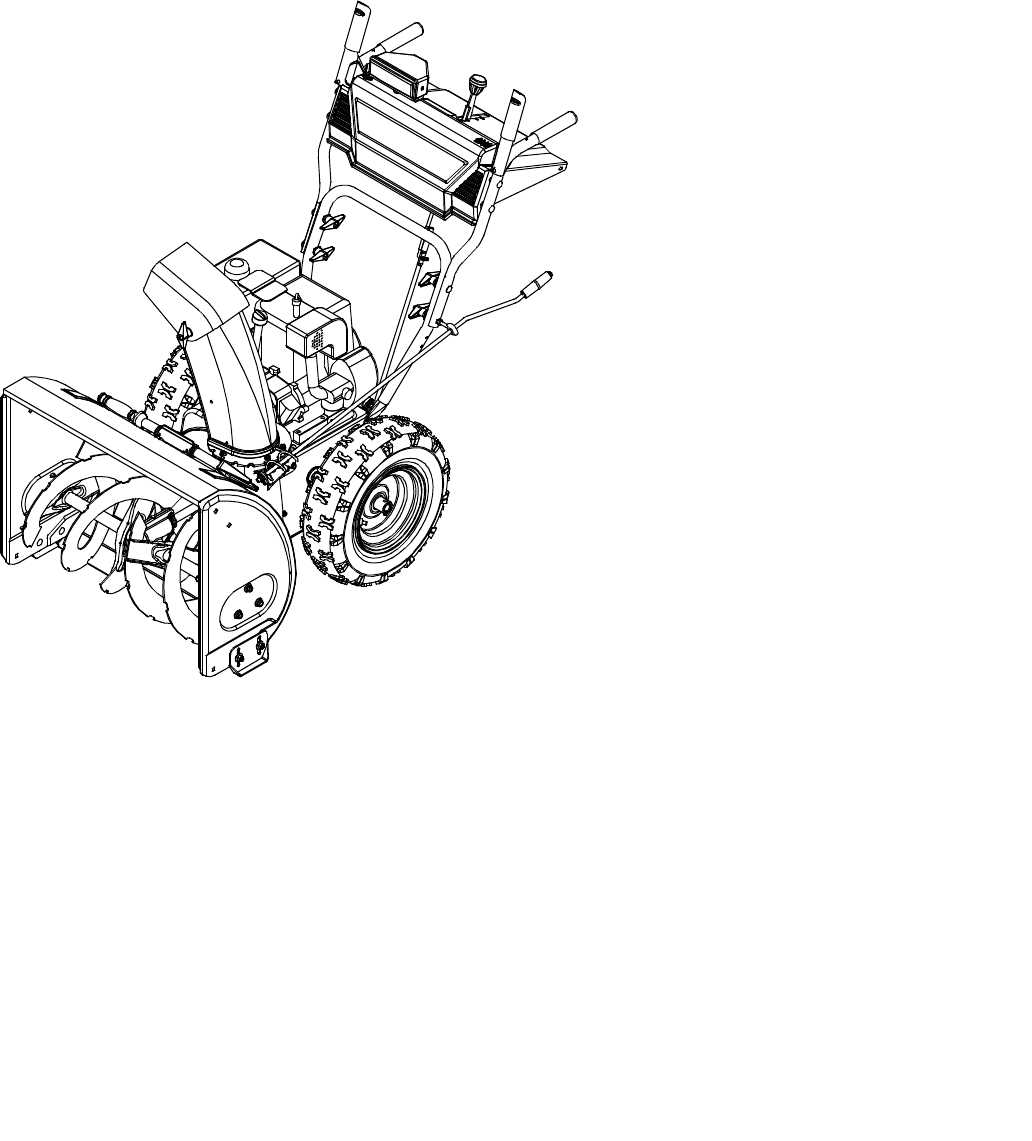

Understanding the Husqvarna Snowblower Parts Diagram

As the chilly months approach, ensuring your winter machinery operates smoothly becomes essential. Familiarizing yourself with its components can significantly enhance performance and longevity. By exploring the various elements that contribute to efficient operation, users can effectively maintain and troubleshoot their equipment.

Each piece of machinery consists of intricate parts, each playing a vital role in its functionality. Grasping how these components work together not only aids in repair but also empowers users to make informed decisions when purchasing replacements. An in-depth look at these sections reveals how they interact to deliver ultimate performance.

