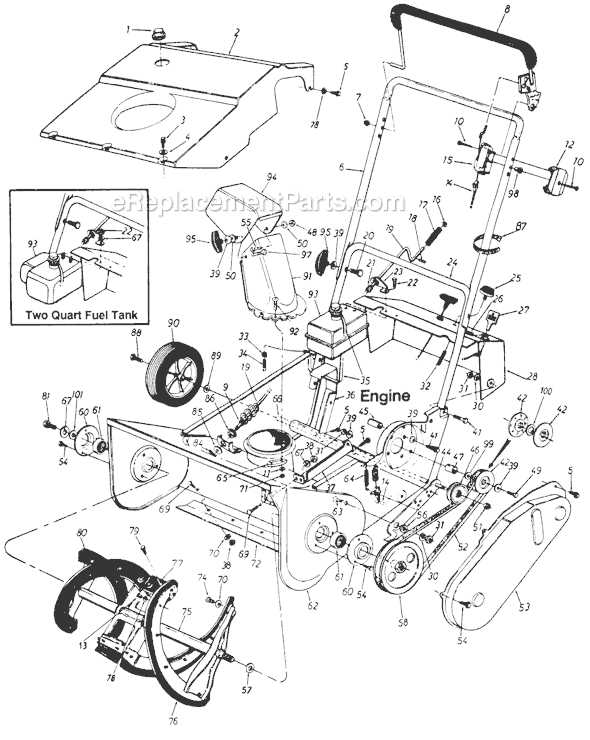

Honda 928 Snowblower Parts Overview

Winter machinery plays a crucial role in maintaining smooth operations during harsh conditions. To ensure its efficient functionality, it’s important to become familiar with the internal mechanisms and external features that keep it running smoothly. Each element is designed to perform a specific role, working together to handle various seasonal challenges.

When diving into the detailed layout of such equipment, one finds a network of interconnected elements, each contributing to its reliable performance. Whether it’s a motorized drive or the clearing mechanism, every component serves a vital purpose, ensuring that the device operates effectively in even the toughest environments. Understanding how these parts align and interact can greatly assist in maintenance and troubleshooting.

Honda 928 Snowblower Parts Overview

Understanding the components of a powerful outdoor machine can significantly improve its maintenance and operation. Each element plays a role in ensuring optimal performance and durability, making it crucial to recognize their functions and placement. This section explores the different mechanical elements that work together to tackle heavy snowfall.

Key Mechanical Components

- Engine System: A robust motor ensures reliable power, delivering consistent performance in varying conditions.

- Transmission Assembly: This part is responsible for transferring energy from the motor, providing controlled movement and maneuverability.

- Auger Assembly: Designed to break through icy buildup, this rotating part aids in efficient snow clearance.

Additional Essential Elements

- Drive Mechanism: It allows smooth navigation across challenging surfaces, contributing to a steady pace during operation.

- Control Levers: These enable

Key Components and Their Functions

Understanding the essential elements and their roles is crucial for ensuring efficient operation and maintenance of the equipment. This section highlights the main parts, describing their purpose and how they contribute to overall performance.

Primary Mechanical Elements

The machinery relies on several fundamental mechanical components that work together to deliver power and manage movement. These include the driving system, which transmits energy to the rotating mechanisms, and the housing unit, which encloses and protects inner parts from external conditions.

Control and Adjustment Mechanisms

Adjustment features play a vital role in adapting the equipment to different conditions. These include adjustable levers, control cables, and guiding handles that allow smooth manipulation of various settings, enabling users to tailor the functionality to specific needs.

