Comprehensive Guide to John Deere 832 Snowblower Parts Diagram

When it comes to maintaining and optimizing your winter machinery, having a clear visual reference is invaluable. Knowing the various components of your equipment can significantly enhance its performance and longevity. This section delves into the essential elements that make up a specific model of snow removal gear, enabling users to tackle any challenges with confidence.

Familiarizing yourself with the internal structure not only aids in effective troubleshooting but also assists in seamless maintenance procedures. Each segment plays a crucial role in ensuring that the entire unit operates smoothly and efficiently. By understanding how these parts interact, you can make informed decisions regarding repairs and upgrades.

In the following sections, we will explore a detailed representation of the equipment’s anatomy. This will provide a clearer understanding of how each component contributes to the overall functionality, empowering you to maximize your investment during those heavy snowfalls.

Understanding John Deere 832 Snowblower

Mastering the functionality of this powerful winter tool is essential for efficient snow removal. This device is engineered for exceptional performance in clearing pathways, driveways, and larger areas, ensuring that snow does not become an obstacle during harsh weather conditions.

Key Features

- Robust construction for durability and longevity.

- High-capacity auger designed to handle heavy snowfall.

- Adjustable chute for optimal snow directing.

- Easy-to-use controls for user-friendly operation.

Maintenance Tips

- Regularly inspect the blades for wear and tear.

- Ensure that all moving parts are well-lubricated.

- Check the belt tension periodically to avoid slippage.

- Clear debris from the auger and chute to prevent blockages.

Understanding these aspects will enhance the experience and prolong the life of the equipment, making winter chores more manageable.

Key Features of the 832 Model

This model stands out for its robust performance and innovative design, making it an ideal choice for handling winter challenges. Users appreciate its reliability and efficiency, ensuring that snow removal tasks are completed swiftly and effectively.

Powerful Engine: Equipped with a high-performance engine, this machine delivers exceptional torque and speed, allowing for effortless clearing of heavy snow.

Wide Clearing Width: The unit boasts an expansive clearing width, enabling users to cover large areas in a single pass, which significantly reduces the time and effort required for snow management.

Adjustable Chute: The highly maneuverable chute provides users with the flexibility to direct snow where it’s needed most, enhancing control during operation.

Durable Construction: Built with high-quality materials, this equipment is designed to withstand harsh winter conditions, ensuring longevity and consistent performance season after season.

User-Friendly Controls: The intuitive control panel simplifies operation, making it accessible for both novice and experienced users. Ergonomic features also enhance comfort during extended use.

Maintenance Accessibility: Designed for ease of upkeep, this model features accessible components, allowing for quick maintenance and minimal downtime.