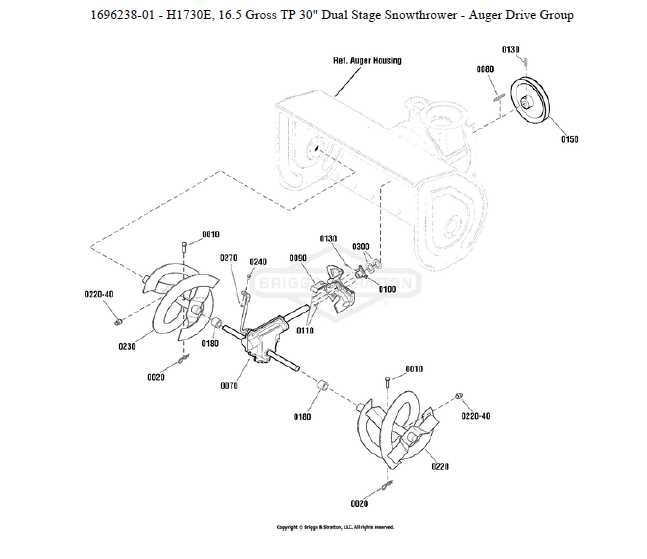

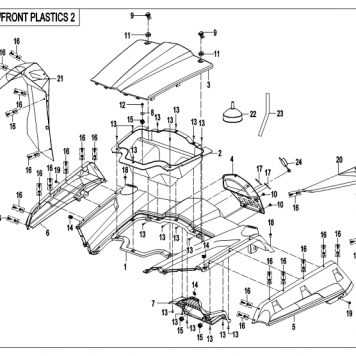

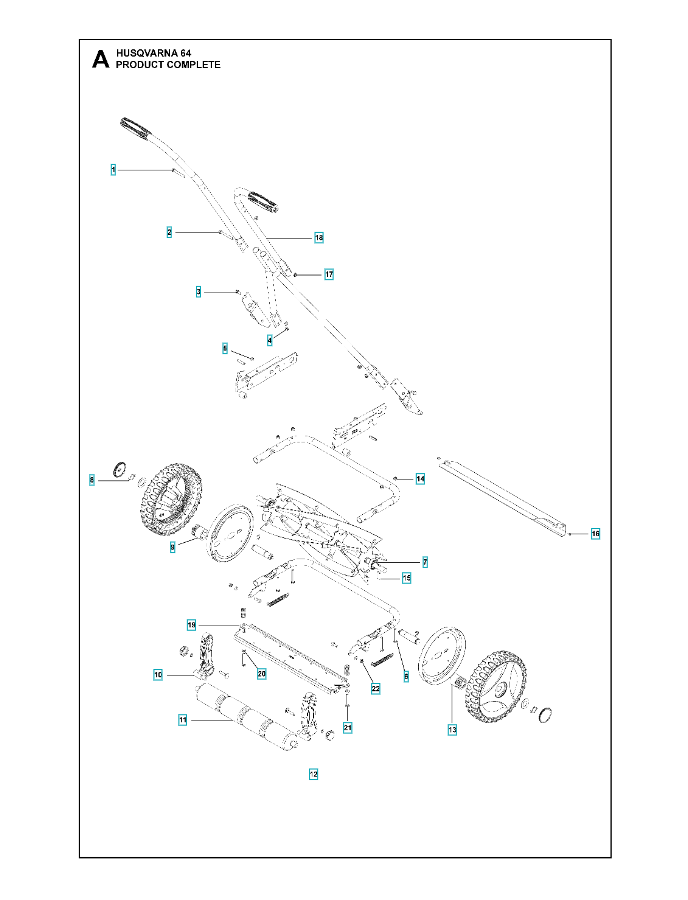

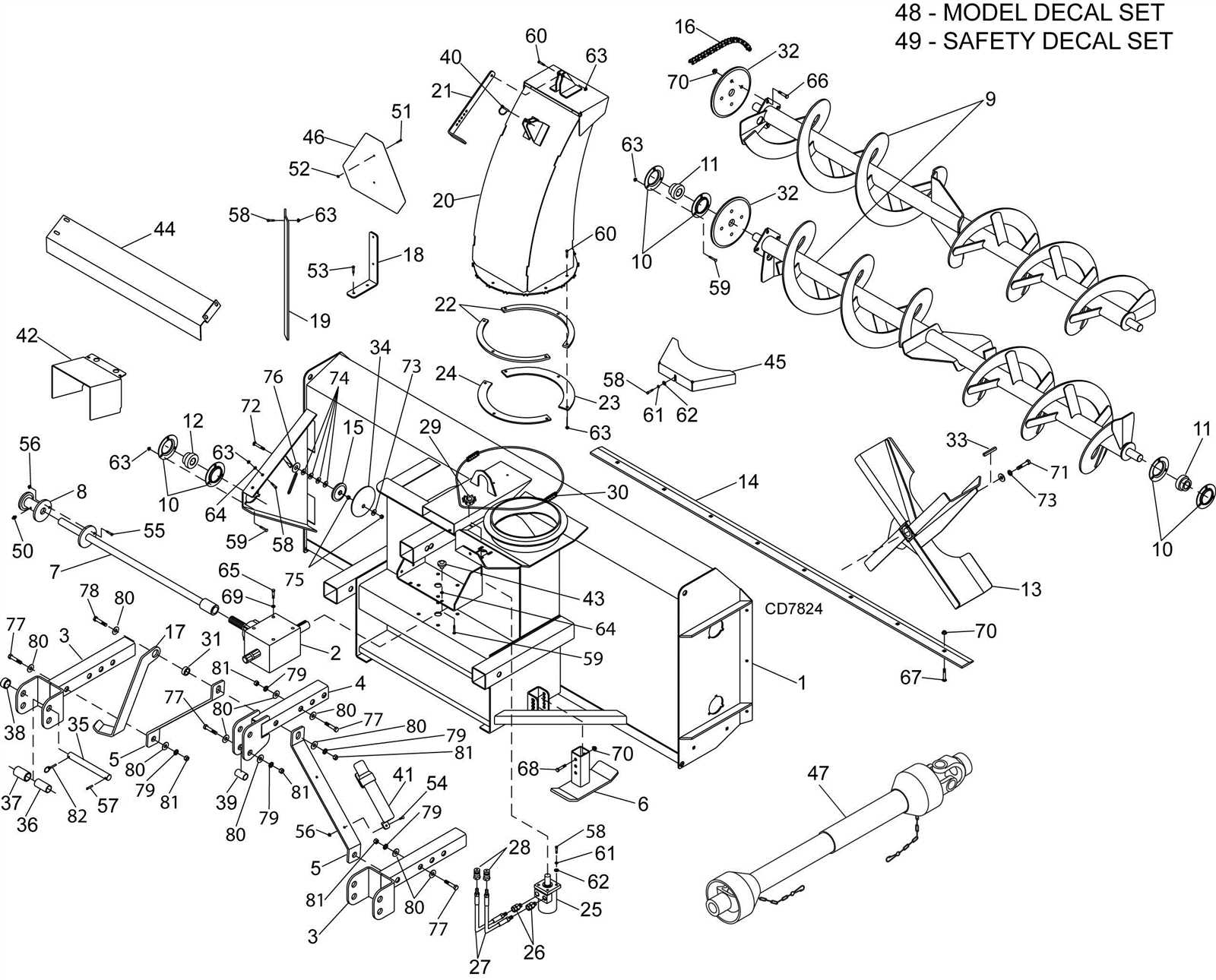

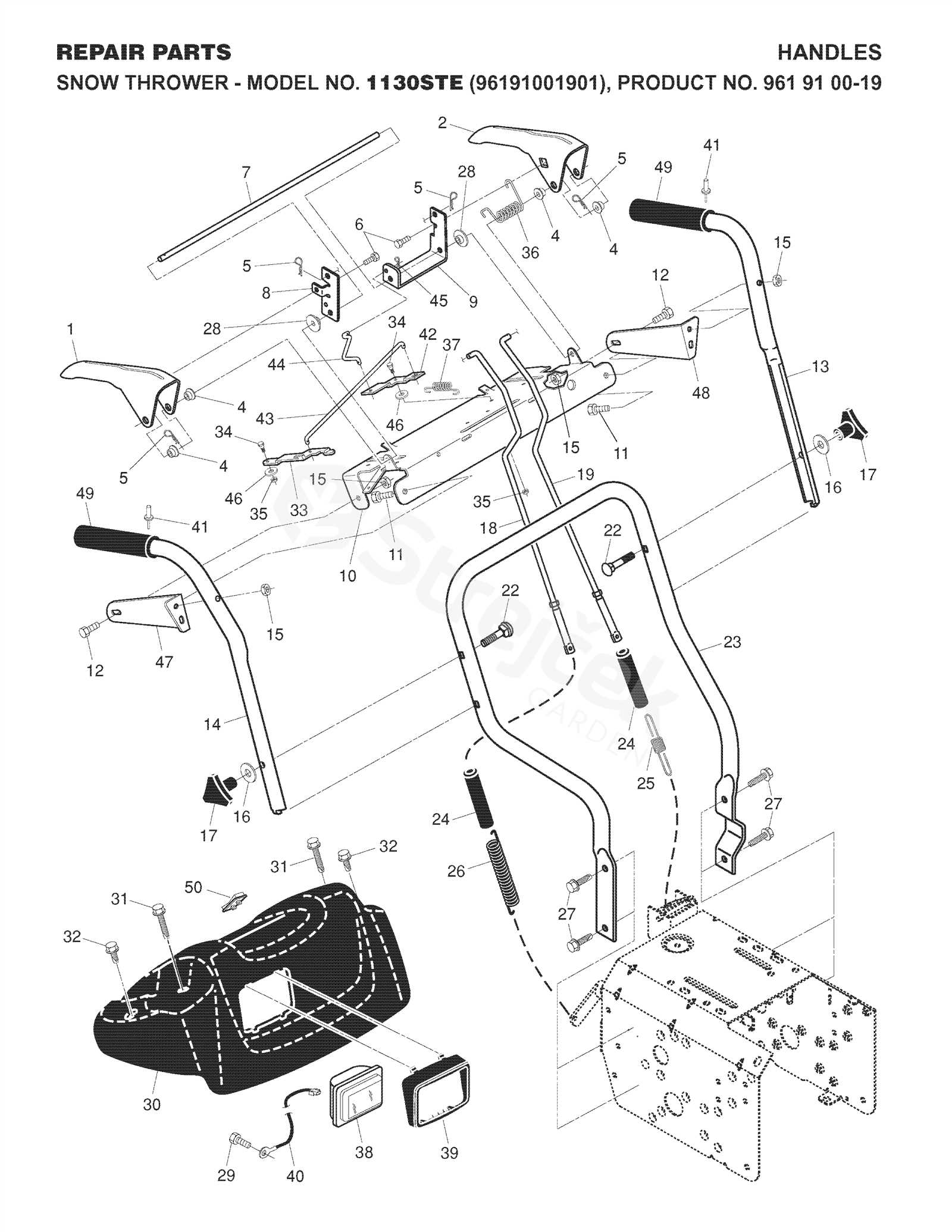

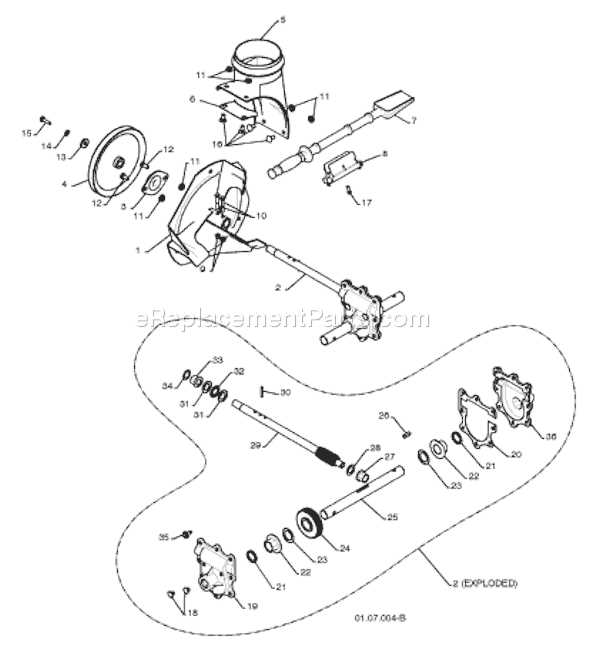

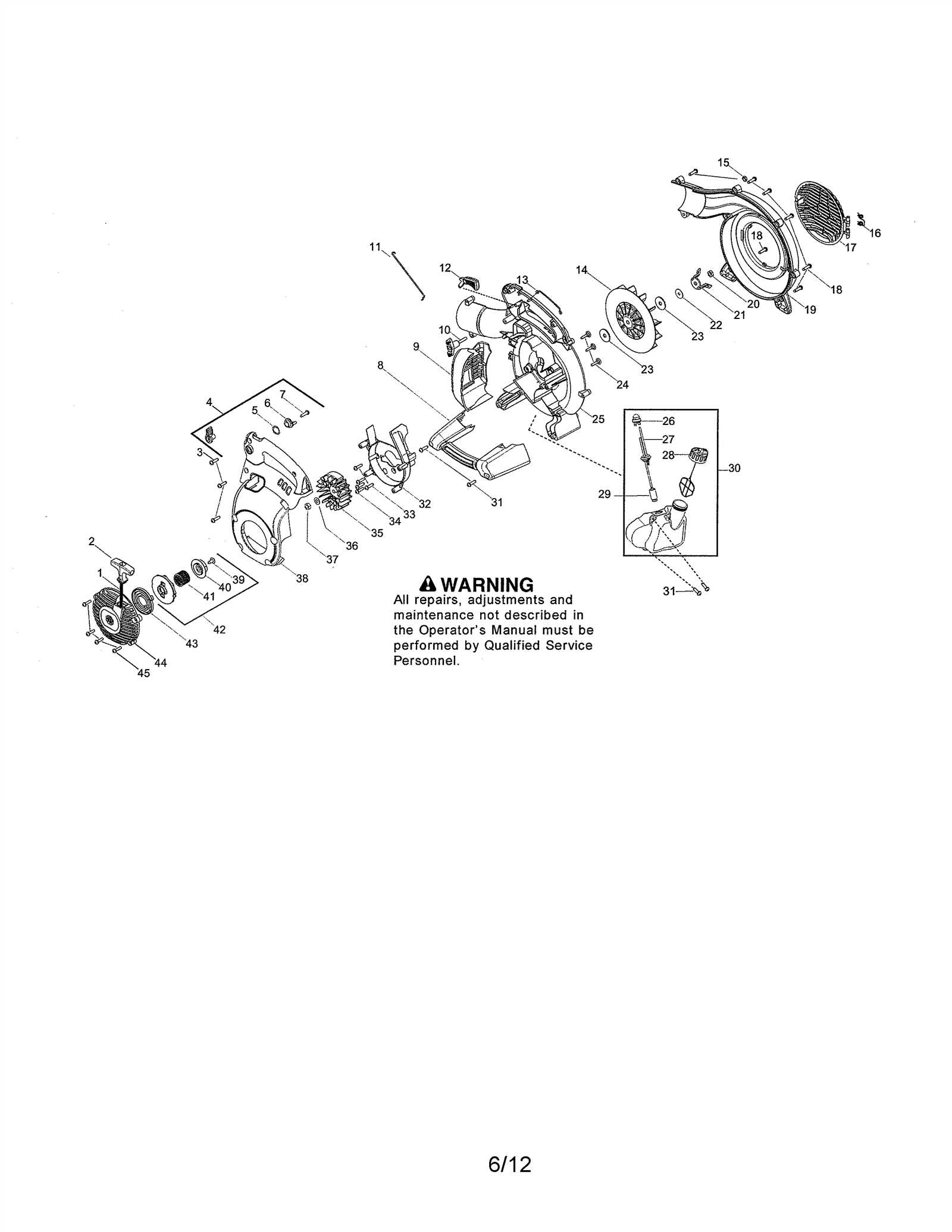

For those seeking to optimize their winter tools, visual aids and schematics can be invaluable. They provide clarity on the assembly and positioning of each element, enabling enthusiasts and professionals alike to delve deeper into the mechanics. This understanding lays the groundwork for effective maintenance and enhances the overall experience during the snowy season.

Understanding Husqvarna Snowblower Components

This section aims to explore the essential elements that contribute to the efficient operation of winter machinery. By examining these components, users can enhance their knowledge and maintenance practices, ensuring optimal performance in cold conditions.