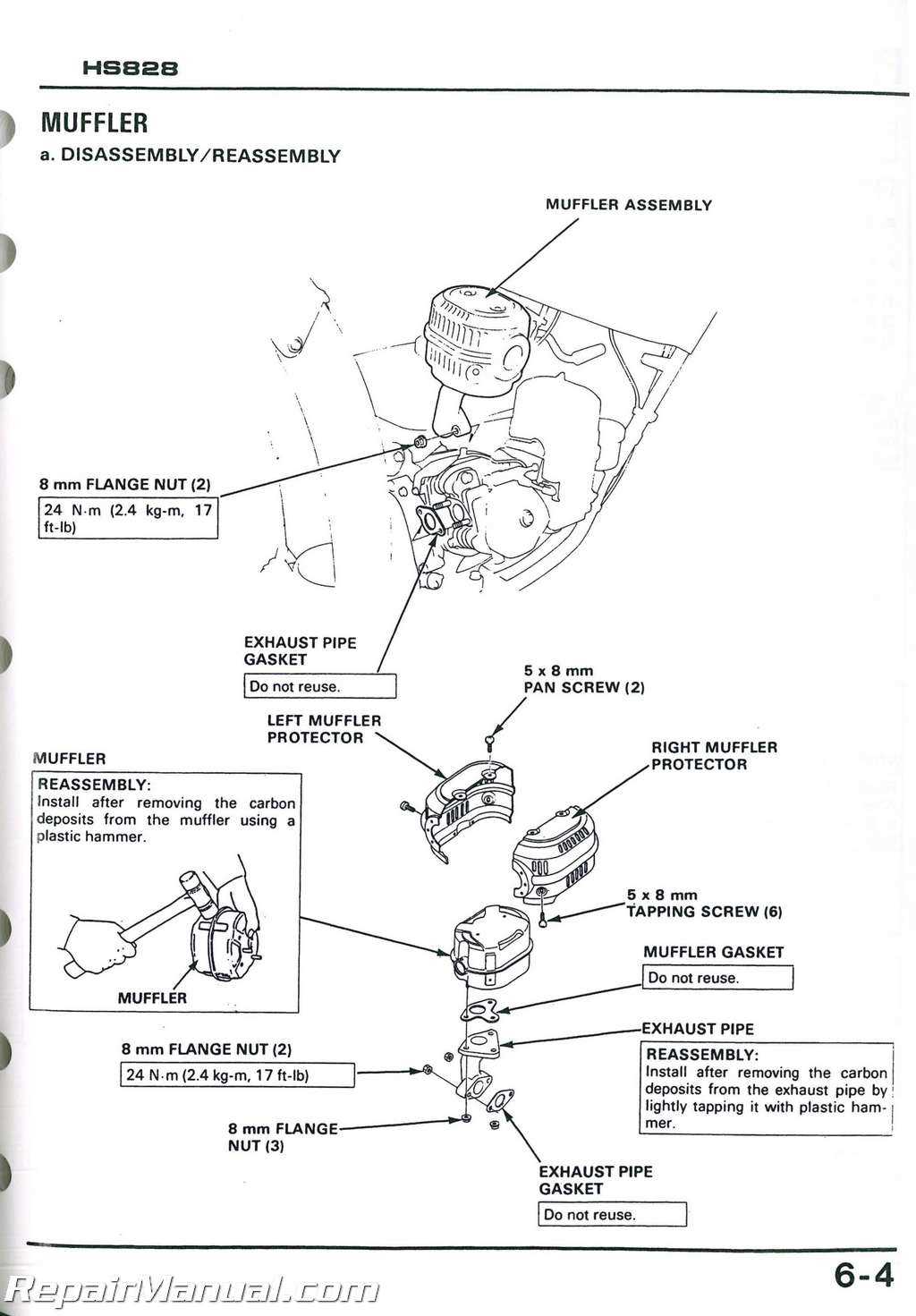

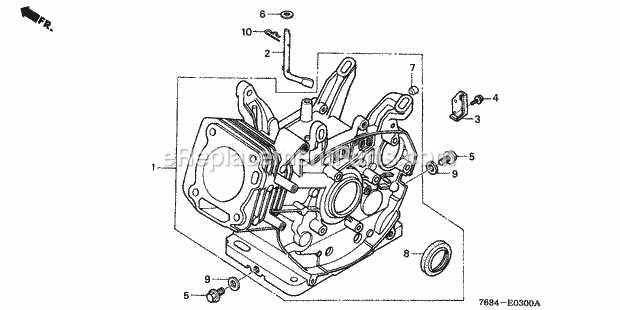

Component Function Driving System Understanding the Engine Structure The internal design of power units is crucial for achieving smooth performance and longevity. A clear understanding of how various components interact allows for better handling and maintenance of mechanical systems. By examining the fundamental aspects of the motor’s framework, one can gain insight into its functioning and upkeep needs.

Key Components Overview

The primary structure includes elements responsible for ignition, fuel delivery, and airflow. These components work together to ensure the smooth conversion of fuel into mechanical energy. Spark plugs and carburetors play a central role in starting the combustion process, while other parts regulate airflow to maintain balance.

Maintenance and Care Tips

Regular upkeep of these elements is essential for sustaining their efficiency. Keeping the airflow channels clean and ensuring proper fuel flow can prevent issues that disrupt operation. Additionally, inspecting the core components periodically helps in identifying any wear and tear early on, ensuring a longer lifespan for the engine.