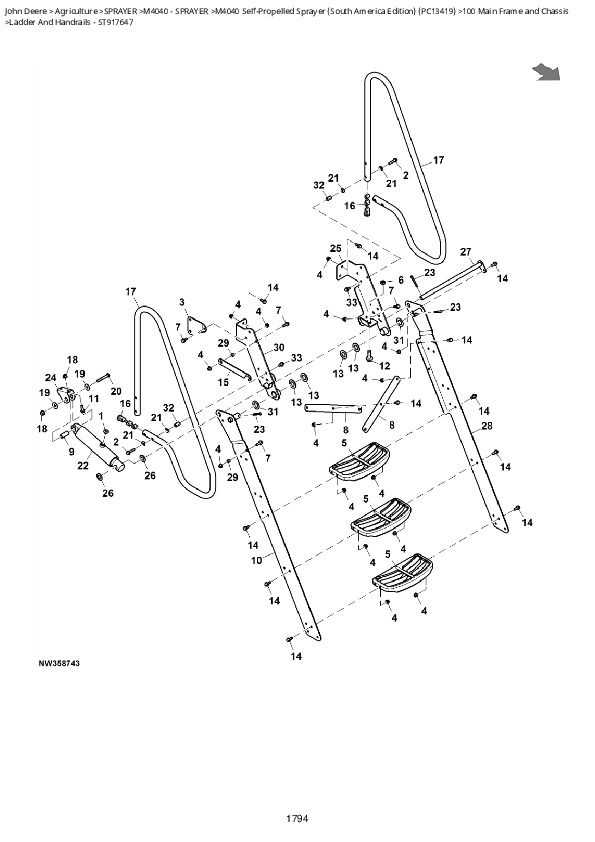

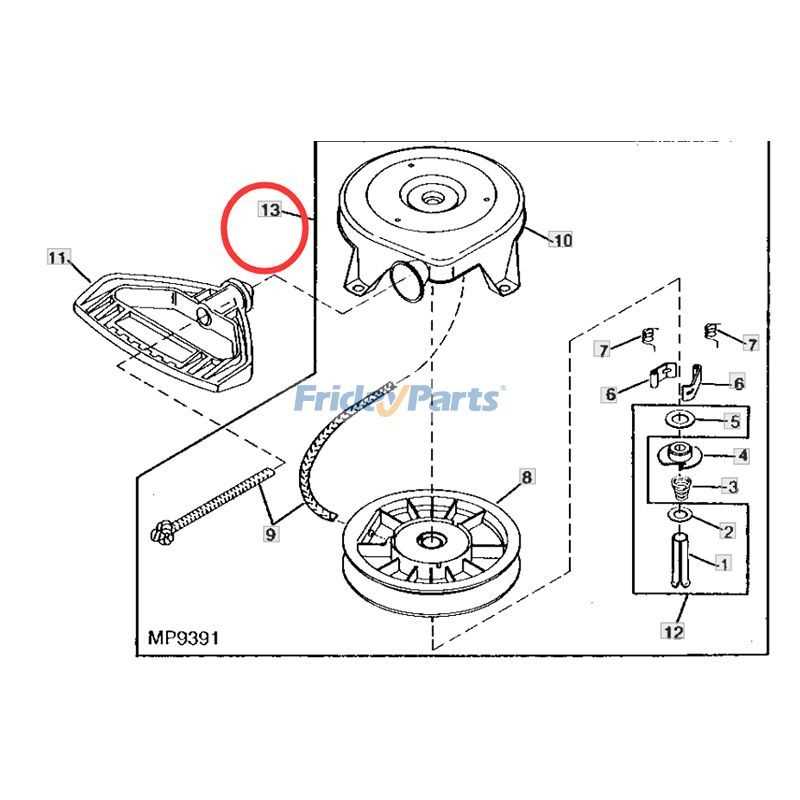

Importance of Parts Diagrams

Understanding the intricacies of machinery requires a clear visual representation of its components. These illustrations serve as essential tools for identifying individual elements and their functions within the overall system.

Effective communication of information is crucial for maintenance and repair. When users can visually reference the arrangement and connection of components, it simplifies troubleshooting and enhances efficiency.

Moreover, having a comprehensive view allows technicians to quickly locate replacement items, ensuring timely repairs and minimizing downtime. This ultimately leads to improved performance and longevity of equipment.

Common Components of the Snowblower

Understanding the fundamental elements of a snow-clearing machine is essential for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance, making it crucial to familiarize oneself with these parts.

| Component | Function |

|---|---|

| AUGER | Collects and directs snow into the chute. |

| CHUTE | Dispenses snow in a specific direction. |

| ENGINE | Powers the entire machine. |

| HANDLEBARS | Provides control and maneuverability. |

| TRANSMISSION | Transfers power from the engine to the wheels. |

Where to Find Diagrams Online

Locating detailed schematics for equipment can significantly enhance maintenance and repair processes. Numerous online resources offer valuable insights into the components and assembly of various machines. These resources cater to both professionals and DIY enthusiasts, ensuring accessibility and ease of use.

Popular Resources

Many platforms provide comprehensive catalogs that include illustrations and specifications. Here are a few reputable sites:

| Website | Description |

|---|---|

| Manufacturer’s Website | Official site often features downloadable manuals and schematics. |

| Online Retailers | Some retailers provide diagrams to assist customers with ordering correct components. |

| Forums and Community Sites | User-generated content where enthusiasts share valuable resources and insights. |

Utilizing Search Engines

Search engines can also be instrumental in finding specific diagrams. Use targeted keywords along with model information to streamline your search. This method can yield quick results and direct you to lesser-known but useful resources.

How to Interpret Parts Diagrams

Understanding the visuals associated with machinery components is essential for effective maintenance and repairs. These illustrations provide a roadmap for identifying, locating, and assembling various elements, ensuring that everything operates seamlessly.

When approaching these visuals, keep the following steps in mind:

- Familiarize Yourself: Start by getting to know the basic symbols and notations used in the visuals.

- Break It Down: Analyze each section separately to understand its function and relationship with other components.

- Refer to the Legend: Use the accompanying key to decode any unfamiliar symbols or terms.