Key Elements of the Machine

Each machine is composed of various parts that work in harmony. Familiarity with these components is crucial for troubleshooting and repairs.

| Component | Description |

|---|---|

| Auger | Collects and moves snow towards the discharge chute. |

| Chassis | The main frame that houses all essential parts. |

| Discharge Chute | Directs the expelled snow away from the pathway. |

Maintenance Tips

Regular inspections of each element can prevent breakdowns. Ensure lubrication, check for wear, and replace any damaged components promptly.

Importance of Parts Diagrams

Understanding the layout and components of machinery is essential for effective maintenance and repair. Visual representations serve as invaluable tools for both novices and experienced users, providing clarity in complex assemblies. Recognizing each element’s role ensures that repairs are conducted accurately and efficiently.

Here are several key reasons why these visual guides are crucial:

- Enhanced Clarity: Illustrations break down intricate systems into manageable sections, making it easier to identify individual elements.

- Streamlined Repairs: With clear visuals, locating and replacing faulty components becomes a more straightforward process.

- Time Efficiency: Familiarity with layouts reduces troubleshooting time, allowing for quicker resolutions.

- Improved Safety: Understanding the configuration helps in handling machinery safely, minimizing the risk of accidents during maintenance.

- Accurate Replacements: Knowing the correct specifications and arrangements prevents the use of incompatible or incorrect components.

Ultimately, these visual aids play a significant role in ensuring optimal performance and longevity of equipment, fostering a deeper understanding of its inner workings.

Common Parts in Snowblowers

Understanding the essential components of winter machines can enhance maintenance and performance. These elements work together to ensure efficient operation in challenging conditions.

- Engine: Powers the entire mechanism and is crucial for functionality.

- Auger: Responsible for gathering and moving the frozen precipitation.

- Impeller: Expels the gathered snow away from the unit.

- Chassis: The framework that supports and houses various components.

- Skid Shoes: Help maintain optimal height and stability on the surface.

Each of these components plays a vital role, contributing to the overall effectiveness of the equipment during harsh winter months.