Blower Assembly and Operation

The assembly of this outdoor equipment’s propulsion system involves various interconnected components designed to efficiently move material. The arrangement of these elements ensures smooth functionality, allowing the mechanism to clear surfaces with precision. Understanding the structure is key to maintaining optimal performance over time.

Key Components and Their Roles

Each part plays a vital role in the overall operation. The system is equipped with blades that rotate at high speeds, ensuring effective movement of debris. A durable enclosure keeps these elements secure, guiding the flow towards the desired direction. Proper alignment during installation guarantees the system operates without interruptions.

Operational Process and Efficiency

The functioning process relies on a balance between power and precision. When activated, the mechanism swiftly gathers material, channeling it through a directional chute. The adjustable settings provide control over the flow, adapting to different conditions. Regular inspection of these settings ensures consistent and reliable output.

Maintenance Tips for Longevity

To ensure a long lifespan, it is crucial to keep the assembly clean and free from obstructions. Lubricating moving parts and checking for any signs of wear will help maintain efficiency. Periodic tightening

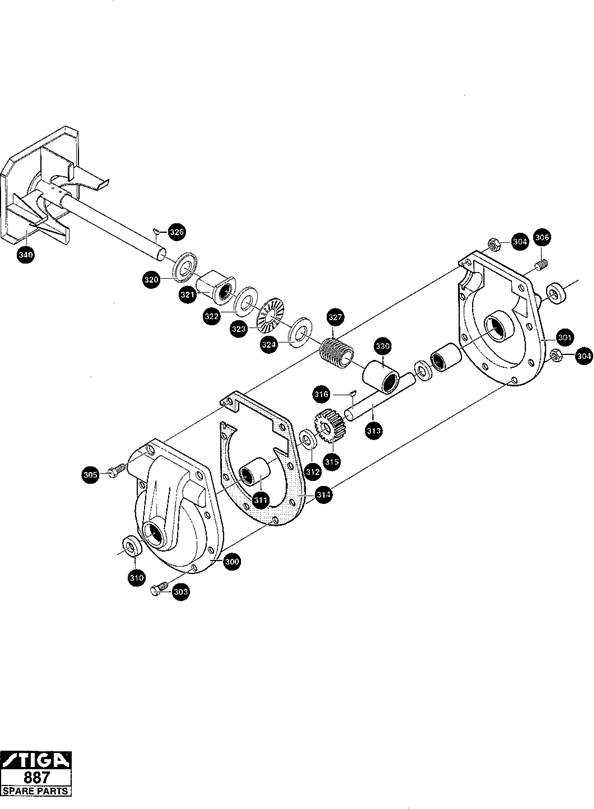

Transmission System Breakdown

The core of the propulsion mechanism relies on a network of interconnected elements that efficiently transfer force to the wheels. This system is designed to regulate speed and torque, providing smooth transitions under varying conditions. Its configuration ensures stability and precision during operation, allowing the machine to adapt to different terrains with ease.

Component Function Drive Belt Transfers motion from the engine to the axle, enabling forward and reverse movement. Axle Assembly Holds the wheels in place and rotates them based on input from the drive mechanism. Friction Disc Adjusts speed by varying the contact point between the disc and the rotating shaft. Shift Lever Allows the operator to select the desired speed and direction of movement. Gearbox M Auger and Impeller Design

The design of the auger and impeller plays a crucial role in ensuring efficient clearing of dense materials. These components work in harmony to break up and channel the accumulated matter, guiding it smoothly through the mechanism for further expulsion. A well-balanced structure helps maintain consistent operation, even in challenging conditions.

Efficient Material Movement

The auger is responsible for the initial collection, rotating to gather and direct the material toward the center. Its shape and orientation greatly impact how effectively it handles various consistencies. Meanwhile, the impeller rapidly propels the gathered material, ensuring it is discharged through the exit path with minimal blockages.

Durability and Design Considerations

Material choice and structural strength are key factors in the longevity of the auger and impeller. Durable materials resist wear and deformation, maintaining performance over time. Thoughtful design helps

Handlebar and Control Mechanism

The control system of this equipment is centered around a user-friendly handlebar that offers easy maneuvering. Designed for comfort, it allows smooth navigation and management of various functions, making the operation more intuitive and less demanding. The ergonomic design ensures a secure grip, even during prolonged use, enhancing the overall experience.

Adjustability and Comfort

The handlebar can be adjusted to suit different heights, providing flexibility for various users. This feature ensures that the operator maintains a natural posture, reducing strain on the arms and back. The adjustable nature of the handlebar makes it suitable for various tasks, allowing for a personalized setup.

