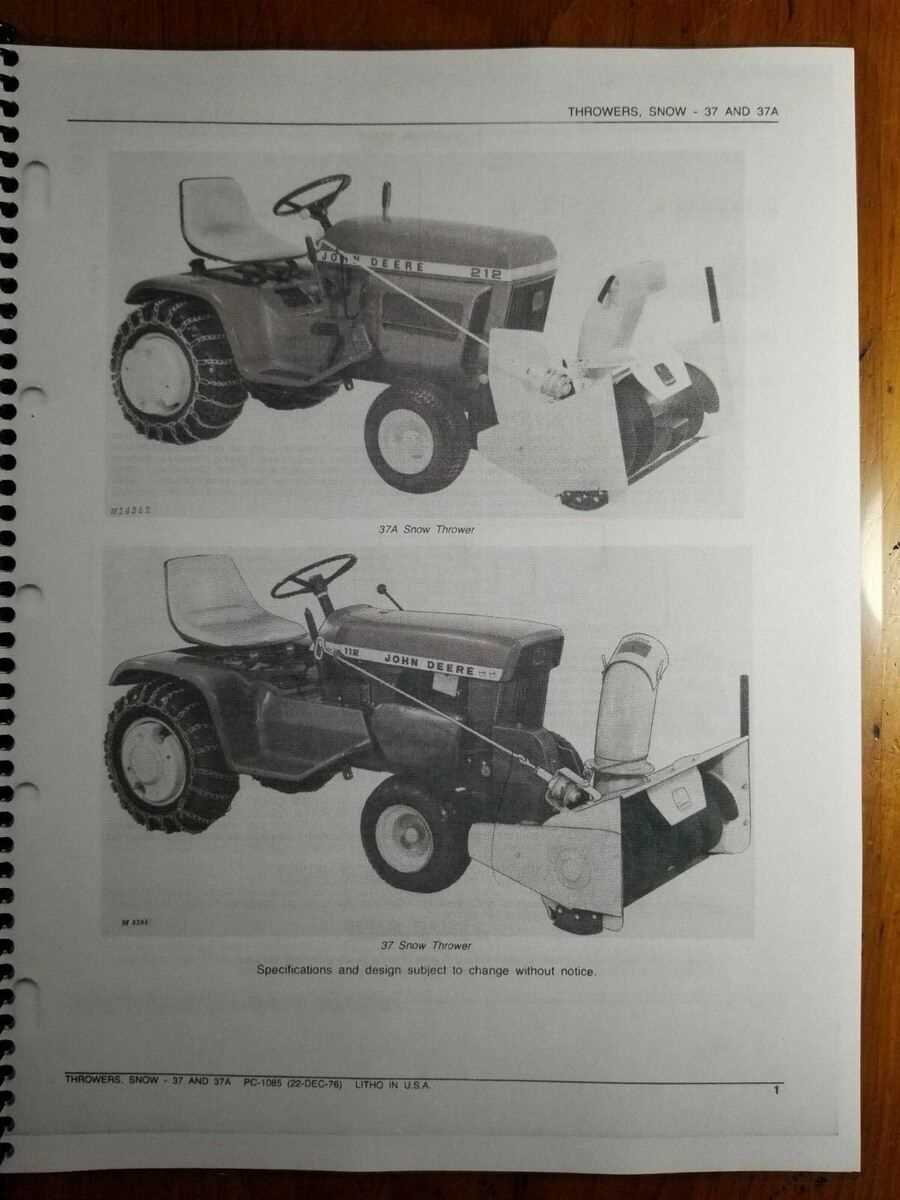

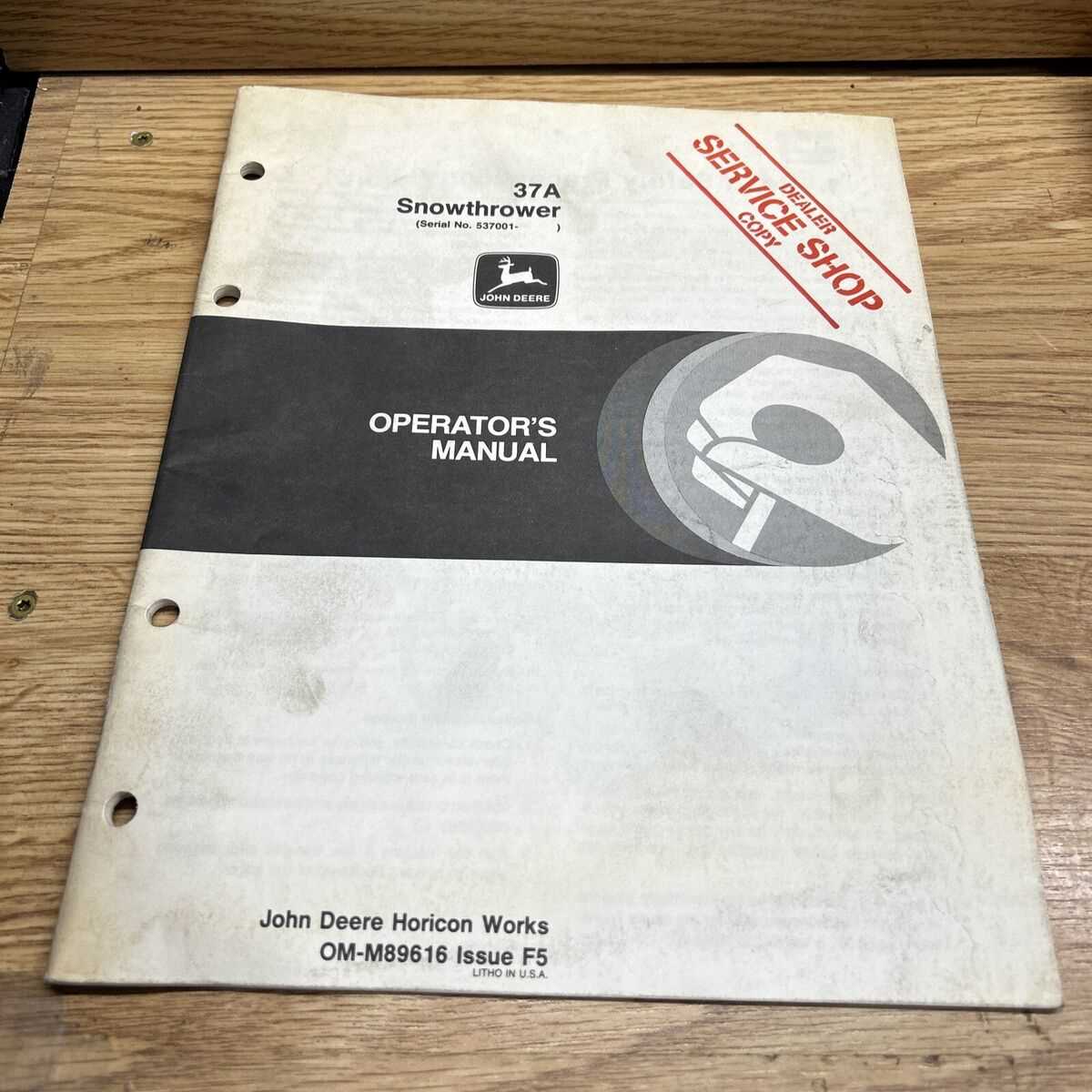

Exploring the Parts Diagram of the John Deere 37A Snowblower

In the realm of winter maintenance equipment, having a clear grasp of the individual elements that contribute to efficient operation is crucial. Each component plays a vital role in ensuring optimal performance, especially in challenging weather conditions. Familiarity with these parts not only enhances usability but also aids in troubleshooting and maintenance.

Delving into the intricate assembly of your winter appliance, one can appreciate the design and engineering that ensure reliability. Recognizing how each segment interacts with others can empower users to make informed decisions regarding repairs and upgrades. This understanding is essential for anyone looking to maximize the longevity and efficiency of their equipment.

By exploring the layout and function of these integral pieces, you can better appreciate the craftsmanship involved. With the right knowledge, managing your winter tool becomes a straightforward task, paving the way for seamless snow removal during the coldest months.