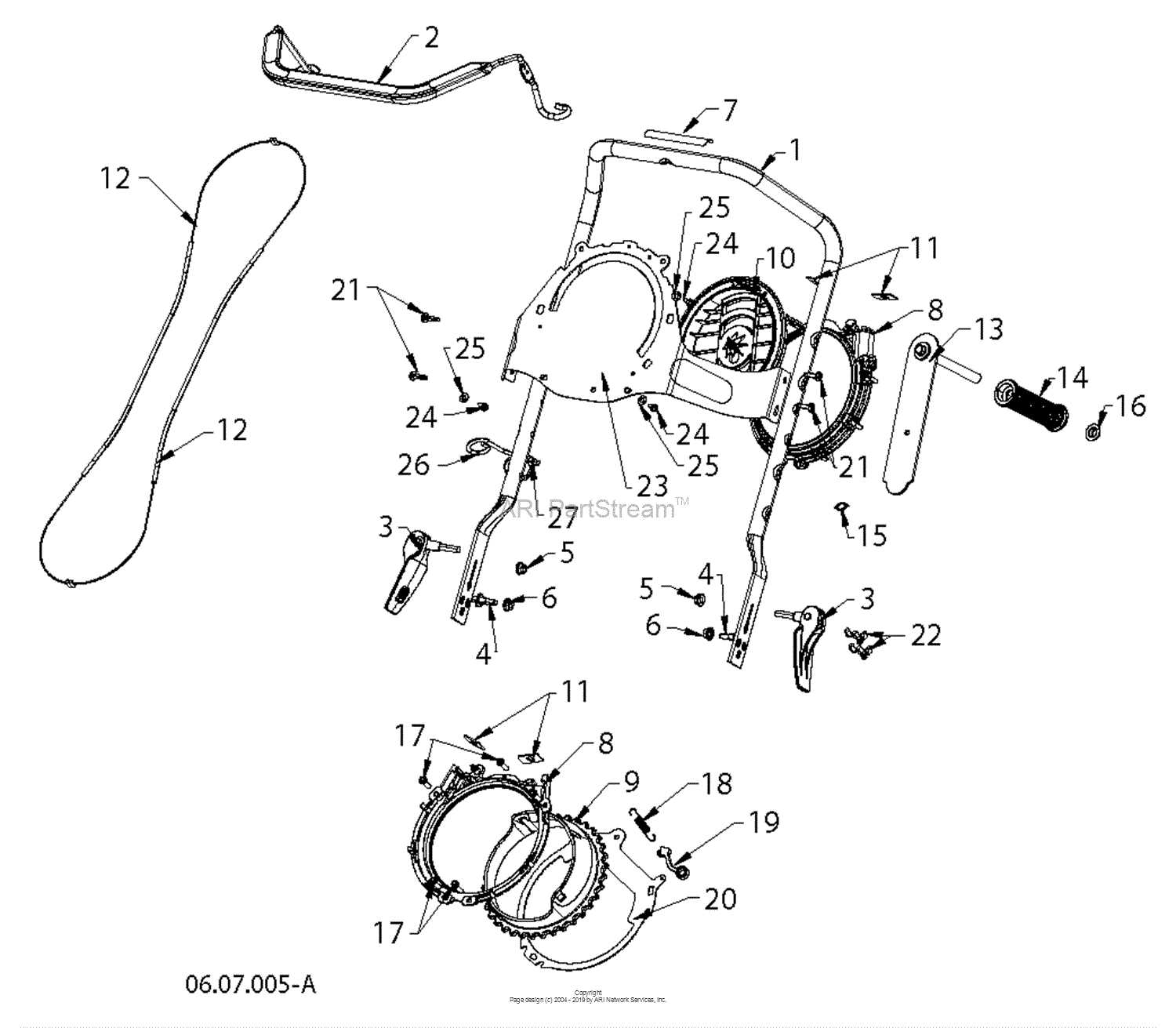

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual representations provide a detailed overview of components, their relationships, and the assembly process. By familiarizing yourself with the layout and symbols used, you can enhance your ability to identify and source necessary items.

1. Familiarize Yourself with the Layout: Typically, these visuals are organized systematically. Begin by observing how the elements are arranged; often, they are grouped based on their function or location within the machine. This will help you navigate through the illustration more efficiently.

2. Recognize Common Symbols: Different symbols may represent various functions or parts. Look for a legend or key, which can clarify these representations. Understanding these symbols will enable you to interpret the information accurately.

3. Identify Component Numbers: Each part is usually assigned a unique identifier. Pay close attention to these numbers as they will assist you in locating the specific components you need when sourcing replacements.

4. Study Connection Points: Notice how components connect to one another. This can reveal the assembly order and may highlight areas where wear and tear could occur, guiding you in your maintenance tasks.

5. Cross-Reference with Manuals: Use these illustrations alongside your user manuals. This will provide additional context and detailed explanations for each component, ensuring a comprehensive understanding of the machinery.

By mastering these techniques, you will become proficient in navigating technical illustrations, making maintenance and repair processes more straightforward and efficient.