Integrated Control Levers

Integrated into the handlebar are control levers that simplify access to essential functions. These levers are strategically positioned for quick ad

Fuel System and Maintenance Tips

Ensuring optimal performance of your snow-clearing equipment involves regular attention to the fuel system. This section covers essential practices and advice to keep the fuel components in excellent condition, enhancing the overall efficiency and longevity of your machine.

Proper maintenance of the fuel system is crucial for reliable operation. Here are some key practices to follow:

- Regular Fuel Checks: Inspect the fuel levels frequently to avoid running low during operation.

- Quality Fuel: Use high-quality fuel to prevent sediment buildup and engine issues.

- Filter Maintenance: Clean or replace fuel filters as recommended to ensure a smooth flow of fuel.

- Inspect Fuel Lines: Regularly check for any cracks or leaks in fuel lines, which could lead to performance problems.

In addition to these maintenance practices, consider the following tips to maximize your equipment’s efficiency:

- Seasonal Fuel Management: At the end of the season, either use up the remaining fuel or store it properly to avoid deterioration.

- Stabilizers: Add fuel stabilizers to prevent degradation and maintain fuel quality during long periods of storage.

- Clean Components: Periodically clean the fuel tank and lines to remove any accumulated debris or contaminants.

By following these guidelines, you can ensure that the fuel system remains in top shape, contributing to the effective operation of your snow-clearing machinery.

Drive Belt Replacement Guide

Replacing the drive belt is essential for maintaining optimal performance in your equipment. This component ensures efficient power transfer from the engine to the working parts, allowing for smooth operation. Over time, wear and tear can lead to decreased efficiency, making it necessary to replace the belt periodically.

Follow these steps to successfully replace the drive belt:

- Safety Precautions:

- Ensure the equipment is turned off and disconnected from the power source.

- Wear appropriate protective gear, including gloves and safety glasses.

- Accessing the Drive Belt:

- Remove any covers or panels obstructing access to the belt.

- Take note of the belt routing for correct installation.

- Removing the Old Belt:

- Loosen any tensioning mechanisms to relieve pressure on the belt.

- Carefully slide the old belt off the pulleys.

- Installing the New Belt:

- Position the new belt according to the noted routing.

- Ensure it is properly seated on all pulleys.

- Reapply tension using the appropriate mechanisms.

- Final Checks:

- Replace any covers or panels removed during the process.

- Test the equipment to ensure smooth operation.

Regular maintenance, including belt replacement, helps prolong the life of your equipment and enhances its efficiency. Always refer to the manufacturer’s guidelines for specific recommendations and procedures.

Chute Assembly and Adjustment

This section outlines the essential components and proper adjustment techniques for the discharge mechanism of the equipment. Understanding these elements is crucial for optimal performance and efficiency during operation.

Components of the Discharge Mechanism

The main parts of the discharge system include:

- Chute: The channel that directs the snow away from the machine.

- Deflector: An adjustable piece that controls the height and distance of the snow throw.

- Mounting Bracket: The support structure that secures the chute in place.

- Adjustment Levers: Mechanisms used to change the chute’s position easily.

Adjustment Procedure

To ensure effective operation, follow these steps for adjusting the discharge mechanism:

- Start the equipment and observe the discharge angle.

- Locate the adjustment lever and move it to change the direction of the chute.

- Test the throw by adjusting the deflector to achieve the desired height.

- Make fine adjustments as necessary while the equipment is running to ensure optimal performance.

Regular checks and adjustments of the discharge system are vital for maintaining efficiency and preventing clogs during use.

Common Issues with Moving Parts

In any machinery, the components responsible for movement can encounter various challenges that may hinder their efficiency. Understanding these common issues can aid in maintaining optimal performance and extending the lifespan of the equipment.

One prevalent problem is the accumulation of debris, which can obstruct the movement of mechanical parts. This can lead to increased friction, causing components to wear down more quickly. Regular cleaning and maintenance can help prevent this issue.

Another concern is the improper lubrication of moving elements. Insufficient lubrication can result in overheating and eventual failure of critical parts. It is essential to regularly check and apply appropriate lubricants to ensure smooth operation.

Additionally, misalignment of components may cause uneven wear and operational inefficiencies. Ensuring that all parts are correctly aligned is crucial for the proper functioning of the machinery.

Lastly, wear and tear over time is inevitable, and it is important to monitor the condition of moving parts regularly. Replacing worn components promptly can prevent more significant problems from arising and ensure the longevity of the equipment.

