maintenance on outdoor equipment, ensuring safety is paramount. Proper precautions not only protect the individual performing the task but also help to prevent potential hazards that could arise from improper handling of tools and machinery.

First and foremost, always disconnect the power source before starting any repair work. This simple step can significantly reduce the risk of accidental activation, which can lead to serious injuries. Additionally, wearing appropriate personal protective equipment, such as gloves and safety goggles, is essential to safeguard against cuts, flying debris, and other unforeseen dangers.

Furthermore, keeping the workspace tidy is crucial. A clean area minimizes the chances of tripping over tools or components, allowing for a smoother and safer repair process. It’s also advisable to work in a well-lit environment, ensuring that all parts are visible and reducing the likelihood of mistakes.

Lastly, consulting the manufacturer’s guidelines can provide valuable insights into safe repair practices. Understanding the specific requirements for the equipment in question can help in avoiding common pitfalls and ensuring that repairs are conducted efficiently and safely.

Where to Buy Certified Parts

Finding high-quality components for your machinery is essential for optimal performance. Whether you are seeking replacements or upgrades, choosing reputable sources ensures durability and compatibility. Here are some reliable options to consider when searching for the best options in your area.

Local Retailers

Your nearest hardware or specialized stores often stock a variety of essential components. Visiting these retailers allows you to see the products firsthand and consult with knowledgeable staff.

Online Suppliers

The internet offers an extensive range of choices. Various websites specialize in selling quality components, often providing detailed descriptions and user reviews.

| Source | Advantages |

|---|---|

| Local Stores | Immediate access, personal assistance |

| Online Marketplaces | Wider selection, competitive pricing |

| Manufacturer’s Website | Guaranteed compatibility, direct purchase |

DIY vs. Professional Repairs

When it comes to fixing equipment, individuals often face a choice between tackling the task themselves or hiring an expert. Each approach has its own set of advantages and challenges, which can greatly influence the outcome of the repair process.

DIY repairs can be a rewarding experience, offering a sense of accomplishment and the opportunity to save money. Many enthusiasts enjoy the hands-on aspect of maintenance and may already possess the necessary tools and skills. Furthermore, tackling repairs independently allows for greater flexibility in scheduling and working at one’s own pace.

On the other hand, professional assistance brings a level of expertise that can be invaluable. Skilled technicians have the training and experience to diagnose issues quickly and efficiently. They often have access to specialized tools and replacement components that might not be readily available to the average individual. Additionally, relying on professionals can provide peace of mind, knowing that the job will be done correctly and safely.

Ultimately, the decision between DIY and professional repairs depends on various factors, including the complexity of the issue, the individual’s confidence and skill level, and the potential costs involved. Careful consideration of these elements will help determine the best course of action for any repair task.

Winter Preparation Tips

As the cold season approaches, it’s essential to ensure that your equipment and home are ready to tackle the challenges that winter brings. Proper planning and maintenance can make a significant difference in how smoothly you navigate through the icy months ahead.

1. Inspect Your Equipment: Before the first snowfall, take the time to thoroughly check all your winter gear. This includes reviewing machinery, ensuring that everything is functioning correctly, and addressing any issues that may arise.

2. Stock Up on Supplies: Having the right materials on hand is crucial. Make sure you have a sufficient supply of essential items like ice melt, shovels, and any other necessary tools to clear paths and driveways.

3. Prepare Your Vehicle: Winter-proofing your vehicle is equally important. Ensure your tires are suitable for icy conditions, and check your antifreeze levels. Keeping an emergency kit in your car can also be a lifesaver.

4. Winterize Your Home: Protecting your living space from the harsh weather is vital. Insulate windows and doors to prevent drafts, and check your heating system to ensure it operates efficiently throughout the season.

5. Create a Safety Plan: In case of severe weather, having a contingency plan is wise. Stay informed about local forecasts and be prepared for possible power outages by having essentials like flashlights and non-perishable food on hand.

By taking these proactive measures, you can enjoy a safer and more comfortable winter, ready to face whatever challenges may come your way.

Choosing the Right Model

Selecting the appropriate machine for clearing snow is crucial for ensuring efficiency and ease of use during winter months. With various models available, it’s important to understand key features that suit your specific needs and conditions. This guide aims to simplify the decision-making process by highlighting essential factors to consider.

Understanding Your Needs

Begin by assessing the size of the area you need to clear. For smaller driveways or walkways, a compact device may suffice, while larger spaces might require a more robust option. Consider the typical snowfall in your region; heavier accumulations may necessitate a model with greater power and capacity.

Evaluating Features

Once you have a clear understanding of your requirements, evaluate the available features. Look for engine power, clearing width, and weight to ensure optimal performance. Additionally, consider options such as electric versus gas-powered machines, as well as features like adjustable speed and throwing distance, which can enhance usability.

Ultimately, choosing the right model involves aligning your specific needs with the capabilities of the available machines. By taking the time to evaluate these factors, you can make an informed decision that will serve you well throughout the winter season.

Innovations in Snowblower Technology

Recent advancements in cold-weather equipment have revolutionized how we manage heavy snowfall. The introduction of new features and enhancements aims to improve efficiency, ease of use, and environmental sustainability, ensuring that users can tackle winter challenges with minimal effort.

One notable development is the integration of electric power systems. These units provide a quieter and more eco-friendly alternative to traditional gasoline engines, reducing both emissions and noise pollution. Battery technology has advanced significantly, allowing for longer operational times and faster charging capabilities, making them suitable for residential use.

Furthermore, smart technology has made its way into modern machines. Users can now control their equipment via mobile applications, enabling remote operation and real-time monitoring of performance metrics. This connectivity allows for optimal management of tasks, leading to increased productivity and convenience.

Another exciting innovation is the enhancement of auger designs. New materials and shapes have improved the ability to break through compacted snow and ice, making the process more efficient and less physically demanding. These improvements ensure that even the most challenging conditions can be managed with ease.

Finally, advancements in ergonomic design have led to more user-friendly models. Features such as adjustable handles, improved grips, and intuitive controls enhance comfort during operation, reducing fatigue and strain. As winter maintenance continues to evolve, these innovations promise a more accessible and effective approach to dealing with snowfall.

FAQs About Snowblower Maintenance

Proper upkeep of your winter machinery is essential to ensure optimal performance and longevity. Understanding common queries related to maintenance can help users avoid pitfalls and keep their equipment in excellent condition throughout the cold months.

Common Questions

| Question | Answer |

|---|---|

| How often should I change the oil? | It is recommended to change the oil at least once per season or after every 25 hours of use to maintain engine efficiency. |

| What fuel should I use? | Using fresh, high-quality gasoline with an octane rating of 87 or higher is advisable, along with fuel stabilizer for long-term storage. |

| How do I check the spark plug? | Remove the spark plug and inspect it for wear or damage. Clean or replace it if necessary to ensure proper ignition. |

| Should I store it with fuel in the tank? | It’s best to drain the tank or add a fuel stabilizer if storing with fuel, to prevent varnish buildup and ensure easy starts next season. |

Maintenance Tips

Regularly inspecting and maintaining your equipment will not only extend its life but also enhance its performance during harsh weather conditions. Taking the time to understand your machine and its requirements can save you both time and money in the long run.