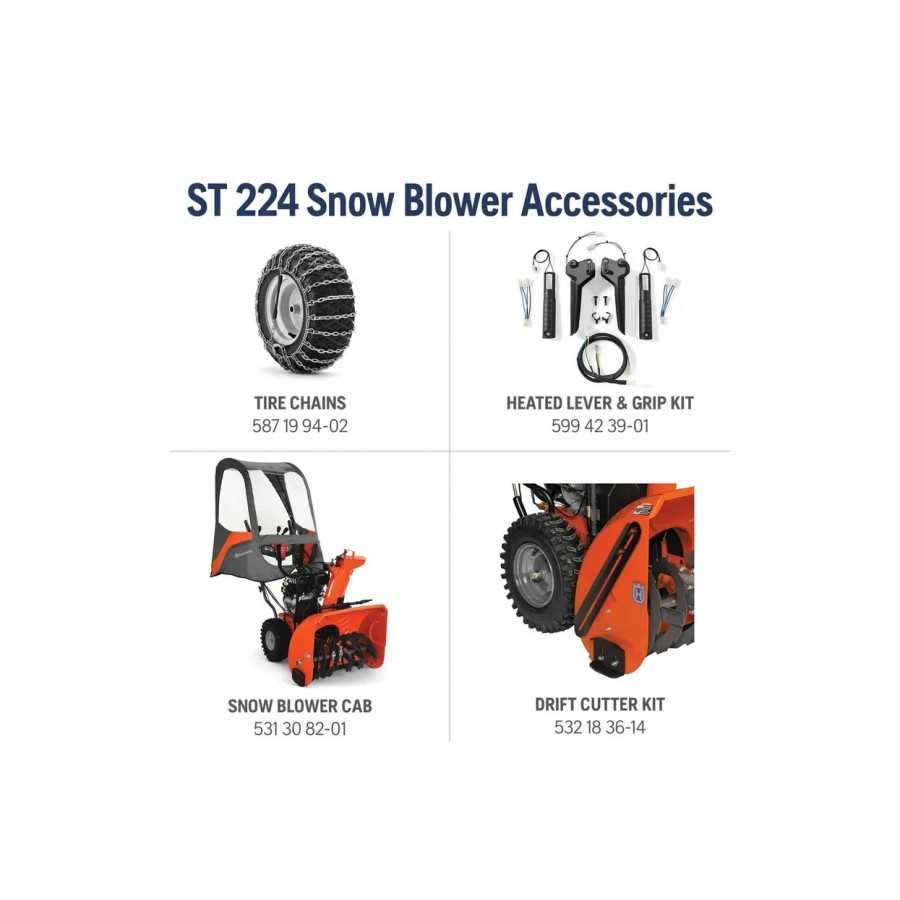

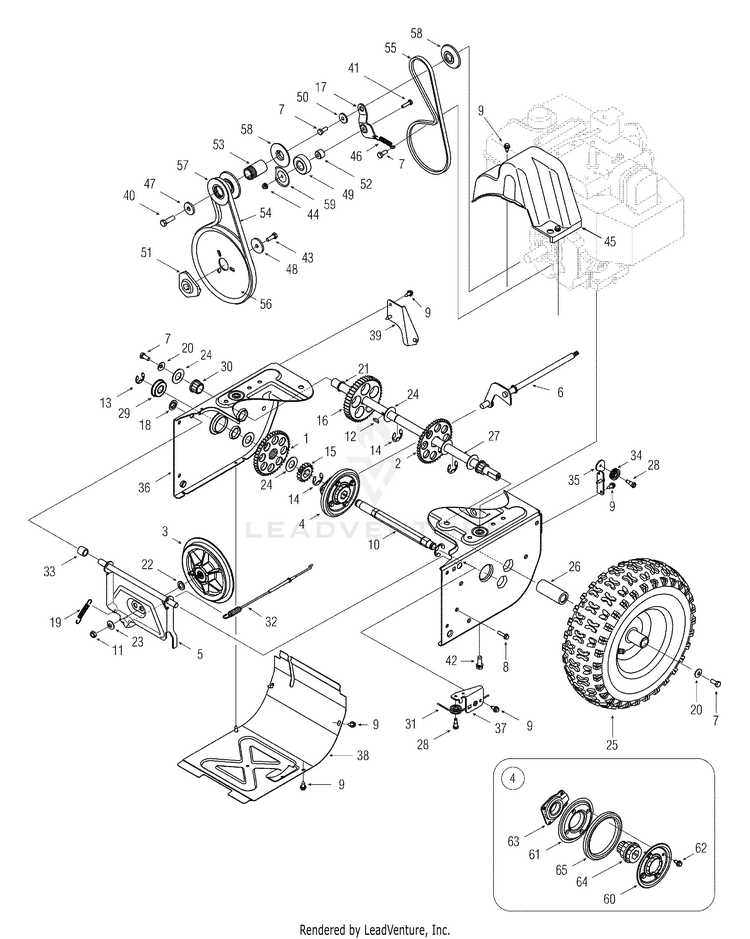

Identifying Snowblower Model Variations

When it comes to winter machinery, recognizing the distinctions between different models is crucial for maintenance and repair. Each variation may feature unique components and configurations, which can impact performance and compatibility with accessories. Understanding these differences ensures that users can efficiently address any issues and optimize their equipment’s functionality.

Model Identification is typically achieved through examining specific characteristics such as engine size, chute design, and handle configurations. By paying close attention to these details, operators can ascertain which model they own and what replacements or enhancements may be necessary.

Furthermore, manufacturer documentation often provides essential insights into model variations. Users are encouraged to refer to user manuals or online resources that outline specifications and features unique to each version. This knowledge empowers owners to make informed decisions regarding upgrades and repairs, ultimately extending the lifespan of their winter equipment.

Maintenance Tips for Snowblower Parts

Regular upkeep of your equipment is essential for ensuring optimal performance during the winter months. By focusing on specific components, you can enhance efficiency and prolong the lifespan of your machinery. Proper maintenance routines not only prevent breakdowns but also save time and money in the long run.

Key Components to Inspect

To keep your equipment running smoothly, it’s important to regularly check certain areas. Here are some vital elements to pay attention to:

| Component | Maintenance Tips |

|---|---|

| Engine | Change oil and check filters regularly. |

| Blades | Inspect for wear and sharpen as needed. |

| Belts | Check for signs of fraying and tension. |

| Fuel System | Use fresh fuel and clean the tank periodically. |

Seasonal Preparations

Before the onset of winter, it’s wise to perform a thorough inspection. Cleaning and lubricating moving parts can significantly enhance performance. Additionally, storing the machinery properly during off-seasons will prevent deterioration and ensure it’s ready when needed.

Ordering Replacement Parts Online

Acquiring essential components for your equipment has never been easier with the rise of online shopping. This method provides a convenient way to find exactly what you need, ensuring your machinery operates at peak performance. By leveraging various platforms, you can quickly access a wide range of options and specifications, tailored to your requirements.