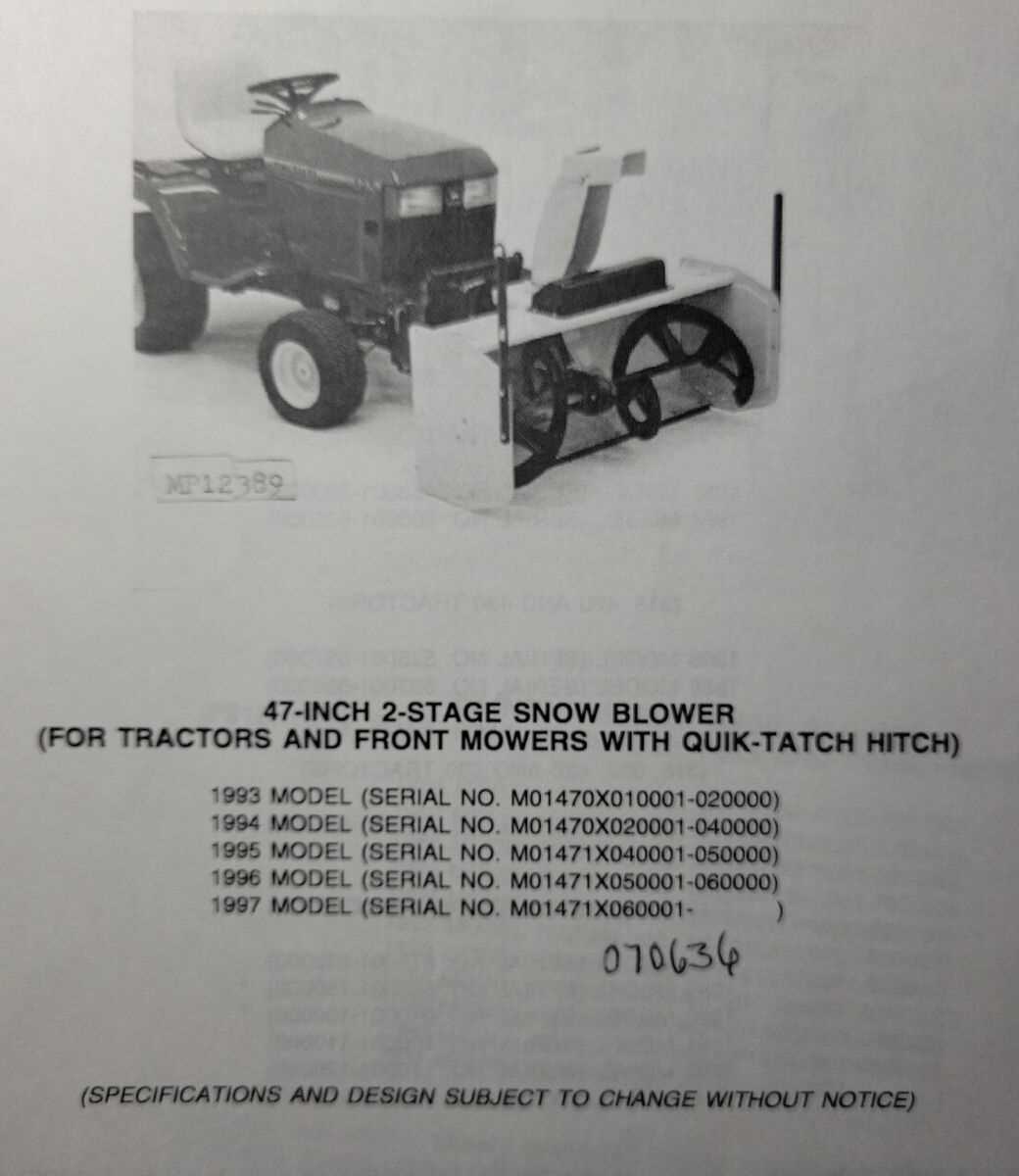

Understanding John Deere 37A Snowblower

This section aims to provide insights into a specific type of equipment designed for efficient snow removal. Understanding its components and functionality is essential for optimal performance during winter months.

The machine is engineered to handle heavy snowfall, making it an invaluable tool for homeowners and professionals alike. Knowing how the various elements work together ensures that users can maintain and troubleshoot effectively.