Wheels, Tracks, and Traction

Effective mobility in outdoor equipment is crucial for optimal performance in various terrains. The design and functionality of wheels, tracks, and traction systems play a significant role in ensuring stability and control during operation. Understanding these components can enhance the user experience and efficiency of the machine.

Types of Mobility Systems

Different mobility systems are utilized in outdoor machinery, each with its unique advantages:

- Wheeled Systems: Ideal for flat surfaces, providing speed and maneuverability.

- Tracked Systems: Offer superior grip on slippery or uneven ground, reducing the risk of getting stuck.

- Combination Systems: Merge the benefits of both wheels and tracks, allowing versatility across various conditions.

Improving Traction

Enhancing traction is vital for effective operation, especially in challenging environments. Here are some strategies:

- Regularly inspect and maintain the mobility components to ensure optimal functionality.

- Utilize tires or tracks designed for specific weather conditions to improve grip.

- Consider adding weight to the machine to enhance stability and traction on slippery surfaces.

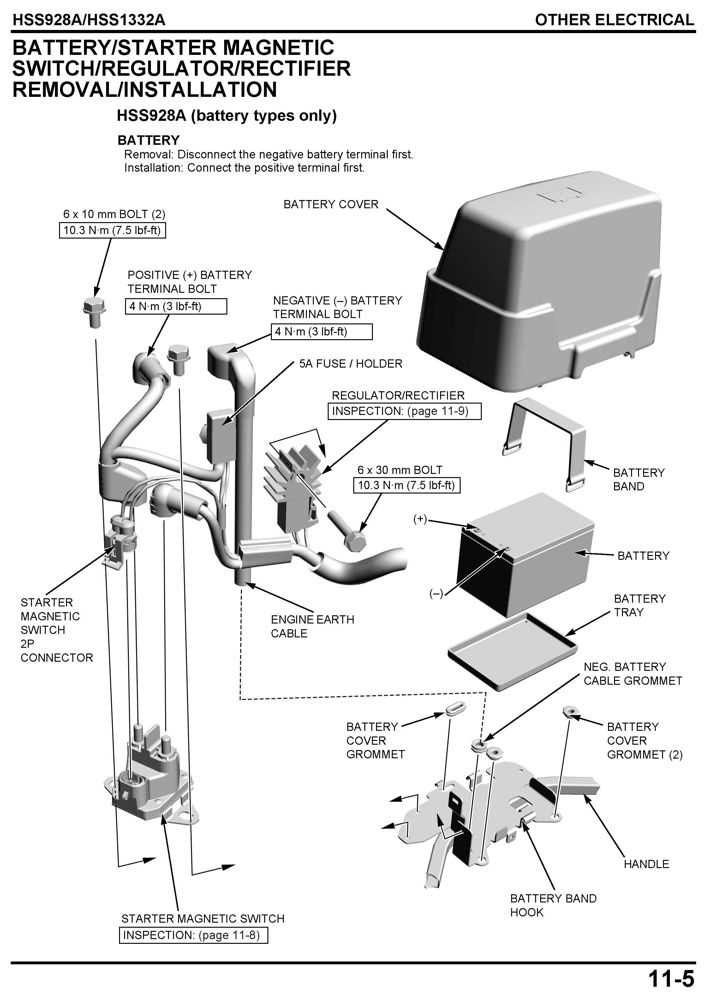

Troubleshooting Electrical Components

Addressing issues related to electrical components is crucial for maintaining optimal performance. Identifying the source of malfunction can often resolve operational difficulties and enhance efficiency. Understanding common problems and their solutions will empower users to tackle challenges effectively.

Start by inspecting the connections and wiring for signs of wear or damage. Frayed wires or loose connections can lead to intermittent functionality. Ensure that all connectors are secure and free from corrosion. If issues persist, test the fuses for continuity. A blown fuse may indicate an underlying electrical problem that requires further investigation.

Next, examine the switches and controls. Faulty switches can prevent the device from starting or responding as expected. Use a multimeter to check the continuity of each switch, replacing any that do not function properly. Additionally, evaluate the control panel for any indicators or lights that may signal errors in the system.

Finally, assess the motor and battery. A weak or dead battery can lead to insufficient power supply, hindering the overall functionality. Ensure the battery is charged and in good condition. If the motor is unresponsive, inspect it for obstructions or mechanical failures that may impede its operation. Regular maintenance and prompt troubleshooting of electrical components will ensure reliable performance.