Finding Reliable Sources

When seeking components, it’s crucial to choose trustworthy vendors. Look for reputable websites that specialize in outdoor equipment. Read reviews and verify their return policies to ensure a smooth purchasing experience.

Utilizing Online Resources

Many online retailers offer detailed schematics to assist in identifying the correct items. Take advantage of these resources to delve deeper into the specifics of what you require. This can help prevent errors and ensure you acquire the ultimate replacements for your machinery.

Where to Find Official Diagrams

When it comes to locating precise illustrations for equipment maintenance, understanding where to search is crucial. Official resources often provide the most accurate and comprehensive information necessary for repairs and servicing.

Manufacturer’s Website

The primary source for official visuals is the manufacturer’s website. Here, users can access a variety of resources, including technical manuals and guides that outline the structure and components of their machinery.

Authorized Dealers

Another reliable option is to visit authorized dealers. These locations often have access to up-to-date materials and can assist in locating specific references tailored to your model.

| Resource Type | Description |

|---|---|

| Manufacturer’s Website | Offers official manuals and detailed illustrations. |

| Authorized Dealers | Provides access to current resources and personalized assistance. |

| Online Forums | A community space for sharing insights and resources among users. |

Signs of Worn-Out Components

Identifying the signs of degraded elements is crucial for maintaining optimal performance and safety. Regular inspection can help prevent malfunctions and extend the lifespan of your equipment. Be attentive to the following indicators that suggest components may need replacement or repair.

- Decreased Efficiency: Noticeable reduction in performance can indicate that certain parts are not functioning as intended.

- Unusual Noises: Grinding, squeaking, or rattling sounds may suggest wear or damage.

- Vibrations: Excessive shaking during operation can be a sign of imbalance or wear in critical areas.

- Visual Damage: Cracks, chips, or other visible defects on surfaces should not be overlooked.

Paying close attention to these signs can help ensure the longevity of your machine and maintain its effectiveness during use. Regular maintenance checks are recommended to address any issues before they escalate.

Tools Needed for Repair Work

Effective maintenance and repair of outdoor machinery require a specific set of instruments to ensure efficiency and accuracy. Having the right tools at your disposal not only simplifies the process but also enhances the quality of the repairs performed.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for loosening and tightening various bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws in different sizes. |

| Socket Set | Allows for easier access to hard-to-reach fasteners. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications. |

| Cleaning Brush | Helps remove debris and buildup from components. |

| Safety Gear | Protects the user while performing maintenance tasks. |

Step-by-Step Repair Process

This section outlines a systematic approach to fixing your equipment efficiently. By following these steps, you can ensure that each part is examined and addressed appropriately, leading to a successful restoration of functionality.

Preparation and Safety

Before beginning the repair, it’s essential to gather all necessary tools and materials. Ensure your workspace is clean and organized. Wear appropriate safety gear to protect yourself from potential hazards during the process.

Disassembly and Inspection

Carefully disassemble the unit by removing the outer casing and any relevant components. Take note of how parts are connected and stored. Inspect each section for signs of wear or damage. Document your findings for reference during reassembly.

| Component | Common Issues | Action Required |

|---|---|---|

| Drive Belt | Fraying or breaks | Replace |

| Auger | Dents or corrosion | Repair or replace |

| Fuel System | Clogs or leaks | Clean or replace |

Once all components have been assessed and necessary actions identified, you can proceed with repairs or replacements as indicated. Following this structured method will help ensure a thorough and effective maintenance process.

Enhancing Performance with Quality Parts

Improving efficiency and durability in machinery often hinges on the components used. Utilizing high-quality replacements can significantly influence the overall functionality and lifespan of equipment. These superior elements not only ensure smooth operation but also contribute to maintaining optimal performance under varying conditions.

Investing in reliable components fosters a seamless integration with existing systems, reducing the likelihood of breakdowns and enhancing user experience. This commitment to quality allows operators to tackle challenging tasks with confidence, knowing their equipment is equipped to handle demands effectively.

Furthermore, selecting premium materials can lead to lower maintenance costs and improved safety, as robust components are less prone to failure. Ultimately, the choice of superior elements is crucial for anyone seeking to maximize efficiency and extend the operational life of their machinery.

FAQs About Husqvarna Snowblower Parts

This section addresses common inquiries regarding essential components and maintenance for your winter machinery. Understanding these aspects can enhance performance and longevity, ensuring efficient operation throughout the season.

What should I do if a component is damaged? Inspect the affected area thoroughly and consider replacing the broken item with a genuine replacement to ensure optimal functionality.

How often should I check the machine’s components? Regular inspections before and after use are recommended to identify wear and prevent potential issues.

Where can I find replacement components? Authorized dealers or reputable online retailers offer a wide selection of replacements for various models.

Can I perform maintenance on my own? Yes, many tasks can be done independently; however, consulting the user manual is advisable for specific guidelines.

What are the signs that a part needs replacing? Unusual noises, decreased performance, or visible wear are key indicators that a replacement may be necessary.