| Component | Function |

|---|---|

| Auger | Grinds and gathers snow for efficient discharge. |

| Impeller | Propels the snow out of the chute. |

| Chassis | Provides structural support and houses components. |

| Skids | Adjustable feet that control the height above the ground. |

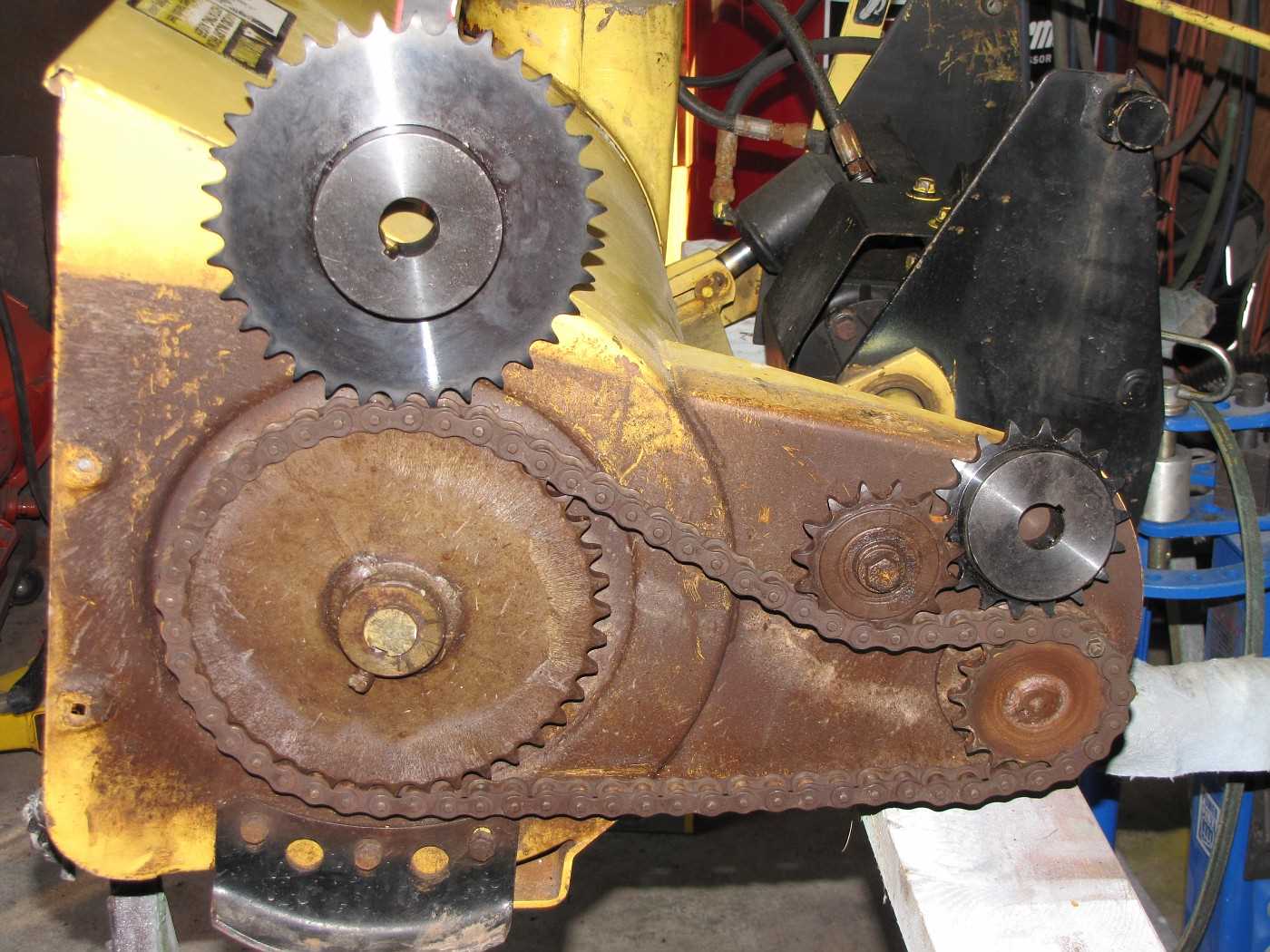

| Drive Belt | Transfers power from the engine to the auger and impeller. |

By familiarizing oneself with the key elements of this machine, users can enhance their understanding and improve their overall experience in managing winter weather challenges.

Essential Components of the Snowblower

Understanding the key elements that contribute to efficient winter clearing is crucial for optimal performance. Each part plays a significant role in ensuring smooth operation and effective removal of snow.

- Auger: This component collects and breaks up the snow for easier discharge.

- Impeller: Responsible for directing the snow away from the machine.

- Chassis: The framework that supports all other components.

- Skid Shoes: These help adjust the height of the clearing path.

- Drive System: This includes belts and gears that provide mobility.

- Engine: Powers the entire mechanism, crucial for performance.

Each of these elements must work harmoniously to achieve the ultimate efficiency in snow management.

Common Issues with Snow Clearing Equipment

When it comes to winter maintenance, understanding the frequent challenges associated with clearing machines is essential for ensuring effective performance. Many users encounter similar problems that can hinder efficiency and lead to frustrating experiences. Recognizing these common issues can help in both prevention and resolution.