- Cross-Reference: Match components with their physical counterparts to ensure accuracy.

By employing these strategies, you can effectively navigate and comprehend complex illustrations, leading to more efficient repair and maintenance processes.

Replacing Worn Parts Effectively

Maintaining equipment in optimal condition is crucial for ensuring performance and longevity. Identifying and replacing deteriorated components can significantly enhance efficiency and prevent further damage. This process requires careful consideration of each element’s condition and timely intervention.

| Component | Signs of Wear | Replacement Tips |

|---|---|---|

| Blade | Chipping, dullness | Use a sharpening tool or replace if severely damaged. |

| Belt | Cracks, fraying | Check tension regularly and replace if wear is visible. |

| Motor | Overheating, strange noises | Inspect connections and consider replacement if issues persist. |

| Housing | Cracks, corrosion | Assess structural integrity; replace if compromised. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a proactive approach to upkeep. Regular attention to key components can significantly enhance performance and extend operational life. Understanding the essentials of maintenance can help you avoid costly repairs and maximize efficiency.

Start by routinely checking the oil levels and replacing it as necessary. Clean air filters frequently to promote optimal airflow and engine performance. Additionally, inspect belts and cables for signs of wear; replacing them before they fail can prevent breakdowns. Keep the unit clean, removing any debris that could impede function.

Regularly sharpen blades to maintain cutting efficiency, and check for any loose screws or connections. Storing the equipment in a dry, sheltered area will protect it from harsh weather conditions. Lastly, consult the manufacturer’s guidelines for specific maintenance schedules tailored to your model.

Identifying Common Issues

Understanding typical challenges that can arise with outdoor equipment is essential for effective maintenance and operation. Recognizing these issues early can prevent further complications and ensure optimal performance. Below are some frequently encountered problems along with their possible causes and solutions.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Insufficient Power | Clogged intake, low fuel, or worn-out components | Clean the intake, check fuel levels, and replace worn parts |

| Unusual Noises | Loose parts, foreign objects, or bearing failure | Tighten connections, remove debris, and inspect bearings |

| Ineffective Clearing | Improper height setting or dull blades | Adjust the height and sharpen or replace blades |

| Difficulty Starting | Weak battery, old fuel, or ignition issues | Charge or replace the battery, refresh fuel, and check ignition |

| Overheating | Blocked airflow or low coolant levels | Clear vents and ensure adequate coolant |

Addressing these common issues promptly can enhance the lifespan and efficiency of your equipment. Regular inspections and maintenance play a vital role in preventing these problems from escalating.

Comparing 832 with Other Models

This section explores the differences and similarities among various machines designed for snow clearing, focusing on efficiency, performance, and user experience. By analyzing these models, we aim to highlight what makes each unique while considering functionality and adaptability in different conditions.

| Model | Engine Power | Clearing Width | Weight |

|---|---|---|---|

| Model A | 10 HP | 28 inches | 200 lbs |

| Model B | 12 HP | 32 inches | 250 lbs |

| Model C | 8 HP | 24 inches | 180 lbs |

| Model D | 11 HP | 30 inches | 230 lbs |

Through this comparison, users can better understand which model suits their needs, ensuring optimal performance during winter months.

Recommended Tools for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for efficiency and effectiveness. A well-equipped toolbox not only enhances the repair experience but also ensures safety and accuracy throughout the process.

Essential tools include wrenches, screwdrivers, and pliers, which are crucial for loosening and securing various components. Additionally, a high-quality socket set can significantly expedite assembly and disassembly tasks. For more intricate work, specialized tools such as torque wrenches and multimeters may be necessary to achieve the ultimate precision.

Finally, safety gear should not be overlooked; gloves and goggles are vital to protect against potential hazards. By gathering these tools beforehand, you can ensure a smoother repair process and achieve optimal results.

Customer Reviews and Experiences

This section explores the insights and feedback from users regarding their experiences with a specific model of outdoor equipment designed for winter maintenance. Many individuals share their stories, highlighting performance, reliability, and usability, which can greatly assist potential buyers in making informed decisions.

Users frequently commend the ease of operation and effective clearing capabilities, making winter tasks less daunting. Positive remarks often include the durable construction and efficiency, enabling quick and thorough snow removal. However, some reviews indicate areas for improvement, such as the need for enhanced maneuverability in tight spaces.

Overall, the collective experiences of customers provide valuable perspectives, revealing both the strengths and potential drawbacks of the equipment, which ultimately helps others in the purchasing process.