Worn Components

One of the most prevalent issues faced is the wear and tear of critical components. Over time, certain elements may degrade due to heavy usage, resulting in decreased functionality. For instance, blades and belts are particularly susceptible to wear, which can lead to reduced effectiveness in clearing snow. Regular inspection and timely replacement of these parts can significantly enhance performance.

Fuel and Starting Problems

Another common concern revolves around fuel delivery and starting mechanisms. In colder temperatures, fuel can thicken, making it difficult for the engine to start. Additionally, carburetor issues may arise, leading to improper fuel-air mixtures. Routine maintenance, including the checking of fuel lines and spark plugs, can mitigate these issues, ensuring smoother operation when needed most.

Benefits of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring longevity and optimal performance. By regularly attending to maintenance tasks, owners can significantly reduce the risk of unexpected breakdowns and costly repairs, while enhancing efficiency during operation.

Enhanced Performance

Routine inspections and adjustments allow equipment to function at its peak, improving overall effectiveness. When components are clean and properly lubricated, they work harmoniously, leading to a smoother experience.

Cost Savings

Investing time in preventive measures can lead to substantial savings over time. Addressing minor issues before they escalate not only prolongs equipment life but also minimizes repair expenses, ensuring that budgets remain intact.

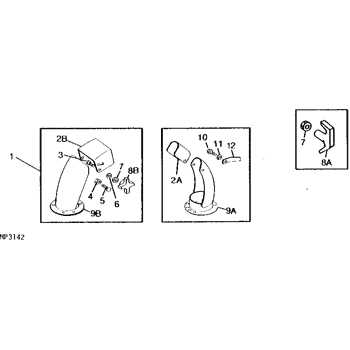

How to Read Parts Diagrams

Understanding mechanical illustrations is essential for effective maintenance and repair of equipment. These visual representations break down complex assemblies into easily identifiable components, allowing users to locate and order necessary items quickly. Familiarizing yourself with the structure and symbols used in these visuals will enhance your ability to troubleshoot and service your machinery efficiently.

Identify the Key Sections: Most visuals are divided into several areas, including the main assembly, sub-assemblies, and individual elements. Begin by focusing on the larger sections before delving into the finer details.

Look for Labels: Components are typically labeled with unique identifiers. These may include numbers, letters, or a combination of both. Understanding these references is crucial for locating the correct replacement items.

Understand the Symbols: Different symbols may be used to denote specific types of parts or functions. Familiarizing yourself with common symbols can aid in quicker comprehension of the overall layout.

Follow the Flow: Many visuals illustrate how components interact within the assembly. Observing the connections and flow can provide insights into functionality and troubleshooting strategies.

By mastering these elements, you will not only simplify your repair process but also gain a deeper understanding of your equipment’s design and operation.

Identifying Replacement Parts Easily

Finding the right components for maintenance can be straightforward with the right approach. Familiarizing oneself with the essential features and terminology enhances the process, ensuring an efficient and effective search.

Utilizing Resources

- Online manuals and guides provide detailed information.

- Manufacturer websites often offer searchable databases.

- Community forums can share valuable insights and experiences.

Steps for Identification

- Gather your equipment and note its model and specifications.

- Refer to visual aids for clarification of specific components.

- Cross-reference with reliable sources for compatibility.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is essential for maintaining its performance and longevity. Ensuring you acquire quality pieces will help prevent potential issues and enhance functionality.

Authorized Dealers

One of the best options is to visit authorized retailers who specialize in genuine components. They often have a comprehensive inventory and knowledgeable staff.

- Local dealerships

- Official brand websites

- Certified distributors

Online Marketplaces

The internet offers a variety of platforms where you can find legitimate components. Ensure you verify the seller’s credibility before making a purchase.

- Reputable e-commerce sites

- Manufacturer’s online store

- Specialty forums and communities

DIY Repairs for Snowblower Components

Maintaining and fixing your winter equipment can save you time and money while ensuring it operates efficiently. Engaging in hands-on repairs empowers you to understand the inner workings of your machine, leading to improved performance and longevity. With the right tools and knowledge, tackling minor issues can be straightforward.

Common Issues and Solutions

Many challenges arise during the colder months, such as clogged chutes or malfunctioning augers. For instance, if you encounter a blockage, a thorough cleaning and inspection can often resolve the problem. Regular maintenance is essential; checking belts and cables periodically can prevent more severe failures down the line.

Tools and Materials Needed

Before beginning repairs, gather essential tools like wrenches, screwdrivers, and lubricants. Having the right supplies on hand ensures a smooth repair process. Investing in a quality repair manual can also provide invaluable insights and step-by-step guidance for various components.

Tools Needed for Snowblower Maintenance

Proper upkeep of outdoor machinery is essential for optimal performance and longevity. A variety of instruments are required to ensure that equipment remains in top condition, preventing unexpected breakdowns during the winter season.

Here’s a list of essential tools that will help in maintaining your equipment efficiently:

| Tool | Purpose |

|---|---|

| Wrench Set | Used for tightening and loosening bolts and nuts. |

| Screwdriver Set | Necessary for adjusting and securing various components. |

| Grease Gun | Essential for lubricating moving parts to reduce friction. |

| Oil Change Kit | For replacing and maintaining proper oil levels. |

| Spark Plug Wrench | Specifically designed for changing spark plugs efficiently. |

| Safety Goggles | Protective eyewear to ensure safety during maintenance tasks. |

Having these tools on hand not only simplifies the maintenance process but also enhances the reliability of your machinery when you need it most.

Comparing OEM vs Aftermarket Parts

When it comes to machinery components, the choice between original equipment and alternative options can significantly impact performance and longevity. Original components typically promise compatibility and quality, while alternatives often present cost-saving opportunities. Understanding the benefits and drawbacks of each can help consumers make informed decisions tailored to their needs.

Original equipment manufacturer items are crafted specifically for certain models, ensuring a perfect fit and adherence to rigorous standards. This assurance often translates to enhanced reliability and durability over time. Conversely, alternative options may vary in quality but can be an attractive choice for budget-conscious users looking for adequate solutions.

Ultimately, selecting between original and alternative items requires careful consideration of factors such as cost, performance expectations, and individual usage scenarios. By delving into the nuances of each type, users can align their choices with their specific requirements and preferences.

Winter Preparation Tips for Equipment

As the colder months approach, ensuring your machinery is ready for the harsh conditions is essential. Proper maintenance and preparation not only enhance performance but also extend the lifespan of your equipment. Here are some key tips to help you gear up for winter.

Routine Maintenance

Start with a thorough inspection of all components. Check fluid levels, including oil and coolant, and replace filters as needed. Cleaning any debris from previous use will prevent issues during operation. Regular maintenance helps avoid unexpected breakdowns.

Winterizing Techniques

To ensure optimal functionality, consider using antifreeze solutions in your systems. Protect vital parts from freezing temperatures by applying lubricants that prevent rust and corrosion. Additionally, storing equipment in a sheltered area can safeguard it from snow and ice damage.

Understanding Warranty Coverage for Parts

Warranties play a crucial role in ensuring the longevity and reliability of mechanical components. They provide assurance that the manufacturer stands behind their products, offering protection against defects and other potential issues that may arise during normal use.

When considering coverage, it is essential to be aware of the following aspects:

- Duration: Warranties typically specify a time frame during which claims can be made.

- Conditions: There may be specific requirements for maintaining warranty coverage, such as regular maintenance.

- Exclusions: Understanding what is not covered is just as important as knowing what is included.

- Transferability: Some warranties can be transferred to new owners, which can add value during resale.

Being informed about these factors helps in making the ultimate decision regarding repairs or replacements, ensuring you maximize the benefits of your warranty.

Resources for Snowblower Troubleshooting

Effective maintenance and prompt resolution of issues are essential for ensuring optimal performance during the winter season. Accessing the right resources can simplify the troubleshooting process and enhance your understanding of the machinery. Here are various tools and materials that can assist you in diagnosing and fixing common problems.

- User Manuals: Detailed guides often contain troubleshooting sections, diagrams, and maintenance tips that can be invaluable.

- Online Forums: Community platforms allow users to share experiences and solutions, providing a wealth of collective knowledge.

- Video Tutorials: Visual aids can simplify complex procedures, making it easier to follow along with repairs.

- Technical Support: Manufacturer hotlines or chat services can provide expert assistance tailored to specific issues.

- Parts Retailers: Websites specializing in equipment can offer parts lists, compatibility information, and replacement options.

Utilizing these resources can empower users to efficiently identify issues and perform necessary repairs, ensuring reliability throughout the snowy months.